Strategic Cost Management & Performance Evaluation Course Material

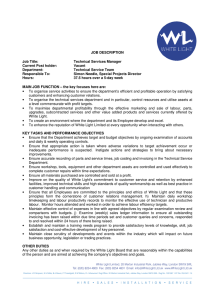

advertisement