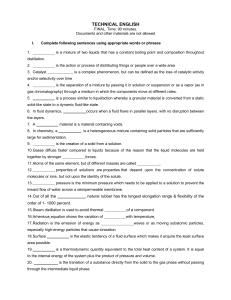

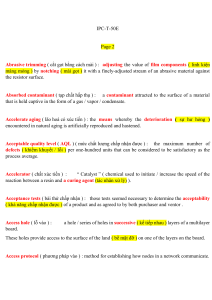

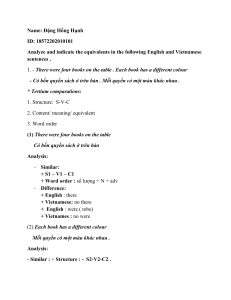

Quality Management Instructor: Vi Nguyen, PhD Global Production Engineering Management (GPEM) Faculty of Engineering Vietnamese German University Seven Basic Quality Tools (Q7) Practice Scatter Diagram: Practice A product development team wants to check if the sugar content of cake affects the taste rating. 25 samples of cake with different sugar content are distributed to random customers in a public area. Analyze the data has collected in the table and check whether there is a linear correlation between the variables. Is it the strong or weak positive/negative relationship? Sugar Content Taste Rating 10 10 4 18 9 14 8 1 11 9 6 5 8 20 9 14 7 20 12 3 6 13 20 16 48.00 42.00 18.40 84.60 37.80 58.80 39.20 8.00 50.00 35.00 24.00 19.00 34.40 84.00 36.90 67.20 34.30 82.00 54.00 14.70 24.60 61.10 96.00 70.40 Scatter Diagram What type of correlation is shown by these graphs? weak negative correlation strong positive correlation zero correlation weak positive correlation weak negative correlation strong negative correlation Flow chart http://www.au.af.mil/au/awc/awcgate/navy/bpi_manual/mod6-flowchrt.pdf Flow chart http://www.au.af.mil/au/awc/awcgate/navy/bpi_manual/mod6-flowchrt.pdf Flow chart Using the information provided in the given text, draw a flow chart describing the different stages involved in the making of coins Production of coins at the mints is a complete process. It starts with the buying of unmixed metals and their testing by the Assay Department. Then the metals are alloyed in oil-fired or electric arc furnaces, and cast into ingots 40 cm wide, 15 cm thick and 6 m long. These ingots are reheated until the temperature is hot enough for hot rolling. During this stage, the ingots pass through a series of rollers until they form long, thin sheets which are of the thickness of a coin. From these thin strips, blank discs are punched. These are the basic raw materials for the manufacture of coins. The blanks are heated to soften them, and they are rolled so that the rim is raised. Finally they are stamped with the design of the coin. At every stage, defective pieces are carefully sorted out, and (with the frequent checking and returning points) strict quality control maintained. Rejects are returned to the alloying stage, together with the waste from the alloy strip. http://www.au.af.mil/au/awc/awcgate/navy/bpi_manual/mod6-flowchrt.pdf Cause and Effect Diagram You experience bad downtime with your Laptop. Draw up a fishbone diagram to identify, sort, and display possible failure causes for this problem. https://conceptdraw.com/a2300c3/preview Cause and Effect Diagram You experience poor gas mileage with your motorbike. Draw up a fishbone diagram to identify, sort, and display possible failure causes for this problem. 1. A quality control team in a Vietnamese company reported the defects in their production line. Draw Pareto diagrams to determine the 3 main errors that need to be addressed. Annotate and explain the results of the presentation No. 1 2 3 4 5 6 7 8 9 10 Lỗi phát sinh Defects Lõm bề mặt Cong vênh Thiếu liệu Ba vớ Đường chảy liệu Bọt khí-rỗ khí Đường kết nối Vết nứt Trầy xước Khác Số lượng Quantity 3500 1587 998 645 327 189 157 132 111 99 Chi phí làm lại sản phẩm của 1 lỗi (USD) Cost per unit 20 7 35 60 3 5 12 40 12 14 2. You experience poor gas mileage with your motorbike. Draw up a fishbone diagram to identify, sort, and display possible failure causes for this problem. 1. A quality control team in a Vietnamese company reported the defects in their production line. Draw Pareto diagrams to determine the 3 main errors that need to be addressed. Annotate and explain the results of the presentation No. 1 2 3 4 5 6 7 8 9 10 Lỗi phát sinh Defects Đường chảy liệu Bọt khí-rỗ khí Ba vớ Vết nứt Lõm bề mặt Cong vênh Thiếu liệu Đường kết nối Trầy xước Khác Số lượng Quantity 2500 1823 1687 901 800 624 421 321 125 98 Chi phí làm lại sản phẩm của 1 lỗi (USD) Cost per unit 20 7 35 60 3 5 15 23 50 14 A quality control team in a Vietnamese company reported the defects in their production line. Draw Pareto diagrams to determine the 3 main errors that need to be addressed. Annotate and explain the results of the presentation No. 1 2 3 4 5 6 7 8 9 10 Lỗi phát sinh Defects Trầy xước Cong vênh Vết nứt Ba vớ Thiếu liệu Bọt khí-rỗ khí Lõm bề mặt Đường chảy liệu Đường kết nối Khác Số lượng Quantity 2221 1612 1311 969 888 621 358 223 128 67 Chi phí làm lại sản phẩm của 1 lỗi (USD) Cost per unit 20 7 35 60 3 5 15 10 35 14 Apply quality tools in A3 Report: Manpower Method Environment PROBLEM Material Cause No. Identified Root Cause Machine Potential Solution