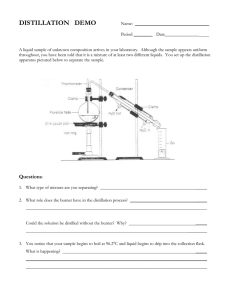

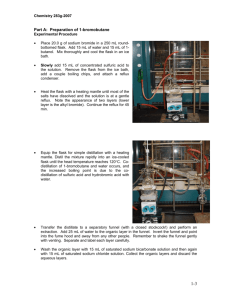

F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Ministry of Education and Science of the Republic of Kazakhstan M. Kh. Dulaty Taraz Regional University APPROVED Head of “Chemistry and chemical technology” department _____________ B. K. Massalimova “_____” ____________20___ METHODICAL INSTRUCTIONS for performing laboratory work In the discipline «BASICS OF ORGANIC SYNTHESIS» For students of specialty 5B060600 - " Chemistry" Taraz 2021 1 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Methodical instructions for independent work on the subject discipline "Basics Of Organic Synthesis" for bachelor of the educational program 6B05314- "Chemistry" Developer of the methodological guide: Kalmakhanova M. S. ______________________ / full name / / signature/ The methodological guide was discussed at the meeting of the Department " chemistry and Chemical Technology Protocol №_____ "______"_____________2021 2 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Introduction to organic synthesis. introduction to the safety engineering of organic synthesis. Laboratory work 1. Basic rules of work in the laboratory organic chemistry 1. Wear goggles over your eyes whenever any student in the room is doing laboratory work. You need goggles even if you wear glasses. 2. Observe all teachers’ instructions and all precautions stated in your lab book or lab sheet. 3. Do not handle apparatus or chemicals until you receive instructions. 4. Unauthorized experiments are strictly forbidden. 5. Be sure to follow directions given to you for lighting a bunsen burner. Should the burner stri back, turn the gas off at the valve. Do not touch the burner. 6. Do not stand too close to any apparatus in which material is being heated or in which reactions are being carried out. 7. When heating a liquid in a test tube, incline the test tube and point its mouth away from yourself and your neighbor. It is safest to do it under the hood. 8. Keep flammable liquids such as alcohol, benzene, and gasoline away from flames. Never pour such liquids into the sink. Use the covered receptacle on the teacher's desk. 9. Be careful to read the labels on the reagent bottles to make sure that you are using the correct chemicals. Excess reagent should never be returned to the original stock bottle. 10. Be careful when pouring acid or basic solutions. Pour these only over a sink. Stoppers should not be allowed to rest on tabletops. Add acid to water dropwise with constant stirring. 11. If any acid or base comes in contact with your skin or clothes, flood it with water immediately. Report it to your teacher immediately thereafter. 12. Do not inhale poisonous gases such as bromine, hydrogen sulfide, etc. Work with these gases as far back in the hood as possible. When it is necessary to smell the gas, the teacher will demonstrate a safe method. 13. Never push glass tubing, or a thistle tube, thermometer, etc. Through a hole in a rubber stopper or cork. Be sure to use water or glycerol and then hold the glass close to the stopper and twist it on. 14. Report all accidents to the teacher immediately. 15. Work quietly. Accidents are less likely to happen in orderly labs. 16. Handle water faucets only when needed for procedure or cleanup. 17. Lab coats or aprons are required. 18. Throw all solids, paper, matches, etc. Into the waste can ‐ not into the sink! 19. Mop up immediately, all materials spilled on the floor. 20. No eating or drinking in the laboratory at any time!! 21. Use tongs or oven mitts to handle hot pieces of equipment. 3 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions First aid in case of an accident 1. in case of contact with clothing,body or eyes splashes of acid or alkali, it is necessary to wash the place with a hard stream of water.After washing with water the burn alkali should be washed with 1%-s ' solution of boric acid, and the burn acid-1% solution of soda. 2. in case of poisoning with various nitrogen oxides, amine, nitroaromatic compounds, etc. During the experiment, it is necessary to immediately remove the poisoned person to fresh air. 3. If during the experiment the reagents contained in the test tube or other substances begin to ignite, they are immediately turned off by covering the mouth with asbestos. If the gorenje is stronger, then it is turned off with dry sand or blanket. Procedure for conducting laboratory work and reporting Before performing laboratory work: 1.it is necessary to familiarize yourself with the relevant topic for laboratory work from the textbook and understand the essence of chemical changes. 2.in a notebook for laboratory work,the student records the progress of laboratory work,passes it to the teacher and sends it for work.At the end of the experiment, you should write down the corresponding reaction equations and answer the questions asked. Liquid separation and purification methods. Laboratory work 2. Simple distillation at atmospheric pressure Simple distillation is usually used either for the purification of liquids that are slightly contaminated with high-boiling components, or for the separation of mixtures whose boiling points of individual components differ by more than 80-100 °C. It is advisable to use this distillation for liquids boiling in the range from 35-40 to 150 – 160 °C. More highly boiling liquids tend to decompose. Devices: Wurtz flask, Liebig refrigerator, alonge, thermometer, receiver, funnel, flask with substance. Assemble the device for simple distillation (Figure 1). The issued liquid is poured into the flask of Vur - ts 1 through a funnel, having previously measured its volume. 1 – 2 pieces of broken brick (boiling water) are placed in the flask. (Why?). A thermometer is inserted into the neck of the flask so that the upper boundary of the thermometer ball is approximately 0.5 cm below the discharge tube of the flask (Figure 2). Otherwise, the thermometer will show a temperature greater or less than the temperature of the distilled liquid vapors. Then water is allowed through the refrigerator. If heating is carried out in a water or oil bath, the temperature of the bath should not exceed the boiling point of the liquid by more than 20 °C (when working in an oil bath, 4 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions an additional thermometer is used to control the temperature of the bath). You can also conduct heating in an air bath. Figure 1. Installation for distillation under atmospheric pressure: 1-distillation flask (Wurtz flask); 2-refrigerator; 3-alonge; 4-receiver The simplest air bath is obtained if an asbestos net is placed between the flame of a gas burner (or electric stove) and a heated flask. Direct heating of flammable liquids on the flame of a gas burner is strictly prohibited! When the liquid boils, adjust the speed of its distillation by heating intensity. The normal distillation rate is 1-2 drops in 3 seconds. After collecting every 2 ml of distillate, record the observed boiling point and make a graph: the volume of distillate-boiling point. If a flat-bottomed flask is used as a receiver, then note the temperature at which the main mass of the substance was distilled. In the latter case, the schedule is not drawn up. Figure 2. Correct installation of thermometers 5 in the distillation flask F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions After the second rapid increase in temperature or its decrease, the heating is turned off. Dry distillation of the substance from the flask is not recommended, as the last drops of the substance condensed in the throat of the flask (phlegm), falling on the dry bottom of the distillation flask, can cause it to crack. After completion of distillation, the volume of the obtained fraction is measured, the percentage yield of the distillate is determined by the formula (1): where Vg -is the volume of distillate; V0 -is the volume of liquid taken for distillation. Determine the refractive index of the distilled on the refractometer. A substance is identified by its boiling point and refractive index. The obtained data and literary constants are entered in Table 1. Table 1 Name substance of the Literature data Т Boiling point, °С The obtained data Т Boiling point, °С The values of the obtained physical and chemical constants and their deviation from the literature data also indicate the degree of purification of substances. Purification of solids. Laboratory work 3.Recrystallization Recrystallization is based on the different solubility of the purified substance and the impurities contained in it in a suitable solvent. The recrystallization process includes the following steps: 1) preparation of a heated saturated solution of the substance; 2) filtration of the hot solution from undissolved impurities; 3) crystallization of the solution by cooling; 4) separation of crystals from the mother liquor; 5) drying of crystals. It is very important to choose the right solvent. It must meet the following requirements: 1) should not react with the substance to be cleaned; 2) dissolve it well when heated and poorly when cooled; 3) easily dissolve (at any temperature) 6 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions impurities or do not dissolve them at all; 4) easily remove from the surface of crystals. When selecting a solvent, the old rule is often used:" like dissolves in like", i.e., compounds are well soluble in solvents that are chemically and structurally close to the solute. For well-studied substances, the solvent and its amount can be selected according to the solubility data available in the reference books. In the laboratory workshop, students use the most safe non-flammable solvents (water, methylene chloride). Table 2 provides reference data on the solubility of certain substances in water. Devices and materials: round-bottom flask, air cooler, cylinder, conical flask, funnel, chemical beaker, glass rod, Bunsen flask and Buchner funnel for filtration at reduced pressure, filters, activated carbon. The substance to be recrystallized (about 1 g) is placed in a flask 1 (Figure 3), equipped with a reverse refrigerator 2. The solvent is poured into the flask in a slightly smaller amount than is necessary for the complete dissolution of the substance at the boiling point of the solvent. (The amount of solvent is calculated based on the reference data). Boiling water is added to the flask and the mixture is heated to a boil. Then, through the return refrigerator with the help of a funnel, such an amount of solvent is added that when boiling the entire substance is completely dissolved. Table 2 Acetanilide Solubility 3 in water, grams per 100 ml 0,5626 3,580 Benzoic acid 0,2718 2,275 Cinnamic acid 0,125 0,5998 Sulfanilic acid 1,0820 6,67100 Salicylic Acid 0,1820 1,7675 Substance 7 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions 2 1 Figure 3. Recrystallization device: 1-round-bottom flask; 2-air refrigerator It should be borne in mind that if any impurities are present in the substance, the calculated amount of solvent will be greater than necessary for the complete dissolution of the substance. Therefore, the addition of new portions of solvent should be stopped as soon as there is no noticeable decrease in the sediment. Sometimes the solid crude substance contains colored impurities of resinous products, which are difficult to separate during recrystallization. In such cases, activated carbon is added to discolor the solution. Usually take it in the amount of 1-2% of the substance taken for cleaning. Coal is applied only to a cold solution, as it emits a lot of air, and this can lead to strong foaming and the release of liquid. Then the mixture is boiled for 3-10 minutes with a reverse refrigerator and the hot solution is filtered. (If the resulting solution is still colored, it is re-boiled with a new portion of coal). Hot filtration is carried out in the device (Figure 4). In the flask 1, pour 1-2 ml of the solvent and immerse it for 1-1.5 cm in a heated bath 2. (If the solvent is water, then the flask can be heated on an asbestos grid). A funnel 3 with a folded filter is placed in the throat of the flask. On the filter in small portions pour the solution of the purified substance brought to a boil. Since the bottom and spout of the funnel are heated by boiling solvent vapor, the filtered solution is transferred to the flask without loss. Figure 4. Hot filtration device 8 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions If a certain amount of recrystallized substance falls on the filter, it should be washed off with small portions of hot solvent. The filtrate is cooled by placing the flask in cold water or snow. With fast cooling, small crystals are obtained, and with slow cooling, large ones are obtained. Usually they try to get medium-sized crystals. If the crystallization centers are formed slowly, they can be created artificially by introducing a "seed" in the form of several crystals of the same substance. The formed crystals are separated from the mother liquor by filtration on the Buchner funnel under reduced pressure (Figure 5).The precipitate is washed twice with a cold solvent, squeezed out on a funnel with a wide stopper, and then transferred to filter paper and dried, depending on the properties of the substance, either in air, covering the crystals on top with another sheet of filter paper, or on a watch glass in a drying cabinet. For dry matter, the yield is determined by the formula: where m -is the mass of the purified product; m0 -is the mass of the substance taken for purification. The purity of the substance obtained during recrystallization is determined by its melting temperature after drying. If the substance melts at a lower temperature than specified in the reference, recrystallization is repeated until a substance with the specified melting point is obtained. Figure 5. Scheme of the filtration unit with suction: 1-Buchner funnel; 2-Bunsen receiving flask; 3-safety 9 flask; 4-water jet pump F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Identification of organic substances. Laboratory work 4. Determination of the melting point of a substance The melting point of a substance may be defined as the temperature at which the substance changes from the solid state to the liquid state. It is a very useful physical constant because a pure substance melts at a definite temperature and has a sharp melting point while an impure substance has a lower melting point and melts over a wide range. Therefore, determination of melting point is a very convenient method to check the purity of a solid substance. Moreover, melting point determination can be used to identify a substance by comparing its melting point with the melting points of known substances. Experiment To determine the melting point of the given solid substance. Requirements 100 ml beaker, thermometer, iron stand, clamp, tripod stand, stirrer, thinwalled capillary tube 8 to 10 cm long and 1 to 2 mm diameter, spatula. Liquid paraffin. Procedure 1. Powder the crystalline substance. Take a capillary tube and seal its one end by heat¬ing (Fig. 3.1). For filling the substance make a heap of the powdered substance on the porous plate. Push the open end of the capillary tube into the heap. Some substance will enter into it. Now tap the sealed end of the capillary tube on the porous plate gently. Fill the capillary tube up to 2-3 mm. 2. Attach the capillary tube to a thermometer which is immersed in a bath of liquid paraffin. The surface tension of the bath liquid is sufficient to hold the capillary tube in position. 10 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions 3. Heat the beaker slowly and go on stirring the liquid in the beaker so that the temperature remains uniform throughout. For this, a glass loop stirrer is moved up and down. When the temperature is within 15° of the melting point of the pure substance, the flame is lowered. Now, the temperature is allowed to rise slowly. 4. The temperature is noted when the substance starts melting. The temperature is noted again when it is completely melted. The average of the two readings gives the melting point of the substance. Precautions 1. Use dry and powdered sample for the determination of melting point. 2. Keep the lower end of the capillary tube and the thermometer at the same level. 3. Packing of the powder should be uniform without any big air gaps in between the solid particles. 4. Heating should be gradual and the bath should be stirred regularly to maintain uniform temperature. 5. The bulb of the thermometer and the capillary sticking to it should not touch the side or the bottom of the beaker. 6. Do not use rubber band for attaching the capillary tube to the thermometer. Observations Temperature at which the unknown substance begins to melt = t1°C Temperature at which the substance completely melts = t2°C Melting point of the unknown substance = (t1+t22) °C 11 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Table: Melting Points of Some Organic Compounds Syntheses of organic substances. Nucleophilic substitution reactions. Laboratory work 5. Synthesis of butyl bromide Alcohols, as well as alkyl halides, can enter into nucleophilic substitution reactions, since due to the acceptor effect of oxygen on the carbon atom bound to the hydroxyl group, there is a deficit of electron density. However, the positive charge on carbon in alcohols is less than in alkyl halides, which reduces the rate of nucleophilic substitution, and the OH group is a " bad " leaving group, since it is a strong nucleophile. Therefore, nucleophilic substitution in alcohols is limited. Regardless of the substitution mechanism, it is carried out in an acidic medium, where protonation of the hydroxyl is first carried out. In this case, the OH group turns into the oxonium group H 2O+, which, having low energy, is a "good" outgoing group. In addition, after protonation, the positive charge on the carbon increases significantly compared to the non-protonated form. Protonated alcohol reacts further by the mechanisms of SN2 or SN1 with the above regularities. Synthesis of butyl bromide 12 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Reagents: n-butyl alcohol -23 ml (18 g) Potassium bromide -37 g Sulfuric acid (=1.84)- 30 ml A synthesis unit consisting of a heater, a round-bottomed flask and a reverse refrigerator is assembled. 35 ml of water is poured into a round-bottomed flask, potassium bromide and butyl alcohol are added, and a reverse refrigerator is attached. A funnel is inserted into the refrigerator foreshoot and 30 ml of concentrated sulfuric acid is poured through it in small portions (2 – 3 ml each) with constant stirring. In the flask, throw boiling water and carefully heat the mixture to a low boil, boil for 1.5 hours. Then replace the reverse refrigerator with a descending one (Liebig's refrigerator), increase the heating and drive butyl bromide into the receiver with water. The distillation is completed when the oily drops of butyl bromide do not sink to the bottom of the receiver. The contents of the receiver are transferred to the dividing funnel, the bottom layer is carefully separated from the water, collecting it in a dry flask. To remove traces of water, butyl bromide is "drained" with anhydrous calcium chloride for 10 to 15 minutes, periodically shaking the cone. When the liquid becomes transparent, the drying process is considered complete. Butyl bromide is separated from the solid precipitate of calcium chloride by decanting (draining over the edge) into a distillation flask. The device for simple distillation is pre-dried thoroughly. The receiver is weighed. Slowly distilled butyl bromide, selecting the fraction boiling in the range of 98-103 ° C. Determine the volume of the resulting product, measure its refractive index. The yield 25 g. Control Question 1. Why is water added to the reaction mixture? 2. What role does sulfuric acid play in the synthesis? Why is it added in small portions, with constant stirring? 3. Why is the reaction product recommended to be collected under a layer of water? 4. Why is the mixture recommended to be shaken periodically during the" drying " of butyl bromide with anhydrous calcium chloride? 5. What is the difference between the mechanisms of SN1 and SN2? List the conditions that favor the course of the substitution reaction by one or another mechanism? 13 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Laboratory work 6. Synthesis of n-butyl acetate Reagents: n-butyl alcohol-12 ml Glacial Acetic acid-10 ml Sulfuric acid (=1.84) Assemble the device shown in Figure 6. In a round-bottomed flask with a capacity of 100 ml, 10 ml of glacial acetic acid, 12 ml of n-butyl alcohol, 5 drops of concentrated sulfuric acid, boiling water are placed. Heat the mixture in a sand or air bath and make sure that the condensate from the reverse refrigerator does not drain too quickly. The mixture of alcohol, ether and water vapor condenses in the reverse refrigerator, the condensate falls into the trap and is stratified in it. A lighter organic layer containing organic substances (which ones?) it returns to the flask, and the lower water layer gradually increases. After the end of the reaction, the flask is cooled, the reaction mixture and the contents of the trap are transferred to the dividing funnel. The lower layer is separated, and the upper one is washed sequentially with water, 5% soda solution and again with water. When washing, it is not recommended to "shake" the dividing funnel strongly, since the ester with washing liquids can form persistent emulsions. "Raw" butyl acetate is dehydrated with calcined sodium sulfate for at least 6-8 hours and distilled collecting the fraction at 124-126 °C. The yield is about 70 %. Similarly, isobutyl acetate (T boiling point= 118 C), isoamyl acetate (isopentyl acetate) (Tboiling point= 142C) are obtained. 14 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Figure 6. Device for removing water from the reaction mixture: 1-flask; 2-trap; 3 – reverse refrigerator Control Questions 1. What substances does the condensate collected in the trap contain? 2. Why is it necessary to monitor the rate of condensate formation? 3. The synthesis of n-butyl acetate is carried out in an acidic medium. Why is a 5% solution of soda used to neutralize the acid in the release of the target product, and not an alkali? 4. What substances are contained in the" raw product " of synthesis? Why does it need to be dehydrated for at least 6 hours? Electrophilic substitution reactions. Laboratory work 7. Synthesis of sulfanilic acid Electrophilic substitution in a number of aromatic compounds is one of the most important types of reactions in organic chemistry. Electrophilic substitution reactions allow the direct introduction of a number of substituents into the ring to form a variety of arene derivatives. The main electrophilic substitution reactions include halogenation, sulfonation, nitration, alkylation, and acylation. 15 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Reagents: Aniline - 10 g Sulfuric acid (ρ =1.8 g/cm3). - 12 ml Activated сarbon In a round - bottomed flask with a long reverse air refrigerator, 12 ml of concentrated sulfuric acid (ρ=1.8g/cm3) is added and 10 g of aniline is gradually added in small portions with stirring. The mixture is heated in an oil bath at 180-190 ° C for 3-4 hours, until the sulfomass sample, diluted in a test tube with water, ceases to emit droplets of aniline when adding a solution of caustic soda. After the reaction is completed, the mixture is allowed to cool slightly and poured hot with stirring into a glass with 200 ml of cold water, while sulfanilic acid crystals are released. The glass with the solution is cooled with cold water and after 20 minutes, the crystals are filtered out on the Buchner funnel, squeezed out and washed with cold water. After dissolving the crystals in hot water, add activated carbon, boil for 5 minutes, filter through a folded filter and allow to cool. The fallen shiny crystals of sulfanilic acid of the composition п-H2N-C6H4SO3H·2H2O are filtered, washed 1 time with cold water and dried between sheets of filter paper. Crystallization water is lost during the weathering in the air. The yield of 10 – 12 g. Control Questions 1. Write the equations of all the intermediate stages of the conversion of aniline to sulfanilic acid. 2. Why, unlike phenol, does aniline not form sulfoxide at room temperature? 3. What precautions should be taken during the synthesis of sulfanilic acid? 16 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Oxidation reactions. Laboratory work 8. Synthesis of benzoic acid Oxidation reactions can be considered as a method for producing oxygencontaining compounds of various classes: alcohols, aldehydes, ketones, carboxylic acids, nitro compounds, etc. In the process of oxidation, the substance, losing electrons, is enriched with oxygen. The oxidation process is directly opposite to the reduction process. The amount of oxidizing agents currently used, however, as well as reducing agents, is very large. The most common compounds in laboratory practice are manganese (VII) and chromium (VI): potassium permanganate in an acidic or alkaline medium, chromates and bichromates in an acidic medium, chromium oxide CrO3. Also oxidizing agents are nitric acid, Fehling reagent (alkaline solution of copper sulfate and potassium tartrate), Tollens reagent (ammonia solution of silver oxide). All oxidizers have different strengths and are used depending on the desire to obtain a particular degree of oxidation of compounds. Organic substances belonging to different classes, in turn, have a different ability to oxidize: for example, benzene homologues are oxidized much more easily than aliphatic hydrocarbons, aldehydes are oxidized more easily than alcohols and ketones. Compounds of the same class have a different ability to oxidize due to their different structure: primary and secondary alcohols are oxidized much more easily than tertiary alcohols, etc. The higher the oxidation ability of a substance, the softer the oxidizer and reaction conditions are required, and vice versa: if the substance is oxidized with difficulty, the oxidizer is required stronger, and the reaction conditions are more stringent-an increase in temperature, a decrease in the pH of the medium. SYNTHESIS OF BENZOIC ACID 17 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Reagents: toluene - 2 g potassium permanganate - 6.2 g Hydrochloric acid In a round-bottomed flask with a capacity of 200 ml, equipped with a reverse water refrigerator, 2 g of toluene, 6.2 g of crushed potassium permanganate and 100 ml of water are mixed. The contents of the flask are heated in a boiling water bath (or sand bath) for 3 hours, with frequent shaking until the solution discolors. If the solution remains colored pink, add a few drops of alcohol or a little oxalic acid solution in small portions, after which the solution discolors. After cooling, the precipitated manganese dioxide is filtered out on the Buchner funnel and washed 2 times with a small amount of hot water. The filtrate is evaporated in a water bath to a volume of 10-20 ml. Again, the precipitated manganese dioxide is filtered out and washed once with 5 ml of hot water. The filtrate (a solution of potassium benzoate) is converted to free benzoic acid by the action of dilute hydrochloric acid (1:1), adding the latter drop by drop to the acid reaction according to Congo red. The fallen crystals of benzoic acid are filtered out on a Buchner funnel, washed with a small amount of cold water, dried in air and the melting point is determined. The yield of benzoic acid is 2 g. Control question 1. why is the reaction flask provided with a reverse refrigerator when obtaining benzoic acid from toluene? 2. Write the equation of the reaction that occurs when a solution of oxalic acid is added to the reaction mixture. 3. Calculate how many milliliters of hydrochloric acid (p=1.18 g/cm3) should be added to the reaction mixture to precipitate benzoic acid according to the method used. 4. Compare the physical properties of toluene and benzoic acid. 5. Which acid is stronger: acetic or benzoic? How does the structure of an acid affect its strength? 6. How does the strength of substituted benzoic acids depend on the nature of substituents in their molecules: electron-donating and electron-acceptor? 18 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Laboratory work 9. Synthesis of butyric aldehyde 3CH3CH2CH2CH2OH + K2Cr2O7 + 4H2SO4 → → 3CH3CH2CH2CH2CHO + K2SO4 + Cr2(SO4)3 + 7H2O Reagents: n-butanol -14.5 g Potassium bichromate - 20 g Concentrated sulfuric acid -16 ml Calcium сhloride Collect the device consisting of a three-necked flask for 250 ml, in the side throat of which a drip funnel is inserted, and in the central one – a dephlegmator connected to a descending refrigerator. 14.5 g of n-butanol is placed in a flask, and a warm solution of 20 g of potassium bichromate and 16 ml of concentrated sulfuric acid in 100 ml of water is placed in a drip funnel. Heat n-butanol to a boil and, when its vapors reach the bottom of the dephlegmator, begin to add an oxidizer solution, making sure that the temperature of the vapors passing into the refrigerator is within 80-85 ° C. The oxidation reaction is highly exothermic, so the heating can be reduced or stopped. After adding all the oxidizer, the flask is reheated, driving away the remaining butanal at a temperature of up to 90 ° C. Butanal with water is collected in the receiver, which is separated by means of a dividing funnel. The product is dehydrated with calcined calcium chloride or anhydrous sodium sulfate and distilled with a dephlegmator. Yield 75 %, melting point 75 ºC. This technique can be used for the synthesis of other aldehydes: propionic, isobutyric, valerian and isovalerian from the corresponding alcohols. Control question 1. What methods of obtaining aliphatic aldehydes do you know? 2. How do various oxidizing agents (KMnO4, K2Cr2O7, MnO2, HNO3) act on alcohols (primary, secondary, tertiary). How does the acidity of the medium affect the result of the reaction? 3. What side reactions occur when primary alcohols are oxidized to aldehydes in an acidic medium? 4. How can further oxidation of the aldehyde be prevented? 5. Write the reaction of the resulting aldehyde with hydroxylamine, sodium bisulfite, prussic acid, conduct aldol condensation. Write the decomposition reaction of the bisulfite compound butanal when heated with an aqueous solution of soda. 19 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions 6. How to prove the presence of an aldehyde group in a compound? Write the reactions of the resulting aldehyde with an ammonia solution of silver oxide, with 2,4-dinitrophenylhydrazine, bromine, and aniline. Reactions involving carbonyl compounds. Laboratory work 10. Synthesis of dibenzalacetone Aldol condensation is the reaction of two aldehyde or ketone molecules (identical or different) in the presence of acids or bases to form β-hydroxyaldehydes (aldoles). The reaction is reversible and can only be carried out if at least one reagent has an H atom in the α-position to the carbonyl group. In this case, ketones react much more difficult than aldehydes. Reagents: Benzaldehyde - 8 g Acetone - 2,2 g Caustic soda - 7,5 g Ethyl alcohol - 60 ml A cooled solution of 7.5 g of caustic soda in 75 ml of water and 60 ml of alcohol is placed in a glass cooled with water and equipped with a mechanical stirrer. The temperature of the solution is maintained at 20-25 ° C. With vigorous stirring, half of the mixture prepared from 8 g of benzaldehyde and 2.2 g of acetone is added to the solution. After 2 – 3 minutes, the solution begins to become cloudy and soon a flake-like precipitate is formed. After 15 minutes, add the rest of the mixture. The vessel in which it was located is rinsed with a small amount of alcohol, which is added to the reaction mass. Mixing is continued for another half 20 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions hour, after which the precipitate is filtered out on the Buchner funnel. The product is thoroughly washed with distilled water and dried between sheets of filter paper. The yield of 7 – 8 g. Perkin's reaction Laboratory work 11. Synthesis of cinnamic acid. This work was discovered by W.G.Perkin Sr. in 1868. This reaction of interaction of aromatic aldehydes with anhydrides of carboxylic acids in the presence of weak bases (alkaline salts of carboxylic acids, tertiary amines, etc.), is carried out with prolonged heating of the starting materials. The yield in the reaction is 50-80 %. Aliphatic aldehydes react according to the Perkin reaction with a very small yield, since they do not withstand the harsh conditions of the reaction; they are mainly polymerized. The reaction mechanism is completely analogous to the mechanism of aldol-croton condensation; the methylene component is a carboxylic acid anhydride with a hydrogen atom in the α-position, the aromatic aldehyde acts as a carbonyl component. Reagents: Benzaldehyde - 21 g (20 ml) Acetic anhydride-30 g (28 ml) Sodium acetate anhydrous-10 g Hydrochloric acid A mixture of freshly distilled benzaldehyde, acetic anhydride and finely ground anhydrous sodium acetate is placed in a dry round – bottomed flask with a capacity of 200-250 ml with a reverse water refrigerator equipped with a chlorocalcium tube. The contents of the reaction flask are heated for 8 hours using a sand bath or a flask heater at low boiling. At the end of the condensation reaction, the hot mixture is poured into a round-bottomed flask with a capacity of 750 ml, 200 ml of hot water is added, and the unreacted benzaldehyde and acetic acid formed during the reaction are distilled with water vapor. The absence of benzaldehyde is checked by a sample with sodium bisulfite. The residue in the distillation flask is cooled, neutralized with dry sodium acetate, 2–3 g of activated carbon is added and boiled for 10 minutes. The hot solution is quickly filtered using a hot filtration funnel. For complete precipitation of cinnamic acid, the filtrate cooled to room temperature is acidified with concentrated hydrochloric acid (about 15 ml) to an acid reaction according to the Congo. The fallen crystals of cinnamic acid are filtered out and dried in the air. If the cinnamic acid is not clean enough, it is recrystallized from water. The yield of cinnamic acid is about 12 g. 21 F 2-1-31-2021 1st edition 01/05/2021 Methodical instructions Control question 1. Write the reaction mechanism of aldol and croton condensation for the synthesis you have performed. Why does the reaction not end with the formation of an aldol? 2. What substances can play the role of the methylene component in condensation reactions? 3. How does the catalyst used activate the condensation reaction? 4. In which cases does the reaction end with the formation of an aldol? 5. What qualitative reactions can confirm the formation of a condensation product in your synthesis? 6. What operations and in what sequence are carried out to separate the resulting product from the reaction mixture? Reactions involving nitrogen-containing compounds. Recovery of nitro compounds. Laboratory work 12. Synthesis of aniline. Recovery of nitro compounds A distinctive feature of nitro compounds is the presence of a nitro group in their molecule: Formally, the oxygen atoms that make up the nitro group are not equal. One is bound to nitrogen by a double bond. The second nitrogen-oxygen bond is considered semipolar: the nitrogen atom as an electron donor carries a positive charge, the oxygen atom as an acceptor is negatively charged. However, due to the conjugation, both connections are absolutely equal, as the following structure shows: 22 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 Depending on the nature of the hydrocarbon radical, nitro compounds are divided into aliphatic and aromatic. The properties of all nitro compounds can be divided into the properties of the nitro group itself and the properties of the α-carbon atom in primary and secondary nitro compounds. A distinctive feature of the nitro group is the ability to recover. When the nitro group is completely reduced, primary amines are formed according to the following scheme: R–NO2 → R–NH2 Ar–NO2 → Ar–NH2 The reduction of aromatic nitro compounds was first carried out in 1842 by the Russian chemist N.N.Zinin, who used ammonium sulphide in an alcoholic medium. In addition, as reducing agents, you can use: – hydrogen sulfide when passing it through a hot alcohol solution of the nitro compound; - sulfides, in particular ammonium sulfide, which can be used to selectively reduce one of the two nitro groups in dinitro compounds; - iron in hydrochloric acid; - zinc in alkali; - lithium aluminum hydride; - molecular hydrogen on catalysts; - hydrazine on a Ni-Re catalyst. Depending on the pH of the medium, different intermediates are formed during the reduction process. Let us trace this dependence on the example of aromatic nitro compounds. SYNTHESIS OF ANILINE Reagents: Nitrobenzene-12.3 g Iron (sawdust) - 20 g Concentrated hydrochloric acid - 60 ml Caustic soda, sodium chloride, diethyl ether. In a round-bottomed flask with a capacity of 250 ml, connected to a reverse refrigerator, 12.3 g of nitrobenzene is mixed with 20 g of crushed iron sawdust. 60 ml 23 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 of concentrated hydrochloric acid is added to the mixture as follows. First, the acid is added in portions of 1 ml, and after adding each portion, the reaction mass is intensively shaken until the violent reaction stops. When 20 ml of acid is added, the rest of it can be added in portions of 10 ml (constantly shaking the reaction mass). If the reaction goes too fast, the mixture is cooled with water. After adding all the acid, the reaction mass is heated for half an hour in a water bath. the reaction is considered complete when the characteristic smell of nitrobenzene 6 disappears. To the reaction mixture, a concentrated solution of alkali (technical) is carefully added to the alkaline reaction and aniline is distilled with water vapor. Distillation is carried out until the distillate becomes completely transparent, after which another 100 ml of liquid is distilled. Crushed table salt (20-25 g per 100 ml of water) is added to the distillate. The salt is dissolved by stirring and, when the mixture settles, the aniline layer is separated in the dividing crow. The water layer is treated with ether by stirring the solution in a separate funnel sequentially with 50, 30 and again with 30 ml of ether. Ether extracts are added to aniline, dried with a small amount of solid caustic soda, and the ether is distilled in a water bath. The remaining aniline in the flask is distilled from a small distillation flask with an air cooler. The yield is about 8 g. The boiling point is 184.4°C, the melting point is 1.022. Qualitative responses 1. The sample with the lignin. Apply one drop of the resulting aniline with a pipette to pieces of newspaper and filter paper. A yellow-orange spot immediately appears on the newsprint. (Newsprint contains a large amount of lignin). The filter paper is pure cellulose and does not stain. The lignin sample is based on the reaction of compounds containing an amino group with aromatic aldehydes released during acid hydrolysis of lignin. 2. Oxidation. Apply 1-2 drops of aniline chloride solution to the slide at a distance of 1.5-2 cm from each other. To the first drop, add one drop of 10% potassium dichromate solution and one drop of 10% sulfuric acid solution. To the second drop, add a drop of saturated bleach solution. The chromium mixture oxidizes aniline to form a black dye insoluble in water. When oxidized with bleach, the solution becomes purple in color. 3. Bromination of aniline. In a test tube, place 1 drop of aniline and 5 to 6 drops of water. Shake the contents of the test tube well and add a few drops of bromine water. A white precipitate appears. Write a balanced equation for the reaction. The reaction can be used as a control when distilling the resulting aniline with water vapor. 24 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 Control question 1. Why do you use a water-cooled reverse refrigerator when reducing nitrobenzene to aniline? (reaction temperature 95-98 ° C). 2. How to determine the end of the reduction reaction? 3. Why is the reaction mixture neutralized with alkali before distilling aniline with steam? 4. How to separate unreacted nitrobenzene from aniline? 5. For what purpose, after steam distillation, table salt is added to the distillate? 6. How to detect aniline in its aqueous solution? 7. What and how is the aniline solution dried in an organic solvent? Laboratory work 13. Synthesis of phenol 25 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 Reagents: Aniline - 9.8 g Concentrated sulfuric acid - 10 ml Sodium nitric acid - 7.5 g Sodium Chloride, Calcium chloride, ether In a glass with a capacity of 300 – 500 ml, pour 50 ml of water and add sulfuric acid while stirring. Aniline is added to the still hot liquid slowly with stirring. The solution is cooled to room temperature and 70 g of crushed ice is added. Upon cooling, aniline sulfate drops out of the solution, but it does not interfere with further work. To the solution thus cooled to 0 ° C, a solution of 7.5 g of sodium nitric acid in 30 ml of water is gradually added with vigorous stirring. After the whole solution is added, check the end of the reaction with the help of iodine-starch paper. If a few minutes after the addition of the last portion of the sodium nitrite solution, a drop of the solution applied to the iodine-starch paper causes it to turn blue, the reaction can be considered complete. Otherwise, add some more sodium nitrite. The reaction of the medium should be acidic. The resulting solution of phenyldiazonium salt is poured into a round-bottomed flask with a capacity of 500 ml and heated to 40-50 ° C (in a low-boiling water bath), until the release of nitrogen is stopped. The resulting phenol is distilled with water vapor; the distillation is completed when the distillate sample with the addition of bromine water will give only a weak turbidity of tribromphenol. The distillate is saturated with powdered sodium chloride, poured into a dividing funnel and several times extracted with phenol ether. The combined ether extracts are dried with calcium chloride, and the ether is distilled in a water bath. Then, replacing the water refrigerator with a short air one, the phenol is distilled by heating the flask on a grid or flask heater. In the receiver, the phenol quickly solidifies into a crystalline colorless mass. Yield 6-7 g. Boiling point 183 ° C, melting point 41 ° C. 26 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 Laboratory work 14. Synthesis of p-nitroaniline red Reagents: p-nitroaniline-0.5 g β-naphthol-0.5 g Sodium nitric acid-0.3 g Sodium acetic acid--2.5 ml 8 n. sodium hydroxide solution -2.0 ml 6 n. hydrochloric acid solution-1.5 ml Dissolve 0.5 g of p-nitroaniline in a cup in 4.5 ml of hot water, add 0.8 ml of 6 n. hydrochloric acid. After cooling the solution to 0-5 ° C, add another 0.7 ml of hydrochloric acid of the same concentration and 2.5-5 ml of water. After cooling the resulting solution with ice to 0 ° C, it is diazotized by adding 2 ml of 2 n sodium nitrite solution drop by drop while stirring with a glass rod. (When precipitation occurs, add more hydrochloric acid of the same concentration before dissolving it). After diazotization (point blue in the face ikramullah paper) the solution is left to stand for 1 – 2 hours, then add a solution of 1 g sodium acetate and 3.5 ml of water. We received solution 1. In another cup, dissolve 0.5 g of β-naphthol in 2 ml of 8 n. solution of caustic soda and bring it to 33 ml with hot water. We received solution 2. After cooling the solution 2 with stirring, it is added to the solution 1 and left to stand for 1 – 2 hours.The dropped dye is filtered out, washed with a 20% solution of sodium chloride, then cold water and dried. The yield is about 1 g. 27 Н ТарМУ 11/1-1.01-2018 Әдістемелік нұсқау 1 баспа 05.05.2018 Control question 1. Why is the diazotization reaction carried out at a reduced temperature? 2. How many moles of acid are actually taken in this synthesis per 1 mole of aromatic amine? What causes the need to use excess acid? 3. How to determine the end of the diazotization reaction? 4. Give the mechanism of the reaction of the azo combination. How do substituents in the benzene ring of the diazonium cation affect the reaction rate? 5. Why are phenols and aromatic amines most often used as azo compounds? 6. What are the optimal pH values for the azo-combination reaction with phenols and amines? Justify the answer. 7. What are the applications of azo dyes are known to you? 28