Presentation_10_3_05..

advertisement

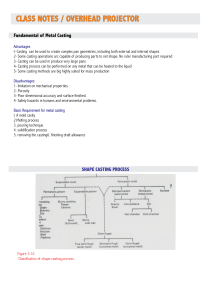

Casting Processes Tim Goldmann – General Overview Caleb Hanson – Molten Metal Phillip Pinsonneault – Mold Design Rey Jordan – Solidification and Inspection Group 7 History of Casting Group 7 Advantages • Complex forms, low cost • Certain shapes cannot be machined • One piece parts vs. multiple piece parts • Design changes are easily incorporated • High volume, low skilled labor • Large, heavy parts can be made easily Group 7 Disadvantages • Problems with internal porosity • Dimensional variations due to shrinkage • Trapped impurities, solids and gasses • High-tolerance, smooth surfaces not possible • More costly than stamping or extruding in some cases Group 7 Expendable Molds • Green Sand • Dry Sand • Shell • Investment • Plaster Group 7 Expendable Molds • Pattern must be produced • New mold for every cycle Group 7 Permanent Molds • Die • Centrifugal • Pressure • Injection Group 7 Permanent Molds • Made of durable material • Multiple use • Built-in Alignment Group 7 Cupola Furnaces Five Zones • Stack • Charging Zone • Melting Zone • Tuyers (Air Intake) • Crucible or Hearth Group 7 Induction Furnaces • Magnetic field • Rapid melting rate • Low pollution Group 7 Foundries • Pattern and Mold Making – Computer Aided Design – Manufacturing – Rapid Prototyping • The Casting Process – Metal Melting – Metal Compositions – Impurities – Pouring into molds Group 7 Foundries Group 7 Foundry Automation • • • • • Pouring into Molds Cleaning Heat Treatment Inspection Automated Guided Vehicles – Automatic Storage – Moving Cores and patterns – Etc. Group 7 Reasons For Automation • Increased Manufacturing Efficiency • Reducing Costs • Reliability in Harsh Environments • Release of Skilled Man Power • Maximize Space • Improved Quality Group 7 Why Fluid Flow? • When Heated Metal Becomes Liquid • Important in Cast Design - Sprue - Well - Runner - Gate Group 7 Fluidity of Metals • • • • • • Viscosity Surface Tension Inclusions Mold Design Degree of Super Heat Mold Material - Thermal Conductivity - Surface Roughness • Heat Transfer Group 7 Tests for Fluidity • There are several different fluidity tests • All use the same principle • Useful in simulating how metal will react • See how far the metal will travel before solidification Group 7 Heat Transfer • Heat transfer is important in many aspects of casting - Pouring - Solidification - Cooling rate - Rate is a function of Volume and surface area Group 7 Design, Materials and Economics Group 7 Design Considerations in Casting • Design of the part • Casting process and material • Locate parting line • Locate design gates • Locate mold features such as sprue, screens and risers Group 7 • Design Consideration of Cast Parts Corners, angles, section thickness – Avoid sharp corners angles and fillets – Stress raisers, cracking, and tearing – Sections should be blended smoothly Group 7 Design Consideration of Cast Parts Group 7 Design Consideration of Cast Parts • Flat Areas – Large flat areas may warp during cooling – Poor surface finish from uneven flow in pouring – Resolve with ribs, and serrations • Circles and Rounds – Lower cooling rate in circles induces hot spots – Shrinkage cavities and porosity Group 7 Design Consideration of Cast Parts • Shrinkage – to avoid cracking during the cooling process there should be shrinkage allowance – Staggered ribs, change the intersection geometry • Patternmaker’s Shrinkage Allowance – 10-20 mm/m Group 7 Design Consideration of Cast Parts • Draft – Used to enable easy removal of pattern without damage to mold – Range from 5 to 15mm/m – Angles of 0.5° to 2° • Dimensional Tolerances – As wide as possible within limits of good performance – Letters and markings Group 7 Locating the Part Line • Part line – separates upper and lower mold – Flat plane, along corners or edges – This will avoid flash at the parting lines Group 7 Locating and Designing Gates • Gates – Connections between runners and the part – Multiple gates preferred – Feed into thick sections of the castings • Runners – Distribution channel for molten metal from the sprue into the gates Group 7 Casting Alloys • Nonferrous Alloys – Aluminum, magnesium, copper, zinc, tin, lead – Good electrical conductivity and resistant to corrosion – Most of these alloys share characteristics of good machinability and can all be welded Group 7 Casting Alloys • Ferrous alloys – Cast irons • Largest quantity of all metals cast • Good wear resistance, hardness and machinability – Cast Steels • Material used under extreme heat conditions • Railroad, mining and construction Group 7 Casting Economics • Cost – Depends on materials, equipment, and labor – Preparations require raw materials, time and effort – Melting, pouring, heating, cleaning, inspections – Equipment cost lowers with large # of castings – Solutions to alleviate unneeded cost are being looked into • Rapid prototyping Group 7 Molten Metal Pour Group 7 Solidification Group 7 Solidification Temperatures Group 7 Dimensional Change Group 7 Pinholes Group 7 Blowhole Group 7 Scab Group 7 Pinholes Group 7 Rough Surface Group 7 References • • • • • ABB, Automation Solutions, 2005, 10/01/2005, www.abb.com Brown Jerry, Primary Metals, 10/01/2005, www.p2pays.org ECO BRASS workability, 10/01/2005, www.ecobrass.com 2.008 Casting, 10/01/2005, www.ocw.mit.edu Wright, Thomas, Processes of Manufacturing, GoodheartWilcox Company, Inc., 1990 • Lindbeck, John R., Product Design and Manufacture, PrenticeHall, 1995 • Kalpakjian & Schmid, Manufacturing Engineering and Technology, Prentice-Hall, Fifth Ed. Group 7