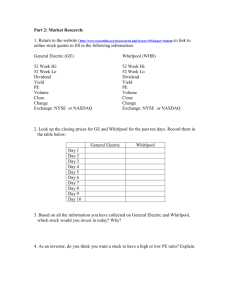

1 Strategic Sourcing at Whirpool China: Finding the Ideal Supplier OPER-4116EL: Purchasing & Sourcing Management Dr. Amirmohsen Golmohammadi Group Members: Tyson Marsolais, Shane Poitras, Cameron Ortiz-Cinanni 2 What is the key problem for Whirlpool in this case and what elements make the problem more challenging for Whirlpool? The key problem for Whirlpool, in this case, is finding the right supplier for DC motors in less than six months, while ensuring the supplier can meet the established requirements and creditability of Whirlpool. There are three main key challenges for Whirlpool in this case that made things more difficult. Firstly, Whirlpool's suppliers had a difficult time accepting the challenging payment terms. Because Whirlpool is one of the largest companies in the world, their requests from suppliers were very aggressive. In the case, it states that “ Whirlpool's procurement teams privileged the consignment stock process, any agreed-upon payment terms started when parts were withdrawn from Whirlpool's components warehouse, located in every whirlpools factory.” beyond that there were certain transportation times and other payment terms that were practically impossible for suppliers to meet, given that they weren’t necessarily predeterminable. Secondly, another challenge is that to create new energy-saving appliances successfully, suppliers had to test these products which were time-consuming and long term. New projects had to be provided with samples and application tests, which made the whole process a long one. Lastly, improving the technology while keeping costs low on appliances is another roadblock towards a solution for Whirlpool's main challenge. Because of the fact that new energy-saving technology is more expensive and harder to create, meant keeping costs as low as previous, was virtually impossible. What are the main strategies that Whirlpool can use to address this problem? The main strategy to solve the problem, in this case, is to find a suitable supplier for the required DC motor parts in order to create new energy-efficient products. This strategy started by issuing a Sourcing Strategy Development (SSD) process which is made up of four important steps for sourcing the best and most suitable suppliers. The steps consist of, Internal analysis, External analysis, Strategy development, and finally, implementation. Step 1 of an internal analysis was important to be able to allocate resources and responsibilities of global and regional activities. Furthermore, Step 2 was looking at the completion and evaluation of the supplier industry as well. A SWOT analysis was helpful in completing Step 2. Next, Step 3 was later used to create the sourcing strategy through Porter's Five Forces Model. Lastly, Step 4, is where the implementation takes place. The plans were put into place and feedback from suppliers and partners may occur here. 3 What is the importance of strategic sourcing and how Whirpool has addressed it? Strategic sourcing is a way to develop channels of supply that consider all ongoing activities within the company to secure the best possible cost, rather than looking for the best cost individually. This allows a company to combine their purchasing power to achieve the lowest possible cost and risk across the supply chain. While this process is long-term it has a lasting impact on a company and how they conduct their business in the future, as long as they re-evaluate sourcing activities, analysis of the market as well as make sure business goals are in accordance with requirements with suppliers (D2l.laurentian.ca, 2022). Whirlpool addressed this by creating a very restricted supply quality system, which goes by Whirlpool’s Supplier Quality System. Based on past experience most Chinese suppliers, even those used by competing brands, couldn't reach the lowest required score on the supply quality system (60/100). To ensure that these practices remained rooted within Whirlpool's competitive strategy they follow a restricted Six Sigma program (Six Sigma is a method that provides organizations tools to improve the capability of their business processes)(ASQ, 2022). Whirlpool’s system was mainly aimed at improving the quality and efficiency of its technology and business processes and products. This allowed Whirlpool the ability to recognize when suppliers developed distinct cost advantages so they could provide the resources to close the gap within a set time frame. Another way Whirlpool has addressed this is by putting boots on the ground visiting new and existing suppliers. Supplier Quality Engineer (SQE) and Supplier Development Engineer (SDE) teams travel from supplier to supplier ensuring development by providing training and or coaching for those working on projects. This way Whirlpool can keep eyes and ears within their supply chain regardless of where that is and can act accordingly to opportunities and challenges respectively. What are the pros and cons of Whirlpool's global sourcing strategy? Global sourcing strategies can become a difficult process for a variety of reasons including, transportation delays, lack of technology, capacity of foreign resources, culture and language differences, quality assurance, political and economic stability, and proper inventory management systems, to name a few. With the understanding of such constraints and barriers, Whirlpool established an international procurement office in Shanghai. This venture for Whirlpool provided a global sourcing strategy that allowed them to support their own manufacturing operations in Asia, as well as provide support for any other operation in the world that sourced components from Asia. 4 With that being said, this global sourcing strategy has come along with a long list of advantages which include, decreasing the company’s transportation delays, decreasing culture and language differences, offering manufacturing support, increasing market share, reducing capital investment, increasing Whirlpool’s production flexibility, as well as gain the ability to focus on core competencies. Although there have been many advantages to Whirlpool’s global sourcing strategy in China, there are also some disadvantages that come along with it. The disadvantages include the inconsistencies with quality and reliability, lack of capable service providers, shortcomings in both transportation and IT infrastructure, as well as high rates of damage/loss in transportation. How are suppliers identified, evaluated, and selected? What do you think of the company’s evaluation matrix? To find suitable suppliers, Whirlpool used a Sourcing Strategy Development (SSD) process, which included four steps for sourcing the right suppliers. The steps included were Step 1: internal analysis, Step 2: external analysis, Step 3: strategy development, and Step 4: implementation. This process allowed Whirlpool to simultaneously identify, evaluate, and ultimately help select a suitable supplier throughout the entirety of the SSD process. Key elements that were used throughout the entirety of the supplier selection process include the must-meet criteria mentioned in the following question, the SSD process, a SWOT analysis, as well as Porter’s Five Forces Model to analyze competitiveness. Based on a supplier's performance within the mentioned key elements, ultimate supplier selection would also come down to the suppliers' acceptance of the following Whirlpool criteria, aggressive payment terms, a long sample-testing process, as well as the supplier continuously challenging themselves in terms of cost and quality improvement. Reflecting on Whirlpool’s evaluation matrix, I think that it is a very thorough evaluation matrix that helps unveil ample amounts of useful information when it comes to supplier selection. The only downside to the evaluation matrix is the vast amount of time required to complete such an elaborate evaluation, as well as the very strict selection criteria that Whirlpool has enforced that come along with it. How do you ensure quality, especially when dealing with a new supplier? Suppliers to Whirlpool have to undergo the four-step process aforementioned, this includes having the proper infrastructure and chains to supply both land and air transportation (the basic needs of Whirlpool's supply chain). Furthermore, suppliers must undergo a long sampling and project testing to keep quality at its best throughout all stages of the supply chain. Whirlpool also has a supplier checklist and must meet the following criteria to become considered as a supplier, they are as follows: 5 - Whirlpool code of conduct and other requirements; Minimum quality audit score; The best total cost of ownership and manufacturing efficiency; Continuous innovation in design and manufacturing for best-in-class quality and technology; - Structured project tracking, design reviews with management tollgates, utilizing design and process - FMEA, fault tree analysis, reverse engineering and other tools where applicable; and - Access to UL, CSA, VDE and other agency approval. The following requirements were dependent on the commodity analyzed: - Laboratory capability for engineering conformance and reliability testing. - Prototype capabilities. By following these requirements Whirlpools is ensuring that sourcing in China remains viable for the business practices. 6 References D2l.laurentian.ca. (n.d.). Retrieved February 11, 2022, from https://d2l.laurentian.ca/d2l/le/content/147365/viewContent/1264446/View What is Six sigma? ASQ. (n.d.). Retrieved February 11, 2022, from https://asq.org/quality-resources/six-sigma What is strategic sourcing and why is it important? Rebound Electronics. (2022). Retrieved February 13, 2022, from https://reboundeu.com/blog/what-is-strategic-sourcing-and-why-is-it-important/