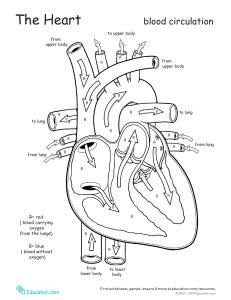

2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. A Mathematical Model of Lung Functionality using Pressure Signal for Volume-Controlled Ventilation Husam Y. Al-Hetari Faculty of Computing University Malaysia Pahang, Malaysia 26300 Gambang, Kuantan, Malaysia and Dept. of Biomedical Engineering Faculty of Engineering University of Science and Technology Yemen husamalhetari@gmail.com Noman Q. Al-Naggar Dept. of Biomedical Engineering Faculty of Engineering University of Science and Technology Yemen nnagar845@gmail.com Muhammad Nomani Kabir* Faculty of Computing University Malaysia Pahang, Malaysia 26300 Gambang, Kuantan, Malaysia (*Corresponding author) nomanikabir@ump.edu.my Mahmoud A. Al-Rumaima Dept. of Biomedical Engineering Faculty of Engineering University of Science and Technology Yemen m.alromaima@gmail.com Yasser M. Alginahi Dept. of Electrical and Computer Engineering University of Windsor 401 Sunset Ave, Windsor, Ontario N9B 3P4, Canada alginah@uwindsor.ca Md Munirul Hasan Faculty of Computing University Malaysia Pahang, Malaysia 26300 Gambang, Kuantan, Malaysia monirul.iiuc@gmail.com Abstract— Mechanical Ventilation is used to support the respiratory system malfunction by assisting recovery breathing process which could result from diseases and viruses such as pneumonia and COVID-19. Mathematical models are used to study and simulate the respiratory system supported by mechanical ventilation using different modes such as volumecontrolled ventilation (VCV). In this research, a single compartment lung model ventilated by VCV is developed during real time mechanical ventilation using pressure signal. This mathematical model describes the lung volume and compliance correctly considering positive end expiration pressure (PEEP) value. The model is implemented using LabVIEW tools and can be used to monitor the volume, flow and compliance as outputs of the model. Two experiments are carried out on the proposed lung model at three input scenarios of volume (400, 500 and 600 ml) for each experiment considering a PEEP value. To validate the model, an artificial lung connected to a VCV with the same scenarios is used. Validation check is conducted by comparing the outputs of the lung model to that of the artificial lung. The experimental results showed that the measured lung model outputs with negative feedback are the same for pressure and flow as the outputs without negative feedback, whereas the measured volume is comparatively lower for negative feedback. Average percent error in the experiment with negative feedback (5.14%) is smaller compared to the experiment without negative feedback (9.28%). Furthermore, the average error of the calculated compliance decreases from 16% (without negative feedback) to 2% (with negative feedback). The obtained results of the proposed method showed good performance and acceptable accuracy. Thus, the model facilitates the clinicians and practitioners as a training tool to learn real-time mechanical ventilation functionalities. Keywords—Mechanical Ventilation; Volume-Controlled Ventilators; Lung Compliance; Positive End Expiration Pressure (PEEP); Negative Feedback; Lung Model; COVID-19 I. INTRODUCTION Mechanical Ventilation plays a crucial role in intensive care unit (ICU) for life support of patients having lung This research is supported by Universiti Malaysia Pahang (UMP) through University Research Grant (RDU1901150). malfunction as a result of diseases such as pneumonia, COVID-19, etc. Mechanical ventilation process delivers and controls flow, pressure and volume of air and gases to a patient’s lung [1]. Mechanical ventilation tries to find optimal positive end expiration pressure (PEEP) level [2, 3] and it uses real time numeric data and waveforms interpretation that helps to assess the patient response to ventilation and to maximize patient comfort and therapeutic benefits [4-6]. Commonly, there are two types of mechanical ventilation: volumecontrolled ventilation (VCV) and pressure-controlled ventilation (PCV) [4, 7]. Both types deliver and control flow, pressure and volume of air and medical gases to the patient’s lung. VCV is commonly used to treat disordered lungs, delivering constant volume to patient’s lung [8]. Mathematical models provide realistic solutions for complex engineering problems [9-12]. A mathematical model can be used to describe patient’s lung mechanics. Furthermore, models are developed to optimize mechanicalventilation therapy. Many studies use a single compartment lung model that can describe lung elastance (1/compliance) and air way resistance [13-15]. The model incorporates lung volume and air flow, as well as PEEP that exerts additional pressure at the end of expiration to reduce alveoli collapse, and reduces the risk of lung damage [3, 16]. In addition, in some cases, PEEP is important to reduce work of breathing. Moreover, titrating PEEP is important during mechanical ventilation to optimize lung characteristics [16, 17]. However, excessive increase in PEEP which adds extra volume can cause ventilator induce lung injury syndrome [18]. Most of the previous works recorded (pressure and flow) signals as input data to validate single compartment model [14, 19, 20]. This study aims to optimize and validate a single compartment lung model supported by VCV through applying one input signal (i.e., pressure) during real-time mechanical ventilation to describe lung volume and compliance correctly [21, 22]. In real practice of VCV, the lung volume should remain constant even in change of pressure [8]. Adding PEEP in the lung model results in increase of lung model output volume, and affects the compliance [23-26]. © IEEE 2020. This article is free to access and download, along with rights for full text and data mining, re-use and analysis. Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply. 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. To overcome this problem and keep the volume constant, we add a negative feedback to the lung model to remove the amount of volume which increases due to PEEP [5, 16]. The pressure signal is collected at real time using interface device (ID) which is made for collecting real-time pressure signal of lung during mechanical ventilation. The model is implemented in LabVIEW tool, which integrates pressure with the volume, airflow and compliance. The proposed model will help to investigate the efficiency of VCV and also improve accuracy in measurement of lung compliance. Moreover, it can help clinicians to minimize risk of lung injury through studying the lung model in real-time mechanical ventilation instead of working on real patient lungs. III. METHODOLOGY Fig. 2 shows the block diagram of the proposed method. The pressure signal is collected at real time from breathing circuit using an ID as shown in Fig. 3; and is sent to the lung model which is implemented by LabVIEW platform as demonstrated in Fig. 4. The rest of the paper is organized as follows. Section II provides the preliminaries of the research work. Section III presents the methodology of building the proposed algorithm. The results and discussion are provided in section IV and finally, the conclusion is presented in section V. II. PRELIMINARIES Fig. 2. Main parts involved in the proposed method Basic functionality of lung mechanics can be described by a single compartment model [15, 19, 27] which is illustrated by Fig. 1. Following this illustration, the lung model can be presented by (1) where pt is the airway pressure, E is an overall lung elastance (1/compliance), Vt represents lung volume, R represents airway resistance, Qt is air flow which equals dVt/dt and p0 represents PEEP. Note that the subscript t represents the time. Fig. 3. Interface device for recording the pressure signal Fig. 1. Illustration of the lung model Thus, the lung model can be formulated as ) Fig. 4. The proposed model in LabVIEW platform (2) 0, which is a first-order ordinary differential equation. The following equation can be used to describe lung compliance (C) [28]: / ) (3) The main components of ID are pressure sensor (MPX2050), instrumentation amplifier (AD620) and analogue to digital converter (ADC0808). LabVIEW is a powerful software that can be used for biomedical control and simulation; therefore, it is used to implement the lung model as shown in Fig. 4. The proposed model is based on a negative feedback from the output volume to the model input as shown in Fig. 5. Thus, the input pressure in the lung model can be presented by where ppl is the plateau pressure which represents pause pressure before expiration and it is approximately equal to the maximum of pressure signal; PEEP is approximately theminimum pressure signal; and VT is the volume change. Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply. (4) 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. Thus, (5) Therefore, (2) can be formulated as: 0 (6) where pt is the airway pressure, is the lung model input (pressure), Vt is the model output (volume), Vmin is the minimum volume and α >1 is constant value. The proposed method is validated using the agreement of the output values of the lung model with that of the artificial lung. The agreement is measured in terms of absolute percentage error ∈, which is calculated using the following equation: O ∈ O O x 100 (7) where OM is the model output and OT is the experimental (true) output. IV. RESULTS AND DISCUSSION Fig. 5. The proposed model with a negative feedback In general, the lung model depends on using two types of input data (pressure and flow signals), but the proposed lung model is based on only one type of input data (pressure signal). The use of one signal as input signal of lung model needs control, mathematical processing and validation. In the present study, two experiments are conducted on reference device and the lung model. The reference device depends on (pressure and flow signals), whereas the lung model depends on one signal (pressure signal) during real-time mechanical ventilation with and without the feedback. The lung model is used to study the outputs: volume V (ml), flow Q (ml/s) and compliance C (ml/cmH2O) using the input pressure p (cmH2O) during real-time mechanical ventilation with and without negative feedback. It is noted that if negative feedback is not considered, the model will act as the previous model described by (1). The artificial lung is connected to VT plus HF Gas Flow analyser [29] that measures the signals of p, V, Q and C during real-time mechanical ventilation. This artificial lung and the analyser are well-known calibrated products manufactured by Fluke Biomedical Corporation. The experimental procedure can be described as follows: • The artificial lung is ventilated using VCV (ICU Electric Ventilator- Model SC-5). The operating mode is as follows: • • • • - Intermittent positive pressure ventilation with respiration rate is 16 breaths per minute (bpm); - Ratio of inspiration time (s) to expiration time (s) is 1:2; - PEEP is taken up to 5 cmH2O. The artificial lung which represents the patient lung is adjusted to compliance C = 20 ml/cmH2O, resistance R = 20 cmH2O/L/s. Two experiments carried out on artificial lung and the lung model include three scenarios with lung volume: 400 ml, 500 ml and 600 ml. The first experiment is carried out without adding feedback; and the second experiment, with a negative feedback. The main parameters of mechanical ventilation: pressure, volume and flow are measured on artificial lung. The lung model uses the same input pressure and computes the corresponding output of volume and flow for three scenarios of different volumes. The compliance obtained by the lung model is calculated and compared to the compliance of artificial lung in each scenario. Fig. 6. Pressure signal at volume 400 ml (without feedback). Fig. 7. Volume signal at volume 400 ml (without feedback). Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply. 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. volumes produced the error as 17.7%, 14.6% and 12.1% in these three scenarios (400 ml, 500 ml and 600 ml), respectively. The average percent error is 9.28% for measured parameters at three scenarios. Fig. 8. Flow signal at volume 400 ml (without feedback). Fig. 11. Flow signal at volume 400 ml (with feedback). Fig. 9. Pressure signal at volume 400 ml (with feedback). Fig. 12. Pressure signal at volume 600 ml (without feedback). Fig. 10. Volume signal at volume 400 ml (with feedback). TABLE I shows the results that are obtained from the two experiments (experiment 1 without feedback and experiment 2 with feedback) and the values of p, V and Q are illustrated in Figs. 6-11 and Figs. 12-17 for VCV at 400ml and 600ml. These results presented for experiment 1 show a clear shifting and drift particularly in volume curves. The outputs of the Fig. 13. Volume signal at volume 600 ml (without feedback). However, the results of p, V and Q obtained from the second experiment which uses the lung model with negative feedback provide that the values of p and Q of the lung model and artificial lung are approximately the same as the measured Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply. 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. values and significant improvement is obtained for V, which is also clear from the curves as shown in Figs. 7 and 10, and Figs. 13 and 16. The calculated percent errors in the second experiment are almost the same for p compared to the first experiment, whereas, the calculated percent errors of measured volume V and Q decreased for three scenarios compared to that obtained in first experiment as shown in TABLE I. The average percent of error in the second experiment (5.14%) is much smaller compared to the first experiment (9.28%). Error (∈) (No Feedback) Error (∈) (With Feedback) 22.08 22.53 2.0 2.0 337.9 335.2 17.7 0.8 38.15 41.64 8.4 8.4 27.22 0.5 0.5 424.4 14.6 1.4 51.42 3.9 3.9 32.4 2.2 2.2 505 12.1 0.9 49.53 18.6 18.6 9.28 5.14 Lung model Output (OM) (No Feedback) Lung model output (OM) (With feedback) Artificial lung measurement (OT) COMPAISON OF P, V AND Q VALUES. Measured Parameters Scenario TABLE I. Pressure 22.08 1 (cmH2O) (Volume at Volume (ml) 394.59 400ml) Flow (ml/s) 38.15 Pressure 2 27.09 27.09 (Volume (cmH2O) at 500ml) Volume (ml) 486.24 430.44 Flow (ml/s) 49.42 49.42 Pressure 3 31.7 31.7 (Volume (cmH2O) at 600ml) Volume (ml) 566.17 509.43 Flow (ml/s) 58.76 Average error TABLE II. one sensor (pressure sensor) instead of two sensors (flow and pressure sensors) for measuring and calculating the outputs of single compartment model of lung achieves good results with small error (5.14%). Moreover, using one data (pressure signal) instead of two types of data (flow and pressure signals) can be used to minimize the related devices and consequently reduce cost. 58.75 Fig. 14. Flow signal at volume 600 ml (without feedback). COMPARISON OF LUNG COMPLIANCE VALUES Artificial lung Absolute Lung Model C Percentage Experiment Scenario C (ml/cmH2O) (ml/cmH2O) OM Error ∈ (%) OT 1 22 18.3 20.2 1 2 21.2 18.6 14 (without 3 20.6 18.1 13.8 feedback) Average error 16.00 1 18.9 18.3 3.3 2 2 18.7 18.6 0.5 (with 3 18.5 18.1 2.2 feedback) Average error 2.00 Obviously, improvement of lung model based on the use of negative feedback is checked by the reduced error in the measured outputs as well as in calculated compliance as shown in TABLE II. The average error in the calculated compliance decreased from 16% (without negative feedback) to 2% (with negative feedback). Thus, in this approach using Fig. 15. Pressure signal at volume 600 ml (with feedback). Fig. 16. Volume signal at volume 600 ml (with feedback). Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply. 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS 2020), 20 June 2020, Shah Alam, Malaysia. [9] [10] [11] [12] [13] Fig. 17. Flow signal at volume 600 ml (with feedback). V. CONCLUSION The lung model normally depends on two types of input data: pressure and flow signals, but in case of using pressure signal, the lung model needs to be optimized by minimizing the error between the model output and the actual lung output. In addition, using just one signal will minimize the related devices and reduce cost. In this study, a single compartment lung model supported by VCV is developed using one input pressure signal during real-time mechanical ventilation. The model is implemented using LabVIEW platform, and validated against a reference gas flow analyser – Fluke Biomedical. The proposed model based on negative feedback shows good performance and acceptable accuracy as demonstrated by experimental results. Therefore, it can be used to compute volume, flow and compliance using the pressure signal of the mechanical ventilation in real time. Hence, the model can be used to evaluate mechanical ventilation performance. This can help the clinicians and apprentices minimize the risk of lung injury through studying on the lung model instead of actual patient lung. REFERENCES [1] L. Gattinoni et al., "Lung recruitment in patients with the acute respiratory distress syndrome," New England Journal of Medicine, vol. 354, no. 17, pp. 1775-1786, 2006. [2] A. Das, P. P. Menon, J. G. Hardman, and D. G. Bates, "Optimization of mechanical ventilator settings for pulmonary disease states," IEEE Transactions on Biomedical Engineering, vol. 60, no. 6, pp. 1599-1607, 2013. [3] A. Sundaresan and J. G. Chase, "Positive end expiratory pressure in patients with acute respiratory distress syndrome–The past, present and future," Biomedical Signal Processing and Control, vol. 7, no. 2, pp. 93-103, 2012. [4] I. Grossbach, L. Chlan, and M. F. Tracy, "Overview of mechanical ventilatory support and management of patient-and ventilator-related responses," Critical Care Nurse, vol. 31, no. 3, pp. 30-44, 2011. [5] Y. S. Chiew et al., "Feasibility of titrating PEEP to minimum elastance for mechanically ventilated patients," Pilot and feasibility studies, vol. 1, no. 1, p. 9, 2015. [6] J. Leatherman, "Mechanical ventilation for severe asthma," Chest, vol. 147, no. 6, pp. 1671-1680, 2015. [7] C. Schranz, T. Becher, D. Schädler, N. Weiler, and K. Möller, "Modelbased ventilator settings in pressure controlled ventilation," Biomedical Engineering/Biomedizinische Technik, vol. 58, no. SI-1-Track-S, 2013. [8] A. Kothari and D. Baskaran, "Pressure-controlled volume guaranteed mode improves respiratory dynamics during laparoscopic [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] cholecystectomy: a comparison with conventional modes," Anesthesia, Essays and Researches, vol. 12, no. 1, pp. 206-212, 2018. Y. M. Alginahi, M. N. Kabir, and A. I. Mohamed, "Optimization of high-crowd-density facilities based on discrete event simulation," Malaysian Journal of Computer Science, vol. 26, no. 4, pp. 312-329, 2013. M. N. Kabir, Y. M. Alginahi, and A. I. Mohamed, "Modeling and simulation of traffic flow: a case study-first ring road in downtown Madinah," International Journal of Software Engineering & Computer Systems, vol. 2, pp. 89-107, 2016. R. Ouache and M. N. Kabir, "Models of probability of failure on demand for safety instrumented system using atmospheric elements," Safety science, vol. 87, pp. 38-46, 2016. M. J. Uddin, Y. Alginahi, O. A. Bég, and M. N. Kabir, "Numerical solutions for gyrotactic bioconvection in nanofluid-saturated porous media with Stefan blowing and multiple slip effects," Computers & Mathematics with Applications, vol. 72, no. 10, pp. 2562-2581, 2016. S. L. Howe et al., "Estimation of Inspiratory Respiratory Elastance Using Expiratory Data," IFAC-PapersOnLine, vol. 51, no. 27, pp. 204208, 2018. R. Langdon, P. Docherty, and J. Chase, "Basis function modelling of respiratory patients with high or low auto-PEEP," IFACPapersOnLine, vol. 50, no. 1, pp. 15121-15126, 2017. D. P. Redmond, K. T. Kim, S. E. Morton, S. L. Howe, Y. S. Chiew, and J. G. Chase, "A Variable Resistance Respiratory Mechanics Model," IFAC-PapersOnLine, vol. 50, no. 1, pp. 6660-6665, 2017. J. M. Halter et al., "Positive end-expiratory pressure after a recruitment maneuver prevents both alveolar collapse and recruitment/derecruitment," American journal of respiratory and critical care medicine, vol. 167, no. 12, pp. 1620-1626, 2003. M. B. Amato et al., "Driving pressure and survival in the acute respiratory distress syndrome," New England Journal of Medicine, vol. 372, no. 8, pp. 747-755, 2015. S. E. Morton, J. L. Knopp, P. D. Docherty, G. M. Shaw, and J. G. Chase, "Validation of a Model-based Method for Estimating Functional Volume Gains during Recruitment Manoeuvres in Mechanical Ventilation," IFAC-PapersOnLine, vol. 51, no. 27, pp. 231-236, 2018. J. H. Bates, Lung mechanics: An inverse modeling approach. Cambridge University Press, 2009. K. T. Kim, S. Howe, Y. S. Chiew, J. Knopp, and J. G. Chase, "Lung Mechanics in Premature infants: Modelling and clinical validation," IFAC-PapersOnLine, vol. 51, no. 27, pp. 225-230, 2018. J. J. Liang, A. K. Qin, P. N. Suganthan, and S. Baskar, "Comprehensive learning particle swarm optimizer for global optimization of multimodal functions," IEEE Transactions on Evolutionary Computation, vol. 10, no. 3, pp. 281-295, 2006. J. B. Odili and M. N. M. Kahar, "African buffalo optimization," International Journal of Software Engineering and Computer Systems, vol. 2, no. 1, pp. 28-50, 2016. N. S. Damanhuri et al., "Assessing respiratory mechanics using pressure reconstruction method in mechanically ventilated spontaneous breathing patient," Computer Methods and Programs in Biomedicine, vol. 130, pp. 175-185, 2016. J. Dellamonica et al., "PEEP-induced changes in lung volume in acute respiratory distress syndrome. Two methods to estimate alveolar recruitment," Intensive Care Medicine, vol. 37, no. 10, pp. 1595-1604, 2011. S. E. Morton et al., "Development of a predictive pulmonary elastance model to describe lung mechanics throughout recruitment manoeuvres," IFAC-PapersOnLine, vol. 51, no. 27, pp. 215-220, 2018. S. E. Morton et al., "Predictive virtual patient modelling of mechanical ventilation: impact of recruitment function," Annals of Biomedical Engineering, vol. 47, no. 7, pp. 1626-1641, 2019. G. R. Arunachalam, Y. S. Chiew, C. P. Tan, A. M. Ralib, and M. B. M. Nor, "Patient asynchrony modelling during controlled mechanical ventilation therapy," Computer Methods and Programs in Biomedicine, vol. 183, p. 105103, 2020. E. J. Van Drunen et al., "Expiratory model-based method to monitor ARDS disease state," Biomedical Engineering Online, vol. 12, no. 1, p. 57, 2013. Gas-flow analyzer, “VT Plus HF Gas Flow Ventilator Analyzer,” [Online]. Available: https://www.flukebiomedical.com/products/ biomedical-test-equipment/gas-flow-analyzers/vt-plus-hf-gas-flowanalyzer [Accessed: November 27, 2019]. Authorized licensed use limited to: IEEE Xplore. Downloaded on August 07,2020 at 01:29:50 UTC from IEEE Xplore. Restrictions apply.