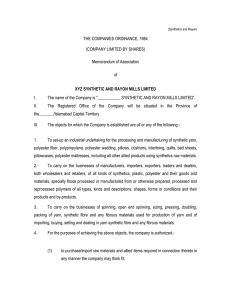

OF The Proposed New Project for Manufacturing of 1. Polyester (PET) Granules (by recycling of PET Bottle scrap) 2. Polyester Filament Yarn (POY/FDY/PSF) from PET Gran. 3. Polyester Texturized Yarn from POY/FDY Activity: 5(d) (Manmade fiber – Other than Rayon) BY Located at: Survey No. 196, 206, 207/1 & 208/1-2, Village – Velugam, Silvassa – 396230. (U. T. of D&NH). Prefeasibility Report M/s. Dodhia Synthetics Ltd. 1. EXECUTIVE SUMMARY 1.0 About project M/s. Dodhia Synthetics Ltd. propose to set up a unit located at Survey no. 196, 206,207/1 & 208/1-2, Industrial Zone, Village - Velugam, Silvassa, U.T. of Dadra and Nagar Haveli - 396230 to manufacture "Polyester (PET) Granules (by recycling of PET Bottle scrap), Polyester Filament Yarn (POY/FDY/PSF) from PET Granules and Polyester Texturized Yarn from POY/FDY" 2.0 Highlights of the project Sr. No. Particulates Description 1. Project Location Survey no. 196, 206,207/1 & 208/1-2, Industrial Zone, VillageVelugam, Silvassa, U.T. of Dadra and Nagar Haveli -396230 2. Project Activity, Category as per amendments Project Activity:-5(d)Category:-B 3. Project Cost 244.97 Crores 4. Total area of Project 36223.00 Sq. Mtrs. (3.62 Hectare) 5. Products with capacity Proposed Product: 1. Polyester (PET) Granules (by recycling of PET Bottle scrap) @ 96000 TPA. 2. Polyester Filament Yarn (POY/FDY) from PET Granules @ 96000 TPA. 3. Polyester Texturized Yarn from POY/FDY @88000 TPA. 6. Power Requirement 20 MWH 7. Utilities (D.G. Sets, Boilers, Thermopack etc...) Proposed Steam boiler: 8 MT/Hr D.G. Set: 3 Nos.(Capacity:500KVA) 8. Fuel Requirements Diesel /FO@16 KL/d for Steam Boiler & HSD@100 L/Hr. for each D.G. set 9. Man Power requirement Proposed: 300 10. Air pollution Control Measures Provided adequate chimney height to Steam boiler &D.G. Sets in order to control utility emissions. 11. Water requirement & waste water generation with mode of disposal Total Water Consumption: 530 KL/Day which will be met through Bore Well nos. 2 • Waste water generation from domestic @ 25 KL/Day and will be disposed off through soak pit system. • Industrial Waste Water @744 m3/d will be treated in the proposed waste water treatment and recycling facilities and @734 m3/d will be reuse back to process and @ 40 m3/d will be used for plantation within the premises. 12. Solid / Hazardous waste Generation Will be managed as per Hazardous Waste (Management, And Transboundary Movement) Rules-2016. 13. Nearest Highway NH-8: 6.44 km West(Approx.) 14. Nearest Railway Station Bhilad (18.50 km NW) 15. Nearest Airport Surat (116 Km N) and Mumbai (130 Km. S) 16. Nearest water body Arabian Sea (28 Km W), Damanganga River - 8.70 Km N, Madhuban Dam-Approx. 10.15 Km NE Proposed project 2 Manmade Fiber-other than rayon, Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 2. INTRODUCTION (i) Identification of Project and proponent. Name of the project Proponent: M/s. Dodhia Synthetics Ltd. M/s. Dodhia Synthetics Ltd. is in the business of textiles since last many years and Dodhia Synthetic’s main focus for putting up this project was to eliminate the dependence on quality and availability of raw material. So, this will be a backward integration for the company, which will a huge benefit, as they will produce raw material in-house not depending on others. While quality and delivery are important factors to our potential clients, price is most often the determining factor in a buying decision. Since, the products will be made of recycled PET, it will have a green tag attached to it. So good-quality products manufactured from recycled resins, big corporation are ready to offer good premium for it. These products can be used in shirting, shutting, Dress Materials, Carpets, Undergarments, Shocks and Shoes. The company is a Limited Company incorporates by the four Directors with many years’ experience. Details related to them are given below: (ii) Sr. No. Name of Director Residential Address 1. Mr. Mansukhlal Meghji Dodhia 2. Mr. Pradeep Meghji Dodhia 3. Mr. Ritesh Mansukhlal Dodhia 4. Mr. Bhadresh Mansukhlal Dodhia Flat No- 2401 / 2402, Takshashila Apartment, Nirmal Nagar, Mulund Goregoan Link Road, Mulund (W), Mumbai – 400 080. Flat No-1601, 16th Floor, Rajyog Residency, Dr. R.P. Road, Opp. Vardhman Nagar, Mulund (W), Mumbai – 400 080. Flat No- 2401 / 2402, Takshashila Apartment, Nirmal Nagar, MulundGoregoan Link Road, Mulund (W), Mumbai – 400 080. Flat No-3402, 34th Floor, "B" Wing, E-6 Sarvodaya Heights, SarvodayaParshwanath Nagar, Nahur, Mulund (W), Mumbai – 400 080. Brief description of nature of the Project M/s. Dodhia Synthetics Ltd. proposes to establish their unit at Survey no. 196, 206,207/1 & 208/1-2, Industrial Zone, Village- Velugam, Silvassa, U.T. of Dadra and Nagar Haveli -396230 for manufacturing of "Polyester (PET) Granules (by recycling of PET Bottle scrap), Polyester Filament Yarn (POY/FDY/PSF) from PET Granules and Polyester Texturized Yarn from POY/FDY". The company aimed to manufacture fancy & specialty yarns with the use of hand on experience and immense knowledge of company directors and the produced yarn will deliver high value fabric. The directors have aimed that M/s. Dodhia Synthetics Pvt. Ltd. is designed to procure the latest available technology for the manufacturing of the product. The expected production of company will suffice yarn demands of Apparel fabrics, home furnishing & industrial textiles. Proposed project 3 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. The industrial sector in the past years has seen a drastic boom and also the keeping in mind the globalization trend, we have identified the demand for the proposed products and with continuous R & D found that it can be developedin-house and produce commercially for domestic market as well as an eye more on export markets. As per the EIA notification‐ 2006 as amended the proposed new project involves the manufacturing of Polyester Filament Yarn (POY/FDY/PSF) using reprocessed PET Granules which falls under item no. “5(d) – Manmade fiber other than rayon as per the EIA notification- 2006, hence required Prior Environmental Clearance. (iii) Need for the project and its importance to the country and or region The proposed project will provide a potential growth opportunity for the company. We have identified the demand for the proposed products and it can be developed in-house and produce commercially for domestic market as well as an eye more on export markets.Its export and also increase the foreign revenue. The products are now well established and acceptable in the international markets. (iv) Demand –Supply Gap The products have very high demand for manufacturing of Texturizing yarn which is used in shirting, shutting, Dress Materials, Carpets, Undergarments, Shocks and Shoes. (v) Imports vs. Indigenous production Proposed products manufacturing in the country will be very much economical compare to Imports of the same and also the export of the same will earn extra revenue generation for our county. (vi) Export Possibility / Domestic / export Markets There is a huge demand of the proposed products in the export market. Our products are widely used and are in demand in the Textile industry. (vii) Employment Generation (Direct and Indirect) due to the project There will be very good opportunity of employment generation directly and indirectly due to proposed new project. Proposed project 4 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 3. PROJECT DISCRIPTION (i) Type of Project including interlinked and interdependent projects, If any : The proposedproject is not interlinkedand interdependentproject of the company. (ii) Location (map showing general location, Specific location, and project boundary & project site layout) with coordinates: The map showing general location, specific location and project boundary and project site layout of M/s.Dhodia Synthetics Ltd. located atSurvey no. 196, 206,207/1 & 208/1-2, Industrial Zone, VillageVelugam, Silvassa, U.T. of Dadra and Nagar Haveli -396230.The latitude and longitude of the project site is 20.138206°N and 72.978677°E Fig. 3.1: Location map showing the Project site and inter-state boundary with 5kms radius Proposed project 5 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. (iii) Profile of Project Site: Sr. Nearest Infrastructure Feature No. Distance from Project Site 1 Geographical Position Lat.: 20.138206°N, Long.: 72.978677°E 2 Elevation above Sea Level 59 Meters (Approx.) 3 Nearest Village Velugam (0.7 km S) 4 Nearest Town Silvassa (14 km N) 5 Nearest National Highway NH 8 (6.44 Km SW) 6 Nearest State Highway Khanvel Road (6.01 Km NE) 8 Nearer RW Station Bhilad (18.50 km NW) 9 Nearest Airport Mumbai (116 Km SW) 10 Nearest Surface water Resource/Reservoir Arabian Sea (28 Km W), Damanganga River - 8.70 Km N, Madhuban Dam-Approx. 10.15 Km NE 11 Forest/Protected Area Reserve forest 2.78 Kms Approx. N. 12 13 14 15 Location of Archaeologically Nil /Historically important places National Park/Sanctuary or DNH Wild Life Sanctuary ~1.10 Km W, Ecologically sensitive Area Vasona Lion safari & Satmaliya Deer Park 9& 6 Km NE Gujarat – 8.50 Km N National or State Boundary Maharashtra – 0.98 km W Silvassa- 14.00 Km N, Madhuban Dam- 10.30 Km NE Tourist Places Dudhani-18.50 KM NE, Khanvel- 8.50 KM E (Approx.) • Plot site Area Statement: Proposed Area (in m2) Area Statement Total Plot Area 36223.00 Construction Area 14275.00 Proposed E.T.P, STP & Open H.W.S. 1450.00 Parking Area 2560.00 Internal Road Area and Open Area 6437.00 Greenbelt Area Proposed project 11975.00 6 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. (iv) Site Layout Plan: Proposed project 7 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report (v) M/s. Dodhia Synthetics Ltd. Details of alternate sites considered and the basis of selecting the proposed site, particularly the environmental considerations gone into should be highlighted : • U.T. of Dadara & Nagar Haveli is industrially developed area for manufacturing of textile products. • There are more than 25 manufacturing units are in operation at large scale level; hence the availability of skilled man power and resources are easy. (vi) • The site is having good connectivity of road, power etc.. to set up industrial unit. • Climate is suitable for textile manufacturing activities. Size or magnitude of operation: As per the proposed project cost the project is covered under Large Scale category of manufacturing industries, it comes under LSI. (vii) Project description with process details (a schematic diagram/ flow chart showing the project layout components of the project etc. should be given): • LIST OF FINISHED PRODUCTS Sr. No. • Name of the Proposed Products Quantity 1. Polyester (PET) Granules (by recycling of PET Bottle scrap) (in MT/Year) 96000 2. Polyester Filament Yarn (POY/FDY/PSF) from PET Granules 96000 3. Polyester Textured Yarn from POY/FDY 88000 INFRASTRUCTURE, MACHINERIES, EQUIPMENT & TECHNOLOGIES : The company has purchased adequate area of land for proposed project. The company proposes to develop and construct building with latest concepts to operate proposed industrial activities efficiently. The company proposes to install latest available technology and required plant and machineries to manufacture proposed products. The company proposed to install adequate and efficient waste water treatment and recycling facilities. The company proposed to install adequate and efficient onsite safety and emergency management system. Proposed project 8 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. MANUFACTURING PROCESS • The company shall use the latest available process technology for the production. This section includes the manufacturing process of the product, chemical reactions, and mass balance of each product. 01. Product: PET Graduals Capacity: 96000MT/Year a. Manufacturing Process: Manufacturing of PET Granules from PET waste bottle is mainly mechanical process and the same will be implemented with latest available technology considering good quality of products. Detailed process is under. 1. Breaking apart hard baled bottles & Loosening in a Tromel. 2. Segregation of PET: Clear, green, blue, brown, etc. Foreign objects: rubber, glass, paper, stones, etc. Other plastics: PE, PP, PVC and Detection of Metals: removal by hand or automatic separators. 3. Pre-sorted PET Bottles for processing in the Washing Plant OR Loose Bottles in Hot Battle Wash System for removal of labels, impurities etc. 4. Size Reduction as well partial removal of impurities e.g. labels & dust, light particles etc… 5. Intensive Rinsing in presence of fresh water, for added washing effect. 6. Removal of lighter materials like paper, other types of floating plastic and slightly sticky substances, glue, labels, dirt etc. 7. Removal of residual humidity from PET flakes by drying. 8. Clean, Dry, Washed PET Flakes will be transferred into granulation extruder. 9. PET Flakes mixed with required additives and PET granules will be made. 10. PET granules will be packed and dispatch for further processing. Proposed project 9 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. b. Process Flow Diagram: INPUT (Hard baled PET Bottles) Bale Breaking & Loosening Sorting – Automatic / Manual Granulator Friction Washer Hot & Cold Wash System Dryers – Mechanical & Thermal Screening & Aspiration Separator &Colour Sorter Collection – Silos / Big Bags PET flakes mixed with additives in Extruder Granulation PET Granules Proposed project 10 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 02. Product: Polyester Filament (POY/FDY/PSF) Capacity: 96000MT/Year a. Manufacturing Process: Partially oriented yarn (POY) and fully drawn yarn (FDY) will be made from PET granule. Step wise process is as follows. 1. Unloading and storage of polyester chips & Granules and Conveying pneumatically by dense phase conveying system. 2. Fluidized bed crystallizer cum dryer. Moisture level of chips is brought to 0.003%. 3. Dried chips are fed into extruder for melting, compression and mixing (homogenization by a moving spiral barrier type screw. Screw barrel is treated in five different constant temperature zones. 4. Melt is filtered up to 20 micron through C.P.F (Continuous Polymer Filter) and fed to various pumps. 5. METERING:Positive displacement pump of different capacity speed controlled by inverter, decides. 6. Melt comes to pack contains various filters and spinneret which decides number of filament in yarn. 7. QUENCHING :Melt in yarn shape is quenched in cold air(23oC) in quench chamber were air is equally distributed by honey combs. 8. Spin finish oil is applied to the yarn for better binding & reduction& static charge generation by positive displacement pump. Speed controlled by inverter. 9. Yarn is given "S" wrap by twp Godet rollers for controlling tension. Driven by inverter. Additional three HOT godet are used for FDY in same process. 10. WINDING:Yarn is wrapped on paper tube by high speed spindle driven auto turret winder 28003400 meter / min for FDY4500 to 5200M/Min. 11. Inspection & Testing and Grading (POY/FDY/NFY/PPFY) can be sale directly or further. 12. Bobbins are sent for further processing i. e. Texturising to get texturized yarn 13. Texturized Yarn is sent to Twisting to get twisted Yarn. 14. Packing and dispatch for further processing to make fabrics. Proposed project 11 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report b. M/s. Dodhia Synthetics Ltd. Process Flow Diagram: Polyester chips /(PET) granules and conveying pneumatically Drying in Fluidized bed crystallizer cumdryer. Dried chips melting, Compression and mixing in extruder. Filtration through C.P.F and METERING Spinning of Yarns as per required denier and QUENCHING Spin finish oil application to Yarn Physical Property control by tension and temperature WINDING of Yarn by high speed spindle driven auto turret Inspection & Testing and Grading (POY/FDY/PSF) can be Sale Directly Or Further Processing Texturizing of Yarn to get Texturized yarn Packing and dispatch for further processing to make fabrics Proposed project 12 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 03. Product: Texturize Yarn Capacity: 88000MT/Year Manufacturing Process and Process Flow Diagram: Raw Material Description: Raw material in unstable condition i.e POY or FDY is purchased from the market as a feed package for texturising machine. Texturising Machine with Heater I & Heater II Description: Texturising is a process of introducing bulk & stretch to the yarn & stabilizing the yarn for further process. This bulk & stretchness is imparted in yarn by following process. 1) Passing the yarn through first and second nip/apron rollers, the speeds of which control the overfeeding or stretching of yarn required as per the base yarn i.e. FOY or POY. 2) After first Nip rollers the yarn is passed through primary heaters mostly contact type at around 2000C. This temperature and rotation of yarn just below primary heaters due to friction disc imparts bulk and stretch to the yarn. The friction discs are of different types having plus or minus points each of them. They are a) Coated ceramic discs b) Solid ceramic discs c) Nickel Diamond discs d) Polyurethane discs. Among all last one i.e. polyurethane discs are more commonly used due to better quality end results. But the only disadvantage is the durability which is less, hence one must change them on regular basis involving higher cost. 3) Just after rotating discs the yarn is passed though secondary rollers & then through secondary heaters mostly non-contact type. At this stage excessive stretch in yarn is taken out hence reducing the elongation and stabilizing the bulk of yarn. The yarn pass through this stabilized zone is known as ‘Texturized yarn’, where as the yarn which is bypassed through secondary heaters is unstable with more crimp in yarn known as ‘Crimped yarn’. 4) The yarn after second heater and third delivery rollers comes to take-up. In the path a certain percentage of finish is applied so that there should not be any problem in next process. The final package of texturised yarn can go upto 5kgs net with 290mm paper tubes. Resultant Yarn Packed in Cartoons Proposed project 13 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report (vi) M/s. Dodhia Synthetics Ltd. Raw material required along with estimated quantity, likely source, marketing area of final products/s, mode of transport of raw Material and finished product : Detailed raw material requirement along with estimated quantity, likely source, marketing are of final products mode of transport of raw material and finish product • Raw material requirements: Name of the products Polyester (PET) Granules Quantity Raw Materials T/T PET Bottles Scrap 1.180 112941.00 Cleaning agents 0.025 2700.00 1.030 96000.00 0.008 864.00 (POY) / FDY 0.950 88000.00 Antistatic oil 0.005 540.00 PET Granules/ PET Chips Polyester Filament Yarn (POY/FDY/PSF) Finish oil Polyester Textured Yarn • T/Year Marketing area of final products: “Texturized Yarn and Partially Oriented Yarn (POY) / Fully Drawn Yarn(FDY)” which are used in the process of weaving and knitting of fabrics meant for suiting, shirting, dress materials and home furnishings. The company has a wider customer base and to cater to the increased market demand, the company proposes production. • Transport of Raw material and Finish products: Sr. Name No. 1. PET Scrap Bottles Storage Capacity 9000 MT Means of Storage Ware house Mode Of transport Source -- Market 2. PET Granules/PET Chips 10000 MT Ware house By road in truck Captive 3. POY/FDY 5000 MT Ware house By road in truck Captive 4. Spin finish oil 30 MT Storage Tank By road in tanker Manufacturer 5. Antistatic oil 10 MT Storage Tank By road in tanker Manufacturer 6. Cleaning agents 10 MT Ware House By road in truck Manufacturer (vii) Resource optimization/ recycling and reuse envisaged in the project, if any , should briefly outlined : The raw materials packed in drums /bags and stored in the warehouse. By adoption continuous improvement in technology and process the reduction in process waste generation will be achieved. By proper and efficient handling of raw materials, wastages of raw materials will be reduced. Proposed project 14 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. (viii) Availability of water its source, Energy/power requirement and source should be given: Availability of water its source, Energy/power required and its source. • Water Requirement Sr. No. • 1 Domestic 50.00 2 Industrial 1500.00 Total 1550.00 Energy Requirements and its source: Sr. No. 1 • (ix) Proposed Quantity (M3/Day) Particulars Particulars Proposed Source Steam Requirement 8 MT/ Hr Will be sourced from 2 no. of boiler having capacity of 4 MT/Hr each. Power Requirements and its source: Sr. Particulars No. Power –Electricity 1 requirement Proposed Source 20 MWH Electricity Department, Silvassa Quantity of waste to be generated (liquid and solid) and scheme for their Management/disposal: Sr. No. 1 2 • • • • • Description Water consumption (M3/Day) Domestic Industrial Processing and washing (Recycled water) Boiler & Cooling Greenbelt (Treated waste water) Subtotal Industrial G. Total Net water requirement, m3/d Total Industrial wastewater generation (m3/d) Reuse of treated effluent to process and washing Reuse of treated effluent for green belt development Domestic Waste water disposal through soak pit Proposed project 15 50.00 Waste Water Generation (M3/Day) 45.00 2000.00 1800.00 1000.00 120.00 3120.00 3170.00 300.00 0.00 2100.00 2145.00 1050.00 2100.00 2000.00 100.00 45.00 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report • M/s. Dodhia Synthetics Ltd. Water Balance Diagram: Total Water Requirement -3170 [Fresh Water - 1070 Recycled Water - 2100] 1304 50 Domestic 2000 Process & Washing 20 Evap. Losses 700 1000 Gardening Cooling / Boiler 45 To Soak pit/ Septic tank 1800 300 Recycled Water to Reuse back to process (2000) and Gardening (100) Waste Water Treatment & Recycling facilities (1800 + 300 = 2100) 3 Note: - All quantity of water consumption and waste water generation are shown in m / day water balance Proposed project 16 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. Effluent Treatment Plant Details: Design Criteria : • • Source of Effluent:, washing and Coolingtower blowdown etc. • Effluent Generation: 2500 m3/Hr. Effluent Characteristics: Sr. No. Parameter 1 2. 3. 4. 5. 6. 7. pH Suspended Solids (mg/lit) Oil & Grease (mg/lit) Colour(units) COD Value (mg/ lit) BOD Value (mg/ lit) Total Dissolved Solids (mg/lit) Untreated Effluent (Inlet) 04– 06 100 - 200 25 200 units 3000 1500 3000 Treated Effluent (Outlet) 6.5 – 8.5 <100 < 10 < 100 <100 < 30 < 2100 PROPOSED EFFLUENT TREATMENT PROCESS DESCRIPTION Dodhia Synthetics is a leading Polyester POY/FDY producer starting with Polyester Chips as Raw Material. They intend to back ward integrate into manufacture of Polyester chips. They have decided to install a Polyester Chip production Plant with Polyester Bottle waste as RAW Material. To produce Good Quality Chips for POY/FDY production, the Polyester Bottle Waste has to be cleaned and flaked to remove all accumulated dust & dirt, remnants of filled material, removal of all non-Polyester contaminations and removal of colored contaminations. For this an Integrated Wash line of 5000 kg/hr, is being installed. Washing and Cleaning is done using only water – hot and cold with and without wash chemicals. Only dilute caustic soda and detergents (optional) and hydrochloric acid are used in the Washing process. The Wash water washes off the dust & dirt washed from the bottles. The caustic soda acts to clean the surface of the polyester flakes off any adhering dust & dirt and. Neutralization of any un reacted caustic soda in the wash water is necessary as caustic soda will severely degrade polyester at process temperatures. The neutralization is done using dilute Hydrochloric acid. The Wash Water is the only Effluent generated during the entire PET Bottle Washing Process. The Washing Process is designed for maximum water recycle. All Water systems have recirculation of Wash water ranging from 50% min to 90% depending on the level of contamination that will be removed by the wash water at that stage. Considering the total Wash line about 70 % of water is internally re-circulated and only about 30 % is sent out to Effluent Treatment Plant. The Quantity of Wash Water sent to ET Plant is about 31-35 KL/hr the Plant capacity of 5000 kg/hr. The major contaminant in the wash water is “suspended solids” followed by BOD/COD caused by the remnant filled material and paper from labels. The ET Plant is designed to remove these contaminants to the standards set by the Pollution Control Boards. Such removal does not cause any additional pollution as the residue/sludge is only sand, BOD/COD are bio degraded in the Effluent Treatment Plant. Proposed project 17 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. Details of the Process: Sr. No. Equipment Process All the Wash water is passed through the Vibratory Filters to remove any paper labels and large dust & dirt. 3 nos such units are used – 1 Vibratory Water Filter two for bottle washing section and one for wet granulation system. Typical Screen mesh used ranges from 100 mesh to 200 mesh depending on water and dirt loading and particle size envisaged in that section. Effluent from the Vibratory Filters is collected in the Equalization 2 Equalization Tank Tank. The capacity of the Tank is about 30 cu.m Provision is made for Acid dosing to make the effluent as “neutral” as possible – pH ~ 7. Two Flash Mixing tanks are used in Series. Tank 1 is for addition of coagulant and Tank 2 is for Poly electrolyte 3 Flask Mixing Dosing tanks with agitators are provided for make-up, storage and dosing of the additives. Flash mixing tanks have agitators to homogenize the solution and effluent. Floculator with a slow speed agitator is used to settle the coagulated 4 Floculator dust & dirt. Settle able large size coagulated particle settle and are removed as sludge from the bottom using sludge pumps. The Effluent leaving the floculator still has high Turbidity due to very small to small size particles of dust & dirt which will not settle. DAF units are used to remove particle, fat, oils and grease from water. It consists of a rectangular/circular tank having a skimmer on the top. Influent enters near the bottom of the tank. Compressed air is mixed with high pressure water in a pressure drum. At elevated pressure 5 Dissolved Air (DAF) Floatation air “dissolves” in the water. This water is pumped into the DAF unit near the influent inlet nozzle. Due to release of pressure air bubbles out of the water as micron size particles and mixes with the incoming effluent in a very intimate way. Micron size air bubbles adhere to the dust & dirt particles and other contaminants and float them to the surface of the tank. A skimmer removes the floating mass into a separate tank. Sludge pumps remove this sludge to the Sludge treatment section. 6 Lamella Settler Lamella Settlers with inclined baffles are used to settle more settle able solids. The Treated effluent is stored in Collection for distribution to Plant and further treatment 7 Collection tank The Quality of Treated Effluent at this stage is sufficient for use in the first stages of Bottle Washing. So about 12,000 lit./hr are directly sent to Bottle Washing Area Proposed project 18 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. For use in the final bottle washing stage, the suspended solids level in the effluent need to be reduced further. Ultrafine filter with or 8 Ultrafine Filtration without carbon bed is used to further treat the effluent. About 2,000 lit. /hr are treated thus. The Treated effluent is stored in Collection for distribution to Plant- final bottle washing stage. An Aeration Tank with fine bubble air diffuser and a Secondary Clarifier is used to reduce the BOD/COD to the required standards. 9 Biological Treatment About 14,000 lit./hr are treated and the treated water is stored in collection tank and sent to Wet granulator via final rinser. Since the final Treated effluent meets the Pollution Control Standards, any bleed out is used for gardening and sanitary use. All the Sludge from the Plant are pumped to the Sludge tank. From 10 Sludge Treatment here the Sludge is pumped into the Sludge Press to dewater. The dewatered Sludge is sent to land fill (TSDF) and the water is recycled back to plant. Proposed project 19 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report Proposed project M/s. Dodhia Synthetics Ltd. 20 Manufacturing: Manmade Fibers –Other Than Rayon • Utility Emission & Control Measures: Sr. No. Particulars Fuel / Power & its Qty 1. Steam Boiler – 2 Nos Capacity: 4 MT/Hr each. Diesel/FO: 16 KL/Day. 2. D.G. Set – 3 Nos (Proposed) HSD : 300 lit/Hr. Each Capacity: 500 KVA each with Acoustic enclosure Probable Pollutants Control Measures & Limits PM <150 mg/Nm3 Stack ht: 30 m SO2 < 100 ppm Diameter: 500 mm NOx< 50 ppm PM <150 mg/Nm3 SO2 < 100 ppm NOx< 50 ppm Chimney ht: 11 m Diameter: 200 mm • Utility Emission & Control Measures: There will not be any direct process gas emission during manufacturing of proposed products. The utility emissions will be generated from the proposed Steam Boiler & D.G. Sets. D.G. Set will be utilized during the power failure and HSD will be used as a fuel for D.G. Set. • Quantity of Solid Waste generation and its management: Types of Waste & Category ETP waste (35.3) Source of Generation From ETP Proposed Quantity per Year 150.00 MT Plastic waste From process 270.00 MT Used oil (5.1) From plant and machineries 100.00 Lit. Mode of Storage Will be collected and stored in to the solid waste storage area Will be Collected manually and stored in solid waste storage area. Will be collected into the drum and stored after accumulation of sufficient quantity Method of Disposal Will be sent to GEPIL site, Randha for final disposal. Will be recycled back /sold to actual users and Plastic wastes Rules-2016 Will be sold to registered refiners/ sent to TSDF site Prefeasibility Report (x) M/s. Dodhia Synthetics Ltd. Schematic representations of the feasibility drawing which give information of EIA purpose: A schematic representation of the feasibility drawing Type of Industry Proposed mfg. unit of “Man Made fiberother than Rayon” Type of category as per EIA notification: Manmade fiber (Activity -5(d)- Category-B) Proposed Activity: The proposed new project involves the production of " PET Granules, Partially Oriented Yarn/ Fully Drawn Yarn and Texturize Yarn Manmade fibers" Site Location: The company located Survey No Survey no. 196, 206,207/1 & 208/1-2,, Industrial Zone, Village- Velugam, U.T. of Dadra and Nagar Haveli -396230.. Public consultation: Not required as the project is located in Industrial zone Submission of Form-1 and Pre-Feasibility Report & Draft TOR • • • • • Resource requirements Raw Material: Sourced from Manufacturer / Traders of the same. Land: New NA Land in Notified Industrial Zone, At Velugam. Water: will be sourced through Bore Well. Power: power will be sourced through DNH Electricity Department Fuel : Local delear Presentation before the EAC for TOR Env. Mgt. Plan (EMP) • Air Pollution Control Measures: Air Pollution control system will be provided. • Greenbelt Area 33% of the Total Area will be developed. • Health & Safety measures will be followed properly • • • • Soak pit/ Septic Tank and ETP for Industrial waste water. No Process waste will be generated. Flue Gas emissions: Adequate chimney height will be provided. Fugitive emission: There is no generation of fugitive emissions. Proposed project 22 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 4. SITE ANALYSIS 4.0 Site Analysis (i) Connectivity: The project is located in Industrial zone of Velugam which is very well connected to National Highway no.8 and Western Railways. And the nearest air port (Mumbai) and port are 150 KM away from the project site by road. (ii) Land Form, Land use and Land ownership: The existing developed land is within the notified industrial zone of U.T. D&NH. The total plot area (36223.00 sq.m.) is belonging to M/s Dodhia Synthetics Ltd. The proposed land is located in the industrial zone of Dadra & Nagar Haveli (notification no.13-1(39)/95/PWD-I/2000/752, dated: 5thJuly 2001) (iii) Existing Infrastructure/ land use pattern Proposed project will be located within notified industrial zone of U.T. D&NHwhich has available infrastructure like water, electricity, roads, rail, transportation and drainage system and TSDF Site. Surrounding area is consisting with agriculture, other industrial units. (iv) Soil classification and Land use classification: General soil classification of the area is as under: • • • Soil Characteristics & Land use classification: Most of the area cultivated, some area non cultivated under sallow and past forest. Surface color: Reddish brown to dark brown, in hilly area very dark, grayish to dark brown and dark Yellowish brown Depth of the soil: 0 to 25 cm (shallow to mod deep) in hilly forest 45 to 150 cms. (Deep to very deep) in predominant slope & flood plain alluvial area. • Predominant Texture: Heavy Texture, predominantly clay. (v) Climate data from secondary sources: Rainfall Data: The northern part has comparatively poor rainfall. Rainfall data was taken fromworldclim.org indicates that the long term mean spanning the period 1965 -2020 is medium to high226 to 259 cm rainfall for the Dadra & Nagar Haveli (DNH Spinners)region as compared to 197 to 242 cm rainfall for the central Gujarat. The isohyetal map for that period shows a high variation in rainfall from the Gujarat, Rajasthan towards the north and south part. • Rainfall data is important in the planning strategy for industry development. The Rainfall map for Dadra &Nagar Haveli shows that Precipitation recorded over a long-term period (1 year) attains a yearly mean maximum of 200- 250 cm for the year 2015. (vi) Social Infrastructure available: • Silvassa infrastructure owes itself largely to the initiatives of Administration, in building the Industrial infrastructure and in attracting young entrepreneurs from Dadra & Nagar Haveli (U.T) Equally, the growth of the social infrastructure – Residential facility, Drinking water, Health-care Facilities , Education Facilities , Socio-Cultural Facilities , Other Public-Semi-Public Facilities ,Police, Fire &Emergency Services ,Communication (Postal Facility) , Recreational Facilities & Open Spaces, Distributive Services, Miscellaneous Facilities, Banking facility Garden etc. - There are good residential and commercial areas Daman and Silvassa (the capital of Dadra and Nagar Haveli) attract both Indian and international Proposed project 23 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. tourists. The nearest Railway station is Vapi on Western Railway. All major Mail/Express trains are available at Vapi. The UT of Dadra & Nagar Haveli is almost touching Mumbai - Baroda - Delhi National Highway No. 8 (Western Express Highway). Silvassa is about 14 Kms from Bhilad& 18 Kms from Vapi. Mumbai 180 Kms, Surat 140 Kms, Nasik 140 Kms and Daman 30 Kms. Proposed project 24 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 5. Planning Description 5.0 Planning Brief. (i) Planning Concept (Type of industries, facilities, transportation etc) Town and Country Planning /Development authority Classification: There is a cluster of numerous large-scale, medium-scale and small-scale industries, engaged in manufacture of variety of products in the notified industrial zone of U.T. D&NH. The notified industrial zone of U.T. D&NH has the entire available infrastructure like water, electricity, roads, rail, and transportation, availability of raw material, TSDF Site and drainage system. (ii) Population Projection: Not applicable (iii) Land use planning (breakup along with green belt etc.): The proposed project is located within the notified industrial zone of U.T. D&NH and due to the proposed project there will not be any change in the land use pattern of the region. Plot Area Statement: Proposed Area (in m2) Area Statement Total Plot Area 36223.00 Construction Area 14275.00 Proposed E.T.P, STP & Open H.W.S. 1450.00 Parking Area 2560.00 Internal Road Area and Open Area 6437.00 Greenbelt Area (iv) 11975.00 Assessment of Infrastructure demand (Physical & Social) : The proposed infrastructure to manufacture products will be built with standard engineering design considering all the relevant parameters related to environment, health and safety. Facilities like road and communication are good. Banks, ATM's and medical facilities are also adequate. (v) Amenities/ Facilities: Education- schools including middle, secondary and higher secondary schools, Collages, social welfare hostels. Medical and Health- Community Health Centre, & Primary Health centre are available near villages Power and water- All the villages are electrified and drinking water facilities are extended to all villages. Rail and Road- The project site is very well connected by road through State Highway no. 8, Western railways. Proposed project 25 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. 6. Infrastructure Details 6.0 (i) Proposed Infrastructure: Industrial Area (Processing Area). After obtaining require prior clearances the developmental activities will be initiated. (ii) Residential Area (Non Processing Area) : No residential area is involved in the proposed project. The employs are accommodated in nearby Residential areas (iii) Green Belt: Green belt area will be provided and maintain at the tune of 33% of the total land area as the project site is within the developed industrial area. (v) Connectivity (Traffic and Transportation Road/ Rail/ Metro/ Water ways etc) : The project site is very well connected by road through National Highway no. 8 and western railways. (vi) Drinking Water management (Source& Supply of water): Water requirement will be fulfilled through Bore well. (vii) Sewerage System: Proposed unit will provide sewerage system to dispose the sewage effluent. (viii) Industrial Waste Management: The company proposes adequate and efficient waste management systems. • Industrial waste water will be treated in the proposed waste water treatment and recycling facilities. • Generated Hazardous waste will be disposed as per rule. 7. (i) Rehabilitation and Resettlement (R&R) Plan: Policy to be adopted (Central/ State) in respect of the project affected persons including home oustees, land oustees and landless laborers (a brief outline to be given): The proposed Industry does not envisage any disturbance to local community or the village since the land is acquired and fully owned by M/s. Dodhia Synthetics Ltd. as Notified industrial zone. The proposed project will not affect the home oustees, land oustees and landless laborers. Hence there is no R & R plan required. 8. Project Schedule & Cost Estimates: (i) Likely date of start of construction and likely date of completion (Time schedule for the project to be given): After obtaining Environmental clearance and Consent to Establish from PCC, the company shall start the proposed construction and commissioning of the project. (ii) Estimated project cost along with analysis in terms of economic viability of the project: Plant & Machinery, Pipeline & Fittings, Electrical Installation, Safety systems, etc. are the major heads considered in the Capital Cost Projection for the proposed project. Environment Protection has also been considered in planning the Cost Projection, which will include Green belt development, safety systems, etc. Proposed project 26 Manufacturing: Manmade Fibers –Other Than Rayon Prefeasibility Report M/s. Dodhia Synthetics Ltd. Capital Cost Projection Sr. No. Proposed Project Cost (Rs. In Crores) Purpose 1. 2. 3. 4. Land Building and Civil Works Plant & Machinery and other fittings Environmental protection measures TOTAL : 4.97 35.00 200.00 5.00 244.97 The proposed investment will be made by company only. The company will provide budgetary provision for the recurring expenses for environmental issues while planning the allocation of funds during the annual budgetary planning. Recurring Cost per annum 9. (i) Sr. No. Component Proposed (Rs. in Crores/annum) 1. Environment & Safety Management System 0.25 2. Greenbelt Maintenance 0.25 3. Enterprise social contribution 0.25 Total 0.75 Analysis of Proposal (Final Recommendations): Financial and social benefits with special emphasis on the befit to the local people including tribal population, if any, in the area: Proposed activity will provide benefits to the local people in terms of financial and social welfare. • Local people will get direct financial benefit by way of employment. • Local people will get some contracts of supply and services to get indirect income. • Company will contribute in improving education and health facilities in nearby area. Proposed project 27 Manufacturing: Manmade Fibers –Other Than Rayon