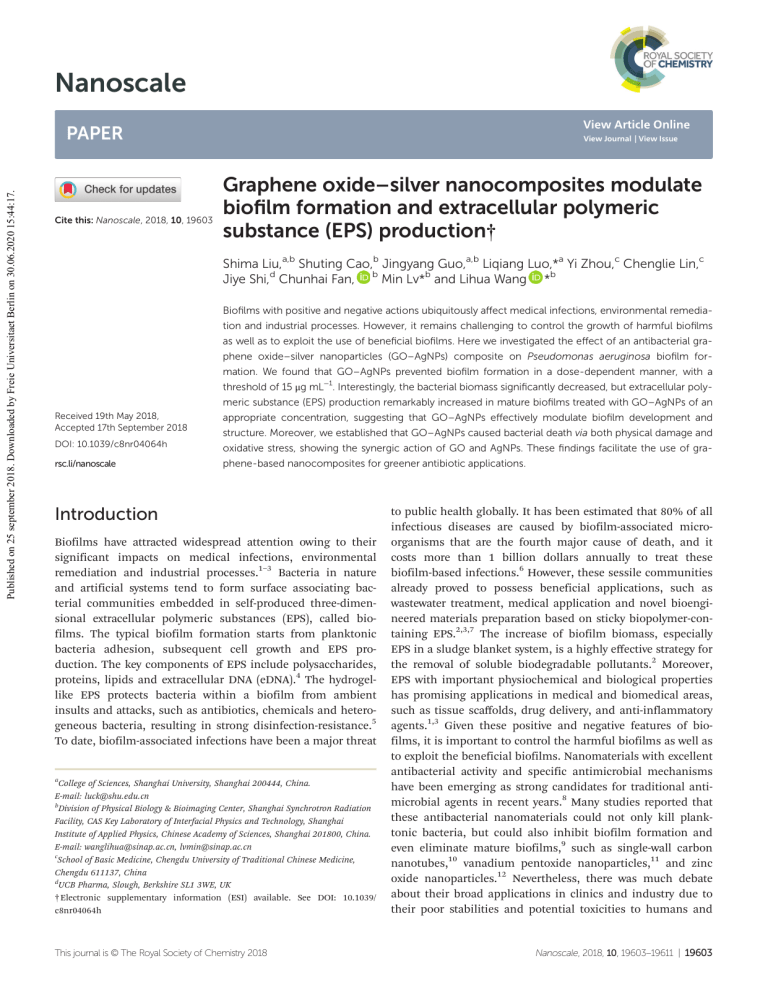

Nanoscale View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. PAPER Cite this: Nanoscale, 2018, 10, 19603 View Journal | View Issue Graphene oxide–silver nanocomposites modulate biofilm formation and extracellular polymeric substance (EPS) production† Shima Liu,a,b Shuting Cao,b Jingyang Guo,a,b Liqiang Luo,*a Yi Zhou,c Chenglie Lin,c Jiye Shi,d Chunhai Fan, b Min Lv*b and Lihua Wang *b Biofilms with positive and negative actions ubiquitously affect medical infections, environmental remediation and industrial processes. However, it remains challenging to control the growth of harmful biofilms as well as to exploit the use of beneficial biofilms. Here we investigated the effect of an antibacterial graphene oxide–silver nanoparticles (GO–AgNPs) composite on Pseudomonas aeruginosa biofilm formation. We found that GO–AgNPs prevented biofilm formation in a dose-dependent manner, with a threshold of 15 μg mL−1. Interestingly, the bacterial biomass significantly decreased, but extracellular polymeric substance (EPS) production remarkably increased in mature biofilms treated with GO–AgNPs of an Received 19th May 2018, Accepted 17th September 2018 appropriate concentration, suggesting that GO–AgNPs effectively modulate biofilm development and structure. Moreover, we established that GO–AgNPs caused bacterial death via both physical damage and DOI: 10.1039/c8nr04064h oxidative stress, showing the synergic action of GO and AgNPs. These findings facilitate the use of gra- rsc.li/nanoscale phene-based nanocomposites for greener antibiotic applications. Introduction Biofilms have attracted widespread attention owing to their significant impacts on medical infections, environmental remediation and industrial processes.1–3 Bacteria in nature and artificial systems tend to form surface associating bacterial communities embedded in self-produced three-dimensional extracellular polymeric substances (EPS), called biofilms. The typical biofilm formation starts from planktonic bacteria adhesion, subsequent cell growth and EPS production. The key components of EPS include polysaccharides, proteins, lipids and extracellular DNA (eDNA).4 The hydrogellike EPS protects bacteria within a biofilm from ambient insults and attacks, such as antibiotics, chemicals and heterogeneous bacteria, resulting in strong disinfection-resistance.5 To date, biofilm-associated infections have been a major threat a College of Sciences, Shanghai University, Shanghai 200444, China. E-mail: luck@shu.edu.cn b Division of Physical Biology & Bioimaging Center, Shanghai Synchrotron Radiation Facility, CAS Key Laboratory of Interfacial Physics and Technology, Shanghai Institute of Applied Physics, Chinese Academy of Sciences, Shanghai 201800, China. E-mail: wanglihua@sinap.ac.cn, lvmin@sinap.ac.cn c School of Basic Medicine, Chengdu University of Traditional Chinese Medicine, Chengdu 611137, China d UCB Pharma, Slough, Berkshire SL1 3WE, UK † Electronic supplementary information (ESI) available. See DOI: 10.1039/ c8nr04064h This journal is © The Royal Society of Chemistry 2018 to public health globally. It has been estimated that 80% of all infectious diseases are caused by biofilm-associated microorganisms that are the fourth major cause of death, and it costs more than 1 billion dollars annually to treat these biofilm-based infections.6 However, these sessile communities already proved to possess beneficial applications, such as wastewater treatment, medical application and novel bioengineered materials preparation based on sticky biopolymer-containing EPS.2,3,7 The increase of biofilm biomass, especially EPS in a sludge blanket system, is a highly effective strategy for the removal of soluble biodegradable pollutants.2 Moreover, EPS with important physiochemical and biological properties has promising applications in medical and biomedical areas, such as tissue scaffolds, drug delivery, and anti-inflammatory agents.1,3 Given these positive and negative features of biofilms, it is important to control the harmful biofilms as well as to exploit the beneficial biofilms. Nanomaterials with excellent antibacterial activity and specific antimicrobial mechanisms have been emerging as strong candidates for traditional antimicrobial agents in recent years.8 Many studies reported that these antibacterial nanomaterials could not only kill planktonic bacteria, but could also inhibit biofilm formation and even eliminate mature biofilms,9 such as single-wall carbon nanotubes,10 vanadium pentoxide nanoparticles,11 and zinc oxide nanoparticles.12 Nevertheless, there was much debate about their broad applications in clinics and industry due to their poor stabilities and potential toxicities to humans and Nanoscale, 2018, 10, 19603–19611 | 19603 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Paper the environment.13 Graphene oxide (GO) as a novel antibacterial material has attracted great attention in biomedicine over the past few decades because of its excellent capacities against bacteria and biocompatibility.14–17 GO is a single-layer sp2 hybridized carbon network with abundant functional groups including hydroxyl, carboxyl and epoxide groups, possessing a large surface area, highly specific mechanical properties, and especially good water dispersibility. These characteristics make GO thoroughly to come into contact with bacteria and disrupt their cellular membrane in aqueous systems, presenting superior antibacterial activity to other graphene derivatives.15 In addition, GO with various defects and functional groups is an ideal platform to fabricate nanocomposites, which provides insights into the preparation of novel antimicrobial agents.18,19 Recent studies focused on the fabrication and application of graphene oxide–silver nanoparticle composites (GO–AgNPs).20 AgNPs are known to be antiseptic to a broadspectrum of bacteria, have low drug-resistance and good biocompatibility in nanobiomedicine.21,22 However, the agglomeration of AgNPs decreases the antimicrobial capacity, and even makes Gram-negative bacteria become resistant to their toxic effect.23,24 Previous studies found that the GO component can effectively prevent the aggregation of AgNPs in GO–AgNPs composites, showing an enhanced inhibition activity compared to pure GO or AgNPs. To date, many studies have mainly focused on the broad-spectrum inhibition of GO–AgNPs against planktonic microorganisms. Actually, bacteria inhabit natural and artificial systems in the form of homogeneous or heterogeneous biofilms rather than planktonic individuals. The community has improved tolerance to antimicrobial Nanoscale agents compared to individual bacteria. Thus, it is crucial to study the impact of GO–AgNPs on the development of biofilms. In this study, we employed Gram-negative bacteria Pseudomonas aeruginosa (P. aeruginosa) as a model organism to investigate the effect of GO–AgNPs on the biofilm formation. A P. aeruginosa biofilm plays an important role in nosocomial infections such as burn wounds and cystic fibrosis (CF).25 We prepared GO–AgNPs composites by in situ reduction of Ag+ to AgNPs on the GO surface, and systematically examined the effect of GO–AgNPs treatments with different concentrations and processing times on the development and structure of biofilms. These findings provided insights into the application of GO–AgNPs for the modulation of biofilms. Results and discussion Synthesis and characterization of GO–AgNPs To prepare GO–AgNPs, a GO nanosheet was synthesized according to modified Hummers’ method.14,26 Then, AgNPs were grown on the GO surface via reducing silver ions.24 Transmission Electron Microscopy (TEM) was used to observe the morphology of GO–AgNPs. The images showed that uniform Ag nanoparticles were decorated on single-layer GO (Fig. 1a & b). The bare GO was about 1 nm thick and has a lateral size in a range from hundreds of nanometers to two micrometers (Fig. S1†). As shown in Fig. 1d, the size range of AgNPs was from 2 to 10 nm by randomly measuring 1504 Ag nanoparticles of 10 TEM images, with an average diameter of Fig. 1 Characterization of the GO–AgNPs composite. (a, b) Typical TEM images of GO–AgNPs (a, zoom out, b, zoom in). (c) HRTEM image of a single Ag nanoparticle and (d) size distribution of AgNPs decorated on GO nanosheets. (e) UV-vis absorption spectra and (f ) the XRD spectrum of GO and GO–AgNPs. 19604 | Nanoscale, 2018, 10, 19603–19611 This journal is © The Royal Society of Chemistry 2018 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Nanoscale 7.06 ± 2.54 nm. The high-resolution TEM (HRTEM) image of the composite showed in the spherical shaped AgNPs with a polycrystalline structure with an inter-planar spacing (d spacing) of 0.237 nm, which was in line with the (111) l d spacing reported in the Joint Committee Powder Diffraction Standards (JCPDS, no. 04-0783).27 UV-vis spectroscopy was carried out to analyze the bonds in GO–AgNPs (Fig. 1e). The absorption spectrum of the GO sheets showed a featured peak at 220 nm, which was attributed to the π–π* transitions of the aromatic CvC bonds.28 However, a new peak appeared at 402 nm, which was attributed to the surface plasmon resonance (SPR) of the spherical AgNPs, indicating the presence of AgNPs on the GO–AgNPs surface.29,30 Inductively coupled plasma-mass spectrometry (ICP-MS) analysis provided additional quantitative evidence for the presence of 1.28 μg mL−1 Ag element in 10 μg mL−1 GO–AgNPs. X-ray diffraction (XRD) was carried out to analyze the crystal structure of pristine GO–AgNPs (red line) and GO (black line). The GO had a sharp peak at 10.8°,31 which was assigned to the (002) inter-planar spacing of 0.82 nm. The XRD spectrum of the GO–AgNPs composite showed typical peaks at 2θ = 38.3°, 44.4°, 64.6°, and 77.6°. These peaks were related to the (111), (200), (220), and (311) crystalline planes of the face-centered cubic Ag crystals, respectively, revealing that GO–AgNPs had been obtained.24,29 Moreover, the d spacing of the (111) plane for Ag was 0.235 nm, the same as the HRTEM result. However, the typical diffraction peak at 2θ = 10.8° decreased remarkably in the GO–AgNPs group, which indicated that AgNPs protected GO layers from self-stacking. The positively charged Ag ions can bind with the negatively charged oxygen-containing functional group of GO via an electrostatic force and be reduced into Ag nanoparticles, which may disrupt the regular layer structures of GO and expand the restacked GO.32,33 These results suggested the successful synthesis of GO–AgNPs composites. Inhibition of the biofilm formation by GO–AgNPs To investigate the effect of GO–AgNPs on P. aeruginosa cell growth and biofilm formation, the optical density method (OD600) based on the turbidity of the bacterial suspension, and crystal violet staining were used, respectively. As shown in Fig. 2, P. aeruginosa growth and biofilm formation decreased dose-dependently after 12 h exposure to GO–AgNPs at concentrations varying from 10 to 25 μg mL−1 under static conditions, suggesting the inhibition of proliferation of P. aeruginosa. The number of bacteria and the biomass of the biofilm both decreased more than 50% in the presence of 10 μg mL−1 GO– AgNPs. At a concentration above 15 μg mL−1, GO–AgNPs completely inhibited biofilm formation. We further confirmed this effect by a combination of fluorescence-based confocal images and computational analysis.34–36 Bacterial cells and EPS of biofilms were labelled with SYTO9 (in green) and concanavalin A-Alexa Fluor 647 conjugate (in red), respectively. The results showed that the biomass of the control biofilm containing bacteria and EPS was about 3 and 50 times higher than the 15 and 25 μg mL−1 GO–AgNPs group, respectively (Fig. 2d–g & Table 1). The coverage of the biofilm without and with 15 and This journal is © The Royal Society of Chemistry 2018 Paper 25 μg mL−1 GO–AgNPs was 99.20 ± 1.60%, 40.80 ± 3.78% and 5.92 ± 1.76% (Table 1). The substratum coverage was defined as the area coverage in the first layer of cell adhesion and proliferation on the substratum.10 Therefore, the reduction of the biofilm could be explained by the fact that GO–AgNPs decreased the adhesion number of the planktonic cell at the initial stage by preventing the growth and proliferation of planktonic P. aeruginosa, and even by inactivating all cells at high concentrations (Fig. 2a). Importantly, GO–AgNPs exhibited remarkably enhanced antibacterial properties compared to bare GO or AgNPs when the amount of GO (21.8 μg mL−1) and AgNPs (3.2 μg mL−1) was approximately equal to that in 25 μg mL−1 GO–AgNPs. As shown in Fig. 2c, both GO and AgNPs had a little influence on the biofilm formation, but GO–AgNPs significantly inhibited biofilm formation. The results showed that P. aeruginosa biofilm formation was fully inhibited by pure GO and AgNPs at the concentrations of 200 μg mL−1 and 8 μg mL−1, respectively (Fig. S3†). The excellent inhibition effect of the GO– AgNPs against bacterial growth and biofilm formation could be ascribed to the synergistic effect of the AgNPs and GO, named the “capturing–killing process”.29,37 Single-layer GO sheets have stronger adsorption properties owing to their large specific surface area and negatively charged oxygen-containing groups, therefore the bacterial cells may be adsorbed onto their surfaces, which promotes the interaction between the bacteria and nanocomposites. In addition, AgNPs are anchored on the surface of GO, effectively preventing their aggregation to maintain high surface reactivity and outstanding antibacterial properties.29 Dynamics of cell growth and biofilm formation To further explore the anti-biofilm formation of GO–AgNPs, we observed the dynamics of biofilm development up to 36 h. Biofilms develop through a series of stages. First, planktonic cells attach to the surface. Second, bacteria grow and secrete EPS to form mature three-dimensional communities. Finally, the single cells from the mature biofilm migrate to new surfaces, which was also considered as the beginning of a new life cycle (Fig. 3a). Fig. 3b shows the control floating cells attached to the surface and the mature 3D structure after 2 and 12 hours, respectively. However, the adhesion of planktonic bacteria treated with 15 μg mL−1 GO–AgNPs delayed to 6 h, and cell proliferation and biofilm maturation extended to 24 h. Interestingly, the maximum biomass of the biofilm exposed to 15 μg mL−1 GO-AgNPs at 24 h is similar to that of the control sample at 10 h, which indicated the recovery of bacterial growth.10,38 Bacteria can survive in the presence of bactericidal antibiotics as non-growing or slow-growing, which is defined as “tolerance”.39 When the antibacterial concentration is lower than a threshold tolerated by microorganisms, slowgrowing bacteria occur in the part of a clonal population, resulting in an extended lag time or cell recovery.40 After 24 h, the biofilm significantly decreased due to the mature biofilm dispersal and reached the saturation mode at ∼36 h. In contrast, P. aeruginosa biofilm exposure to 25 μg mL−1 GO–AgNPs Nanoscale, 2018, 10, 19603–19611 | 19605 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Paper Nanoscale Fig. 2 Effects of GO–AgNPs on the biofilm formation. (a) The bacterial growth and (b) biofilm formation in the presence of different concentrations of GO–AgNPs. (c) The comparison of the inhibition efficacy of GO–AgNPs to GO and AgNPs. The concentration of AgNPs, GO, and GO–AgNPs was 3.2 μg mL−1, 21.8 μg mL−1 and 25 μg mL−1, respectively. *** indicate significant differences at p < 0.001. (d) The confocal images of the biofilm structure. Live cells stained with SYTO9 dye (green), and EPS stained with Con-A Alexa Fluor (red). Scale bar, 100 μm. Bacteria and EPS across the biofilm thickness under the different culture conditions. (e) Control, (f ) 15 μg mL−1 and (g) 25 μg mL−1 GO–AgNPs. The insets of (b) and (c) are the digital images of the biofilm stained CV. Table 1 Confocal analysis of biofilm growth for 12 h in media with GO–AgNPs Analyses Control 15 μg mL−1 25 μg mL−1 Total biomass (μm3 μm−2) Cell biomass (μm3 μm−2) EPS biomass (μm3 μm−2) Substratum coverage (%) Average thickness (μm) Roughness coefficient 27.88 ± 4.68 26.28 ± 4.13 1.46 ± 0.45 99.20 ± 1.60 35.42 ± 1.53 0.12 ± 0.04 9.13 ± 2.10 8.60 ± 1.51 0.53 ± 0.13 40.80 ± 3.78 14.13 ± 4.23 0.88 ± 0.19 0.58 ± 0.07 0.46 ± 0.05 0.12 ± 0.01 5.92 ± 1.76 0.63 ± 0.08 0.78 ± 0.22 Data are shown as mean ± standard deviation. was totally inhibited. The growth of total and suspended bacterial cells showed a similar tendency to biofilm formation. The planktonic bacterial growth curve includes the lag, log and stationary phase. As shown in Fig. 3d, control bacteria grew and reached the stationary phase after 14 hours OD600 (1.35) compared to after 24 hours OD600 (1.16) in the case of 15 μg mL−1 GO–AgNPs. Remarkably, the growth of bacteria 19606 | Nanoscale, 2018, 10, 19603–19611 was entirely inhibited during the whole 36 h culture period when the concentration of the GO–AgNPs was increased to 25 μg mL−1. These results suggested that GO–AgNPs have a threshold tolerated by P. aeruginosa like other antibacterial agents.10 At concentrations lower than threshold, the toxicity of the GO–AgNPs to bacteria may occur only temporarily, and then the cells restore normal growth and biofilm formation. The GO–AgNPs concentration over 15 μg mL−1 caused complete inhibition of bacterial growth and biofilm formation. Thus, the biofilm formation could be regulated by selecting the optimal concentration of GO–AgNPs. GO–AgNPs exposure affects the mature biofilm structure CV staining demonstrated that the total biomass including bacterial cells and EPS of the mature biofilm treated with 15 μg mL−1 GO–AgNPs was close to that of the untreated group.41 To characterize the detailed structure and component of biofilms, we used confocal imaging to evaluate the biomass of bacterial cells and EPS respectively. As shown in Fig. 4a & b, This journal is © The Royal Society of Chemistry 2018 View Article Online Paper Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Nanoscale Fig. 3 Dynamics of cell growth and biofilm formation. (a) Schematic illustration of the development of biofilms untreated and treated with GO– AgNPs. (b) CV staining images of biofilms. (c) Dynamics of biofilm formation. (d) The growth curves of the total and suspended bacteria. Bacteria were exposed to GO–AgNPs to form biofilms for 36 h at a concentration of 0, 15 and 25 μg mL−1, respectively. GO–AgNPs addition significantly decreased bacterial cells ( p < 0.05) but enhanced EPS production of the biofilm ( p < 0.001) compared to that of the control sample, which revealed that GO–AgNPs with antibacterial properties stimulated bacteria’s resistance to harsh environments through EPS overproduction. We carried out SEM to observe the bacterial morphology and biofilm structure. The control and the P. aeruginosa biofilm exposed to 15 μg mL−1 GO–AgNPs were similarly fully covered with multilayer P. aeruginosa biofilms, with a thickness of ∼6.14 μm and ∼6.80 μm, respectively (Fig. 4c), which is consistent with the quantitative analysis of confocal images shown in Table S1.† However, we found a remarkable increase This journal is © The Royal Society of Chemistry 2018 of EPS secreted by the bacteria exposed to GO–AgNPs, providing a more compact structure than the control as shown in Fig. 4c (top-view). These findings indicated that the optimal concentration of GO–AgNPs could effectively prevent the proliferation of bacteria but improve EPS production, which benefits wastewater treatment in industry. The mechanism of GO–AgNPs action Graphene-based nanomaterials have been proved to cause membrane disruption due to their strong interaction with bacteria.14,42 As shown in Fig. 5, the change of the bacterial morphology when treated with GO–AgNPs was dose-dependent. Nanoscale, 2018, 10, 19603–19611 | 19607 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Paper Nanoscale Fig. 4 Biofilm structure in the mature stage. (a) The confocal images and analysis of the biofilm. Live cells were stained with SYTO9 dye (green), and EPS was stained with Con-A Alexa Fluor (red). Scale bar, 100 μm. Bacteria and EPS across the biofilm thickness under the different culture conditions. (i) Control, (ii) 15 μg mL−1 GO–AgNPs. (b) The biomass of the biofilm components containing bacteria and EPS. (c) SEM images of the biofilm in the top and side view respectively. Scale bar, 1 μm. Few cells were damaged in the biofilm in the presence of 15 μg mL−1 GO–AgNPs (Fig. 5b), explaining the recovery of bacterial growth and biofilm formation. In contrast, most of the bacteria lost the integrity of the cellular membrane (Fig. 5c & d, white arrow). Thus, physical damage induced by the interaction between the blade-like graphene composites and bacteria is responsible for the decrease of adhesion bacteria in the development of biofilms. It is difficult to measure the thickness of a biofilm by SEM (Fig. S4†). Besides, ROS is considered as another universal mechanism in nanomaterial toxicity.15,43 We carried out an ESR technique with DMPO to ascertain the generation and species of ROS.44,45 A hydroxyl radical (•OH) reacts stably with DMPO to form DMPO-•OH adducts in water. Nevertheless, a superoxide radical (•O2−) is very unstable in water and undergoes facile disproportionation, which reacts with DMPO to generate DMPO-•O2− adducts in ethanol. It has been reported that DMPO-•OH possesses four characteristic peaks with an intensity of 1 : 2 : 2 : 1,44 but they were not observed in our experiment (Fig. 6a). GO–AgNPs and GO gave six characteristic peaks with intensities similar to the spectra reported in the previous studies of DMPO-•O2− adducts. However, no typical signal was found in AgNPs. These ESR results confirmed that •O2− radicals existed in GO– based nanomaterials. Previous studies reported that the superoxide radical attacks the lipids and proteins of the cellular membrane, which results in the loss of cellular integrity and Fig. 5 SEM images of bacterial morphologies in biofilms with and without GO–AgNPs. (a) Control (b) 15 μg mL−1 and (c) 25 μg mL−1. (d) High-magnification images of (c) (the indicated portion). 19608 | Nanoscale, 2018, 10, 19603–19611 This journal is © The Royal Society of Chemistry 2018 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Nanoscale Paper Fig. 6 ROS generation and the effect of nanomaterials. (a) DMPO spin-trapping EPR spectra detected ROS production. (b) Oxidation of GSH by antibacterial nanomaterials, 3.2 μg mL−1 AgNPs, 21.8 μg mL−1 GO and 25 μg mL−1 GO–AgNPs. The positive control is 1 mM H2O2. Data are represented as mean ± s.d. * indicates the significant difference at p < 0.05 compared with the control. **p < 0.01, ***p < 0.001. the death of cells. Thiol groups of these biological molecules are very susceptible sites for attack by ROS.46 Thus, we employed Ellman’s assay to confirm the oxidation capacities of these nanomaterials.15 Fig. 6 shows that 28.57 ± 0.37%, 22.20 ± 0.23% and 4.47 ± 2.21% of GSH was oxidized by GO–AgNPs, GO and AgNPs, respectively. GO–AgNPs showed superior oxidation activity to AgNPs, but similar to GO. Thus, the generation of ROS by GO–AgNPs here possibly resulted from GO and finally caused bacterial membrane disruption and activity loss. Given the harmful and useful actions of bacterial biofilms, it is important to regulate their development. On the one hand, various antibacterial agents are widely used to prevent biofilm growth, such as antibiotics, metal ions and nanomaterials. On the other hand, researchers have devoted their efforts to improving the production of EPS for wastewater treatment and new bioengineered material fabrication based on a biopolymer-based sticky structure.1,2 The typical biofilm develops through several stages, including planktonic bacteria adhesion, aggregation and growth, biofilm formation, maturation and dispersal (Fig. 3a). In our study, the addition of GO–AgNPs would first encounter planktonic cells and subsequently participate in the formation of a biofilm. The floating bacteria in the medium significantly reduced in a dosedependent manner after GO–AgNPs addition, resulting in the biofilm formation inhibition. The exponential and stationary stages of the planktonic cells were delayed in the presence of GO–AgNPs at a concentration of 15 μg mL−1. The development of treated biofilms also lagged behind the untreated sample. Above the concentration of 15 μg mL−1, GO–AgNPs killed almost all planktonic bacteria at the initial stage, leading to no biofilm formation. Moreover, the combination of Ag nanoparticles and GO remarkably improved the antimicrobial and anti-biofilm activities compared to pure GO or AgNPs. Physical damage and oxidative stress are the two most common mechanisms of nanomaterial toxicity toward microorganisms. The generation of ROS triggered by both GO and AgNPs has been considered as a primary mode of toxic action.47,48 A very high oxidative stress often causes bacterial metabolic disorder and This journal is © The Royal Society of Chemistry 2018 cellular membrane disruption, leading to inactivation or even death of bacterial cells.22,43 On the other hand, both GO and AgNPs can destroy the cellular membrane by physical interactions, but different mechanisms of action were illustrated. AgNPs with a large specific surface area tend to adsorb and accumulate on the bacterial surface when brought into contact with bacteria, causing the loss of bacterial membrane integrity and cellular death.48 However, single-layer GO with sharp edges can penetrate the microbial cellular membrane, and then seriously damage the cellular membrane and result in the leakage of the cell content and the final death of bacteria.14,16,49 Besides, each of them have their own specific antibacterial mechanism. For example, Ag ions (Ag+) released from AgNPs play an important role in bacterial inactivation.28,31 GO nanosheets with flexible properties and strong absorption enable them to wrap the bacterial surface and block the exchange of substances inside and outside of cells, inhibiting bacterial growth and proliferation.50 The enhanced antibacterial properties of GO–AgNPs may result from the synergistic effect of GO and AgNPs described as the “capturing–killing process”.29,51 The GO–AgNPs composite like the other two nanomaterials has strong absorption capacity for the bacterial cells owing to its high surface area, which improves the contact between the bacteria and Ag nanoparticles.19,49,52 AgNPs anchored on the surface of GO effectively overcame the drawback of agglomeration, improving their antibacterial activity. AgNPs could trigger the death of bacteria through destroying the cellular integrity, division and function of respiration, because of their interaction with sulfur-containing proteins and DNA.21 Additionally, GO–AgNPs generated •O2− radicals and oxidized GSH, suggesting potential oxidative stress to cells. Although previous studies reported that AgNPs can inactivate bacteria through oxidative stress, we did not detect ROS production by itself. The oxidative capability of GO–AgNPs should be mainly from GO that can mediate the production of ROS by the adsorption of O2 on its defect sites and edges. Taken together, direct killing of bacteria was the main reason for the inhibition of biofilm formation in the Nanoscale, 2018, 10, 19603–19611 | 19609 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Paper presence of GO–AgNPs. Kulshrestha et al. reported that GO– AgNPs led to the down-regulation in the gene expression of Streptococcus mutans (S. mutans) including comDE, spaP and virR. These genes played crucial roles in adherence and the quorum sensing cascade of S. mutans.53 We noted that GO– AgNPs inhibited the adhesion of bacteria and proliferation, but also improved EPS secretion. Our findings suggested that GO–AgNPs could be potentially applied as a regulator for biofilm development as well as EPS production. Conclusions In this study, we provided a new strategy for regulating bacterial growth and biofilm formation. At the set time (12 h), the inhibition of GO–AgNPs showed characteristic dose-dependent behavior. GO–AgNPs exhibited a stronger inhibition activity than pure GO and AgNPs, which was attributed to the synergic action between GO and AgNPs. Interestingly, the dynamics of bacterial growth and biofilm formation found that GO–AgNPs had a threshold of 15 μg mL−1 tolerated by P. aeruginosa. GO– AgNPs at this concentration made the bacterial growth and biofilm development slower, but both of them could recover the normal total biomass at the mature stage. Surprisingly, the bacterial biomass significantly decreased, but EPS biomass notably increased. Above this concentration, biofilm formation was completely prevented, which could be attributed to physical damage and oxidative stress by GO–AgNPs. The effects of GO–AgNPs on the biofilm not only provided insights into the application of GO-based nanomaterials, but also into biofilm modulation in industrial and clinical treatments. Experimental section Sample preparation, characterization and analysis can be found in the ESI.† Conflicts of interest There are no conflicts to declare. Acknowledgements This work was supported by the National Key R&D Program of China (2016YFA0201200, 2016YFA0400900) and the National Natural Science Foundation of China (U1432116, 11675251, 61571278). References 1 J. A. Hornemann, A. A. Lysova, S. L. Codd, J. D. Seymour, S. C. Busse, P. S. Stewart and J. R. Brown, Biomacromolecules, 2008, 9, 2322–2328. 19610 | Nanoscale, 2018, 10, 19603–19611 Nanoscale 2 Z. Ding, I. Bourven, G. Guibaud, E. D. van Hullebusch, A. Panico, F. Pirozzi and G. Esposito, Appl. Microbiol. Biotechnol., 2015, 99, 9883–9905. 3 R. Xiao and Y. Zheng, Biotechnol. Adv., 2016, 34, 1225–1244. 4 H.-C. Flemming and J. Wingender, Nat. Rev. Microbiol., 2010, 8, 623–633. 5 J. Yan, C. D. Nadell, H. A. Stone, N. S. Wingreen and B. L. Bassler, Nat. Commun., 2017, 8, 327–337. 6 J. D. Bryers, Biotechnol. Bioeng., 2008, 100, 1–18. 7 P. Dranguet, S. Le Faucheur and V. I. Slaveykova, Environ. Toxicol. Chem., 2017, 36, 3194–3205. 8 H. A. Hemeg, Int. J. Nanomed., 2017, 12, 8211–8225. 9 Z. Chen, Z. Wang, J. Ren and X. Qu, Acc. Chem. Res., 2018, 51, 789–799. 10 D. F. Rodrigues and M. Elimelech, Environ. Sci. Technol., 2010, 44, 4583–4589. 11 F. Natalio, R. Andre, A. F. Hartog, B. Stoll, K. P. Jochum, R. Wever and W. Tremel, Nat. Nanotechnol., 2012, 7, 530– 535. 12 G. Applerot, J. Lellouche, N. Perkas, Y. Nitzan, A. Gedanken and E. Banin, RSC Adv., 2012, 2, 2314–2321. 13 T. F. Mah and G. A. O’Toole, Trends Microbiol., 2001, 9, 34– 39. 14 W. Hu, C. Peng, W. Luo, M. Lv, X. Li, D. Li, Q. Huang and C. Fan, ACS Nano, 2010, 4, 4317–4323. 15 S. Liu, T. H. Zeng, M. Hofmann, E. Burcombe, J. Wei, R. Jiang, J. Kong and Y. Chen, ACS Nano, 2011, 5, 6971– 6980. 16 Z. Guo, C. Xie, P. Zhang, J. Zhang, G. Wang, X. He, Y. Ma, B. Zhao and Z. Zhang, Sci. Total Environ., 2017, 580, 1300– 1308. 17 B. Z. Ristic, M. M. Milenkovic, I. R. Dakic, B. M. TodorovicMarkovic, M. S. Milosavljevic, M. D. Budimir, V. G. Paunovic, M. D. Dramicanin, Z. M. Markovic and V. S. Trajkovic, Biomaterials, 2014, 35, 4428–4435. 18 A. K. Geim and K. S. Novoselov, Nat. Mater., 2007, 6, 183– 191. 19 M. D. Rojas-Andrade, G. Chata, D. Rouholiman, J. Liu, C. Saltikov and S. Chen, Nanoscale, 2017, 9, 994–1006. 20 A. C. de Moraes, B. A. Lima, A. F. de Faria, M. Brocchi and O. L. Alves, Int. J. Nanomed., 2015, 10, 6847–6861. 21 S. Chernousova and M. Epple, Angew. Chem., Int. Ed., 2013, 52, 1636–1653. 22 S. Eckhardt, P. S. Brunetto, J. Gagnon, M. Priebe, B. Giese and K. M. Fromm, Chem. Rev., 2013, 113, 4708–4754. 23 A. Panacek, L. Kvitek, M. Smekalova, R. Vecerova, M. Kolar, M. Roderova, F. Dycka, M. Sebela, R. Prucek, O. Tomanec and R. Zboril, Nat. Nanotechnol., 2018, 13, 65–71. 24 Y. Z. Zhou, J. Yang, T. T. He, H. F. Shi, X. N. Cheng and Y. X. Lu, Small, 2013, 9, 3445–3454. 25 J. W. Costerton, P. S. Stewart and E. P. Greenberg, Science, 1999, 284, 1318–1322. 26 W. S. Hummers and R. E. Offeman, J. Am. Chem. Soc., 1958, 80, 1339–1339. 27 W. Shao, X. Liu, H. Min, G. Dong, Q. Feng and S. Zuo, ACS Appl. Mater. Interfaces, 2015, 7, 6966–6973. This journal is © The Royal Society of Chemistry 2018 View Article Online Published on 25 september 2018. Downloaded by Freie Universitaet Berlin on 30.06.2020 15:44:17. Nanoscale 28 Q. Q. Guo, Y. Zhao, X. M. Dai, T. Q. Zhang, Y. J. Yu, X. G. Zhang and C. X. Li, ACS Appl. Mater. Interfaces, 2017, 9, 16835–16848. 29 W. P. Xu, L. C. Zhang, J. P. Li, Y. Lu, H. H. Li, Y. N. Ma, W. D. Wang and S. H. Yu, J. Mater. Chem., 2011, 21, 4593– 4597. 30 Y. Su, T. Peng, F. Xing, D. Li and C. Fan, Acta Chim. Sin., 2017, 75, 1036–1046. 31 J. Z. Ma, J. T. Zhang, Z. G. Xiong, Y. Yong and X. S. Zhao, J. Mater. Chem., 2011, 21, 3350–3352. 32 X. Fu, F. Bei, X. Wang, S. O’Brien and J. R. Lombardi, Nanoscale, 2010, 2, 1461–1466. 33 K. S. Hui, K. N. Hui, D. A. Dinh, C. H. Tsang, Y. R. Cho, W. Zhou, X. Hong and H.-H. Chun, Acta Mater., 2014, 64, 326–332. 34 L. Gao, Y. Liu, D. Kim, Y. Li, G. Hwang, P. C. Naha, D. P. Cormode and H. Koo, Biomaterials, 2016, 101, 272–284. 35 B. M. Geilich, I. Gelfat, S. Sridhar, A. L. van de Ven and T. J. Webster, Biomaterials, 2017, 119, 78–85. 36 S. Wang, S. Deng, X. Cai, S. Hou, J. Li, Z. Gao, J. Li, L. Wang and C. Fan, Sci. China: Chem., 2016, 59, 1519–1524. 37 L. Liu, J. C. Liu, Y. J. Wang, X. L. Yan and D. D. Sun, New J. Chem., 2011, 35, 1418–1423. 38 M. Lv, S. Su, Y. He, Q. Huang, W. Hu, D. Li, C. Fan and S. T. Lee, Adv. Mater., 2010, 22, 5463–5467. 39 I. Levin-Reisman, I. Ronin, O. Gefen, I. Braniss, N. Shoresh and N. Q. Balaban, Science, 2017, 355, 826–830. This journal is © The Royal Society of Chemistry 2018 Paper 40 S. F. Elena and R. E. Lenski, Nat. Rev. Genet., 2003, 4, 457. 41 G. A. O’Toole, J. Visualized Exp., 2011, 47, 2437–2438. 42 O. Akhavan and E. Ghaderi, ACS Nano, 2010, 4, 5731– 5736. 43 S. Gurunathan, J. W. Han, A. A. Dayem, V. Eppakayala and J. H. Kim, Int. J. Nanomed., 2012, 7, 5901–5914. 44 Y. Zhou, X. J. Zhang, Q. Zhang, F. Dong, F. Wang and Z. Xiong, J. Mater. Chem. A, 2014, 2, 16623–16631. 45 R. F. Dong, B. Z. Tian, C. Y. Zeng, T. Y. Li, T. T. Wang and J. L. Zhang, J. Phys. Chem. C, 2013, 117, 213–220. 46 P. Sharma, A. B. Jha, R. S. Dubey and M. Pessarakli, J. Bot., 2012, 2012, 1–26. 47 X. F. Zou, L. Zhang, Z. J. Wang and Y. Luo, J. Am. Chem. Soc., 2016, 138, 2064–2077. 48 B. Le Ouay and F. Stellacci, Nano Today, 2015, 10, 339–354. 49 Y. S. Tu, M. Lv, P. Xiu, T. Huynh, M. Zhang, M. Castelli, Z. R. Liu, Q. Huang, C. H. Fan, H. P. Fang and R. H. Zhou, Nat. Nanotechnol., 2013, 8, 594–601. 50 O. Akhavan, E. Ghaderi and A. Esfandiar, J. Phys. Chem. B, 2011, 115, 6279–6288. 51 S. Kellici, J. Acord, A. Vaughn, N. P. Power, D. J. Morgan, T. Heil, S. P. Facq and G. I. Lampronti, ACS Appl. Mater. Interfaces, 2016, 8, 19038–19046. 52 X. Cui, H. Chen and T. Yang, Acta Chim. Sin., 2016, 74, 392–400. 53 S. Kulshrestha, S. Qayyurn and A. U. Khan, Microb. Pathog., 2017, 103, 167–177. Nanoscale, 2018, 10, 19603–19611 | 19611