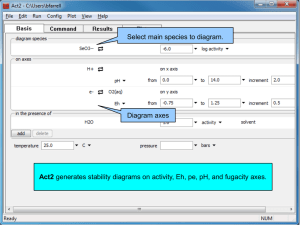

B49CE Multiphase Thermodynamics Topics in VLE, LLE and Miscibility Topic 1 Pure Species Phase Equilibrium 1 Learning Objectives • After studying this “Pure Species Phase Equilibrium” topic you should be able to: • Write down phase equilibrium criterion for a pure species. • Identify and differentiate between the potentials for heat transfer, work transfer and interphase mass transfer. • Define (for a pure species) the chemical potential, the fugacity and the fugacity coefficient and write down relationships between them. • Show how the fugacity may be determined from measurable data. 2 Learning Objectives • Explain the background to Corresponding States Principle and compressibility factor. Outline and distinguish between the two-parameter and the three-parameter Law of Corresponding States. • Review and solve problems using generalised compressibility factor charts. • Demonstrate how charts may be used to determine the fugacity coefficient and fugacity knowing only reduced temperature, reduced pressure and acentric factor. • Show how the fugacity coefficient and the fugacity may be calculated for both a saturated and a subcooled liquid. 3 Recommended Textbooks • Smith, J.M., van Ness, H.C., Abbott, M.M., Introduction to Chemical Engineering Thermodynamics. McGraw-Hill. 7th ed.,2005. • S.I. Sandler. Chemical and Engineering Thermodynamics. Wiley, 3rd ed., 1999. • R.E. Sonntag, C. Borgnakke. Fundamentals of Thermodynamics. Wiley, 5th ed., 1998. • M.J. Moran, H.N. Shapiro. Fundamentals of Engineering Thermodynamics. Wiley 2nd ed., 1993. • J.R. Howell, R.O. Buckius. Fundamentals of Engineering Thermodynamics. McGraw-Hill, SI ed., 1987. 1.1 Introduction In previous courses (Process Engineering B) a general chemical reaction was written as follows: aA bB cC dD • At chemical equilibrium the concentration of each species A,B,C,D taking part in the reaction was related to the equilibrium constant K through the expression: C c Dd K Aa Bb • This provides the criterion for “chemical equilibrium” but it only applies (in this form) to an ideal system. >>> Later it will be shown how this may be adapted and applied to non-ideal systems. 5 What is also important is the degree to which a given species will transfer from one phase to another. This type of problem is known as “phase equilibrium”. • Important operations, such as distillation, gas absorption and liquid-liquid extraction, are concerned with the transfer of species between different phases. • The rate at which a species is transferred from one phase to another depends on how far the system is from equilibrium • This degree of departure from equilibrium is usually referred to as the driving force or simply the “potential”. • Far from equilibrium the potential is high with high rates of transfer – the opposite applies close to equilibrium. >>> One of the first things that needs to be done is to identify the “potential” that controls phase equilibrium/ interphase mass transfer. 6 1.2 Criterion for Phase Equilibrium Thermal equilibrium implies no temperature gradients; thus, temperature differences across an uninsulated boundary is the “potential” for heat transfer. • Mechanical equilibrium implies no pressure gradient; thus, pressure differences across a moveable boundary (caused by an unbalanced force) is the “potential” for work transfer. • The “potential” that drives interphase mass transfer is not immediately obvious. • However, it is only when this potential approaches zero that the system may be assumed to be in phase equilibrium and only then will net interphase mass transfer approach zero. >>> This subject deals mainly with mixtures. However, best place to start is phase equilibrium involving a single species; an example might be a steam-water system. 7 1.2.1 Pure Species Phase Equilibrium Consider a closed system with two phases but only one component (this could be a steam-water system): • Take it that both phases within this closed system are at a constant T & P and that any heat or work, Q or W , that is transferred takes place reversibly. • Initially the system is not in phase equilibrium. The entropy change of the surroundings dSSURR is given by dS SURR dQSURR TSURR >> But>> dQ SURR dQSYS • If heat transfer is reversible, then TSURR TSYS and dS SURR dQSYS TSTS 8 The second law (Process Engineering B) is given by dSSYS dSSURR 0 • Substitute the entropy change of the surroundings intothe second law to get dS SYS dQ SYS TSYS 0 dQSYS TdS Substitute for dQSYS in here • The non-flow energy equation (Process Engineering B) is given by dQSYS dU PdV To get dU PdV TdS 0 Note, these are all SYSTEM properties. 9 If T & P remain constant this may be written dU T ,P d PV T , P d TS T , P 0 d U PV TS T ,P 0 Substitute for G inhere • The Gibb's energy (Process Engineering B) is defined as G H TS >>> G U PV TS To dGT ,P 0 get • The inequality dGT ,P 0 applies to irreversible processes when the system is NOT in equilibrium >>> The equality dGT ,P 0 applies to reversible processes when the system IS in equilibrium 10 The inequality dG 0 is the direction for spontaneous change. But when the system is at equilibrium The Gibbs free energy is an EXTENSIVE property (kJ/K) (i.e. depends on quantity of material) dG 0 • Take two phases: the phase and the phase (this could be water and steam respectively): G ng G ng Total both phases: G n g n g In which g and g are the molar Gibbs energies (kJ/mol) of each phase separately (intensive properties, i.e. not dependant on quantity of material) and n and n are the number of moles in each phase. 11 Thus, at phase equilibrium d ng ng 0 gdn ndg gdn n dg 0 • But it has been shown (Process Engineering B) dg vdP sdT • If T & P remain constant, then in each phase and dg 0 thus it follows To get dg 0 g dn g dn 0 dn Must arrive here gdn gdn 0 dn 1 mole from here 12 Thus, for phase equilibrium between these two phases g gdn 0 g g • Only when this driving force is zero g g 0 , willnet mass transfer stop and only then can the two phases coexist in equilibrium. • The molar Gibbs free energy IS the “potential” for pure species phase equilibrium. This potential must be the same in each phase for interphase mass transfer to stop. • Water and steam at 101.325 kPa have exactly the same molar Gibbs energy at 100oC. (and only at 100oC) >>> This means that pure water and steam can only co-exist in equilibrium at 1 atm when the temperature is 100oC (NBP). 13 1.2.2 Pure Species Chemical Potential This “potential” is the so called “chemical potential” and, for a pure species, it is denoted by the symbol . • In Process Engineering B it was shown that, for a pure species, the chemical potential is equal to the molar Gibbs energy. Thus, for a pure species g • Notice that the chemical potential, like all driving forces must be intensive (just like T & P ). • Thus, for phase equilibrium between these two phases Thus, two phases in equilibrium leads to this phase constraint and hence F=1. >>> The in either phase depends only on T & P . Satisfying the phase constraint means if T is independent , then P must be a dependent variable and vice versa. 14 1.2.3 Pure species Gibbs Energy Pressure dependence See notes for its derivation, but it has already been shown (Process Engineering B) that, in terms of total properties G, V and S , the total Gibbs energy depends on T & P : dG VdP SdT • It follows that the partial change in total Gibbs energy w.r.t. pressure must be given by G V P T • In terms of purely intensive properties these become dg vdP sdT & g v P T 15 1.2.4 Pure species Chemical Potential Pressure Dependence But the Gibbs free energy of a pure species is its chemical potential g ,thus v P T • Hence, the isothermal variation of with P is then d vdP • Integrate the above expression, at constant temperature, between some very low pressure state P* and any higher pressure state P . P * P* d vdP 16 Integrating this leads to P * vdP P* • There are no absolute values for chemical potential (just like internal energy, enthalpy and Gibbs free energy). • Thus, if is finite at some specified pressure P , then *in some lower pressure state P* will depend on the integral on the right of the equation. • It is clear that as P* 0 , then v and the integralon the right also tends to infinity. >>> Thus if is finite at somespecified pressure P , then the chemical potential at some very low pressure * , i.e. at low pressure *tends to minusinfinity. 17 April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 18 The variation in chemical potential versus pressure is also highly non-linear. • Both these features make the chemical potential “badly behaved” (mathematically speaking) at low pressure. • The value of properties as pressure approaches zero is very important as gases become ideal at this low-pressure limit and the ideal gas state is used as a reference state. • It would be better to define the chemical potential in terms of some new property that increasingly tended to some ideal gas property at low pressure. • A good idea would be to define an “auxiliary property”, one that depends directly on but one that behaves differently at low pressure. dg i g v ig dP To seek this new auxiliary property consider how Gibbs energy varies with pressure for an ideal gas. 19 The superscript “ig” denotes that the gas is an ideal gas. Substitute the ideal gas EOS into the previous expression. d ig RT dP P dig RTd ln P In which is the temperature- dependent constant of integration. >Integrate> ig RT ln P >> For an ideal gas, these expressions show how the isothermal change in chemical potential depends only on the pressure. 1.3 Pure Species Fugacity The same expression may be applied to a real fluid so long as the real pressure P is replaced by some new property which allows the equation to hold for real fluids. >>> This new property is given the symbol f , has the same units as pressure (kPa) and is called “fugacity”. 20 Thus, for a real fluid changes in the chemical potential are given by In which is the temperature- dependent constant of integration. d RTd ln f >Integrate> RT ln f • The fugacity may be considered an auxiliary property of the chemical potential, changes in this auxiliary property are linked directly to changes in chemical potential. • The next step is to see how the fugacity behaves at low pressure….. remember the chemical potential was badly behaved at low pressure. • Subtract these last two equations to get d ig RT d ln f P d ig RT d ln Where is the dimensionless fugacity coefficient 21 Thus, the “fugacity coefficient” is defined as: f P • However, take the integrated expression RT ln f , and subtract ig RT ln P , then we see that the constant of integration cancels which leads to RT ln ig • Then at: P 0 0 ig • And whenever: P0 1 As P 0 then 1 >>> Thus, the low pressure limit (ideal gas value) of the fugacity coefficient is ONE. 22 The expression that connects the chemical potential to its auxiliary property (fugacity) is given by RT ln f ig RT ln << >> P • The term on the left is the difference between the chemical potential of a real fluid and that of an ideal gas – both at the same T & P . If the real fluid is an ideal gas ig 0 ig • And, because the constant of integration cancels it follows that, for an ideal gas: ig 1 f ig P Notice as P 0 , f P . Whereas as P 0 , . 23 The “fugacity coefficient” was defined asfollows: f P • But since f ig P , it follows that the fugacity coefficient of a pure species could equally well be defined by f f ig The fugacity coefficient does exact the same job for the fugacity. • The fugacity coefficient is a correction factor that corrects the fugacity between the ideal gas state and real fluid state (at the same T & P ). • Notice the fugacity coefficient does a very similar job to the compressibility factor Z Z Pv v RT vig The compressibility factor corrects the molar volume v (m3/mol) between ideal gas state and real fluid state (at same T&P) 24 1.3.1 Fugacity as a Criterion for Equilibrium For a pure species the criterion for phase equilibrium between solid, liquid and vapour phases at the Triple Point is as follows: S L Substitute for in here V • But it has been shown: RT ln ig >>> ig RT ln To ig RT ln S ig RT ln L ig RT ln V get • But at equilibrium all phases are at the same T & P. S L V f S f L fV The criterion for phase equilibrium is the same in terms of fugacity as it was in terms of chemical potential. 25 1.3.2 Fugacity in terms of Residual Volume When trying to find numerical values for the fugacity it is better to first find the fugacity coefficient, since it is dimensionless. • Once is known f may be calculated from the definition: f P or f f ig • It has been shown that Gibbs energy depends only on T & P dg vdP sdT • For an isothermal process d vdP dig vig dP For an ideal gas Subtract one from the other d ig v v ig dP 26 Integrate the previous equation from P 0 , where ig 0 to any other higher pressure P ,where ig 0 , leads to ig v v ig dP P 0 • The term on the right v v ig is known as the “residual volume” (m3/mol) and in many texts this is given the Aside symbol v R. R • Any residual property m is just the difference between the real fluid property m and the ideal gas property mig, both measured at the same T & P. R • Thus, any residual property m ( property m is generic and could be v, u, h, s, g ) is defined as follows; m R m mig 27 The previous expression in terms of residual volume is now P ig v R dP 0 Equate these two Expressions….. • But it was also shown that RT ln ig To get P 1 R v dP ln RT 0 • This expression is VERY important because it links the fugacity coefficient (thus also the fugacity) to measurable properties. 28 1.3.3 Worked Example 1.1 Estimate the fugacity of gaseous propane at 2.4 MPa and 344 K using the following data for propane at 160o F (complete this example by hand in the workbook). Molar Mass of propane is 44.097 kg/kmol P v vig (MN/m2) (m3/kg) (m3/kg) 0 0.1724 0.3447 0.6895 --0.3691 0.1810 0.08652 - 1.0342 1.2066 1.3790 2.4000 0.05512 0.04598 0.03903 0.01783 P v R P (m3/kg) (kN/m2) (kJ/kg) - - - vR 1 RT v R P 29 Estimate of fugacity coefficient at 24 bar and 344 K: …............. Estimate of fugacity at 24 bar and 344 K: f …............. 30 ig R Pave PvR3RP vv 10 P 1.3.3 Worked Example 1.1 32 ig R Pave PvR3RP vv 10 P 1.3.3 Worked Example 1.1 P 1 1 R Ln v dP 18303.9 J / kg 0.2822 8314 J / kmol . K RT 0 344 K 44.097kg / kmol f Ln 0.2822 p f 0.7541 p f 0.7541 2.4MPa 1810kPa 33 1.3.4 Fugacity in terms of Z-Factor The fugacity coefficient relation below may be successively rearranged as follows: P 1 R v dP ln Using residual RT 0 property definition ln 1 RT v v dP P ig 0 v v ig dP ln RT RT 0 P Pv Pv ig dP ln RT RT P 0 P P dP ln Z 1 P 0 Pv Z RT Pvig RT Z ig 1 34 1.3.5 Compressibility Factor Charts If no experimental data is available, Z-factors may be obtained from charts or tables. This approach has been discussed in Process Industries C. • A three-parameter generalised correlation for the Z-factor takes the general form Z Z(Tr , Pr , ) • Where two of the parameters are reduced temperature Tr and reduced pressure Pr, given by T Tr TC P Pr PC Remember to use absolute units for BOTH temperature and pressure >>> The third correlating parameter is the “acentric factor” and is usually given the symbol . 35 Three-parameter correlations are based on the threeparameter Law of Corresponding States: “All fluids with the same acentric factor and at the same Tr and Pr deviate from ideality to the same extent and, therefore, have the same compressibility factor Z ”. • The acentric factor is easily determined by a single vapour pressure measurement Psat at a specified reduced temperature of Tr 0.7 : sat (P log 10 r ) Tr 0.7 1 • Where, Prsat P sat PC The Z-factor is usually estimated from two charts: 1. The “simple” fluid chart, giving Z(0) . 2. The “non-simple” fluid chart giving Z(1). 36 These two component parts of the Z-factor are combined as follows: Z Z 0 Z 1 • The superscripts are used to identify the component parts of the Z-factor; they are NOT powers of “Z”. • The “Z0” component assumes uniform charge distribution. So-called simple fluids, such as Ar, Kr and Xe have these characteristics. • The “Z1” component is a correction for non-uniformcharge distribution. All other non-simple fluids require this adjustment. • Thus, the acentric factor for Ar, Kr, Xe must be ZERO. >>> The Z0 and Z1 charts are on the next slide – to use them all that is needed are the critical properties of the fluid. 37 The Z0 Simple FluidChart: • The Z-factor is usually estimated from two charts: 1. The “simple” fluid chart, giving Z(0) . 2. The “non-simple” fluid chart giving Z(1). The Z1 Non-Simple FluidChart: Z Z 0 Z 1 38 1.3.6 Worked Example 1.2 Estimate the fugacity of gaseous propane at 2.4 MPa. and 344 K. Estimate the compressibility factor Z (at each Pr ) from the charts in Appendix A. Complete this example by hand in this workbook using the following critical and other properties for propane: Molar Mass 44.097 kg/kmol Critical Temperature 369.8 K Critical Pressure 42.48 bar Acentric Factor 0.152 P Z 0 Z 1 Pr Tr Z (MN/m2) 0 0.1724 0.3447 0.6895 1.0342 1.2066 1.3790 2.4000 0 1 0 1 39 P (MN/m2) 0 Z 1 P P (kN/m2)-1 (kN/m2) 0 Z 1 P P - 0.1724 0.3447 0.6895 1.0342 1.2066 1.3790 2.4000 ZP1P Estimate of fugacity coefficient at 24 bar and 344 K: ………….. Estimate of fugacity at 24 bar and 344 K: f ………….. 40 Tr T 344 0.93 Tc 369.8 Pr P 0.1724 0.0406 Pc 4.248 P ln Z 1 0 dP 0.2995 P exp( 0.2995) 0.7412 f P 0.7412 2.4MPa 1.779MPa 17.79bar 1779kPa 41 Example Zo: April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 42 1.3.7 Fugacity Directly from Charts Rather than finding fugacity from Z-factor charts, it may be found directly from its own charts. Start with the relationship below: P ln Z 1 0 dP P • In terms of reduced properties this is given by Pr Substitute for Z in here dPr ln Z 1 Pr 0 • Also, Tr Z Z 0 Z 1 To get dP ln Z 0 1 r Pr 0 Pr Pr Z1 Tr 0 dPr Pr Tr 43 Examine this expression: dPr 0 1 ln Z Pr 0 Pr Pr dPr Z Pr 0 1 Tr Tr • The first term on the right can be evaluated from Z 0 data. The second term can be evaluated from Z1 data. • Each integral represents component parts of ln . Label these integrals ln0 and ln 1 respectively. ln ln 0 ln 1 0 1 >>> The integrals have been evaluated as functions of reduced temperature and reduced pressure and are available in the form of 0 and 1charts (tables are also available). 44 The 0 Simple FluidChart: >> These are “low pressure” charts. The Non-Simple Fluid Chart: 1 0 1 >>> Both low & high pressure charts are available in Appendix B. 45 1.3.8 Worked Example 1.3 Estimate the fugacity of gaseous propane at 2.4 MPa. and 344 K using the charts supplied in Appendix B. Complete this example by hand in this workbook using the following critical and other properties for propane: Molar Mass 44.097 kg/kmol Critical Temperature 369.8 K Critical Pressure 42.48 bar Acentric Factor 0.152 Tr ………….. Pr ………….. ………….. 0 1 ………….. ………….. f ………….. 46 Tr T 344 0.93 Tc 369.8 Pr P 24 0.565 Pc 42.48 Using the charts supplied in Appendix B: 0.770.89 0 1 0.152 0.7565 f P 0.7565 2400kPa 1816kPa April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 47 April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 48 1.3.9 Fugacity of Pure Saturated Liquid The P v and P Tdiagrams may be linked to each other: CONSTANT “T” P Psat P C 4 3 4 2 LIQUID 1 A B v C 2&3 1 SOLID TP VAPOUR T • Notice how the saturated vapour curve on the right hand, P T , diagram……… • Corresponds to two-phase envelope on the left hand, P v , diagram. >>> Points 1, 2, 3 and 4 all lie on an isotherm. Whether fluid is liquid or vapour depends on the P in relation to Psat. 49 If P P sat , then fluid is a single-phase vapour – see state “1”. If P P sat , then fluid is a single-phase liquid – see state “4”. If P P sat , then fluid state is anywhere within thetwo-phase envelope (anywhere between state “2” and state “3”) • State “2” corresponds to a saturated vapour state (dryness fraction one) where no liquid is present. • State “3” corresponds to a saturated liquid state (dryness fraction zero) where no vapour is present. • From state “2” and state “3” the dryness fraction varies from one to zero respectively. Within the two phase envelope “2-3 ” the state is continually changing while both T & P remain constant, so that dg vdP sdT >>> dg 0 50 Integrating the previous expression between saturated liquid and saturated vapour states leads to g V2 g 3L 0 >>> gV2 g 3L • For a pure species the Gibbs free energy is the chemical potential, thus the above may be written V2 L30 >>> V2 L3 • And, in view of the pure species phase equilibrium criterion f 2V f 3L 0 >>> f 2V f 3L • And, since the pressure is constant from “2-3” V2 3L 0 >>> V2 3L >>> Thus, there is no change in Gibb’s energy, chemical potential, fugacity or fugacity coefficient along a tie-line. 51 When a phase change occurs the fugacity is calculated in a three-step process as follows: 1. The fugacity of the saturated vapour f satV is found, at the target temperature, by integrating volumetric data from zero pressure to the vapour pressure Psa.t f ln sat P State 2 satV Psat dP 0 Z 1 P Solve the integral on the right hand side, then find f satV . 2. The fugacity of the saturated liquid f must be the same. f satV f satL satL in equilibrium The fugacity of the saturated liquid is now known. 3. The fugacity of the compressed (or subcooled) liquid f L can then be estimate using the method given in the next section. 52 1.3.10 Fugacity of a Compressed Liquid The expression below was derived earlier: d vdP • The fugacity was defined earlier by d RTd ln f • Equating these two expressions leads to v d ln f dP RT This links the fugacity to measurable properties • Integrating (along an isotherm) from Psat to any higher pressure P f 1 satd ln f RT f P vdP Psat 53 The left side of the equation becomes fL 1 ln sat f RT P vdP P sat • Notice how the lower limit of integration is Psat and not zero pressure; thus, the right hand integral does not tendto infinity. • Also, liquid molar volume v is a weak function of pressure and, as a first-order approximation, it may be regarded as constant • The molar volume is often taken to be the saturated liquid molar volume vsat L ……an average value may also be used. ln fL f sat vLsat RT P dP Psat 54 Completing the integration on the right leads to f L vLsat P Psat ln sat f RT • Sometimes written as sat sat v L sat L P P f f exp RT • Since sat f sat / Psat this is often written as sat sat v P P L sat sat L f P exp RT >>> The above derivation assumes liquids at low/moderate pressure, where the pressure, P PC ; above this the assumption of near constant v starts to break down. 55 1.3.11 Worked Example 1.4 Estimate the fugacity of liquid propane at 4.8 MPa and 344 K using the same gaseous P v T data for propane at 160oF (344 K) as provided in Example 1.1. The vapour pressure of propane at 344 K is 2.56 MPa. Molar Mass of propane is 44.097 kg/kmol v v ig vR P v R P (MN/m2) 0 (m3/kg) --- (m3/kg) - (m3/kg) - (kN/m2) - (kJ/kg) - 0.1724 0.3691 0.3447 0.181 0.6895 0.08652 1.0342 0.05512 1.2066 0.04598 1.3790 0.03903 2.4000 0.01783 P 2.5600 1 RT v R P 56 Fugacity coefficient of saturated vapour at 25.6 bar and 344 K sat ………… Fugacity of saturated vapour at 25.6 bar and 344 K f sat ………… The specific volume and pressure data for the liquid (pastthe point of saturation) is given below: v P 10 3 (MN/m2) (m3/kg) 2.551 2.446 2.758 2.446 3.447 2.404 4.800 2.338 Fugacity of liquid at 48 bar and 344 K f L ……… Fugacity coefficient of liquid at 48 bar and 344 K L ……… 57 Pave Pv 3 PP vv 10 From worked example 1, 2.56 2.56 dP 18.3039kJ / kg 19.5242kJ / kg 2.4 2.4 P 1 1 R Ln v dP 19524.2 J / kg 0.3010 8314 J / kmol.K RT 0 344 K 44.097kg / kmol Ln f 0.3010 p f 0.7401 p f 0.7401 2.56MPa 1895kPa April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 58 Ln f f sat 1 RT P 1 5385.1J / kg 0.0830 sat vdP 8314 J / kmol.K P 344 K 44.097kg / kmol f 1.0865 1895kPa 2059kPa April 2018 v4 © Heriot-Watt University, B49CE, Multiphase Thermodynamics 59 1.3.12 Fugacity Coefficient Using Cubic EOS Please refer to Appendix C to see how the Peng-Robinson EOS may be used to find the fugacity coefficient of a pure species. • Also outlined in Appendix C is how to estimate the pure species vapour pressure using an EOS. • This approach is based on the fact that two co-existing phases must have the same fugacity coefficient. • The material in Appendix C may be needed later for Design and Research Projects. Software packages, such as HYSYS, often calculate thermodynamic properties this way. Other Appendices: • Appendix A includes compressibility factor charts, both simple and non-simple fluid charts. • Appendix B includes coefficient charts, both simple and non-simple fluid charts (at high & low pressure). 60