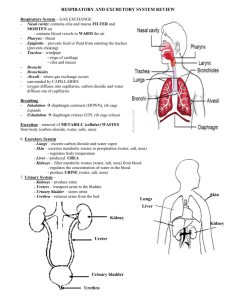

ME222T- Home Assignment-1 TITLE: ` Wearable Artificial Kidney (WAK) NAME: Mohit ROLL NO.: 190505 Anand Introduction: The ESRD (end-stage renal disease) is a condition where our kidneys stop functioning. The patients are supposed to undergo dialysis in which the blood of the patient is circulated outside the body for purification. But it has several disadvantages, dialysis is a painful procedure, and also needs to be done routinely and frequently ( approx. 12 hours per week consisting of 3 sessions on an average). Due to its frequent nature, it also proves to be expensive. And also it is not as effective as our kidneys. Therefore, for this, the Wearable Artificial kidney is proposed which the patient can move around with, and which ends the flaws of dialysis. But there still are some issues faced on the making of the WAK. Problem Definition: 1. The WAK should have exceptional design and material selection to reduce its weight and size for the patient to not face any difficulty in moving while wearing it. 2. The body produces a large amount of urea which needs to be absorbed by the dialysis machine. Due to its harder adsorbility and unreactive nature, it is hard to find materials suitable for WAK . So we need such materials that can adsorb a great amount of urea in a smaller space such that the weight and size of the artificial wearable kidney is small enough for a person to carry around with. 3. To regulate blood and dialysate flow in and out of the WAK in proper amounts we require batteries. And to denote any malfunction, such as bubble formation or leakage or any other complications we may require other smaller devices containing sensors run by the battery. The selection of battery is such that it does not affect other processes and works without any side effects on the patient's body. Objectives: 1. A good adsorbent of urea which can adsorb large amounts of urea in a small surface area and thus keep the size of WAK relatively small and simple.It also should have no other complications on the body and harm other functions of the body is required. 2. A lightweight material for making the WAK so as to reduce the weight of the WAK such that it can be worn by the patient and the patient can move anywhere without any difficulty. Proposed Solutions: 1. Use of modified REDY-type sorbent system for dialysate regeneration(sorbent regenerative tidal dialysis): The REcirculation DialYsis (REDY) system which was used up until now had several drawbacks and issues.A major issue was that as there was high production of toxic Ammonia using this system, therefore, high amount of zirconium phosphate was used to bind to ammonia. But if the dialysate was regenerated it would lead to much less water and other materials usage. In the modified type dialysate regeneration, rather than removing dialyser discharge ( rich in solutes) to waste - as with the older current systems - the effluent repetitively recirculates across a sorbent which does adsorption, ion exchange or catalytic conversion of all solute such that, at exit from the column, pure water solution emerges. This then remixes with a known electrolyte concentrate for representation to the dialyser. Due to this the system becomes independent of the availability of water and just the amount of water needed to start the system is required. An integrated infusion system balances the Ca/Mg contents to the required levels and adds glucose to compensate for the dilution and absorption of glucose by the patient. About the mean plasma sodium concentrations high levels due to this method, water can be circulated to the patient’s body to reduce to a normal level. 2. Decomposition Oxidation): of the Urea produced using EO( Electro Using electro-oxidation, the harmful urea is converted into harmless gases ( namely carbon dioxide, oxygen and nitrogen ) that can later be removed from the dialysate using the bubble trap device and also the components required for Electro-Oxidation are quite lightweight so this greatly reduces the weight and bulkiness of WAK. As for the other toxic side-products generated, they can be removed by passing alternating current in the EO-module. But currently no material has been found out for direct urea oxidation so indirect urea oxidation is carried out. 3. Using MIPs (Molecular Imprinted Polymers) : In molecular imprinting, a polymer matrix is synthesized with its binding site complementary to urea (i.e., the template molecule). MIPs are chemically and thermally very stable, they are also regenerabilitive, and solvent resistant when compared to human natural antibodies. This proves beneficial Urea solvent in WAK as the MIP does not recognize other nitrogenous solutes and thus preventing absorption of useful molecules such as the amino acid( which contain nitrogen) MIP-MANUFACTURING PROCESS 4. Use of CNT to make filters: CNT can be used as adsorbent for the urea produced and other toxins present in the blood. Filter pads coated with CNT can be used in hemodialysis and peritoneal dialysis systems. And as there is no reaction of CNT with urea, so no toxic side-products are produced. The sorption and release system is shart-termed use till it reaches its maximal capacity. The content of the sorption and release system are customized according to individual patient needs. Moreover they are flexible and lightweight and can be used with other nanomaterials to make the filter pads. Conclusions: So thus so far there hasn’t been a perfect material found for WAK with zero side-effects and complications. However the research is going on, and we may find a suitable option in the future. I found out about the regenerative dialysis but it builds up excess sodium levels in the plasma, in the electro-oxidation of urea, there is no direct procedure available and also no perfect electrode for the process ( with zero flaws) has been found out and also how to maintain pH of the electrolyte . The MIPs are an efficient method for filtering out urea and research is going on in it. I can also use CNT as a filter for urea and lower its hydrophobicity using doping, or by attaching amine, amide groups. Thus, in the near future we will be able to build a WAK which weighs less than 5 kgs and is free of complications. References: ● https://www.sciencedirect.com/science/article/pii/S0142961219308 531 ● http://www.nanotech-now.com/news.cgi?story_id=37942 ● https://insight.jci.org/articles/view/86397 ● https://pubmed.ncbi.nlm.nih.gov/20609091/ ● https://www.sciencedirect.com/science/article/pii/S2452199X2030 0840 ● https://www.eurekalert.org/pub_releases/2018-10/acs-tst101718.ph p _________________________________________________________ END