Modeling Fuelcells

with ANSYS Fluent

Shaoping Li, PhD

Principal Software Developer

Manager, Fluent Reacting Flow Dev.

ANSYS, Inc. USA

1

Outline

• Model Framework

• Fuel Cell Models

❑ Resolved Membrane Approach

o PEMFC (质子交换膜燃料电池 – 低温)

o SOFC (固体氧化剂燃料电池 – 高温)

o Electrolysis (电解 – 高温)

❑ Unresolved Membrane Approach

o SOFC

o Electrolysis

❑ New PEMFC Module – 重点!

• Some Examples

Model Framework

• All fuelcell modeling capabilities are provided as add-on modules with the standard FLUENT

(with no additional charges)

• Users can write their own customized functions and link to the add-on module (usually for

the purpose of using their own properties and in-house model parameters or coorelations)

• GUI and TUI for easy model setup and input.

Fluent Addon Modules:

0. None

1. MHD Model

2. Fiber Model

3. Fuel Cell and Electrolysis Model

4. SOFC Model with Unresolved Electrolyte

5. Population Balance Model

6. Adjoint Solver

7. Single-Potential Battery Model

8. Dual-Potential MSMD Battery Model

9. PEM Fuel Cell Model

10. Macroscopic Particle Model

Enter Module Number: [ ]

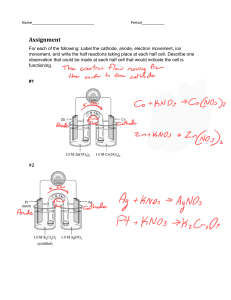

Fuel Cell Principles (e.g. PEMFC)

• 氢离子 and 电子 are produced in anode catalyst

layer:

H 2 2H + + 2e −

•氢离子 and 电子 travel via the membrane and

external circuit, respectively, to the cathode

where they combine with oxygen to produce

water:

1

O 2 + 2e − + 2H + H 2 O

2

Cooling

water

passage

Cooling

water

passage

2e-

Current collector

Cathode

Flow channel

Gas diffusion layer

O2

H2O

Pt catalyst layer

Membrane

Anode

Pt Catalyst layer

Gas diffusion layer

Flow channel

H+

H2

Current collector

Cooling water passage

2e-

Fuel Cell and Electrolysis Model

1. FuelCell and Electrolysis Module 简介

Integrated model framework for PEMFC, SOFC & Electrolysis

with MEA being included in the computational domains

Domains Modeled

(Resolved MEA e.g. PEMFC)

Cooling Channel(s)

Anode Collector

Gas Channel

Anode GDL

Anode Catalyst Layer

MEA

Membrane

Cathode Catalyst Layer

Cathode GDL

Fuelcells Modeled

➢ PEMFC

➢ SOFC

➢ Electrolysis

Gas Channel

Cathode Collector

Cooling Channel(s)

PEMFC, SOFC, Electrolysis

Proton Exchange Membrane

Fuel Cell (PEMFC)

--- low temperature

Solid Oxide Fuel Cell (SOFC)

--- high temperature

Electrolysis

--- high temperature

H2

H + + e−

2

1

O2 + H + + e − H 2 O

4

H 2 + O 2− H 2O + 2e −

1

O2 + 2e − O 2−

2

H 2O + 2e − H 2 + O 2−

O 2−

1

O2 + 2e −

2

(Anode)

(Cathode)

(Anode)

(Cathode)

(“Anode”)

(“Cathode”)

Highlights of Key Model Capabilities

• Integrated model framework for PEMFC, SOFC & Electrolysis

• Multi-component diffusion for gas species transport

• Liquid water transport in porous media, clogging to gas diffusion and

reaction sites (PEMFC)

• Non-isotropic electric conductivity in porous GDL (PEMFC)

• Compatibility with non-conformal interface meshing

• User-Modifiable Properties/Correlations

• Automated udf library path, independent of FLUENT version numbers

Mathematical Model Description (dual potentials)*

• Electro potentials:

−

‐ solid phase potential: ( e transport in conducting solid)

‐ membrane phase:

( H + transport in MEA )

( ee ) + S e = 0.0

( mm ) + S m = 0.0

•Surface over-potential (activation loss):

• Advantages: = e − m − Voc

‐ Account for current transport in all regions

‐ Facilitate modeling of contact resistance at material interface

ref

* All Math Descriptions are valid for the new PEMFC module too !

Mathematical Model Description (transfer currents)

Butler Volmer

S a = ja ,ref (

S c = jc ,ref (

jref

ci

ci ,ref

ch 2

ch 2,ref

co 2

co 2,ref

a

) (e

c

a F

RT

) ( −e

volumetric reference exchange

current density

local species molar concentration

and its reference value, respectively.

concentration dependence,

a

a F

RT

c

−e

−

+e

c F

RT

−

a

c F

RT

)

c

)

the transfer coefficient,

subscripts a and c indicate the

anode and the cathode side,

respectively

Boundary Conditions for e

inside catalyst layers

Se = −Sa 0

(anode)

Se = + Sc 0

(cathode)

anode

cathode

Boundary Conditions for m

inside catalyst layers

Sm = +Sa 0

(anode)

S m = −Sc 0

(cathode)

anod

catalyst

emembrane

MEA

catalyst

m

=0

n

Use S a dV = S c dV to obtain a unique solution

Van

Vca

Local Sources Due to Electrochemistry (e.g. PEMFC)

−

‐ H2-equation:

M o2

−

S c dV

4F

‐ O2-equation:

‐ H2O-equation:

M h2

S a dV

2F

+

M h 2o

S c dV − rw dV

2F

‐ Conservation of current and mass requires

S dV = S dV

a

Van

c

Vca

物性参数 (User-Customizable)- e.g. PEMFC

• Most commonly used correlations are coded as default options

• Users can overwrite with their own formulation/data

Default membrane phase electric conductivity (Springer et al)

1268 (

m = (0.514 − 0.326) e

Default osmotic drag coefficient

1

1

− )

303 T

(Springer et al)

Default membrane water diffusivity (Dutta et al)

Gas diffusivity (Wang, Bird, Kaviany)

nd = 2.5

22

Dw = D exp{2416(

Di = (1 − s)b D o i (

p0 T 1.5

) ( )

p T0

1

1

− )}

303 T

Solution Procedure

• Specify solid phase potential BCs at cathode current collectors (cell

voltage or average current density),

Vcell or I ave

• Solve the system of equations for

u, v, w, p, yi , T , e , m , s,

S

=

a

dVa

• If run-to-voltage, average current is:

I ave

• If run-to-current,

Vcell = e |cathode wall

cell voltage is:

• Polarization curve

( I ave, Vcell )

Amem

Some Examples

Tubular Cell SOFC

cathode

193,475 computing cells

electrolyte

air pipe

anode

O2

current

Stack Simulation - SOFC

10-cell stack, concentration limited,

matches theoretical limiting current

I = m O2

F

M O2

O2 mass fractions at x-plane

O2

Stack Simulation - SOFC

4-Cell Stack: 2.25 million computing cells.

H2

O2

Non-Conformal Interface

Straight-Serpentine Channels:

607,097 cells

anode interface

cathode interface

SOFC with Internal Reforming (tubular cell)

steam reforming: CH4 + H2O --- 3H2 + CO

water-shift:

CO + H2O →H2 + CO2

I=5.458 A

CH4

H2

CO2

High-Temperature Electrolysis

h2o

h2

• Split Water vapor into Hydrogen and Oxygen

• cell voltage is higher than open-circuit voltage

• endothermic process

o2

T

1e-5

SOFC with unresolved Electrolyte

SOFC with unresolved electrolyte

Domains Modeled

SOFC Module GUI Panel

(Unresolved MEA)

Anode Collector

Gas Channel

Anode GDL

Anode Catalyst Layer

MEA

Membrane

Cathode Catalyst Layer

Cathode GDL

Gas Channel

Cathode Collector

• MEA is not included in the computing mesh

• MEA is modeled as wall-wall interface

• Advantage:

less costly

• Disadvantage: no inormation about MEA; not

compatabile with non-conforming mesh

• Capabilities: very similar to its resolved counterpart

No more discussions here

For details, see theory

manual & user-guide

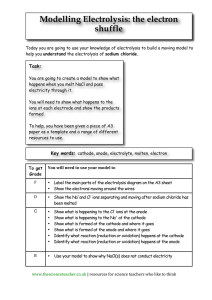

New PEMFC Module

New PEMFC Module (since FLUENT 17.0)

New

New

•

•

•

•

•

Developed under externally funded projects

New

Several significant improvements over the old PEMFC module

Much improved numerical robustness

New water management concept that guarantees mass conservation

Recommended for pmefc applications !

Model Options

New Concept for Water Management

➢ Water can exist in 3 forms

• Dissolved in the ionomer

• Water vapor in the porous

media and gas channels

• Liquid water in the porous

media and gas channels

➢ Water is generated in the

dissolved phase !

➢ Deviation from equilibrium as

driving force for phase changes

Liquid Water Transport in Porous Media

▪

Implemented new liquid water equation in Porous Media

--- solve capillary pressure equation in MEM, CAT, MPL, GDL

--- determine saturation from pc-s relations.

KK rl

( i l s) =

( pc + p g ) + S gl − Sld

t

l

Gas-to-Liquid

New

from GDL to channel

New

Dissolved Phase Water Transport in MEA

▪ Transport equation for dissolved (3rd phase) water in MEA

(catalyst-membrane-catalyst assembly) (Wu 2009)

New

i

nd

+ M w im = M w l Dw + S + S gd + S ld

i M w,H 2o

t

EW

F

EW

Reaction

Old:

M W , H 2O

S =

Rcat

2F

M w l Dw = 0

EW

---------

Gas-to-Dissolved

Liquid-to-Dissolved

solved only in membrane

new osmotic drag treatment through the entire MEA

water is produced in dissolved phase (rather than vapor phase)

mass transfer with other two phases: vapor and liquid (absorption/desorption)

mass conservation is always observed

Liquid Water Transport in Gas Channels (optional)

▪

Solve liquid saturation in gas channels to obtain meaningful values to model pressure

drop through viscous momentum resistance, using a user-modifiable function in

pemfc_user.c

New

vl = v g

( l s ) + ( l vl s ) = ( Dliqs )

t

default resistance:

R momentum = f ( s ) = s

liquid saturation in cathode channel

static pressure

with liquid

w/o liquid

Addition of Micro Porous Layer (MPL)

➢ Include MPL as separate layers with different properties

from GDLs

Polarization

1.00

w/o MPL

0.90

with MPL

0.80

0.70

V (v)

New

0.60

0.50

0.40

0.00

0.20

0.40

0.60

I (A/cm2)

0.80

1.00

1.20

The Two Potentials

− I leak

New

Leakage Current

Temperature-Dependent

New

Overpotentials

New

Nernst half cell potentials

Cathode Particle Model

New

➢ considers mass transfer resistance in microstructure

Case

I (A/cm2)

Cathode Particle Model On

0.886205

rp=0, Rion=0

0.924535 (+4%)

Cathode Particle Model Off

0.924535

Other Improvements

1. Calculation of thermal conductivity for multiphase fluid

2. Use Entropy to compute reaction heat

3. Variable phase change rates

4. Thermal contact resistance

What is solved ? and Where?

Anode to

cathode

e- Pot.

uds-0

H+ Pot.

uds-1

Pc

uds-2

Cur. Coll.

Solid

Channel

Fluid

GDL

Fluid

y

y

MPL

Fluid

y

y

Cat. Layer

Fluid

y

Membrane

Solid

Cat. Layer

Fluid

y

MPL

Fluid

y

y

GDL

Fluid

y

y

Channel

Fluid

Cur. Coll.

Solid

uds-3

s

uds-4

y

y

y

y

y

y

y

y

y

y

y

y

y

PEMFC: O2 Mass Fraction and Temperature

T

yO 2

anode

cathode

cathode: mass fraction of O2 reduces along the channel due to reaction

anode: no O2 crossover due to presence of membrane

PEMFC: Liquid Distribution and its Effect on Performance

Liquid saturation at the cathode catalyst layer

Cell Performance

s

Polarization

1

without liquid

water

with liquid

water

0.9

anod

e

flow

V_cell (V)

0.8

cathod

e flow

0.7

0.6

0.5

0.4

0.3

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2

I (A/cm^2)

• global & local polarizations

• current density distribution

Model Validation

50 cm2 MEA of Mench et al (2004)

Inlet

Channel depth: 3.18; width: 2.16

➢ 48 gold-plated steel current collecting

ribs embedded into an insulating slab

o

o

o

➢ Tcell = 80 C ; P = 1.5atm; Ta = 90 C ; Tc = 80 C

71.12

➢ an = 1.875; ca = 1.5, 2.25

Outlet

2.54

➢ mass flow rate was kept constant in

each cathode stoichiometry run

70.99

Figure 1. Schematic diagram of the test cell of Mench et al

[1]: all numbers in mm

Current Density Measurement Locations

Segmented current collector right under the cathode ribs

(Segmented areas are actually continuous)

Species Mass Fractions in Gas Channels

H

O2

2

ca = 1.5

Vcell = 0.45

Liquid Saturation at Different Cell Voltage

location: mid-plane of cathode gas diffusion layer

Vcell = 0.4 V

Vcell = 0.6 V

ca = 1.5

Vcell = 0.8 V

Global Polarization

Polarization

1.00

Experiment: 2.25 equiv.

Experiment: 1.50 equiv.

0.90

FLuent: 1.50 equiv.

Fluent: 2.25 equiv.

0.80

V (v)

0.70

0.60

0.50

0.40

0.30

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

I (A/cm2)

Computed (lines) and measured (symbols) global polarization

curves for cathode stoichiometry of 1.5 and 2.25 equiv.

Local Polarization

1.5

Local Polarization

2.25

x/L=0.109

x/L=0.109

Local Polarization

x/L=0.283

1.0

x/L=0.717

0.9

x/L=0.891

0.8

0.7

V (v)

0.6

1.0

x/L=0.283

x/L=0.717

0.9

x/L=0.891

data: x/L=0.891

0.8

data: x/L=0.891

data: x/L = 0.717

0.7

data: x/L = 0.717

data: x/L=0.283

V (v)0.6

data: x/L=0.109

0.5

data: x/L=0.283

data: x/L=0.109

0.5

0.4

0.4

0.3

0.3

0.2

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.2

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

I (A/cm2)

I (A/cm2)

Computed (lines) and measured

(symbols) local polarization curves for

cathode stoichiometry of 1.5 equiv.

Computed (lines) and measured

(symbols) local polarization curves for

cathode stoichiometry of 2.25 equiv.

Local Current Density

1.5

I (A/cm2)

2.25

0.85 V

0.80 V

0.70 V

0.85 V

0.80 V

0.70 V

0.65 V

0.55 V

0.45 V

0.65 V

0.55 V

0.45 V

0.40 V

0.35 V

data- 0.85 V

0.40 V

0.35 V

data- 0.85 V

data- 0.80 V

data- 0.70 V

data- 0.65 V

data- 0.80 V

data- 0.70 V

data- 0.65 V

data- 0.55 V

data- 0.45 V

data- 0.40 V

data- 0.55 V

data- 0.45 V

data- 0.40 V

I (A/cm2)

data- 0.35 V

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

x/L

Computed (lines) , measured (symbols):

cathode stoichiometry of 1.5 equiv.

data- 0.35 V

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

fractional distance from cathode inlet

Computed (lines), measured (symbols):

cathode stoichiometry of 2.25 equiv.

Guidelines for solution control

1. Under-Relaxation Factors (URF’s) for Transport Equations

a. Pressure: 0.3 ~ 0.5

b. Momentum: 0.3

c. All other equations: 1.0 (do not use anything less than 1.0)

2. Under-Relaxation Factors (URF’s) for Source Terms (in PEM Fuel Cell Model panel)

a. Liq.-Vap. Source: reduce to as low as 0.02 (often required)

b. Dis’d-Vap./Liq. Source: reduce to as low as 0.02 (often required)

c. Osmotic Drag Source: 0.5~1.0

d. GDL Liquid Removal: 0.2~0.5

3. AMG Solver In Solve→Controls→Advanced→Multigrid… panel

Choose F-Cycle as Cycle Type for all variables.

- can be done by clicking “F-Cycle for All Equations” in the PEMFC GUI panel.

4. Parallel Partition

Use Laplace Smoothing for better mesh quality

5. …. see “Best Practices for PEMFC Simulation”

Useful Documents for Fuel Cell Modeling

➢ ANSYS Advanced Fluent Add-On Modules

➢ Tutorial Package

➢ Best Practices for PEM Fuel Cell Simulations

Areas for Future Improvement

o material data for porous GDL/MPL in actual PEM operation for accuracy

o more accurate characterization of membrane and catalysts --quantitative relationship of microstructure and compositions with cell

performance

o reliable experimental data under well-defined operating conditions for

systematic model validations (global, local, transient)

Looking forward to working with industrial/academic leaders

Membrane Water Transport

Current modeling of osmotic drag and back diffusion is

mostly based upon Springer et al’s paper of (1991)

Jw

Jw

diff

osm

nd M h 2o

=

i

F

=−

m

Mm

M h 2 o D w

nd = 2.5

22

Dw = D exp{2416(

1

1

− )}

303 T

Questions:

• Validity of measured correlations for today’s membranes ?

Liquid Water Transport in Porous Media

Liquid water flux is mostly modeled using Darcy’s law

K K rl dpl

lVl s = l

s

l ds

cos

pc =

J ( s, )

0.5

(K / )

1.417 (1 − s ) − 2.12 (1 − s ) 2 + 1.263 (1 − s ) 3 ( 90 0 )

J ( s, ) =

2

3

( 90 0 )

1.417 s − 2.12 s + 1.263 s

hydrophilic

hydrophobic

Questions:

• pc-s relation was obtained in the study of geosciences such as soil

or sand, not valid for GDL used in PEMFC

• Lack of sensitivity to wetting property

Liquid Water Transport in Gas Channel

In practice, flow in gas channel is two-phase and strongly

affected by channel surface wettability.

However, a programmatic approach is adopted, mainly to

model the effect of increased pressure drop due to the

presence of liquid water.

谢谢!