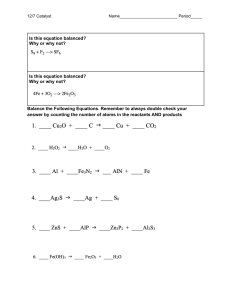

Candidate code: jyj422 (001307 -0014) Topic: Kinetic Study of Synthesis Research Question: What is the effect on the rate of using different acids as a catalyst for esterification reaction? Introduction Esterification, as the name suggests, is the process of creating esters. These organic compounds are widely used in flame retardants, gasoline, oil additives, and perfumes (Helmenstine, 2019). The use of esters in perfumes is what separates it from most other chemical compounds and proves the importance of these compounds in our daily lives. As esters are an essential component of several products, many industries require enormous amounts of these compounds. However, as esterification is a slow reversible exothermic reaction (Azhar et al., (n.d)), industries compromise their equilibrium conditions to produce the maximum amount of ester in the least possible time. Although an exothermic reaction, heat is provided coupled with a concentrated H2SO4 catalyst to increase the reaction rate for esterification. (Azhar et al., (n.d)) The catalyst simultaneously lowers the activation energy (Ea). Increasing the temperature increases the average kinetic energy of the reactant molecules, so more molecules acquire Ea, resulting in greater successful collisions. Catalysts can accelerate a reaction without polluting its results. It was surprising that industries only used concentrated sulfuric acid as a catalyst for esterification, but it was unclear why. However, as part of school policy, all SL students must attend HL classes, and in one class, the teacher discussed electrophiles and nucleophiles. It was discussed that esterification is a nucleophilic substitution reaction that only requires an H+ ion, which any acid can provide. Therefore, why is only sulfuric acid used in industrial esterification and not any other concentrated acid? To answer this question, this experiment evaluates the effects and reliability of 3 concentrated acids as catalysts in the esterification reaction for 2propyl ethanoate to determine whether there is a better catalyst than the conventionally used one. Background: As esters are organic compounds, they experience specific arrangement patterns that divide them into functional groups. Functional groups are important as they are critical in defining the reaction (Libretexts, 2020). The ester functional group forms due to substituting the alcohol and carboxylic functional group. The alcohol functional group involves a single bond between a carbon and an OH (also called hydroxyl) (Libretexts, 2020). The hydroxyl group reacts with the carboxyl group (COOH) from the carboxylic acid to form the ester functional group and water. As esterification is a slow process, it requires an acid catalyst to lower the activation energy of the reaction and assist in the nucleophilic substitution reaction between the hydroxyl and carboxyl groups, as shown in Fig. (1). The carboxyl group is protonated by an H+ ion from the H2SO4 catalyst as oxygen shares an electron with it; oxygen gains a positive charge. As oxygen is more electronegative than carbon, it steals one of the double C=O bond to eliminate its positive charge. However, a positive charge is formed on C, leaving it susceptible to a nucleophilic attack from the hydroxyl group. The hydroxyl oxygen shares an electron with the positive C and acquires a positive charge. As oxygen is more electronegative than H, it attracts the OH to balance the positive charge, leaving an H+ ion. This H+ ion receives an electron from the oxygen in the OH in carboxyl, forming a positive charge on that oxygen. The positive oxygen atom of the carboxyl pulls the C-O bond to balance its charge and leave a positive charge on C. The oxygen, therefore, forms H2O, and the elimination of water occurs. The positive C atom attracts a bond from the oxygen, forming a C=O bond and leaving a positive charge on O. The positive oxygen pulls an electron from its O-H bond, Page 1 of 12 Candidate code: jyj422 (001307 -0014) and deprotonation occurs. The released H+ bonds with the OSO3H- to form H2SO4. Hence, esterification is complete, and the catalyst does not pollute the products. Fig. (1): Nucleophilic substitution reaction of esterification. (Khan Academy. (n.d.)) The ester functional group consists of a carbon bonded to 2 oxygen. As shown above, there is a double bond between the carbon atom and one oxygen atom and a single bond between the carbon atom and the other oxygen atom. The parent alcohol and carboxylic acid react together by extracting the water molecule and combining the two reactants (Libretexts, 2021). Once the ester is formed and extracted, it has several applications such as perfumes, preservatives, toothpaste, hair-care products, cosmetics, deodorants, moisturizers, etc. Varying the reactants in esterification can help obtain these unique properties (BYJU'S, 2021). Still, the industries producing these esters need to increase the rate of reaction as much as they can and to do so, they use catalysts. However, not all catalysts affect the rate of reaction in the same way, and it is crucial to use the right one to minimize the reaction time. Hypothesis: Ha: The reaction will occur but will be slower with hydrochloric and nitric acids compared to sulfuric acid. H0: The reaction will occur but can be faster for nitric and/or hydrochloric acid and will be faster compared to sulfuric acid. Apparatus: 1. 2. 3. 4. 5. 6. 7. Stirring rod Hot water bath. Bunsen Burner PPE (safety glasses, safety shield, nitrile gloves, neoprene aprons) Thermometer dropper Pipette Page 2 of 12 Candidate code: jyj422 (001307 -0014) 8. Test tubes 9. Beaker 10. Test tube rack 11. Tripod claw for a thermometer 12. Tripod stand for the water bath Reactants Required: Purely chemical Ethanoic acid (CH3COOH) Purely chemical 2-propanol (C3H8O) Sulfuric Acid (concentrated) Hydrochloric acid (concentrated) Nitric Acid (concentrated) Variables: Independent variable Dependent variable Controlled variables Type of catalyst used. Rate of change in temperature The concentration and volume of the reactants 2-propanol and ethanoic acid (reactants). Amount of catalyst (5 drops) Procedure: 1) Prepare a water bath at 70°𝐶and maintain that temperature (70°𝑪 is an elevated temperature and could cause burn; therefore, manage hot apparatus with caution). 3) Using a pipette, take 5.0 ml of alcohol in a test tube. Page 3 of 12 Candidate code: jyj422 (001307 -0014) 4)Using a pipette, take 10.0 ml of ethanoic acid in a separate test tube. 5)Using a dropper, take five drops of catalyst and add it to the alcohol in the test tube (Use PPEs when dealing with concentrated acids). 6)Place both test tubes in the water bath and monitor the temperature of each liquid using separate thermometers (As water would be near boiling point, be careful when transferring the test tubes as any contact could cause burns). 7) Wait until the temperature of all 3 test tubes is equal to the water bath at 70°𝐶. 8) Pour the alcohol and catalyst test tube into the acid test tube within the bath (use clamps to hold the test tubes as they would be hot). 9)Monitor temperature using a thermometer. 10)Record the time taken to reach the maximum temperature. 11)Find the temperature difference between the maximum temperature and the controlled temperature of the bath. 12)Repeat the experiment with different catalysts. Methodology: The reaction rate is usually calculated using the mass of the reactant consumed per unit time and the mass of product created per unit time. If this is not possible, color change, electrolyte difference, or volume of gas produced are used. Since both the reactants in this experiment are solvents and produce no precipitate, the reaction rate must be measured through the invisible product: the heat of reaction. As esterification is an exothermic reaction that produces heat as a product, the rate of temperature change would help analyze how much product is produced per unit time, therefore measuring the reaction rate due to varying catalysts. However, the reaction is slow, so heat is required to increase the rate of reaction in addition to a catalyst. To provide heat, usually, a rheostat would be used; however, as the lab’s equipment was not so updated, a hot water bath was used to heat all the reactants to the desired equal temperature, which would provide the particles enough kinetic energy to overcome the activation energy and react successfully. A half-filled metal pot with water was placed on a lit Bunsen burner which heats the water to the desired temperature of 70°𝐶. Whenever during the experiment, the temperature rose above 70°𝐶, the heat was turned off to maintain the temperature, allowing the water bath and the reactants to remain at a constant temperature so that when the reactants are later mixed, the temperature change recorded by the thermometer was only due to the heat released because of the reaction and not because of the difference in temperature of the reactant. After maintaining the temperature of the water bath, the reactants were measured according to steps 3, 4, and 5 of the procedure. The test tubes were placed in a test tube holder rack and placed in the water bath. Once the temperatures of the reactants were constant at 70°𝐶 step 9 was conducted while keeping the ethanoic acid tube submerged in the water bath and the thermometer still in place. Otherwise, the temperature reading would have dropped if the test tubes were pulled out and mixed. This would have led to inaccurate temperature readings as there would have been a temperature difference between the reaction system and the hot water bath. So, the increase in temperature due to the transfer of energy would have Page 4 of 12 Candidate code: jyj422 (001307 -0014) overshadowed the increase in temperature due to the exothermic reaction. Mixing the reactants while keeping the ethanoic test tube in the water bath kept the reactants at a constant temperature. The focus was solely on the increase in temperature due to esterification. Once the reactants were mixed, the temperature change was measured (temperature change above the temperature when the reactants were mixed). The maximum temperature reached and the time taken were noted for calculations. The reaction had occurred, and there was 2-propyl ethanoate, water, and excess ethanoic acid present in the solution. The experiment was finished at this stage because now the ester would have been extracted in esterification. However, the final crude ester was not separated from the excess acid as the experiment aimed to record the reaction rate through the change in temperature due to different catalysts to ensure the most effective one. Raw data: Catalyst: H2SO4 Catalyst: HCl Time (hours: minutes) (±0.1 ms) Temperature ±0.5°C 0:00 (test tubes added to the water bath) 75.0°C 0:05 70.0°C 0:10 69.0°C 0:15 70.0°C (reactants mixed now) instant rise to 71°C 0:20 70.0°C 0:25 70.0°C Time (minutes: seconds) (±0.1 ms) Temperature ±0.5°C 0:00 (test tubes added to the water bath) 70.0°C 0:05 72.0°C 0:10 70.0°C (reactants mixed and instant rise to 71.5°C) 0:15 71.5°C Page 5 of 12 Candidate code: jyj422 (001307 -0014) Catalyst: HNO3 Time (minutes: seconds) (±0.1 ms) Temperature ±0.5°C 0:00 (test tubes added to the water bath) 72.0°C 0:05 70.0°C 0:10 70.0°C (reactants mixed and instant fall to 69.0°C) 0:15 70.0°C Processed data: Balanced Esterification Equation: C3H8O + CH3COOH → CH3COOCH2CH3 + H2O Step#1: Calculating average bond enthalpies: Average Bond Enthalpies: Reactants: Propan-2-ol: Ethanoic Acid: 2(C-C) = 692 3(C-H) = 1242 7(C-H) = 2898 (C=O) = 804 (C-O) = 358 (C-O) = 358 (O-H) = 463 (O-H) = 463 Average Bond enthalpy of reactants = 7624 kJ/mol Products: 2-propyl ethanoate: H2O: 10 (C-H) = 4140 2(0-H) = 926 3(C-C) = 1038 (C=O) = 804 Page 6 of 12 Candidate code: jyj422 (001307 -0014) 2(C-O) = 716 Average Bond enthalpy of products: 7624 KJ/Mol Enthalpy change: 7624-7624 = 0 (according to average bond enthalpies given in the data booklet) This goes against the theory that an enthalpy change of reaction value would be calculated through the bond enthalpies. However, it was learned that the bond enthalpy values are an average of the bond across all different chemical substances. Therefore, if the enthalpy change of reaction value is minimal, this inaccuracy of the bond enthalpies may provide such answers. Hence, research was conducted to find the enthalpy change of this reaction, and this value was obtained: Heat of this reaction (𝛥𝑟 𝐻 0 ) = −1.289 kJ/mol (Mekala, 2021) Hr Step#2: Calculate the moles of acid and alcohol used. Moles of Alcohol used: 𝑑 = 𝑚/𝑣 d= 786 kg/m3 =0.786 g/ml (density of alcohol) (Fleming, 2020) The Volume of alcohol= 5ml Mass = (Density * Volume) = 0.786 * 5 __________________ eq. (i) = 3.93 g Sol. (i) Using Sol. (i): Actual Mass = Percent Purity * Total Mass = 3.93g * 0.99______________ eq.(ii) = 3.89g Sol. (ii) Mr (2-propanol) = 60.1g/mol Using Sol.(ii): moles of 2-propanol = 3.89/60 eq. (iii) = 0.0648 mol. of alcohol _________________________________Sol. (iii) Moles of Acid used: d= 1.05g/cm3= 0.00105 kg/ml (density of ethanoic acid) (Acetic acid (n.d)) Volume of ethanoic acid= 10ml Mass= (Density*Volume) = 1.05 * 10__________________________eq. (iv) 10.5 g Sol. (iv) Using Sol. (iv): Actual Mass = Percent Purity * Total Mass = 10.5 * 0.99 ____eq. (v) = 10.395g _______________________________________________________Sol. (v) Mr (ethanoic acid) = 60.052 g/mol Using Sol. (v): moles of ethanoic acid= 10.395g/ 60.052 g/mol______________ eq. (vi) Page 7 of 12 Candidate code: jyj422 (001307 -0014) = 0.173 mol. of ethanoic acid_________________________________________ Sol. (vi) C3H8O + CH3COOH → CH3COOCH2CH3 + H2O Mole ration of Alcohol to Acid is 1:1 Comparing Sol. (vi) and Sol. (iii), it can be determined that 0.0648 moles of acid are required (as 0.173 moles of acid were available, acid was in excess, and the alcohol was the limiting reagent which determines how much ester is produced.) Using Sol. (iii): Alcohol: Ester = 1: 1 ________________________________ eq. (vii) 0.0648 mol. of ester _____________________________________________Sol. (vii) Step#3: Calculate the enthalpy change of reaction: Using Hr from step#1 and Sol. (iii) from step#2: Mass of reaction mixture: 15g Theoretical energy released: 𝛥𝑟 𝐻 0 = Hr / no. moles -1.289 kJ/mol*0.0648 Heat= 0.08359 kJ (theoretical value) eq. (viii) Sol. (viii) Step#4: Theoretical temperature change for esterification reaction of 2-propyl ethanoate 𝑄 = 𝑚𝑐𝛥𝑇 𝑄 = 0.08359 𝑘𝐽 (Energy value taken from Sol. (viii)) (Engineering ToolBox. (n.d.)) Mass= 0.014285 kg (sum of Sol. (ii) and Sol. (v)) (Theory of conservation of mass) Specific Heat Capacity of Ethanoic acid= 2.043𝑘𝐽/(𝑘𝑔𝐾) (ScienceDirect, (n.d.)) Δ Temperature=? As acid was in excess, it is assumed that there would be ester and excess ethanoic acid present in the mixture after the reaction. As excess ethanoic acid would have more moles than the ester, most of the mixture would be ethanoic acid. Therefore, it can be assumed that the specific heat capacity of the mixture is the same as ethanoic acid. 0.08359 ΔT= (0.014285)(2.043) = 2.7°𝐶 Sol#8 As the reactants were the constant variable, the value in Eq#7 can be assumed as the theoretical temperature change value for the three trials conducted in this experiment. Step#5: Comparing the experimental results with the theoretical value of Eq#7: Theoretical temperature change = 2.7°𝐶 Page 8 of 12 Candidate code: jyj422 (001307 -0014) Temperature increases with catalysts: Concentrated H2SO4 = 1°𝑪 Concentrated HCl = 1.5°𝑪 HNO3 = -1°𝑪 Safety Precautions: As concentrated acids were used in this experiment as catalysts, safety precautions were crucial. It was essential to wear a lab coat, medical face mask, protective gloves, eye protection, and footwear that completely covered the feet throughout the experiment. Moreover, this experiment had to be conducted under the supervision of the chemistry teacher and the lab in charge due to the hazardous chemicals used. The concentrated acids had to be managed only by the lab in charge as per safety precautions. The lab in charge looked after the school lab for several years and was qualified as per the IB guidelines to manage corrosive chemicals. Moreover, the temperature of the water bath had to be maintained, which required constantly turning the Bunsen burner on and off. Therefore, the lab in-charge’s assistance was utilized when dealing with hot or flammable equipment. The test tubes within the water bath were also managed by the lab in charge when mixing the reactants. The chemical bottles had to be capped as soon as used to prevent fumes from filling up. The apparatus that was in contact with the reactants were thoroughly rinsed, and the equipment used for the catalysts was rinsed by the lab in charge, as the lab in-charge entirely managed the concentrated catalysts. Error / Uncertainty: Thermometer = ±0.5°𝐶 (Variable uncertainty as systematic uncertainty was proved to be zero by the steam point and ice point method). Pipette = ±0.02 𝑚𝑙 (Stone, 2008) Stopwatch = ±0.1 𝑚𝑠 Evaluation: A hot water bath was set up to provide heat to the reaction as expressed in the methodology; however, initially, it was decided to set the temperature at a constant of 80°𝐶. While experimenting, the boiling points of 2-propanol and ethanoic acid (reactants) were checked. It revealed that the boiling point of 2-propanol is 82.5°𝐶. Therefore, it was decided to lower the constant temperature of the water bath by 10°𝐶. As the temperature of the water bath was controlled by manually turning the burner on and off, the temperature of the water could potentially have reached the boiling point of the alcohol, which would have lowered its volume in the reaction. At 70°𝐶, all the reactants would have enough energy to react faster, especially coupled with the effect of the catalyst. Moreover, once the water bath had reached the constant temperature, the test tubes were added, and thermometers were placed in both the test tubes to monitor their temperature. Surprisingly, the alcohol and catalyst test tube were heating slower than the ethanoic acid. Initially, it was assumed that this difference was due to differences in specific heat capacities. After a while, the ethanoic acid was at the same temperature as the water bath. However, the alcohol and catalyst were still much below 70°𝐶. After waiting for a few more minutes, it was suspected that there could be a problem with the thermometer, so another thermometer was added to the alcohol test tube. Soon, it was evident that the previously used thermometer was inaccurate as the new thermometer was giving a reading much closer to the 70°𝐶 mark. In contrast, the previous one was still displaying a lower temperature. Therefore, it was decided to calibrate the lab’s Page 9 of 12 Candidate code: jyj422 (001307 -0014) thermometers using the steam point and ice point method (Raiseupwa.com (n.d)). After assessing four thermometers, it was discovered that three were accurate and one was inaccurate. The three were giving completely accurate readings. For the ice point experiment, they precisely showed 0°𝐶. For steam point, they precisely showed 100°𝐶. Therefore, the systematic uncertainty was zero when measuring the dependent variable; however, there was still a possibility of random errors. After having the lab in charge inspect the old thermometer, he confirmed that the thermometer bulb was broken. The experiment was restarted with the correct and accurate thermometers. After waiting for a bit longer, the reactants were mixed when the entire system was at 70°C. It was decided that the test tubes would be lifted from the water bath, and the contents of one would be poured into the other. The lab in-charge’s assistance was utilized to take out the test tubes and pour the alcohol and catalyst into the acid test tube. However, as mentioned in the methodology, it caused the temperature to fall below the temperature of the water bath, which could affect the temperature reading and temper the results. As the required quantity was only the temperature change due to the esterification reaction, this method would not have been effective. The temperature rise would have also been due to the difference in the temperature of the water bath and the reaction. Therefore, the procedure was modified. The alcohol and catalyst solution were poured into the ethanoic acid solution while keeping the ethanoic acid test tube in its place in the water bath. This would keep the temperature of that test tube at a constant level equal to the water bath, and any increase in temperature observed would be due to the exothermic reaction. The experiment was repeated with the updated methodology, and the results were surprising. The temperature increase observed was around 1 ⁰C and occurred instantaneously. This was because of the lesser amounts of reactants used. Also, the temperature of the alcohol was near its boiling point, so the particles had enough kinetic energy. This high kinetic energy coupled with the catalyst allowed the reaction to occur instantly. As the reaction was exothermic, an increase in the thermometer’s temperature reading would indicate the product being formed. The greatest temperature change was expected for the concentrated sulfuric acid as it is considered the best catalyst in the industry for esterification; its reaction should have produced a higher reading than the other catalyst. However, after conducting the experiments, the HCl reaction recorded a maximum temperature of 71.5⁰C, whereas the H2SO4 reaction recorded only 71⁰C. Therefore, according to the experiment, HCl is the more efficient catalyst as it produces more heat, one of the products of an exothermic reaction. The results were confusing. Therefore, I further researched catalysts in esterification and why HCl is not used in place of sulfuric acid. The research revealed that esterification reactions produce ester, heat, and water. The heat is emitted, and the ester and water remain in the solution, of which only the ester is required. Concentrated sulfuric acid is used because it acts as a dehydrating agent and a catalyst. As a result, it helps remove the water from the solution, which concentrated HCl or concentrated HNO3 could not do. Moreover, the Cl- ions can take part in any side reactions with the alcohol, polluting the results. Limitations: As the reactants had to be at the same temperature, they had to be heated. However, the water bath created relied on a Bunsen burner, and the temperature had to be monitored using a thermometer. Manually trying to control the temperature could have affected the temperature readings and the reaction rate. An electric heater or a rheostat that could maintain the temperature at 70⁰C could eliminate this limitation. The temperature was recorded using analog thermometers which could be subject to human error. One of the thermometers used initially was broken, which caused the first trial to fail. The thermometer was changed and made sure it was working perfectly. Moreover, the system was not insulated, allowing most of the heat to escape, resulting in lower thermometer readings. Using a digital thermometer would produce more Page 10 of 12 Candidate code: jyj422 (001307 -0014) accurate results. Overall, the apparatus used was unsuitable for esterification reactions, and other available apparatus had to be used to make this experiment work. Moreover, this experiment was based on a few assumptions, such as in step#4 that the specific heat capacity of the ester is the same as the acid as there was excess acid left after the reaction and that the temperature change recorded by the thermometer would only be due to the formation of ester. These assumptions might have increased the absolute error as the volumes were minute. Moreover, small amounts of reactants were used, and each catalyst was only tried once. The small volumes can lead to a higher overall percentage error even for a very small uncertainty. This limitation occurred as small volumes are preferred in reactions where heat changes are being measured as it does not dilute within large volumes. Conclusion: The alternate hypothesis has been confirmed as a catalyst does affect the rate of reaction, and each catalyst produces a different rate of reaction. Surprisingly, HCl caused a higher reaction rate than H2SO4. These results were confusing, and triggered further research into esterification to explain why H2SO4 is the conventional catalyst. H2SO4 is di-protic, which allows a higher concentration of H+ ions for nucleophilic substitution. H2SO4 is also a dehydrating agent and has the Le Chatelier's effect as it removes the water from the reaction. Therefore, as the reaction is reversible, removing some of the product shifts the equilibrium to the product’s side, allowing more of the ester to be produced. Moreover, with the water gone, the ester can be separated from the mixture by neutralizing the excess acid and using fractional distillation to separate the final ester. In conclusion, the effect from each catalyst was nearly the same however, H2SO4 is the best catalyst for esterification due to being di-protic and a dehydrating agent, as water is one of the products of esterification and removing water from the solution provide the ester. Appendix: Ice Point: Steam Point: Thermometers: Safety Precautions: Page 11 of 12 Candidate code: jyj422 (001307 -0014) References: Helmenstine, A. M. (2019, October 16). Organic Chemistry is all around us. ThoughtCo. Retrieved February 16, 2022, from https://www.thoughtco.com/organic-chemistry-in-everyday-life-608694 BYJUS. (2021, June 28). Ester - definition, structure, esterification along with properties & uses. BYJUS. Retrieved February 16, 2022, from https://byjus.com/chemistry/ester/ Libretexts. (2020, August 30). 2.9: Organic Functional Groups. Chemistry LibreTexts. Retrieved February 16, 2022, from https://chem.libretexts.org/Courses/Nassau_Community_College/Organic_Chemistry_I_and_II/02%3A_Structure_ and_Properties_of_Organic_Molecules/2.09%3A_Organic_Functional_Groups Libretexts. (2021, September 24). 9.8: Carboxylic acids and esters. Chemistry LibreTexts. Retrieved February 16, 2022, from https://chem.libretexts.org/Courses/Sacramento_City_College/SCC%3A_CHEM_330__Adventures_in_Chemistry_(AlviarAgnew)/09%3A_Organic_Chemistry/9.08%3A_Carboxylic_Acids_and_Esters Mott, V. (n.d.). Esters. Lumen: Introduction to Chemistry. Retrieved February 16, 2022, from https://courses.lumenlearning.com/introchem/chapter/esters/ Raiseupwa.com. What is the Ice point method? (n.d.). Retrieved https://www.raiseupwa.com/users-questions/what-is-the-ice-point-method/ March 8, 2022, from Mekala, M. (2021, January 1). Kinetic studies on esterification of acetic acid with isopropyl alcohol in presence of novel Solid Catalyst. De Gruyter. Retrieved March 22, 2022, from https://www.degruyter.com/document/doi/10.1515/ijcre-2020-0141/html?lang=en Engineering ToolBox. (n.d.), Liquids and fluids - specific heats.. Retrieved April 1, 2022, from https://www.engineeringtoolbox.com/specific-heat-fluids-d_151.html Khan Academy. (n.d.). Carboxylic acid reactions overview (article). Khan Academy. Retrieved April 4, 2022, from https://www.khanacademy.org/test-prep/mcat/chemical-processes/carboxylic-acids/a/carboxylic-acid-reactionsoverview Azhar, S., Rahman, S., Abu Bakr, M., & Ahmad, Z. (n.d.). Preliminary Study of the Heat Release From Esterification Process, 10. from https://ijens.org/104403-5656%20IJET-IJENS.pdf Fleming, E. (2020, February 9). What is the density of 2-propanol? SidmartinBio. Retrieved April 6, 2022, from https://www.sidmartinbio.org/what-is-the-density-of-2-propanol/ Acetic acid. ScienceDirect, (n.d.). Retrieved April https://www.sciencedirect.com/topics/chemical-engineering/acetic-acid 6, 2022, from Stone, D. C. (2008, June 12). Uncertainties for Volumetric Glassware. Department of Chemistry, University of Toronto. Retrieved April 7, 2022, from https://sites.chem.utoronto.ca/chemistry/coursenotes/analsci/stats/volumetric.html Page 12 of 12