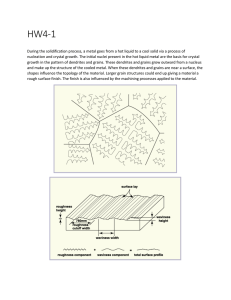

Metal Casting Fundamentals: Solidification Processes & Defects

advertisement

MANUFACTURING PROCESSES Processing BMM3643 Manufacturing Processes Shaping processes Assembly Surface Technology Topic 1 : Fundamentals of Metal Casting Solidification processes Cleaning & surface treatments Forming processes Coating & deposition processes LECTURER: Nur Azhani Abd Razak Department of Mechanical Engineering azhani@ump.edu.my Particulate processing Solidification of Metals Involves liquid metal turning back into solid metal. The significant factors; Type of metals Thermal properties (metals & the mold) Relationship volume & surface area Shape of the mold Pure Metals Have a clearly defined melting point. Temperature remains constant during freezing. Solidifies from the walls of the mold toward the center of the part. Mechanical fastening Permanent joining processes Threaded fasteners Welding Permanent Fastening methods Brazing & soldering Adhesive bonding Material removal Grain Structure for Pure Metals Two types of grains are formed for a pure metal Fine equiaxed grains Columnar Rapid cooling at the walls produces fine equiaxed grains Columnar grains Grow opposite of the heat transfer throughout the mold following the chill zone Equiaxed grains If crystals can grow approximately equally in all directions – equiaxed grains will grow. Large amounts of under cooling is needed near the wall of the mold. Cast Structures of Metals Preferred Texture Development Figure 10.1 Schematic illustration of three cast structures of metals solidified in a square mold: (a) pure metals; (b) solid-solution alloys; and (c) structure obtained by using nucleating agents. Source: G. W. Form, J. F. Wallace, J. L. Walker, and A. Cibula. Development of a preferred texture at a cool mold wall; note that only favorably oriented grains grow away from the surface of the mold. Source: Kalpakjian (2016). Manufacturing Engineering and Technology, 8th edition. Alloy Solidification Solidification Patterns (a) Figure 10.3 Schematic illustration of alloy solidification and temperature distribution in the solidifying metal. Note the formation of dendrites in the mushy zone. Solidification in alloys begins when the temperature drops below the liquidus TL and is complete when it reaches the solidus, TS. Within the TL and TS temperature range, the alloy is like a slushy with columnar dendrites. (b) Solidification patterns for gray cast iron in a 180-mm (7-in.) square casting. Note that after 11 minutes of cooling, dendrites begin to reach each other, but the casting is still mushy throughout. It takes about 2 hours more for this casting to solidify completely. (b) Solidification of carbon steels in sand and chill (metal) molds. Note the difference in solidification patterns as the carbon content of the metal increases. Source: H. F. Bishop and W. S. Pellini. Cast Structures (a) (b) Riser-gated Casting (c) Schematic illustration of three basic types of cast structures: (a) columnar dendritic; (b) equiaxed dendritic; and (c) equiaxed nondendritic. Source: D. Apelian. Schematic illustration of a typical risergated casting. Risers serve as reservoirs, supplying molten metal to the casting as it shrinks during solidification. Source: American Foundrymen’s Society. Schematic illustration of cast structures in (a) plane front, single phase, and (b) plane front, two phase. Source: D. Apelian. Fluidity Test 1. Sprue – is a vertical channel though which the molten metal flows downward in the mold. 2. Runners – channels that carry the molten metal from the sprue to the mold cavity. 3. Gate – is the portion of the runner though which the molten metal enters the mold cavity. 4. Risers – serve as reservoirs to supply the molten metal necessary to prevent shrinkage. Temperature Distribution Temperature distribution at the interface of the mold wall and the liquid metal during the solidification of metals in casting. A test method for fluidity using a spiral mold. The fluidity index is the length of the solidified metal in the spiral passage. The greater the length of the solidified metal, the greater is its fluidity. Solidification Time Hot Tears in Casting Examples of hot tears in castings. These defects occur because the casting cannot shrink freely during cooling, owing to constraints in various portions of the molds and cores. Exothermic (heat producing) compounds may be used as exothermic padding to control cooling at critical regions to avoid hot tearing. Solidified skin on a steel casting. The remaining molten metal is poured out at the times indicated in the figure. Hollow ornamental and decorative objects are made by a process called slush casting, which is based on this principle. Source: After H.F. Taylor, J.Wulff, and M.C. Flemings. Casting Defects Examples of common defects in castings. These defects can be minimized or eliminated by proper design and preparation of molds and control of pouring procedures. Source: After J. Datsko. Internal & External Chills Various types of (a) internal and (b) external chills (dark areas at corners) used in castings to eliminate porosity caused by shrinkage. Chills are placed in regions where there is a larger volume of metal, as shown in (c). Solubility of Hydrogen in Aluminum Solubility of hydrogen in aluminum. Note the sharp decrease in solubility as the molten metal begins to solidify. Thank You