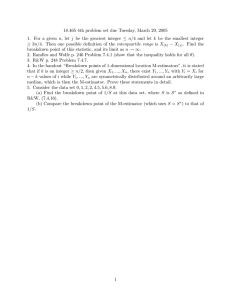

The current issue and full text archive of this journal is available at www.emeraldinsight.com/1463-5771.htm BIJ 21,2 Strategic approach to breakdown maintenance on construction plant – UAE perspective 226 P.B. Ahamed Mohideen Received 1 May 2012 Revised 19 June 2012 Accepted 19 June 2012 Plant Maintenance, ASCON, Dubai, United Arab Emirates, and M. Ramachandran Bits Palani Dubai Campus, Dubai, United Arab Emirates Abstract Benchmarking: An International Journal Vol. 21 No. 2, 2014 pp. 226-252 q Emerald Group Publishing Limited 1463-5771 DOI 10.1108/BIJ-05-2012-0030 Purpose – The purpose of this paper is to develop a systematic strategic approach to handle corrective maintenance onto the failures/breakdowns of construction equipment. For the maintenance crew/team, a breakdown code management is proposed, which will provide focused and unambiguous approach to manage any kind of breakdowns in construction equipments. Design/methodology/approach – The past breakdown records of a construction organization in the UAE are considered for analysis. From the failure data, through cause effect analysis (CEA) tools, the components and the breakdown codes namely breakdown main codes (BMC) and breakdown sub-codes (BSC) are formulated. With Pareto analysis, the critical codes are identified and validated through failure modes and effects analyses (FMEA) tools for the critical effect on the affected components. From this identified BSC’s further closer failure identification codes namely breakdown symptom codes (BSyC) and breakdown reason codes (BRC) are identified through fault tree analysis (FTA) tools. The approach to modified breakdown maintenance management (MB2M) with breakdown maintenance protocol (BMP) is envisaged. Findings – The study was conducted on four different types of heavy lifting/earth moving/material handling system of equipment and further focused with two earth moving equipment namely dumpers and wheel loaders. Failure analysis is performed and the failure ratio and the component contribution to the failures are identified. Based on the information, the preliminary codes namely BMC and BSC are identified through CEAtools and the BMC and BSC are identified to find the most contributing codes to the maximum number of failures through Pareto analysis. Further the critical sub-codes are further verified through FMEA tools on the severity levels of the sub components due to these codes. The FTA methods are used to identify the closer reasoning and relations of these codes and the further codes namely BSyC and BRC are identified which are the exact cause of the failures. The management of breakdowns is further proposed through MB2M which includes BMP which provides all resources for the breakdowns. Research limitations/implications – The failure data collected are only pertaining to the Middle East region and applicable to similar regions for similar plant mix in construction companies. The sample equipment is only part representative of the construction equipment. A more robust model can be suggested in the future covering all aspects and for other regions as well. Practical implications – The proposed methodology and model approach is highly adaptable to similar industries operating in the Middle East countries. Originality/value – Many authors have studied the preventive maintenance models and procedures and proposals have been proposed. On the breakdown maintenance management of construction equipment, very few studies have been proposed mostly on the cost analysis. This model attempts to provide a code management solution to manage the unpredictable failures in construction equipment through failure data analysis on a construction organization. Keywords Construction, Pareto analysis, Cause effect analysis, Failure mode effect analysis, Fault tree analysis, Plant and equipment Paper type Research paper Introduction: The United Arab Emirates (UAE) construction industry is expected to witness a compound annual growth rate (CAGR) of around 20 percent from 2010 to 2013, according to the “UAE Construction Industry Outlook for 2012” report by industry intelligence provider RNCOS, as rapid economic development continues to drive construction activities and infrastructure development in the emirate. The construction industry always aims at improving the quality standards of the people of the world and the environment, by innovations in new materials, new systems, execution techniques, safety, machineries, etc. The building and construction sector is the third largest sector of the UAE economy after oil and trade and it has experienced rapid growth in recent years. The level of construction spending per capita is high – second only to Japan. The future prospects for the sector in the UAE also hold much promise. The recent worldwide economic downturn has meant changes in the UAE’s dynamic business environment. With less construction work available and heavy competition for projects, construction companies working in the UAE have been forced to reassess their strategies in order to remain viable. The clients of UAE who award the construction contracts have decision criteria which include the company’s performance on quality, safety and as well the strength of their fleet (plant and equipment). The relative maintenance management systems followed by these companies which enable reliability of these equipment are also considered as an evaluation factor by the clients. Essentially it is important to have consistent and efficient maintenance management systems, for the construction companies operating in the UAE and in every other nation, for ensuring their continuity in business. For construction companies, as the plant and equipment yields extra output, productivity, reduced manpower, resources, ease of work, providing easy approach on complexity, timely execution, etc. which all directly and indirectly improve the overall improvement on the cost, time and quality and hence providing better profitability to the construction project, the plant and equipment have to be always available for useful service for effective execution of the construction projects. Maintenance, as a system, plays a key role in reducing cost, minimizing equipment downtime, improving quality, increasing productivity, providing reliable equipment and, as a result, achieving the organizational goals and objectives (Bashiri et al., 2011). Plant and equipment perform to their optimum level if they are maintained properly. Cost reduction in the maintenance process can add further improvements to the enterprise profit, while accurate and fool proof maintenance action can sustain continuous and reliable operation of the equipments. The inter dependent activities in construction industry requires the continuous working of all the machineries at all times without interruption for the better progress of the projects, enhanced productivity and desired profits (Waeyenbergh and Pintelon, 2002). Construction equipment breakdown attributes As the machinery dependency rate has become vital in all trades of work, it is imperative that all the machineries perform their function to the optimum level. For the intended and optimum performance of the machineries, the maintenance of the same is very much essential. Whatever may be the trade or field, maintenance is paramount, at least to have a trouble free working environment, for various systems, equipments and fields. Cost reduction in the maintenance process whether it is preventive or corrective in nature, Strategic approach 227 BIJ 21,2 228 can add further improvements to the enterprise profit, while accurate and fool proof maintenance action can sustain continuous and reliable operation of the equipments. Maintenance management is the systems and procedures tailor made for the organization’s plant and equipment so that they are maintained to the optimum level with least cost and maximum efficiency. It is also about optimization of one/all of the maintenance strategies like breakdown maintenance, preventive maintenance, predictive maintenance, condition based maintenance and reliability centered maintenance, in an orderly manner to have an effective maintenance system (Mishra and Pathak, 2002). The importance of the maintenance on the plant and equipment is such that, more enlightened companies have demonstrated an increased production capacity by as much as 20 percent by implementing proper maintenance management systems in their organizations (Ricky, 2003). Etienne-Hamilton (1994), envisaged maintenance functions as a full partner of every organization striving together with it all the other functions to achieve the firm’s strategic goals. There has been an exponential growth on the new maintenance concepts and techniques. Hundreds have been developed over the past years, and more are emerging. The breakdown of equipment occurs due to the unpredictable failure of components and due to gradual wear and tear of the parts, which cannot be prevented. In order to have a trouble free working of these equipment there need to be a right strategy of maintenance. Even with the right maintenance strategy in place, the breakdown of these plants is inevitable and unavoidable. The construction plant breakdowns make massive disruption to the smooth construction activities which are inter dependent and affect the overall productivity and efficiency of the construction schedules. The breakdowns should not be underestimated since they tend to make the project overrun on time and results in subsequent loss of revenue to the project. Repeated breakdowns will almost certainly result in delays to the contract, loss of client goodwill, loss of company reputation, risk to safety, etc. As mentioned in Figure 1, the attributes for construction equipment failures. The reasons can be due to the attributes mentioned in Figure 1. The newer developments in the breakdown maintenance management include (Figure 2): . Decision support tools, such as hazard studies like cause effect analysis (CEA) tools, failure modes and effects analyses (FMEA) and expert systems. . FLOW process analysis including fault tree methods fault tree analysis (FTA) to find out route causes. . Improved maintenance techniques, such as condition monitoring, breakdown models, etc. . Selecting the equipments which have the designs with a much greater emphasis on reliability and maintainability. . To create a major shift in organizational thinking towards participation, team working and flexibility. . Improvising the interest on breakdown maintenance performance by the crew, by adopting easier approach towards execution method, etc. A major challenge, faced by construction industry maintenance personal nowadays is to learn what these techniques are, and also to decide which are worthwhile and not Strategic approach 229 Figure 1. Attributes of construction equipment failures implemented in their own organizations. If the right choices and strategies are implemented, it is possible to improve the asset performance and at the same time, reduce the cost of maintenance and can be summarized as follows: . To select the most appropriate techniques to deal with each type of failure process in order to fulfill all the expectations of the owners of the assets, the users of the assets and of society as a whole. . To make the techniques to be more innovative and to remove the concept of ambiguity and fear amongst maintenance crew by way of its easy approach and clear directives. . In the most cost effective and enduring manner with the active support and cooperation of all the people involved including the operatives, end-users and so on. . To provide generalized approach/method which can provide ready-made solution to many problem areas and act as a model tool which can be easily applied by the crew. . To remove the grey areas and ambiguities when approaching and executing repair on a failed system/component/process. BIJ 21,2 230 Figure 2. Newer developments and focus on the breakdown maintenance management model . To have determination and deterrent free execution on breakdown maintenance through right protocols. Literature review According to Campbell and Jardin (2001) maintenance is a business process turning inputs into usable outputs. Maintenance costs are a major part of the total operating costs of all manufacturing or production plants, and depending on the specific industry, maintenance costs can represent between 15 and 60 percent of the cost of the goods produced (Mobley, 2002). As per Varghese (2000) given that 20 percent of the cost of such projects is associated with the required construction equipment, it is expected that the demand for construction equipment will increase substantially in the coming years. The inter dependant activities in construction field requires the continuous working of all the machineries at all times without interruption on the projects for better progress, productivity, and profits. The machinery dependency rate has become very high due to fast track projects in the present time (John, 2003). Fast track construction projects are highly dependent on the construction machineries. Achieved availability is the probability that a system or equipment, when used under stated conditions is an ideal support environment (i.e. readily available tools, spares, personnel, etc.), which will operate satisfactorily at any point in time (Blanchard and Fabrycky, 1998). The wear and tear rates of the machineries are likely to be very high due to extreme conditions prevailing at construction sites. Human operators in close proximity with the work operate most of the machineries in the construction industry and the maintenance cannot be overlooked (Randy and Burl, 1988). The optimal level of maintenance occurs at the point of minimal total maintenance costs – the point where the sum of the cost of equipment losses and maintenance activity costs is minimized (Fredendall et al., 1997). More stand-by units may increase the system’s availability but do not decrease the incidents of system failures (Kumar and Granholm, 1998). Reliability, availability and maintenance (RAM) models represent the logical relationships between each plant component, system and human action concerning their effects on generation and can be used to quantitatively predict the magnitude of each individual contributor to losses described by the plant load duration curve (International Atomic Energy Agency, 2001). In the future the only companies left in the business will be those who know and are able to control the reliability of their products (Kececioglu, 1991). Hall and Daneshmend (2003) reiterated that reliability and availability modelling can be viewed as an integral part of a unified “analysis” function, dealing with a myriad of information flows including data from sensors on equipment, data and information from operator interfaces on-board equipment, historical operational and maintenance information, current operational and maintenance information. Collections of quality failure and repair data are usually necessary in system reliability and availability analysis for getting reliable and accurate results (Blischke and Murthy, 2003). According to Fonseca and Knapp (2001) in reliability and maintainability studies a small number of researchers have seriously addressed the issue of handling uncertainties especially related with failure data of systems. Lu and Meeker (2007) developed general statistical models and data analysis methods for using degradation measures to estimate a time-to-failure distribution. Lu et al. (2007) extended the problem of reliability estimation to a component operating in real-time changing environments. Gebraeel et al. (2005) proposed an exponential model in which the deterministic parameters represent a constant physical phenomenon common to all the components of a given population, while the stochastic ones follow a specific distribution and capture variations among individual components, nominally identical. The distributions of the stochastic parameters across the population of components (a priori distributions) together with the monitoring information collected for each component (a posteriori distribution) are used to compute the residual life distribution for the individual component. A Bayesian approach is employed to update the prior information of each individual component at any instant. Curcuru and Galante (2010) proposed a procedure for computation of the maintenance time that minimizes the global maintenance cost. By adopting a stochastic model for the degradation process and by hypothesizing the use of an imperfect monitoring system, the procedure updates by a Bayesian approach, the a priori information, using the data coming from the monitoring system. Meselhy et al. (2010) developed a periodicity metric functional resetting procedure to evaluate and quantify function resetting due to a given maintenance policy to reduce complexity in the system. The developed periodicity metric can be used as a criterion for comparing different maintenance policy alternatives and as a tool for predicting system performance under a given maintenance policy. Very few researchers have conducted studies done on the data capturing and modeling of breakdowns as breakdowns contribute lots of uncertainties to the plant Strategic approach 231 BIJ 21,2 232 performance and productivity. Rapinder Sawhney (2009) mentions that tremendous efforts have been made to develop different types of maintenance strategies for enhancing the performance of equipment but nothing has been done to actually streamline breakdown maintenance activities (BMA). The failures and breakdowns occurs due to the unpredictable failure of components on the equipments and as well due to the gradual wear and tear of the parts, which cannot be prevented during dynamic working of these equipment with varied environmental conditions prevailing. To ensure the plant achieves the desired performance, maintenance managers need a good track of performance on maintenance process and maintenance results. This can be attained through development and implementation of a rigorously defined performance measurement framework and indicators that are able to measure important elements of maintenance function performance (Peter et al., 2010.) Failures in production systems may cause high losses, for instance in the form of lost production time or volume, negative impact on the environment, lost customers, warranty payments, etc. (Todinov, 2006). Efficiency and effectiveness of the maintenance system are essential for organizations’ success and survival. Parida et al. (2005) highlight the need for measuring the system’s performance. Arts et al. (1998) point out that performance measures are tools to achieve control in order to reduce maintenance costs and increase productivity. If the only strategy of any organization is to react only when the machine fails, then breakdown maintenance will also be called as run-to-failure maintenance and the organization which follows such strategy is known to adopt only the reactive maintenance strategy. Breakdown maintenance is also called as run-to-failure maintenance for organization who does not have any maintenance functions/crew in place and generally maintenance is always overlooked. It may be described as a fire-fighting approach to maintenance and the equipment is allowed to run until failure (Swanson, 2001). All the activities following the reactive maintenance strategy will be described as fire-fighting approach techniques of maintenance. With the run to failure type of maintenance the equipment is allowed to run until failure, then the failed equipment is repaired or replaced (Paz and Leigh, 2004). In these strategies generally the maintenance activities are not planned. Generally reengineering is always required for proper proactive maintenance in industries (Mostafa, 2004). To ensure the plant achieves the desired performance, maintenance managers need a good track of performance on maintenance process and maintenance results. This can be attained through development and implementation of a rigorously defined performance measurement framework and indicators that are able to measure important elements of maintenance function performance (Peter et al., 2010.) The costs for maintenance conformance are mainly associated with preventive maintenance, but also some corrective maintenance must be accepted by the organization. Costs for indispensable corrective maintenance relate to those corrective maintenance actions that are indispensable. Salonen and Deleryd (2011) predicts the reasons for these kinds of actions as that when no preventive actions are feasible for preventing the breakdowns to occur, e.g. when components have random failure distribution and lack measurable deterioration or when preventive actions are not financially justified. Very few the authors have examined the effect of break down maintenance on the construction plant. No detailed algorithms for breakdown maintenance in construction plant or models based on the records of break down maintenance have been reported in the literature. The current research work aims to develop a systematic procedure to identify a strategic procedure to minimize the loss in a construction industry due to breakdown maintenance. The study focuses on the study of the breakdowns in the system rather than developing a preventive maintenance for the breakdowns, the focus is to how quickly the system can recover from the break down that has incurred in the system. The real-time reporting of the plant history is examined to understand and determine the factors affecting the breakdown process, overcoming these factors to manage the breakdowns effectively. This current paper discusses the application of various breakdown maintenance management improvement tools including decision support tools, RCA tools, CEA tools, FMEA tools and the protocol approach systems which all augment further values to the maintenance systems and strategies by reducing the downtime duration and also will further pave the way for the effective realization of better productivities of the plant and equipment involved in the construction industries. The breakdown codes of breakdown main code (BMC), and breakdown sub-code (BSC) are further identifies the breakdown system code (BSyc) and the breakdown reason code (BRC). Optimization of the breakdown maintenance with better techniques will by all means yield an effective maintenance system for the organizations. Construction equipment breakdowns Today world class competitiveness is a must for construction companies. With the financial crisis in place all over the world, multi tasking, globalization, venturing into new related fields, cutting of costs, ensuring effective utilization of the resources have become necessary for the organizations. As the competition grows, there tends to be a technological push combined with the market pull, and the increased number of customer requirements at reduced costs put forward a lot of challenges for the organizations, who need to ensure effective utilization of their resources and ensure at least minimum profits. As the cost of operation needs to be reduced, even the equipment manufacturers tend to make products, which may be subjected to speedy wear and tear possibilities and reduced life cycles and to add more, these plant and equipments need to work under higher stress always. As most of the construction equipments perform their maximum hours of services under extreme climatic conditions (ambient temperatures raising as high as 508C sometimes unlike, Europe or Asia), as well as rugged working atmospheres in the UAE, even with the adaptation of various preventive maintenance strategies on these construction equipments the breakdowns of these equipments are inevitable and unavoidable. As the breakdown of plant and equipment is a common unavoidable problem, it is better to manage the breakdowns in an efficient manner. Hence good management tools on breakdown management of construction equipment are always essential. A tower crane breaking down in a construction site, creates chaos and leads to a situation, where hundreds of workmen become idle due to stoppage of works which are parallel and dependent. Whatever may be the trade or field, breakdown maintenance is always unlike by the end-user as it is unproductive. But breakdowns are inevitable. When any failure/breakdown occurs, on these plants, to bring back and to regain its intended serviceability requirements, the breakdown maintenance process has to be flawless and also speed is the essential factor. The repair has to be carried out during production/working hours and continues up to continuous shifts till the problem is rectified, leading to high labor costs. The supervision of the breakdown maintenance process also will have Strategic approach 233 BIJ 21,2 234 limitations and may become less as the duration extends due to continuance of the breakdown, which really affects the quality of breakdown maintenance process. Generally people make a faulty assumption that the cost of the breakdown is the only cost incurred in getting the equipment back into service, but the true cost is considerably higher. The overall costs include, the direct cost of the repair, the on-costs of wages paid to idle operatives, the cost of production affected, cost of alternate plants arranged, cost of regaining the momentum, cost due of loss of goodwill from the clients/customers and the overall cost of loss in production. When these additional costs are added to the breakdown/emergency repair cost in terms of material and labour, the cost of the breakdown becomes substantial. It also follows the fact that the magnitude of the breakdown repairs and the process duration will be greater, than if the rectification was carried out under controlled conditions, so preventing premature failure even after rectification. Furthermore, if spare parts are not immediately available in the event of an unexpected breakdown, one may face the extra costs of sub-contracting and leasing equipment for production during the extended period of shutdown while the spare parts are manufactured and fitted, thus increasing the cost. It can, therefore, be stated that normally, unless an item of equipment is so situated that it will not interrupt the intended production, breakdown maintenance is inherently, inefficient on all accounts, creating an indeterminate workload and loss of morale on the maintenance staff and there can be no justification for the continued breakdowns in construction industry. With all the above facts in place it is very much evident that the breakdown maintenance execution process is generally not a likeable and preferred one as it involves cost, human efforts and will not be prudent, if executed in an unplanned, non-sequential manner. The proposed newer methods and tools paves way for better execution of the breakdown maintenance and will help in the long way to reduce the breakdown durations, to improve on the breakdown frequencies and also to create interest amongst the crew to execute the breakdown maintenance effectively. Research methodology As per the previous paper, five year breakdown data of major construction equipments of a construction organization at Dubai, UAE have been studied effectively. The breakdown performance is tabulated from the breakdown registers, plant history cards, job cards for effectively identifying various types of breakdowns for a large category of construction equipment. The five year analysis yielded various kinds of breakdowns and the related breakdown factors. Based on the nature and cause of the breakdowns, the breakdown reasons/parameters are formulated and coded as BMC, breakdown sub-codes (BSC). Pareto analysis of the breakdowns are performed for breakdown reasons of each major equipment, year-wise, and the 80 percent of the BMC and BSC are identified and presented in the part 1 studies of this paper (Ahamed Mohideen et al., 2011). This paper studies the verification of these selected BSC based on the severity effect of affected components through FMEA tools. Further identification of breakdown symptom codes (BSyC) which have the possible cause effect on the BSC and the breakdown reason codes (BRC) which are the root causes of the individual problems are identified through FTA methods. These codes help us to identify the major contributing elements of the breakdowns and the related root causes of the breakdowns. Each BRC will be associated with a loop combination of BMC-BSC-BSyC-BRC loop and will have an associated breakdown maintenance protocol (BMP). Each BMP for each specific failure/breakdown is a best fit solution for specific breakdown which will have stand-alone solution/work around and the required resources to manage a specific breakdown with reference to a component/system/machinery/fleet. Figure 3 details the flow process the methodology followed in formulating the BSyC and the BRC for the construction equipment. Strategic approach 235 Case study The firm under investigation has more than 779 different construction machineries which exclude transportation vehicles. The machineries mix included light equipment, heavy equipment, light machinery, heavy plant, and heavy machinery. Since light equipment (290) is relatively smaller in size, replacement is always possible. Light equipments are not included in our study. Heavy plant like tower cranes and hoists (81) which operate basically with electric power only were not considered for analysis. The selected equipment included, wheel loaders, skid steer loaders, back hoe loaders, dumpers, mobile cranes, forklifts, compressors, generators and roller compactors. The total number of machineries considered is 180. This represents 36.81 percent of the population of the equipment excluding the light equipment. A total of 881 (Table I) breakdowns from the five year record of the breakdown maintenance data for the selected plant and equipment have been analyzed. The documents considered include the breakdown registers, jobs cards, plant history cards, etc. The breakdown data of the selected nine machineries has been taken from the list of total breakdown records of all the machineries available with the target organization. Since the focus is on these nine machineries, the list of 881 breakdown data only on these machineries has been considered for the analysis. To determine the most critical machine in the system, the ratio of the number of breakdown to available machines Figure 3. Flow process of the MB2M Table I. Breakdown details of the critical machines in the system 9 4 5 6 7 8 3 2 1 Wheel loader Mobile crane Back hoe loader Fork lift Skidsteer Genset Dumper Air compressor Roller compactor Sl no. Machine 2006 Breakdown details of the critical machines in the system 2007 2008 2009 236 9 10 20 14 9 3 2 8 36 23 14 2 5 4 29 21 6 2 1.11 1.42 1.5 0.4 2 1.24 1.09 2.33 4.5 8 21 2 4 11 31 19 4 2 9 26 16 8 15 53 26 14 18 1.12 1.23 8 2 1.36 1.7 1.36 3.5 9 9 21 2 4 11 39 19 4 2 12 17 5 7 13 85 23 25 44 1.33 0.8 2.5 1.75 1.18 2.17 1.21 6.25 22 11 21 5 4 14 97 19 5 3 7 17 10 3 9 79 20 20 34 0.63 0.8 2 0.75 0.64 0.81 1.05 4 11.66 11 21 5 4 14 97 19 6 3 10 8 2 2 9 43 24 8 35 0.91 0.38 0.4 0.5 0.64 0.44 1.26 1.33 11.66 48 88 36 22 54 296 116 81 140 1.02 0.93 2.88 1.08 1.16 1.27 1.19 3.48 11.76 Average No. of Breakdown/ No. of Breakdown/ No. of Breakdown/ No. of Breakdown/ No. of breakdown/ breakdown/ machine No. of machine machine No. of machine machine No. of machine machine No. of machine machine No. of machine Total machine available breakdown/ ratio available breakdown/ ratio available breakdown/ ratio available breakdown/ ratio available breakdown ratio breakdowns ratio 2005 BIJ 21,2 is calculated. The machine with the highest ratio is identified as the critical machine as indicated in Table I. Wheel loaders, mobile cranes, back hoe loaders, generators and dumpers are identified as the most critical machines with the highest breakdown order in the system. Mobile cranes and generators being the utility and not only core construction machines and find application in other fields of industry and as well they are very much available in the market on rental basis as JIT, and hence wheel loaders and the dumpers are considered for further focus study. On the construction field the utilization of these wheel loaders and dumpers exist almost to the entire duration of the project for various earth moving and material handling operations and as well the availability of dumper on rental basis is almost scarce in the market and wheel loader always find lots of demand with various construction companies and the demand in the market is always high for this equipment. The last five year breakdown records for the wheel loader and dumper are further examined. The breakdown records are classified into main categories of failure namely: engine failures (mechanical failure), transmission failures, propeller shaft failures, differential failures, axle/wheel failures, steering failures, hydraulic failures, and electrical failures. A systematic examination on various breakdowns is performed and is classified into one of the above categories based on the major factor for failure as provided in Table II. The order of frequency of breakdowns on both the equipment varied generally while wheel loader accounted for more frequent failures on the wheel assembly where the dumper had more frequent failures accounted on the engine side. Since these machines are critical in nature for the analysis, all the failures on these equipment are considered to be critical and a detailed analysis on breakdown codes for these equipment were to be performed (Figures 4 and 5). The basic plant/equipment failure may happen due to any of the component or multiples of components failures. As mentioned in above tables, the failures can be due Sl no. 1 2 3 4 5 6 7 8 9 Sl no. 1 2 3 4 5 6 7 8 9 10 Wheel loader-analysis of type of failures based on occurrence (2005-2009) Type failures 2005 2006 2007 2008 2009 Total Wheel assembly 6 11 27 24 16 84 Hydraulic 0 2 3 3 9 17 Electrical 0 3 8 0 4 15 Engine 1 0 2 4 3 10 Axle drive 0 1 3 0 1 5 Differential 0 0 1 1 1 3 Steering 0 1 0 1 1 3 Transmission 1 0 0 1 0 2 Propeller shaft 1 0 0 0 0 1 Dumper-analysis of type of failures based on occurrence (2005-2009) Description 2005 2006 2007 2008 2009 Total Engine 6 10 8 4 7 35 Electrical 1 7 1 2 4 15 Clutch 4 2 6 2 0 14 Propeller shaft 2 3 3 1 4 13 Gear box 1 1 2 7 0 11 Wheel 7 0 0 0 3 10 Hydraulic 1 1 2 0 4 8 Drop box 0 1 1 2 2 6 Steering 1 1 0 1 1 4 Differential 0 0 0 1 1 2 Strategic approach 237 Average 16.80 3.40 3.00 2.00 1.00 0.60 0.60 0.40 0.20 Average 7 3 2.8 2.6 2.2 2 1.6 1.2 0.8 0.4 Table II. Types of failures on wheel loader and dumper BIJ 21,2 Process Flow of a Construction Mini Dumper 238 Electricals Engine Clutch Hydraullcs Steering Chassis Figure 4. Process flow of the mini dumper Gear Box Propeller Shaft Wheel Assembly Drop Box Differentials Process Flow of a wheel Loader Wheel Assembly Axle Drive (Right) Electricals Engine Differential (Front) Propeller Shaft Hydraullcs Steering Axle Drive (Left) Chassis Figure 5. Process flow of wheel loader Axle Drive (Right) Transmission Propeller Shaft Differential (Rear) Axle Drive (Left) Wheel Assembly Cabin to engine, electrical, transmission, gear box, propeller, wheel, axle, hydraulic, steering or other related component failures. The outcome of the CEA provided an insight into the possible break down factors in the component systems of the equipment. These breakdown factors revealed their relationships with the various components and their impact on the overall performance of the machine. To effectively categorize the breakdowns in relation with their components, various codes namely BMC and BSC were developed in relation to various components. To identify the BSC’s from BMC second level CEA is performed on the identified BMC as shown in Figure 6. The BSCs are developed based on the various breakdown data, logical discussions, and on the breakdown knowledge of the maintenance crew (Table III). We use these inputs into the Pareto’s model and intend to study the effect of critical breakdown codes on to the group of BMC which contribute to 80 percent of the breakdowns and with that we identify the critical BMC’s and the subsequent BSC’s. These BSC’s which are part of the critical BMC’s are verified with FMEA tools. The focus of this tool is to identify the most contributing breakdown factors on the construction equipment namely dumpers and wheel loaders, which accounts for 80 percent of the breakdowns, but less in numbers. With further detailed study of these breakdown codes a proper system of breakdown maintenance management is formulated. Basically this Pareto analysis help to understand the most contributing Strategic approach 239 Figure 6. CAE diagrams to identify the breakdown codes breakdown factors, and we can improve upon the execution of breakdown maintenance process by dissociating and relating this breakdown factors with further sub factors and a good improved and a modified breakdown maintenance management (MB2M) system is prepared which results in effective execution of breakdown maintenance. Thus, significant factors based on their criticality are identified for the benefit of the organization as a whole. The critical BMC’s pertaining to Pareto study reveal the fact that the following codes only attribute to 80 percent or more breakdowns to the dumpers and wheel loaders are identified. Based on these studies of Pareto analysis the critical contributing breakdown codes namely BMC and their relative sub-codes, BSC’s are identified and tabulated. The total number of initially arrived BMC codes, which were the causes of various breakdowns of the components on wheel loaders and dumpers were 62 (which were the cause of various breakdowns/failures on wheel loaders and dumpers for the year 2005-2009) and have been reduced to 27 with the Pareto analysis. The results are tabulated below. Similar exercises were performed with all the nine equipment under study and the resultant BMC and BSC codes are listed in Table IV. Failure mode effect analysis for critical BSC FMEA is an analysis technique which facilitates the identification of potential problems in the design or process by examining the effects of lower level failures. With FMEA results actions and provisions are made to reduce the likelihood of the problem occurrence and mitigating the relative risk, in case of occurrence of the problem. The FMEA team determines, by failure mode analysis, the effect of each failure and identifies single failure points that are critical. The approach involves statistical data collection especially related with the frequency of subcomponent failures and their likelihood of non-detectability and severity it imposes on system performance. The results of the analysis help managers and engineers to identify the failure modes, their causes and BIJ 21,2 240 Fault main Sl no. code Engine failures 1 AA1 2 AA2 Break down main codes (BMC) and break down sub-codes (BSC) Fault subFault description code Fault description Solution Engine major overhauling Engine over heating A6 A5 A17 A19 A24 A39 A42 A43 A44 3 AA3 Coolant oil excessive consumed A3 Cool water leak – radiator hose Radiator service A28 Engine low oil pressure A37 A1 A8 A38 A45 A50 A51 A53 5 Table III. Breakdown main codes (BSC) and breakdown sub-codes (BSC) AA5 Engine oil excessive consumed Fan radiator pully lock broken Fan leaf broken – radiator Engine over heat Belt cut Radiator choked Cool water leak – radiator or tank A27 AA4 Water leak – water pump change Engine fan belt cut Cheased A59 A2 A7 4 Engine cylinder head gasket problem Temperature increased A4 A16 A18 Gasket changed Temperature switch changed Water pump change Engine fan belt changed Engine overhauling work Fan radiator pully lock changed Fan leaf changed – radiator Radiator serviced Radiator fan clutch/fan belt changed Radiator core changed Radiator top tank Radiator hose Cool water leak radiator service Water leak rail pipe bolt Water rail pipe bolt cut/repair changed Water leak/pump gasket Water pump gasket changed Oil pump problem Oil pump kit changed Engine overhauling Radiator top tank work Oil pump leak Pump kit changed Engine oil, collenet oil Oil coller serviced mixing Engine oil/fuel mixing Injector and fuel pump calibrated Meter/oil viscose Oil viscosity checked Cut – engine work Engine major overhauling Engine low oil pressure Engine overhauling work Oil seal leak – rear end Oil seal change – fly wheel side Oil leak – cover packing Cover packing changed Oil leak – filter body Filter body assay changed (continued) Fault main Sl no. code Break down main codes (BMC) and break down sub-codes (BSC) Fault subFault description code Fault description Solution A26 A31 A32 A46 6 AA6 Engine vibration A9 A10 A12 7 AA7 8 AA8 Engine knocking noise Engine speed variation A33 A30 A35 A36 AA9 10 AA10 11 AA11 12 AA12 Fuel pump failures 13 BB1 FIP, injector calibration 14 BB2 15 BB3 Air relief valve problem – compressor Accelerator cable cut A54 A55 Accelerator spring cut Improper colour of – exhaust Engine starting A41 trouble Start A34 Engine cranking will not start Timing cover seal changed Cooler body welded Compressor unit – hose changed Oil separator hose cut/ Oil separator hose compressor unit changed Engine mounting front r Engine mounting front R changed Engine mounting front L Engine mounting front L changed Engine mounting rear Engine mounting rear L1 L1 changed Valve leak Air separator changed Engine rpm suddenly raised Engine stops while running Problem A40 9 Oil leak – timing cover seal or crank seal Oil leak cooler body Oil leak – Display on LCD 241 Air relief valve kit changed Accelerator cable changed ECB board changed Fuel control relay changed Cam shaft sensor changed Accelerator spring changed – Fuel line checked, fuel filter changed Coupling changed A49 Engine – compressor coupling broken Engine noise – – Fan radiator pully lock changed – B1 Fuel pump problem Fuel pump calibrated B15 Engine over heated automatically tripped Fuel pump problem Injectors changed/ thoroughly flushed Fuel pump calibrated Fuel pump problem Fuel pump calibrated Proble Working Hand primer changed Fuel lift pump changed (continued) Engine knocking B1 sound Engine cranks but B1 did not start B9 B20 Strategic approach Table III. BIJ 21,2 Fault main Sl no. code 16 BB4 242 17 BB5 Break down main codes (BMC) and break down sub-codes (BSC) Fault subFault description code Fault description Solution Engine hard to start Engine speed variation 18 19 BB6 BB7 Engine vibration Engine emits white smoke 20 BB8 Lack of power 21 BB9 Excessive fuel consumption Table III. Table IV. Pareto analysis results Sl no. Equipment 1 2 Wheel loader Dumper Total BMC B1 Fuel pump problem Fuel pump calibrated B16 Engine not cranking B17 Problem B2 Injector problem Injector serviced fuel line checked Fuel line checked and feed pump changed Injector calibrated B18 Low alternator problem B2 B1 Injector problem Fuel pump problem Fuel line/injector/pump recharge Injector calibrated Fuel pump calibrated B2 B1 B2 B1 Injector problem Fuel pump problem Injector problem Fuel pump problem Injector calibrated Fuel pump calibrated Injector calibrated Fuel pump calibrated B2 B7 Injector problem Fuel inlet pipe leak Injector calibrated Fuel inlet pipe changed Pareto analysis on the BMCs BMC contributor for 100% breakdown (identified) 26 36 62 Critical BMC identified based on Pareto analysis 11 16 27 correct them during the stages of design and production. It may also rank each failure according to the criticality of a failure effect and its probability of occurring. The BSC which are developed from the critical BMC’s should be verified and ascertained properly that they are the true representative codes and a dependency rate can be established. The failure mode effect analysis is performed on these selected BSC’s to find out how influential these codes with respective to the various sub components with which they are associated. This exercise helps us to know that if these sub components which are associated with the selected BSC failure cause, are not having higher severity ratings with the failure, then the selection of these BSC’s as the critical BSC’s will not be a true statement. Hence we are finding few of the selected BSC’s and their relative components severity ratings with the FMEA Analysis. The following BSC’s are selected for analysis (Tables V and VI). Failure mode and effect analysis (BSC – A38: engine oil and coolant oil mixing) Failure effect Failure Effect Component Function mode Local System rate Oil cooler To maintain oil temperature Inter cooler To maintain oil temperature/friction Water pump To maintain engine temperature Cylinder head It houses the inlet and assay exhaust valve arrangements and continues coolant route throughout the engine Cylinder liner The cylinder liners receives combustion heat through the piston and rings and transmit the heat to the coolant Engine block Oil cooler gasket/ ”o” ring damage Inter cooler damage Water pump seal cut Water pump gasket weak Engine cylinder head gasket Engine cylinder head crack/ water gallery Engine liner crack Coolant oil colour changed Coolant oil colour changed Oil viscosity and Low oil film thickness reduced Lubrication not Low getting properly Engine oil level increased Radiator Low pressure reduced/cooling function will not working properly High Compression reduced and getting starting treble with emitting smoke Coolant continuous route function failure/ too heat developed Combustion and High stoke system failure Engine cooling system failure/ performance reduced Emitting smoke Engine with excessive efficiency sound reduced Liner “O” Cooling pressure ring cut reduce/oil pressure and film reduced It houses the engine parts Block Engine and oil/coolant route crack – compression throughout the engine coolant or reduced/ oil route excessive smoke with noisy developed Strategic approach 243 Very high Very high Decrease the engine performance Medium Oiling system failure/getting quick High A38 is the BSC denoting the engine oil and coolant oil mixing. The performance of the engine is very much dependant on the engine oil. The engine oil’s purity level is important for the lubrication of the engine internal parts and any contamination will reduce the performance of the engine. This also results changes in volume of cooling oil, Table V. FMEA for engine oil and coolant mixing BIJ 21,2 244 Failure mode and effect analysis (BSC – L13: front bucket automatically lowered whole operating) Failure effect Failure Effect Component Function mode Local System rate Operating control valve Bucket cylinder Table VI. FMEA for front bucket automatic lowering Solenoid switch To control pressure and oil flow regulating function Seals and “o” rings Spool and pins and valves Convert fluid power to mechanical Ram force and linear motion. Its main and operation is pull and push seals operation and hoses Gland and nuts Its function is to control the flow Switch oil to ram r cylinders and contacts Hydraulic oil Oil level and Medium leaks pressure reduced Oil leaks and Operation and High pressure control unstable released Engine oil pressure reduced/ sound developed Cylinder movements too slow Switch not work Engine oil Very high lubrication system failure and engine seized Bucket Medium operation failure Bucket tilting and pull and push operating failure Very high or/hence excess smoke from the engine and also creates more adverse effects due to wear and tear on the engine. The parts which are associated with this failure effect include cylinder head assembly, cylinder liner, water pump, engine block, oil cooler and the inter cooler. When we analyze the severity rating of this component due to this sub-code, the rating is very high and high, respectively, for two each of the four components, while low for two of the components. This justifies that the sub-code BSC A38, is very critical in nature for the performance of the engine and should be considered for further analysis on breakdown maintenance. L 13 – This BSC is related to the automatic lowering of the front bucket of the wheel loader, dumper and other earth moving machinery. The front bucket is an important component which performs the tilling/collection operation of the machine and has sharp edged teeth in front. The automatic lowering of front bucket during operation will lead to serious safety hazards and untoward happenings on the machine. The operator will not have enough control on it or he will be seriously disturbed while performing his operation of this machine. The related components which initiate this failure or affected due to this failure include hydraulic cylinder, solenoid valve and the control valve. The severity ratings of malfunctioning of the components are estimated to be very high for two of the components and high for one of the components. Hence this BSC Code L13 is a valid code and should be considered for further analysis. FTA for arriving breakdown symptom and reason codes FTA is one of the most widely used methods in system reliability and failure probability analysis. A fault tree is a graphical representation of a logical structure representing undesired events (“failures”) and their causes. The logical structure is created by using logic gates and represent undesired events by using basic events. Reliability parameters are assigned to the basic events. The technique is widely used in system reliability studies. FTA offers the ability to focus on an event of importance, such as a highly critical safety issue, and work to minimize its occurrence or consequence. The probability of the top-level event can be determined by using mathematical techniques. The resulting fault tree diagram is a graphical representation of the chain of events in your system or process, built using events and logical gate configurations. FTA is acknowledged as a key tool for increasing safety. It is unique and indispensable in analyzing risks and determining various combinations of hardware, software, and human error failures that result in a specified risk or system failure. FTA is useful both in designing new products/services and in dealing with identified problems in existing products/services. In the quality planning process, the analysis can be used to optimize process features and goals and to design for critical factors and human error. As part of process improvement, it can be used to help identify root causes of trouble and to design remedies and countermeasures. This technique is used in determining the breakdown factors namely BSyC and BRC. The BSC’s are subjected to the analysis of FMEA and subsequently the FTA is performed to understand the logical reasoning of problems/failures to determine the BSyC and BRC. Basically the root cause of the specific breakdown is known as the BRC and the symptoms of this root causes are the symptom codes namely BSyC. The resultant BSyC and BRC are prepared for all the critical BMC and BSC’s and listed (Figure 7 and Table VII). How to use this MB2M system for the UAE construction companies? The MB2M along with BMP can be applicable to all kinds of construction plant and equipment. The construction equipment working at the UAE as discussed in previous chapters, are subjected to working in different atmospheric conditions. The breakdown of these plant and equipment happen in construction sites of UAE often. The construction companies, operating in this region, can adopt to utilize the BMP technique/model for their fleet. The failure data is the prerequisite for any organization who deal with equipment. The failure data give an opportunity to maintenance crew on the analysis of the same and reaching conclusions about the failure patterns existing with the organization. The operatives/maintenance technicians/maintenance department/user departments must be given the initial awareness of the breakdowns and the conventional approach of the breakdown maintenance. They should be provided with the components and breakdown codes knowledge of BMP. As per their previous breakdown records (if maintained by the company), if all the listed codes fit in with their breakdown history, then the same can be used. If there are newer breakdowns which are not covered, then the newer BMP can be developed. As BMP gives the clear idea of how to approach and execute the breakdown maintenance, this system/model will be accepted by the maintenance/operation crew and can be easily implemented. As described in Figure 8, the flow process describes the impact of BMP process to the conventional breakdown maintenance flow process. Various stake holders namely and the process itself adds value addition to the effective execution of the breakdown maintenance process due to the presence BMP input. Strategic approach 245 BIJ 21,2 Engine oil and Coolant oil mixing Oil Related Problem Engine Performance Problem 246 Oil Cooler gasket damage Starting Trouble Engine oil level increased Coolant oil colour changed Engine cylinder head gasket Water pump gasket weak Water pump scal cut Inter cooler core damage Engine compression reduced Engine head crack Emitting smoke with excessive sound Inter cooler core damage Engine block crack Engine head water gallery broken Liner gasket damaged Engine cylinder/ Liner crack Inter cooler core damage Engine cylinder head gasket Coolant Oil Excessive Consumed AA3 Engine Oil and Coolant Oil Mixing Mixing A38 Radiator Coolant Color Changed A38Sy1 Figure 7. FTA diagrams for BSyC and BRC identification Engine Oil Level Increased A38Sy2 Starting Trouble A38Sy3 Engine Compression Reduced A38Sy4 Emitting Smoke and excessive noise A38Sy5 Oil Cooler Gasket Damage A38R1 Water Pump Seal Cut A38R3 Engine Cylinder Head Gasket Cut A38R6 Engine Block Crack A38R8 Engine Cylinder Liner Crack A38R11 Inter cooler Core Damage A38R2 Engine Inner Gasket Damage A38R4 Engine Head Crack A38R7 Engine Head Water Gallery Broken A38R9 Engine Cylinder Head Gasket A38R12 Inter cooler core damage A38R10 Inter Cooler Core Damage A38R1 3 Water Pump Gasket Weak A38R5 The application of this tool will give sufficient knowledge to the entire crew starting from the operator of the equipment up to the maintenance engineer of the equipment. The systematic approach of breakdown management will be ensured with all concerned. The code language will be ruling with the maintenance crew and the easy diagnosis/fault finding will be an easy and unambiguous approach followed with clear demand of the resources. The spare parts can be pre planned at the stores as inventory based on the frequency of various BMP’s happening with sites. The sites which have a group of equipment can be planned for a limited BMP as the history of failures of these machines would have been known to all the users at the initial stages itself. Most of the construction companies working in this region are similar in nature with the equipment base and the maintenance crew base. The occurrence of failure is also similar and consistent as per the environmental conditions and the general output demands from the equipment are always uniform. All of these factors justify the usage and application of this technique of breakdown management to be useful to the construction companies in the UAE (Figure 8). Breakdown sub-code Breakdown symptoms Breakdown reasons A38 Engine oil and coolant A38Sy1 Radiator coolant colour A38R1 oil mixing changed A38Sy2 Engine oil level increased A38R2 A38Sy3 Starting trouble A38Sy4 Engine compression reduced A38Sy5 Emitting smoke with excessive sound A38R3 A38R4 A38R5 A38R6 A38R7 A38R8 A38R9 A38R10 A38R11 A38R12 A38R13 Oil cooler gasket damage Inter cooler core damage Water pump seal cut Engine liner gasket damage Water pump gasket weak Engine cylinder head gasket cut Engine head crack Engine block crack Engine head water gallery broken Inter cooler core damage Engine cylinder/liner crack Engine cylinder head gasket Inter cooler core damage Conclusions This article has dealt with the construction plant breakdown analysis and the real-time reporting of plant history to understand and determine the factors affecting the breakdown management, overcoming these factors to manage the breakdowns effectively. During breakdown of construction plant, if we consider the breakdown itself as a production process, it is always better to identify the wasteful activities, in other words, lean study of the breakdown process is very much essential. This helps in identifying the unwanted activities, and as well reengineering of the breakdown process, by means of a BMP and the entire process called as MB2M which will keep the entire crew ready with required resources including spares, space, technicians, and other essential items. With the BMP and MB2M in place, a broken down plant, either at site or at the repair yard, gets focused attention upon its arrival to the site/workshop with the breakdown/complaint, wherein a system of activities are performed as planned and the effective execution of breakdown maintenance is ensured. MB2M is to make the breakdown analysis more efficient. Generally, for any kind of breakdown there are main codes, sub-codes, symptom codes and reason codes. For the breakdown crew to attend to breakdown maintenance, if the reason for the breakdown is informed or indicated, the approach towards rectifying the breakdown become easy. The crew gets ready with the right attitude, focus, preparedness as well as related tools and tackles to attend to the breakdown. The reason codes further denote various protocol initiatives required for every kind of unique breakdown which will keep the entire crew ready with the focused breakdown execution. Strategic approach 247 Table VII. BSyC and reason codes identification from BSC BIJ 21,2 Malfunctions reported by operative/end user 248 Operatives/Site Mechanics have confidence to approach the breakdowns Fault identified with Breakdown Codes Yes Fault Identified? No Operators confidence is positive with the BMP in place Inform Maintenance Crew Operator attending to resolve the mailfunction Operative/End User attempts to restore the machine function. The Operator/site mechanic informs the exact problem and the related BMP Problem Identified? Yes Any Replacement of Parts/spares required? Is the breakdown resolved? No All the resources covered with the BMP Problem identification is part of BMP Process with codes Requisition of Parts/Spares Yes No Parts are part of the BMP and sent along Parts Repaired Parts Replaced Receiving the parts Communications with Stores Operation of Machine Ensured All the written procedures and completed upon BMP information Yes External Agency/ Supplier does trouble shooting Parts Replacements Figure 8. Breakdown flow process – modified To get external agencies/supplier support Advanced Diognostic supports Requirements Advance Supports for Repairs Requirements No Is the problem identified? Yes Parts Procurement Parts Replaced Replacement Parts Required? No As detailed in Table VIII, MB2M has the components like duration/time management; resources like spare parts, lubricants, machining, technicians with level grading required, and depending on the complexity of the breakdown senior engineering skills/management required, etc. When we apply this new technique on the existing conventional approach of breakdowns we get proposed savings on efficiency level of the breakdown process and thus it projects a lean study approach on the effective execution of the breakdown management process. The main idea is to make the process more efficient by specific criteria codes and apply those codes to identify and locate/trouble shoot the failures when there is a breakdown maintenance call. If the specific repair meets these criteria then we go ahead and execute that particular plan. If not sufficing the adequate criteria (like meeting only 2/5, etc.) and if they are falling short of the verification of codes/confirmations, then a new MB2M and BMP is created for the new breakdown. Whenever any breakdown occurs, the crew will get a call from the user/site, etc. and upon information, they will check the main code of the b/d which is very generic, and further it will drop down to sub-code which tells the specific area of b/d, then we go to the symptom codes which speaks about the closer reasoning and further we go to the reason code which makes us to have an approach on the BMMP according to the reason code. A38 Code Description Oil cooler gasket damage Inter cooler core damage Water pump seal cut Engine liner gasket damage Water pump gasket weak Engine cylinder head gasket cut Engine head crack Description 24 16 2 16 2 8 2 A38R12 Engine cylinder head gasket A38R13 Inter cooler core damage – 8 A – – A – – – – – 16 A A A – A – – – – – – – – – – 30 A A A A A A A B A A A A A B B A B B B A B A B A B A Required Required Required Cooler service/coolant Pumpkit/assy/coolant “o” ring/liner/Eng. oil/ coolant Gasket/paste/coolant Required Required Required Engine head/gasket/ coolant/engine oil Block assy/valves/seat/ guides Gallery pipe/gasket/ coolant Inter cooler service/ coolant Liner/rings/gasket/ bearing/coolant/engine oil Gasket/coolant Cooler service/coolant Required Required Required Required Required Gasket/coolant Required Required Work place “o” ring/coolant Hrs Mins SM M AM Spares Engine block 20 crack Engine head water 5 gallery broken A38R10 Inter cooler core 8 damage A38Sy5 Emitting smoke with A38R11 Engine cylinder/ 32 excessive sound liner crack A38R7 A38R6 A38R5 A38R4 A38R3 A38R2 A38R1 Code A38Sy4 Engine compression A38R8 reduced A38R9 A38Sy3 Starting trouble A38Sy2 Engine oil level increased A38Sy1 Radiator coolant Engine oil and coolant oil mixing colour changed Code Description Breakdown sub-code Modified breakdown maintenance management (MB2M) Estimated Technician repair category/ Breakdown symptoms Breakdown reasons time rate Strategic approach 249 Table VIII. Modified breakdown maintenance with resources template BIJ 21,2 250 When there is a breakdown call on coolant oil excessive consumed, the person ON CALL checks the local maintenance team, as to whether there is engine oil and coolant oil mixing and further whether there is any: . change of radiator coolant color change appears; . has the engine oil level increased; . whether there is any starting trouble; . whether the compression pressure on the engine is less/reduced; and . whether the engine emits smoke with excessive noise? All these questions if checked and feedback received, if one or all of the reasons are present with the breakdown, then the crew which attends to the breakdown goes with the PROTOCOL which includes all the preparedness to back up the rectification process. References Ahamed Mohideen, P.B., Ramachandran, M. and Ramasamy Narasimmalu, R. (2011), “Construction plant breakdown criticality analysis – Part 1: UAE perspective”, Benchmarking: An International Journal, Vol. 18 No. 4, pp. 472-489. Arts, R.H., Knapp, G.M. and Mann, L. Jr (1998), “Some aspects of measuring maintenance performance in the process industry”, J. Qual. Maint. Eng., Vol. 4, pp. 6-11. Bashiri, M., Badri, H. and Hejazi, T.H. (2011), “Selecting optimum maintenance strategy by fuzzy interactive linear assignment method”, Applied Mathematical Modeling, Vol. 35, pp. 152-164. Blanchard, B.S. and Fabrycky, W.J. (1998), System Engineering and Analysis, Prentice-Hall, Upper Saddle River, NJ. Blischke, W.R. and Murthy, D.N.P. (2003), Case Studies in Reliability and Maintenance, Wiley, New York, NY. Campbell, J.D. and Jardin, A.K.S. (2001), Maintenance Excellence, Marcel Dekker, Inc., New York, NY. Curcuru, G. and Galante, G. (2010), “A Predictive maintenance policy with imperfect monitoring”, Reliability Engineering & System Safety, Vol. 95 No. 9, pp. 989-997. Etienne-Hamilton, E.C. (1994), “Managing maintenance for zero breakdowns”, Operations Strategies for Competitive Advantage, Dryden Press, Orlando, FL, pp. 378-421. Fonseca, D.J. and Knapp, G.M. (2001), “A fuzzy scheme for failure mode screening”, Fuzzy Sets and Systems, Vol. 121 No. 3, pp. 453-457. Fredendall, L.D., Patterson, J.W., Kennedy, W.J. and Griffin, T. (1997), “Maintenance: modelling its strategic impact”, Journal of Managerial Issues, Vol. 9 No. 4, pp. 440-453. Gebraeel, N., Lawley, M., Li, R. and Ryan, J. (2005), “Residual-life distributions from component degradation signals: a Bayesian approach”, IIE Transactions, Vol. 37 No. 6, pp. 543-557. Hall, R.A. and Daneshmend, L.K. (2003), “Reliability and maintainability models for mobile underground haulage equipment”, Canadian Mining & Metallurgical Institute Bulletin, June, pp. 159-165. International Atomic Energy Agency (2001), “Reliability assurance programme guidebook for advanced light water reactors”, printed by the IAEA in Austria. John, M. (2003), 21st Century Maintenance Organization Part II: The Path Forward, available at: www.mt-online.com/articles/0303_21st century.cfm Kececioglu, D. (1991), Reliability Engineering Handbook, Vol. 1, Prentice-Hall, Englewood Cliffs, NJ. Kumar, U. and Granholm, S. (1998), “Reliability technique: a powerful tool for mine operators”, Mining Resource Engineering, Vol. 1 No. 1, pp. 13-28. Lu, C.J. and Meeker, W.Q. (1993), “Using degradation measures to estimate a time-to-failure distribution”, Technometrics, Vol. 35 No. 2, pp. 161-174. Lu, S., Tu, Y.-C. and Huitian, L. (2007), “Predictive condition-based maintenance for continuously deteriorating systems”, Quality Reliability Eng. Intl., Vol. 23, pp. 71-81. Meselhy, K.T., ElMaraghy, W.H. and ElMaraghy, H.A. (2010), “A periodicity metric for assessing maintenance strategies”, CIRP Journal of Manufacturing Science and Technology, Vol. 3/2, pp. 135-141. Mishra, R.C. and Pathak, K. (2002), Maintenance Engineering and Management, Prentice-Hall, New Delhi. Mobley, R. (2002), An Introduction to Predictive Maintenance, 2nd ed., Butterworth-Heinemann, Oxford, October. Mostafa, S.I. (2004), “Implementation of proactive maintenance in the Egyptian glass company”, Journal of Quality in Maintenance Engineering, Vol. 10 No. 2, pp. 107-122. Parida, A., Chattopadhyay, G. and Kumar, U. (2005), “Multi criteria maintenance performance measurement: a conceptual model”, Proceedings of the 18th International Congress COMADEM, Cranfield, UK, 31 August-2 September, pp. 349-356. Paz, N.M. and Leigh, W. (2004), “Maintenance scheduling: issues, results and research needs”, International Journal of Operations and Productions Management, Vol. 15, pp. 47-52. Peter, M., Liliane, P., Ludo, G. and Harry, M. (2010), “Development of maintenance function performance measurement framework and indicators”, International Journal of Production Economics, Vol. 131 No. 1, pp. 295-302. Randy, R. and Burl, G. (1988), “Maintenance management concepts in construction equipment curricula”, Journal of Construction Education, Vol. 3, pp. 102-117. Rapinder Sawhney, S.K. (2009), “Developing a value stream map to evaluate breakdown maintenance operations”, International Journal of Industrial and Systems Engineering, Vol. 4 No. 3, pp. 229-240. Ricky, S. (2003), Best Maintenance Repair Practices, Butterworth-Heinemann, Oxford. Salonen, A. and Deleryd, M. (2011), “Cost of poor maintenance: a concept for maintenance performance improvement”, Journal of Quality in Maintenance Engineering, Vol. 17 No. 1, pp. 63-73. Swanson, L. (2001), “Linking maintenance strategies to performance”, Int. J. Production Economics, Vol. 70 No. 2001, pp. 237-244. Todinov, M.T. (2006), “Reliability analysis based on the losses from failures”, Risk Analysis, Vol. 26, pp. 311-335. Varghese, M.M. (2000), “Latest construction machineries and equipments”, available at: www. indiaconstruction.com/coverstory Waeyenbergh, G. and Pintelon, L. (2002), “A framework for maintenance concept development”, International Journal of Production Economics, Vol. 77 No. 3, pp. 299-313. Further reading Dodson, B. (1994), “Determining the optimum schedule for preventive maintenance”, Quality Engineering, Vol. 6 No. 4, pp. 667-679. Strategic approach 251 BIJ 21,2 252 RNCOS (2010), UAE Construction Industry Outlook, December, available at: www.rncos.com/sea rch.php Schonberger, R.J. (1986), World Class Manufacturing: The Lessons of Simplicity Applied, The Free Press, New York, NY. About the authors P.B. Ahamed Mohideen is pursuing research in the field of breakdown maintenance management on construction plant and equipment. He is a Research Scholar with Birla Institute of Technology and Science, Pilani, India. Presently, he is working as General Manager with ETA Ascon Group, a multinational organization located at Dubai. He has been a maintenance professional for the last 19 years, working with large base of construction plant and equipment, and he participates in many technical seminars and forums in the region. P.B. Ahamed Mohideen is the corresponding author and can be contacted at: pbahamed@gmail.com M. Ramachandran is the Founder Director of BITS Pilani, Dubai Campus. He has contributed a great number of research works on energy management studies. He is associated with many international journals and has published many papers in this field. To purchase reprints of this article please e-mail: reprints@emeraldinsight.com Or visit our web site for further details: www.emeraldinsight.com/reprints