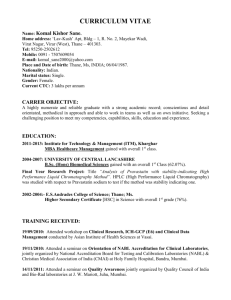

NABL 114 NABL NATIONAL ACCREDITATION BOARD FOR TESTING AND CALIBRATION LABORATORIES NABL GUIDELINES for FOOD TESTING LABORATORIES ISSUE NO : 02 ISSUE DATE: 05.07.2005 AMENDMENT NO : 00 AMENDMENT DATE: - AMENDMENT SHEET Sl no Page No. Clause No. Date of Amendment Amendment made Reasons Signature QM Signature Director 1 2 3 4 5 6 7 8 9 10 National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Last Amend No: 00 Amend Date: - Page No: i CONTENTS S.NO SECTION PAGE NO. Abbreviations 1 Introduction 2 1. Scope 3 2. References 5 3. Terms and Definitions 6 4. Management Requirements 9 5. Technical Requirements 10 Annexure A 6. Food Sampling for Microbiological Analysis 18 Annexure B 7. Design of Sampling Containers for Foods 21 Annexure C 8. Codex Alimentarius References 23 9. Bibliography 24 10. Technical Committee Members – Food Testing 26 National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: ii ABBREVIATIONS A2LA American Association for Laboratory Accreditation AOAC Association of Official Analytical Chemists BIS Bureau of Indian Standards CRC Certified Reference Chemical. e.g As per example FAO Food & Agricultural Organisation GC-MS Gas Chromatograph- Mass Spectrometer IEC International Electrochemical committee ILAC International Laboratory Accreditation Cooperation ISO International Standards Organizations IUPAC International Union of Pure and Applied Chemists IUPAP International Union of Pure and Applied Physics MDQ Minimum Detectable Quantity NABL National Accreditation Board for Testing and Calibration Laboratories PE Polythylene PET Polyethylene Terphthalate RC Reference culture UKAS United Kingdom Accreditation Service National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 1/ 27 INTRODUCTION The requirements specified in ISO/ IEC 17025, General requirements for the competence of testing and calibration laboratories, are stated in general terms and, while they are applicable to all test and calibration laboratories, explanations might be needed. Such explanations on applications are herein referred to as applications. Applications should not include additional general requirements not included in ISO/ IEC 17025. Applications can be thought of as an elaboration of the generally stated criteria (requirements) for specified fields of test, test technologies, products, materials or specific tests. (ISO/ IEC 17025 Appendix B). This document is intended to provide guidance for laboratories implementing ISO/ IEC 17025 for food testing, especially in support of international food trade activities. This document does not re-state all the provisions of ISO/ IEC 17025 and laboratories are reminded of the need to comply with all of the relevant criteria detailed in ISO/ IEC 17025. The clause numbers in this document follow those of ISO/ IEC 17025 but since not all clauses require interpretation, the numbering may not be continuous. Laboratories are also reminded of the need to comply with relevant statutory or legislative requirements. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 2/ 27 1.0 SCOPE 1.1 The Codex Alimentarius (Codex) has become the key reference for consumers, food processors, national food control agencies and the international food trade. Furthermore the Agreement on the Application of Sanitary and Phytosanitary Measures (SPS) and the Agreement on Technical Barriers to Trade (TBT) both encourage the international harmonization of food standards and also cite Codex standards, guidelines and recommendations as the preferred international measures for facilitating international trade in food. (See http://www.codexalimentarius.net/) However it should be recognized that the Codex is only intended as guidelines, and governments themselves must decide what use to make of them. 1.2 APEC has drafted a Mutual Recognition Arrangement on Conformity Assessment of Foods and Food Products. This calls for consistency with SPS and TBT requirements as well as with Codex standards, including the recommendations of the Codex Committee on Food Import and Export Certification Systems. APEC and the Codex committee are supporting laboratory accreditation activities to ISO/ IEC Guide 25 (now ISO/ IEC 17025) from a body that operates to ISO/ IEC Guide 58 (now ISO/ IEC 17011). Accreditation Bodies that are signatories to the APLAC and ILAC MRAs have demonstrated that they meet ISO/ IEC Guide 58 and that the laboratories they accredit meet ISO/ IEC Guide 25 and/ or ISO/ IEC 17025 for a specific scope of testing/ calibration. 1.3 The subject document is intended as a NABL specific guideline document for food testing laboratories in harmony with the wider interests of the Codex Alimentarius recommendations. 1.4 Food analysis is inter-disciplinary in nature. The phenomenal growth in our knowledge of food sciences and analytical techniques has facilitated accurate reporting of food composition. Food testing is required to evaluate food products for their nutritive and safety values in terms of microbiology, mycotoxins, pesticide and other chemical residues, toxic metals, additives and packaging materials, in addition to their proximate, biochemical, biophysical and engineering analysis. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 3/ 27 1.5 The scope of Food Testing Laboratories is applicable mainly to the following disciplines/ areas of activity: Food Chemistry; Food Microbiology; Food Rheology and other Physical Testing; Food Toxicology; Functional Testing; Molecular Biology (including genetically modified organisms); Sensory Testing. Specific guidance for the accreditation of each discipline is not addressed in this document. There are several good guidelines in the bibliography that apply to food testing laboratories, including: A.1 for chemical laboratories A.4 for microbiological laboratories A.10 for sensory testing National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 4/ 27 2.0 REFERENCES 2.1 APLAC MR—001, Procedures for Establishing and Maintaining Mutual Recognition Arrangements Amongst Accreditation Bodies. 2.2 ISO/ IEC 17025:1999, General requirements for the competence of testing and calibration laboratories. 2.3 ISO/ IEC Guide 2, General terms and their definitions concerning standardisation and related activities (now ISO/ IEC 17000). 2.4 ISO Guide 30:1992, Terms and definitions used in connection with reference materials. 2.5 ISO/ IEC Guide 58, Calibration and Testing Laboratory Accreditation Systems General Requirements for Operation and Recognition (now ISO/ IEC 17011). 2.6 ILAC-G2, Traceability of measurements. 2.7 ILAC P10, Policy on Traceability of Measurements. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 5/ 27 3.0 TERMS AND DEFINITIONS For the purpose of the Guidelines, the relevant terms and definitions given in ISO/ IEC Guide 2 apply. Terms published in guidelines from the AOAC/ FAO/ IAEA/ IUPAC expert consulting groups are especially useful (Bibliography Ref. A7). 3.1 Culture An isolated microorganism grown on laboratory medium. 3.2 Food testing laboratory A laboratory that performs tests on food products, ingredients, in process samples, food packaging materials for additives, chemical analytes and microorganisms and associated environmental aspects. 3.3 Reference culture (RC) Microbiological culture with characteristics sufficiently well established to be used to calibrate/ verify tests systems and test media and validate methods. 3.4 Verification Confirmation by examination and provisions of evidence that specify requirements have been met. Example: Verification of a microbiological test process would be the adequate recovery of Salmonella from a known inoculated sample run concurrently with other samples on the adequate recovery of selective/ differential versus non-selective (TGY) Staph. aureus on media incubated concurrently with other samples. For Quantitative test such as Staph. aureus, there must be a quantitative assessment of recovery of such as ≤50% of differences or 1- log 4 of differences. 3.5 Limit of Detection Determined by repeat analysis of a low level test portion and is 5 times the standard deviation of those results. This level is likely to be different for different matrices and thus should be reported along with the identity of the matrix used to determine the detection limit. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 6/ 27 3.6 Linearity Linearity is determined by the analysis of samples with analyte concentrations spanning the claimed range of the method. The results are used to calculate a regression line against analyte concentration using the least squares method. It is convenient if a method is linear over a particular range but it is not an absolute requirement. For those methods where linearity is not attainable, an algorithm for calculations specific for that analyte/ matrix combination may be employed. 3.7 Measurement Uncertainty An estimate attached to a measurement, which characterizes the range of values within which the true value is asserted to lie (ISO/ DIS 3543-1). 3.8 Selectivity The extent to which a method can determine particular analyte(s) in a complex mixture without interference from the other components in the mixture. A method which is perfectly selective for an analyte or a group of analytes is said to be specific. Applicability of the method should be studied using various samples, ranging from pure standards to mixtures with complex matrices. In each case, the recovery of the analyte(s) of interest should be determined and the influences of suspected interferences duly stated. Any restrictions in the applicability of the technique should be documented in the method. 3.9 Sensitivity The difference in analyte concentration corresponding to the smallest difference in the response of the method that can be detected. It is represented by the slope of the calibration curve and can be determined by a least square procedure, or experimentally, using samples containing various concentrations of the analyte. 3.10 Chromatography A technique for separation for identification of complex mixture of compounds. 3.11 Resolution A measure of the separation in chromatography, which takes into account both the retention differences of the analysed components and the column efficiency. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 7/ 27 3.12 Linear dynamic range The range of the analyte over which the response of the detector is constant to within 5% and over which the chromatographic instrument operates with the greatest precision. 3.13 Minimum instrument detectable quantity (MDQ) The minimum quantity of the sample for which the detector will give a visible response. The letters 'S/ N' usually refers to a signal to noise ratio of 2 or 3. 3.14 Lot An identifiable quantity of food commodity delivered at one time and determined to have common characteristic, such as origin, variety, type of packing, consignor, markings etc. 3.15 Sub-lot Designated part of a large lot in order to apply the sampling methods on that designated part. Each sub - lot must be physically separate and identifiable. 3.16 Sample A quantity of the material taken from a single place in the lot or sub lot. 3.17 Aggregate Sample All the lot or sub lot samples are to be mixed and a representative sample is to be taken for an analytical purpose. OTHER SOURCES OF DEFINITIONS a) ISO 8402:1986 Quality Vocabulary b) ISO/ IEC Guide 30 (1972) c) A2LA Food Microbiology Programme Requirements, July 1998 d) A2LA Food Chemistry Programme Requirements, July 1998 e) ISO/ DIS 3543-1 f) EAL-G-18 1996 – Accreditation of Laboratories for Microbiological Testing g) EURACHEM Guidance Document No. 1 and WELAC Guidance Document WGD 2 on Accreditation for Chemical Laboratories. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 8/ 27 4.0 MANAGEMENT REQUIREMENTS The numbering of the clauses below refers to the numbering of ISO/ IEC 17025.Where clause numbers from that standard are omitted no further clarification is required for food testing laboratories. 4.3 Document Control 4.3.2.2b Laboratory should use Codex as a guideline for standard methods and should also monitor the requirements of their National and other Regulatory Authorities to ensure that documents and methods they are using continue to be suitable and are in compliance with applicable requirements, especially while carrying out testing that falls under a regulatory mandate. 4.4 Review of Requests, Tenders and Contracts 4.4.1c Such reviews should take into account the current regulatory requirements and specifications of the regulatory authority(s) when selecting the appropriate test method. 4.9 Control of nonconforming testing and/or calibration work and 4.10 Corrective action and 5.10.9 Amendments to test reports 4.9, 4.10 and 5.10.9 The requirements in these sections of the standard are very important, especially when dealing with food safety issues. Laboratories should seek regulatory guidance if necessary and ensure that the needs of the client are met. Rapid notification to clients and perhaps regulators of results indicating nonconforming food may be necessary to prevent/ reduce public health incidents. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 9/ 27 5.0 TECHNICAL REQUIREMENTS 5.2 Personnel Personnel need to clearly understand the nature of the foods they are testing and reasons for testing when undertaking contract review and method selection. Technical management A large multi - disciplinary laboratory shall have trained, competent supervisory level, food scientists/ chemists/ microbiologists on staff having at least a bachelor's Degree in Food science/ Nutrition/ Biochemistry/ Chemistry/ Microbiology/ Biotechnology with at least one year of relevant laboratory experience. The people filling these positions shall have successfully completed at least one training course from a recognised institution or worked in an accredited laboratory. NOTE: For a small laboratory with a limited scope, same qualification/ training (from recognised institution) requirements will apply for the respective fields of testing. Other Support Staff The laboratory technicians or equivalent should have higher secondary certificate in science and atleast one-year experience or training in a relevant laboratory. 5.3 Accommodation and environment 5.3.1.1 The Codex guidelines for the design of food laboratories are applicable. 5.3.1.2 Laboratories should be designed to meet both the generic and specialised activities. Generic activities include wet chemistry, which requires extensive fixed benches with provision of water, power, sinks, cupboards, fume cupboards, reagent shelves, glassware cleaning and storage. In comparison, instrument rooms may have less extensive and even flexible arrangement of movable tables and benches. 5.3.1.2 Specialised rooms are required for clean-air-work or for work on substances, which need special care for reasons of safety (e.g., working with radioactive materials or storage or work on toxic substances). National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 10/ 27 5.3.2.1 Dust, both from environmental sources or from other samples, must be avoided since dust contamination of test materials is sporadic and uneven and is likely to be missed by normal quality control checks. Ventilation intakes and fume cupboard exhaust must be placed carefully so as to avoid re-circulation of laboratory air and the associated risk of contamination of test materials and hazard to laboratory staff. Work surfaces and floor shall be made of impervious, smooth, easy to clean materials. There shall be sufficient work place for each analyst. Walls and ceilings shall be made of materials that are smooth and easy to clean. 5.3.2.2 There shall be at least 300-lux light intensity at working surfaces other than those required for specified tests. 5.3.3.1 For certain chemical analysis, design of the laboratory needs to be specific to ensure segregation of trace analysis from highly concentrated formulations and from pure substances used in preparing analytical standards. The segregation must apply to all facilities for washing/ cleaning equipment, washing and storage of glassware, use of protective clothing etc. 5.3.3.2 It is recommended that the media preparation and media/ glassware sterilization areas be separated from the testing areas. 5.3.3.3 Laboratories located in facilities where products or ingredients are manufactured are not to test for infectious pathogens (such as Listeria monocytogenes, Salmonella species, Escherichia coli 0157:H7, Shigella species, Campylobacter species, Vibrio cholerae, Clostridium perfringens) unless the laboratory is physically separated with limited access, equipped with bio-safety cabinets and is supervised by a qualified microbiologist. 5.3.3.4 Environmental contamination by microorganisms is to be controlled by appropriate air-filters and air-exchange systems. Monitoring or control verification is to be performed using air sampling devices, air setting plates, surface swabs or other appropriate means. These checks are critical to aerobic plate count procedures and yeast and mould tests and their equivalent is desirable in trace chemistry laboratories. Laminar flow, positive pressure or such environment shall be provided, wherever necessary. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 11/ 27 5.3.3.5 Eating, drinking and smoking should be prohibited in the laboratory. Separate area, physically separated from the laboratory, may be provided for such activities. 5.3.4 Entry in laboratory areas shall be restricted as appropriate for reasons such as security, safety or sensitivity to contamination. Where such restrictions are in force, staff shall be made aware of the intended use of the areas and the restrictions imposed on working within such areas. 5.3.5.1 The responsibility for the house keeping activities must be clearly defined with respect to the following duties: a) cleaning of floors, vertical surfaces, horizontal surfaces, interiors of refrigerators, freezers, fume cupboards, controlled environment store; b) control of contents of refrigerators, freezers, fume cupboards, controlled environment stores; c) checking the performance of air-conditioning of dust extraction equipment and of fume cupboards; 5.3.5.2 It is important for laboratories to have a pest control programme/schedule. 5.3.5.3 The laboratory is to have adequate fire safety measures. 5.4 Test and calibration methods and method validation 5.4.1 General Internationally, test method validation and measurement of uncertainty are subjects for active discussion. The laboratories should monitor these discussions to remain abreast of the most recent developments and their impact on accreditation requirements. Discussions from Codex on the subject, including some reference documents are available on their website: www.codexalimentarius.net. International discipline specific documents are also being developed and sites such as CITAC. EURACHEM and AOAC should also be monitored (see bibliography section for website addresses). National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 12/ 27 5.4.2 Selection of methods Where regulatory authorities prescribe methods to be used for testing under their regulations, laboratories shall ensure that the requisite method is used as appropriate. The Codex Alimentarius, Harmonization of food standards are recommended as acceptable references for sourcing of test methods when these are not specified by regulation or by the client. 5.4.5 Validation of methods It is recommended that standard methods be used as far as possible to ensure compatibility of results. When laboratory-developed methods need to be used, matrix interference and other biases should be considered. It is recommended that laboratory-developed test methods be validated either by using a matched matrix reference material or, if it is not available, a sample spiked with the analytes of interest. Laboratories may consult reference A15 on single-laboratory validation. For microbiology, there are CEN and ISO documents in final draft phase for method validation; the AOAC Research Institute plans to publish these once they are finalized. Laboratories may use them once they become available. 5.4.6 Estimation of uncertainty of measurement Every measurement has an uncertainty associated with it, resulting from various stages of sampling, analysis and other factors. Typically, the major contributors of uncertainty are: a) sampling and sub-sampling/ lack of sample homogeneity b) extraction/ digestion/ sample preparation c) inherent instability of reference standard and reference material d) calibration of equipment and instrument e) variation of environmental and supply condition f) operator variation g) non-repeatability of result National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 13/ 27 Testing laboratories shall have and apply procedures for estimation of uncertainty of measurement, particularly in those cases where the limits of compliance of a parameter are critical, and for validation of non-standard test methods. For estimation of measurement of uncertainty, reference should be made to ISO/TS21748 Guidance for the use of repeatability, reproducibility and trueness estimates in measurement uncertainty estimation. Often for food testing, overall intermediate precision will include most if not all major sources of uncertainty. The laboratories may also refer to Eurachem Document on Uncertainty – www.measurementuncertainty.org. 5.5 Equipment 5.5.1 General laboratory equipment such as incubators, refrigerators, freezers, ovens, waterbaths, centrifuges, autoclaves, furnaces etc. shall be periodically cleaned, maintained and calibrated at predetermined intervals to be decided by the laboratory and based on the fact as to when they affect the quality of test results. Calibration of such equipments should have traceability to accredited calibration laboratories or to National Physical Laboratory or to other National Metrology Institutes and may use Certified Reference Materials for this purpose. Where CRMs are not available, the laboratories may use/ develop Reference Materials and validate through proficiency testing. 5.5.2 Microscopes shall be serviced annually or earlier whenever the need arises. The eyepiece and objective lens shall be checked and if necessary, cleaned after each use. 5.6 Measurement traceability 5.6.1.1 For the purpose of food microbiological analysis, reagents such as culture media, sera etc. are critical materials that shall be verified for the performance against cultures obtained from nationally/ internationally recognized culture collection centres. 5.6.2.1 Calibration 5.6.2.1.1 For volumetric and mass measuring equipment, results of the calibration measurements relative to tolerances and appropriate calibration certificates demonstrating tractability to national standards shall be maintained. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 14/ 27 5.6.2.1.2 The measuring instruments shall be calibrated using reference materials and performance standards shall be verified and documented (for instance, consistency of retention times and resolution of analytes in chromatographic system; wavelength accuracy of spectrophotometers; linearity of detectors, etc). 5.6.2.1.3 The calibration record shall specify the date of calibration, due date for next calibration, periodicity of calibration and reference standards used for calibration. Often analytical chemistry instruments will be calibrated every time they are used or atleast daily. NOTE: The laboratory shall have the responsibility of determination of the adequacy of testing/ measuring equipment. For this, it may refer to factors such as ruggedness of the instrument, frequency of usage, accuracy of measurement, etc. 5.6.2.2 Testing 5.6.2.2.1 Most food test methods are empirical (the result depends on the defined method) and therefore traceability is to the consensus result to that method and matrix. Even minor deviations from the detail of the standard must be validated for all practices to which the method is to be applied and to all matrices, to confirm that the results are the same as those obtained from defined standard methods. 5.6.3 Reference standards and Reference Materials. 5.6.3.1.1 The use of RCs and CRCs to quantify recovery on every occasion that a test is performed. 5.6.3.1.2 Certified reference cultures shall be traceable to a nationally or internationally recognized type culture collection. 5.6.3.1.3 Reference culture from laboratory sources shall be identified and traceable to standard reference sources. 5.6.3.1.4 Reference cultures shall be handled to maintain their biochemical reaction and Physiological characteristic of integrity. 5.6.3.1.5 The laboratory shall have an effective system of maintaining the stability, sensitivity and purity of the reference cultures. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 15/ 27 Note: An example of an effective system is given below: RCs and CRCs shall not be transferred more than five times from the original source. After the fifth transfer, the laboratory may purchase another culture from a type culture collection or re-identify the culture for key biochemical and physiological characteristics using nationally or internationally recognized reference sources. Alternatively, the type culture may be grown, then freeze dried, kept in frozen storage, etc. and used periodically thereby extending the length of time after which they must be repurchased or re-identified. 5.6.3.2 Reference materials may either be in pure form or in desired matrix. 5.7 Sampling Laboratories may need to provide sampling protocols to their clients which includes collection, handling, packaging and transportation. Preserving sample integrity and preventing contamination are important issues, especially when dealing with a perishable product and the possibility of cross contamination. Where laboratory is to report on the results for a food shipment, valid statistical sampling is required and a component for variation should be included in the uncertainty estimate. Sampling includes sub-sampling in the laboratory. Therefore, policy and procedures for sub-sampling must be documented and validated. Solid foods provide particular challenges. 5.7.1.2 Food sampling for microbiological analysis (enclosed as Annexure A). 5.8 Handling of Test and Calibration Items 5.8.1 It is critical for food testing laboratories to preserve sample integrity and to avoid contamination and deterioration. Food is frequently perishable and should be stored in a manner to prevent deterioration such as refrigeration for short time storage. Some parameters deteriorate rapidly and analysis should be done upon receipt. Chain of custody issues could apply to certain regulatory samples. Design of Sample Containers for Foods (enclosed as Annexure B) National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 16/ 27 5.9 Assuring the Quality of Test Results Laboratories should have quality control procedures in place with rigor appropriate to the test and its intended use. For example, the approach may differ if a substance is banned by law or if there is a regulatory limit for the substance. The laboratory should implement a quality control plan. Typically, this plan should include blanks, control samples, spike recoveries and/or duplicates, where applicable. 5.9 b) Laboratories are required to take part in APLAC/ EA/ NABL or other Proficiency Testing Programmes, which are conducted in accordance with ISO/ IEC Guide 43.Proficiency testing records should include: • full details of the analyses? examination undertaken and the results and conclusions obtained; • an indication that the performance has been reviewed • details of the investigations and corrective action undertaken, where necessary. PT activity is also recommended by Codex (Annexure C) 5.10 Reporting Test Results Laboratories are encouraged to make a reference to their accredited status by using NABL logo. Laboratories must delineate the accredited tests vis-à-vis non- accredited tests in all their test reports. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 17/ 27 Annexure A Food Sampling for Microbiological Analysis A representative sample is essential when the microorganisms are sparsely distributed within the food. Whenever possible, submit samples to the laboratory in the original unopened containers. If products are in bulk or in containers too large for submission to the laboratory, transfer representative portions to sterile containers under aseptic conditions. Use containers that are clean, dry, leak-proof, wide-mouthed, sterile and of a size suitable for samples of the product. Containers such as plastic jars or metal cans that are leak-proof may be used. Whenever possible avoid glass containers, which may break and make the sample susceptible to contamination. Deliver samples to the laboratory promptly with the original storage conditions maintained as nearly as possible. Transport frozen or refrigerated products in approved insulated containers of rigid construction so that they will arrive at the laboratory unchanged. Collect frozen samples solidly frozen at all times. Cool refrigerated samples in ice at 0 - 4°C and transport them in a sample chest with suitable refrigerant capable of maintaining the sample at 0 - 4°C until arrival at the laboratory. Do not freeze refrigerated products. Unless otherwise specified, refrigerated samples should not be analyzed more than 36 hrs after collection. A. Sampling plans 1. Salmonella a. Sample Collection Because of the widespread occurrence of Salmonella in foods, sampling plans for the samples containing these organisms have received considerable attention. The number of samples from a particular lot of food varies according to the sampling category to which a food is assigned. For the Salmonella sampling, three categories of food are identified. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 18/ 27 Food category – I Foods that would not normally be subjected to a process lethal to Salmonella between the time of sampling and consumption and are intended for consumption by the aged, the infirm and infants. Food category – II Foods that would not normally be subjected to process lethal to Salmonella between the time of sampling and consumption and are intended for consumption by the normal adult population. Food category – III Foods that would normally be subjected to a process lethal to Salmonella between the time of sampling and consumption. The numbers of sample units to be collected in each food category are as follows: Food Category I:60 sample units, Food category II : 30 sample units, Food category III: 15 sample units. Submit all collected samples to the laboratory for analysis. b. Sample analysis The laboratory will analyze each sample for the presence of Salmonella according to methods described in the manual. Take 25 g analytical unit at random from each 100 g sample unit. When a sample unit consists of more than 1 container, aseptically mix the contents of each container before taking the 25 g analytical unit. To reduce the analytical workload, the analytical units may be composited. The maximum size of 1 composite unit is 375g or 15 analytical units. The minimum number of composite units to be tested for each food category is as follows: Food category – I Four composite units; Food category – II: Two composite units; Food category – III: Three composite unit. For each 375g composite, the entire amount of 375 g is analyzed for Salmonella. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 19/ 27 Keep the remainder of the sample unit in a sterile container as a reserve. Refrigerate perishable samples and those samples supporting microbial growth. An analytical control is required for each sample tested. The sampled lot is acceptable only if analysis of all composite units is negative for Salmonella, if one or more composite units are positive for Salmonella, the lot is rejected, provided that the environmental control is negative for Salmonella. A lot will not be resampled unless the environmental control for Salmonella is positive. 2. Listeria Sample collection For crabmeat, shrimp, processed imitation seafood (surimi), crayfish and lobster (cooked or paraboiled), langostinos (cooked), smoked or salted fish, cheese, milk, ice cream and other dairy products, collect ten sub-samples (or retail packages) at random each of the size of 227 g (8 oz). Do not break or cut larger retail packages to obtain a 227 g sub-sample. Collect the intact retail unit as the sub-sample even if it is larger than 227g. Make two composites from the 10 sub-samples. Prepare each composite by removing 100 g from each of 5 sub-samples. Each composite will contain a total of 500 g. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 20/ 27 Annexure B Design of Sample Containers for Foods 1. 1. Frozen and refrigerated foods; 2. Highly Perishable foods; 3. Liquid foods; 4. Semi solid or viscous foods; 5. Fragile foods; 6. Solid dry foods; 7. Miscellaneous. Frozen and refrigerated foods: a. These require packaging materials having very good low temperature resistance, seal integrity, absence of corrosion and long durability. Packages made of all varieties of low and high-density polyethylene, PET/ foil/ PE pouches and bags and co-extruded structures based on PE, polyamides and polyester films shall be used. b. Cast poly propylene and glass containers should be avoided. Tinplate containers may corrode at the seams. 2. Highly perishable foods: a. These comprise fresh fruits and vegetables meat, fish and poultry as well as marine products. All these products have moisture contents and hence have short shelf life due to microbiological and chemical deterioration, and also require clean and hygienic wraps. b. Partially permeable to water vapour and oxygen packaging materials such as low- density polyethylene, thin gauge polypropylene and polyvinyl chloride can be used. Completely impermeable packages are not recommended. Materials such as used jute bags should not be used. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 21/ 27 3. Liquid foods: a. These require absolute leak-proofness, bacterial impermeability as well as good mechanical protection. Many liquid foods are sensitive to radiation of visible and ultraviolet regions necessitating light opaque packaging. b. For short- term storage, polyolefin films of more than 25 microns can be used. Glass and metal containers provide long term protection. Multi- layered flexible structures could also be used. 4. Semi-solid or viscous foods: a. These have packaging requirements similar but less severe to those of liquid foods. Filling and dispensing pose problems. b. Suitable containers include wide- mouth glass jars, and rigid plastic containers with appropriate closures. 5. Fragile foods: a. These include food products like biscuits, paste products, confectionery and snack foods. These require greater physical or mechanical protection against breakage during transportation and storage. b. Packages with suitable constructional features such as cartons, boxes and with appropriate cushioning materials like expanded plastics are suitable. 6. Solid dry foods: a. Most of the dry foods except those having high fat and volatiles contents require less stringent packaging conditions. They are predominantly sensitive to water vapour and hence require barrier materials. b. Suitable containers for these solid dry foods include flexible packages made of monolayer or multilayer structures, paper- board containers with over wrap as well as lined packages. Trace chemical analysis: The food samples meant for this should preferably be packed in glass containers. The foods for analysis of elemental composition may be packed in plastic containers. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 22/ 27 Annexure C Codex Alimentarius References The Codex Alimentarius Commission was created by FAO and WHO to develop food standards, guidelines and related texts such as codes of practice under the joint FAO/WHO Food Standards programme. The main purpose of the Codex Programme are protecting health of the consumers and ensuring fair trade practices in food trade, and promoting coordination of all food standards work undertaken by international governmental and non-governmental organizations. The Codex website is at http://www.codexalimentarius. The Codex Alimentarius Volume 13 contains Methods of Analysis and Sampling. Codex SECTION 8.6 CAC?GL 27-1997, Guidelines For The Assessment Of The Competence Of Testing Laboratories Involved In The Import And Export Control Of Food, provides a framework for the implementation of quality assurance measures to ensure the competence of testing laboratories involved in the import and export control of foods. The guidelines are intended to assist countries in the application of requirements for trade in foodstuffs in order to protect the consumers and to facilitate fair trade. Codex recommends adoption of ISO/IEC 17025 by the laboratories involved in the import and export control of foods. They also recommend participation in appropriate proficiency testing schemes for food analysis which conform to the requirements laid down in “ The International Harmonized Protocol for Proficiency Testing of (Chemical) Analytical Laboratories”, Pure & Applied Chemistry 65 (1993) 2132-2144, the use of method of analysis which have been validated according to the principles laid down by the Codex Alimentarius Commission; and use of internal quality control procedures, such as those described in the “Harmonized Guidelines for Internal Quality Control in Analytical Chemistry Laboratories”, Pure & Applied Chemistry 67 (1995) 649-666, Alinorm reports are available in the Meeting and events section under Reports. Subjects such as proposed draft guidelines for measurement uncertainty have been discussed and recommendations formulated: ALINORM 03/23, APPENDIX V National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 23/ 27 BIBLIOGRAPHY A1. EURACHEM Guide, Guide to Quality in Analytical Chemistry – An Aid to Accreditation, Edition 2002. This is available as a free download from http://www.vtt.fi/ket/eurachem A2. EURACHEM/CITAC Guide CG4, Quantifying Uncertainty In Analytical Measurement (Second Edition), EURACHEM Secretariat, BAM, Berlin, 2000. This is available as a free download from http://www.vtt.fi/ket/eurachem A3. EURACHEM Guide, The Fitness For Purpose for Analytical methods, A guide to method validation and related topics. Also available as a free download from http://www.vtt.fi/ket/eurachem A4. EA 4-10 Accreditation for Microbiological Laboratories Edition July 2002 rev 02. The publication has been prepared by the working group food of the EA Laboratory Committee in collaboration with Eurachem. This is also available as a free download from http://www.vtt.fi/ket/eurachem A5. Harmonized Guidelines for Internal Quality Control in Analytical Chemistry Laboratories”, Pure & Appl. Chem. 67 (1995) 649-666. A6. Quality Assurance Principles for Analytical Testing Laboratories, 1992 AOAC International – Frederick M Garfield, AOAC International Updated version: Quality Assurance Principles for Analytical Laboratories, 2000 AOACInternational – Frederick M Garfield, Eugene Klestra and Jerry Hirsch.http://www.aoac.org/ A7. Principles and Practices of Method Validation, edited by A. Fajgelj and A. Ambrus, The Royal Society of Chemistry. Includes “Guidelines for single-laboratory validation of analytical methods for trace-level concentrations of organic chemicals”; these guidelines were elaborated by the AOAC/FAO/IAEA/IUPAC expert consultation group. A8. The APLAC website maintains a list of Technical Publications available form its members at the following address http://www.aplac.org/documents/technical.htm These publications refer to all subjects and include amongst them guidelines for the accreditation of food laboratories along with evaluation checklists. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 24/ 27 A9. AOAC International, Accreditation Criteria for Laboratories Performing Pharmaceutical, Food Microbiological, and Food Chemistry Testing, http://www.aoac.org A10. EA-4/09, Accreditation for sensory testing laboratories, 2003. Many other documents are also available on the EA – European co-operation for accreditation web site, especially the E4 series that relates to ISO/IEC 17025. http://www.european-accreditation.org/ A11. APLAC PT003 Proficiency testing directory. Available in the documents section of the APLAC website. http://www.aplac.org Guidelines for Food Testing Laboratories – TC 007 Draft No 1 Issue Date: 12/4 Page 11 of 12 A12. EPTIS Database, EPTIS is a non-commercial directory service aiming at creating transparency in the international proficiency testing (PT) market and strengthening the role of PT as a valuable proof of technical competence. EPTIS is a joint publication of 16 European partners and open for further international participation. It is hosted by the German Federal Institute for Materials Research and Testing BAM and supported* by EA, Eurachem, Eurolab and ILAC. http://www.eptis.bam.de/ A13 The Codex Alimentarius, http://www.codexalimentarius.net/ A14 ILAC P10: 2002 ILAC Policy on Traceability of Measurement Results This document provides a policy on traceability of measurement results, which is intended to be implemented by ILAC members and to encourage the development of supporting bodies such as CIPM/BIPM. Unless otherwise noted in the text for some clauses, this policy is effective as of 1 January 2003. http://www.ilac.org A15: “Harmonised Guidelines for single-laboratory validation of methods of analysis”, IUPAC Technical Report, M. Thompson, S. L. R. Ellison, and R. Wood. National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 25/ 27 TECHNICAL COMMITTEE MEMBERS - FOOD TESTING Dr. V. Prakash Director Central Food Technological Research Institute Mysore - Chairman Dr. A.K. Chakrabarty Adviser, DST & Director, NABL - Co-Chairman Dr. N.V. Rama Rao Dy. General Manager (R&D) M/s Hindustan Organics Ltd Rasayani 410 207 (Maharashtra) - Member Dr. J. Chakrabarti Director Central Food Laboratory 3, Kyd Street Calcutta - 700 016 - Member Dr. S.R. Gupta ADG – Health Services DGHS, Nirman Bhavan New Delhi - 110 001 - Member Dr. S.K. Sood Consultant Hematologist Sir Gangaram Hospital New Delhi - Member Dr. S.K. Saxena Director FRAC, Tansen Marg New Delhi - Member Dr. N. Anandavally Amma Asst. Director Export Inspection Agencies Rose Marie, Thoppumpady Cochin - 682 005 - Member National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 26/ 27 Dr. P.P.S. Dhillon President All India Food Processors Association 206, Aurobindo Market New Delhi - 110 016 - Member Dr. M.N. Krishnamurthy Formerly Head, FSAQCL Central Food Technological Research Institute, Mysore - Member Dr. M.M. Krishna Head Applied Technology Protein Technologies International EI Dupont India Limited, 8th Floor, DLF Plaza Tower DLF Qutab Enclave Phase-I Gurgaon - 122 002 - Member National Accreditation Board for Testing and Calibration Laboratories Doc. No: NABL 114 Issue No: 02 NABL Guidelines for Food Testing Laboratories Issue Date: 05.07.2005 Amend No: 00 Amend Date: - Page No: 27/ 27 National Accreditation Board for Testing and Calibration Laboratories 3rd Floor, NISCAIR 14, Satsang Vihar Marg New Mehrauli Road New Delhi – 110 067 Tel.: 91-11 26529718 – 20, 26526864 Fax: 91-11 26529716 Website: www.nabl-india.org