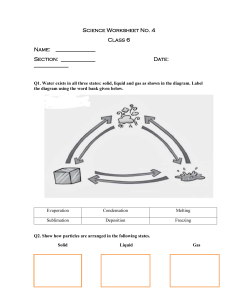

SLIDE 0 Mulungushi University School of Science, Engineering and Technology Department of Engineering Bachelor of Engineering in Mechanical Engineering MEE 242 Engineering Materials II Lecturer: Dr. Hamweendo A. LECTURE 11: IRON AND STEEL PRODUCTION Slide 1 ENGINEERING MATERIALS MEE 242 LESSON 11: IRON PRODUCTION At the end of this lesson you will know: 1. Raw materials required for iron production, 2. Iron production process in blast furnace, 3. Composition of pig iron product. Slide 2 RAW MATERIALS REQUIRED IN IRON PRODUCTION 1. IRON ORES : • Hematite (𝑭𝒆𝟐 𝑶𝟑 ): The principal ore used in the production of iron, (contain up around 70% iron). • Other ores (Contains 50%-70% iron): Magnetite (Fe3 O4 ) Siderite (FeCO3 ) Limonite(Fe2 O3 .x𝐻2 0. where x = 1.5 approx.) • Scrap iron and steel are also widely used today as raw materials in iron- and steel making Slide 3 2. OTHER RAW MATERIALS REQUIRED IN IRON-MAKING •Coke : Supplies heat for chemical reactions and produces carbon monoxide (CO) to reduce iron ore, •Limestone: used as a flux to react with and remove impurities in molten iron as slag’ •Hot gases (CO, 𝐶𝑂2 , 𝐻2 , 𝐻2 𝑂, 𝑁2 , 𝑂2 , and fuels): used to burn coke. Slide 4 PROPORTIONS OF RAW MATERIALS IN IRON-MAKING To produce one ton of iron, about seven tons of raw materials are required : • 2.0 tons of iron ore • 1.0 ton of coke • 0.5 ton of limestone • 3.5 tons of gases A significant proportion of the by products from iron production are recycled. Slide 5 IRON-MAKING IN A BLAST FURNACE • Blast furnace is a refractory-lined chamber with a diameter of about 9 to 11 m and a height of 40 m. • To produce iron, a charge of ore, coke, and limestone are dropped into the top of a blast furnace • Hot gases are forced into the lower part of the chamber at high rates to accomplish combustion and reduction of the iron ore to iron by various REDOX reactions . Figure1: Blast furnace for iron production. Slide 6 REDUCTION-OXIDATION (REDOX) REACTION IN IRON MAKING Hematite reaction with coke: Reduction of 𝑭𝒆𝟐 𝑶𝟑 , Oxidation of CO. 𝑭𝒆𝟐 𝑶𝟑 + CO = 2FeO + 𝑪𝑶𝟐 ……..(1) 𝑪𝑶𝟐 reacts with coke to produce more CO: Oxidation of Coke 𝑪𝑶𝟐 + C (coke) = 2CO ……..(2) CO reduces Fe0 to Fe and is oxidized to 𝑪𝑶𝟐 FeO + CO = Fe + 𝑪𝑶𝟐 ……..(3) Slide 7 COMPOSITION OF PIG IRON FROM THE BLAST FURNACE • Iron tapped from the blast furnace is called pig iron. • Pig iron contains over Carbon (4%) + Silicon (0.3-1.3%), Manganese (0.5-2.0%), Phosphorous(0.1-1.0%), and Sulphur ( 0.02-0.08%) • Further refinement of pig iron is required to produce cast iron and steel (see lesson 13): To convert pig iron into gray cast iron, we use a furnace called a cupola. To produce steel from pig iron, the amount of impurities in pig iron must be lowered to desired levels. Slide 8 END OF TOPIC 11: IRON PRODUCTION By now you : 1. Raw materials required for iron production, 2. Iron production process in blast furnace, 3. Composition of pig iron product.