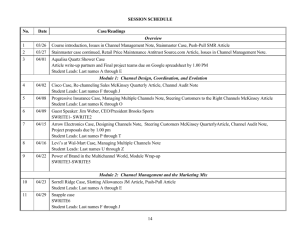

Sustaining Quality and Operations Excellence Laws of Physics for Successful Quality and Operations Transformation Date: May 2012 ABSTRACT Working Draft - Last Modified 22/05/2012 17:13:43 As industry leaders, we still see more than half of our quality and operations excellence initiatives "fail" (or, more precisely, because we rarely acknowledge failures -- quietly and politely fade into irrelevance and obscurity), McKinsey & Company Printed 3/15/2012 9:53:42 AM .....but years of successful experience and empirical data from industry leaders have also established, beyond reasonable doubt, the key factors and their interrelationships, as reliable and predictable as the "laws of physics", for sustained success and performance improvement in quality and operational excellence. What can we learn from the successes of industry leaders? | 1 “Laws of Physics” for Sustained Quality and Operations Excellence (OE) 1. Be clear and aligned on “the destination” (i.e., with meticulous alignment to enterprise vision, mission, strategic objectives, targeted performance and practices) 3. Approach Quality and OE “systemically” (i.e., based on thorough accounting for interdependencies in related processes and systems) 4. Go to “the work” to make the change (i.e., the only change that matters -- “go deep”, to the line level) 6. “Have a pre-flight checklist and flight plan….and follow it.” (i.e., Design and implement programmatically -- with attention to key enablers and key success factors) 7. Leaders must “LEAD” (i.e., with active, visible support and role modeling) McKinsey & Company | 2 Printed 3/15/2012 9:53:42 AM 5. Adults “learn by doing” (i.e., Employ adult learning principles and concepts in training and capability-building.) Working Draft - Last Modified 22/05/2012 17:13:43 2. It‟s a “Transformation” -- Design and implement “holistically” (i.e., with balanced and complete attention to the technical processes and systems, management systems, Text and organizational capabilities and behaviors) 1 Be clear and aligned on “the destination” Operational Excellence (OE) focuses on simultaneously driving continuous performance improvement in Quality, Efficiency, and Time Efficiency ▪ Etc… Operational Excellence Time Printed 3/15/2012 9:53:42 AM ▪ Etc… Quality Quality of Outcomes ▪ HSE performance, … ▪ Asset reliability and integrity… ▪ Conformance to Product specifications, … Working Draft - Last Modified 22/05/2012 17:13:43 Efficiency in Delivery ▪ Process Efficiency, e.g. reduction of waste, cycle times, WIP, etc. ▪ Economic Efficiency/Profitability ▪ Labor Productivity ▪ Equipment Utilization ▪ Total Cost of Ownership ▪ Energy Efficiency ▪ Overheads Timeliness of delivery ▪ Process cycle times, e.g. asset turnarounds, establishing new contracts, implementing a new practice across assets, …. ▪ Event response times, e.g. asset trips, well interventions ▪ Etc… McKinsey & Company | 3 Be clear and aligned on “the destination” Implementing management systems to deliver “sustained competitive advantage” requires more aggressive approaches to standard-setting and programmatic implementation Excellence Targeted Impact? Value Creation Efficiency Business Competitive Requirements Legal & Regulatory Compliance Risk Mitigation Loss Reduction Minimum Standards? Programmatic Implementation allows achievement of: • Higher level of standardisation (e.g., practices, procedures, tools, methods, application of best practices, etc.) Printed 3/15/2012 9:53:42 AM Value Preservation Working Draft - Last Modified 22/05/2012 17:13:43 Sustained Competitive Advantage Impact 1 • Higher consistency and completeness in implementation (e.g., enablement, performance management, change management, etc.) Programmatic Implementation McKinsey & Company | 4 2 It‟s a “Transformation” -- Design and implement “holistically” “Business Transformations” are fundamental changes that penetrate deep within an enterprise and lead to substantial and sustained performance improvement Requires integrated program and dedicated leadership: not business as usual Financial and operating performance Organizational and individual skills and competencies McKinsey & Company | 5 Printed 3/15/2012 9:53:42 AM Transformation is a conscious transition to a sustainable way of working at a higher level of business performance, based on fundamental shifts in ▪ Ambition ▪ Mindset and behaviors ▪ Capabilities, systems, and processes Not just incremental improvements – a quantum leap Working Draft - Last Modified 22/05/2012 17:13:43 Crosses a threshold; new levels of performance maintained over time 2 It‟s a “Transformation” -- Design and implement “holistically” Large-scale performance transformations are very challenging and most do not meet their objectives due to incomplete/non-holistic approach How successful was the transformation overall in reaching the targets your company set? Percent of respondents from executive survey (N = 2,994) Working Draft - Last Modified 22/05/2012 17:13:43 Extremely successful 6 Successful Very successful 28 52 Unsuccessful Not successful at all Don‟t know 5 Printed 3/15/2012 9:53:42 AM Somewhat successful 34% Only of company executives considered their transformations successful 10 SOURCE: July 2008 McKinsey Quarterly Performance Transformation Survey McKinsey & Company | 6 2 It‟s a “Transformation” -- Design and implement “holistically” Unsuccessful performance transformations often result in minimal impact, at the cost of valuable time and resources Successful transformations Unsuccessful transformations ▪ Unsuccessful transformations Cumulative improvement % of COGS 25 20 15 15% 10 0 0 12 24 36 48 60 Duration Months time and resources that could have been used elsewhere2 – Average of 5 months from discussion to implementation – 80% affected large portion of company – 80% strongly involved CEO or business unit leader – 30% of executive staff directly involved 1 Impact from successful transformations from direct company experience and research of operationally excellent companies. Impact from unsuccessful transformation illustrative only and not drawn from source work 2 Select results from McKinsey Quarterly survey SOURCE: McKinsey Operations Practice; July 2008 McKinsey Quarterly Performance Transformation Survey McKinsey & Company | 7 Printed 3/15/2012 9:53:42 AM 5 ▪ …and require large amounts of Working Draft - Last Modified 22/05/2012 17:13:43 result in lost impact… – E.g., by as much 15% of COGS over several years1 – Benefit in first 15-18 months requires focused initial wave – Longer-term benefits from continuous improvement 2 It‟s a “Transformation” -- Design and implement “holistically” Common failure modes in large-scale improvement programs Business results Working Draft - Last Modified 22/05/2012 17:13:43 Failure to sustain ▪ No change in day-to-day behaviors ▪ Change agents – not the line – leading the change ▪ No capability upgrade at the site level ▪ Improvements not baked into budgets Failure to scale ▪ Multiple bottom-up efforts with competing methodologies and no overarching blueprint ▪ Limited leadership capacity ▪ Waning focus from senior team Time Sites involved People involved Printed 3/15/2012 9:53:42 AM Failure to launch ▪ Stuck in diagnostics – leaders unable to align on what to do, where to start ▪ Managers not held accountable for performance ▪ Employees resistant 1-3 years <10 100s <50 1,000s Network 10,000s McKinsey & Company | 8 2 It‟s a “Transformation” -- Design and implement “holistically” Reliable and sustained delivery of the targeted business objectives and benefits requires Related Technical components Technical Components Management Infrastructure Components • Processes and Practices, • Procedures Organizational Components • Facilities and equipment • …. Technical Components Technical Components Management Infrastructure Components Organizational Components Related Management Infrastructure Components • Resources and budgets • Performance measures, monitoring, and reporting • Reliability Continuous Improvement Printed 3/15/2012 9:53:42 AM Management Infrastructure Components • Methods, tools, and technology Working Draft - Last Modified 22/05/2012 17:13:43 Alignment with overall vision, strategy and objectives (KPIs) •… Organizational Components Technical Components Management Infrastructure Components Organizational Components Leadership Commitment and Support (Active, Visible, Engaged) • Reliability Management Principles and Practices Competency and Capability Building • Maintenance QA Training and Competency • Contractor Management •… McKinsey & Company | 9 2 It‟s a “Transformation” -- Design and implement “holistically” Formalized Performance Management processes and objectives must be part of every holistic, sustainable Business Transformation Set direction and context ▪ ▪ Execute and manage performance and health 4. Hold robust performance dialogues Business – Review business performance and risks Individual – Review talent and individual performance ▪ ▪ ▪ 2. Create realistic budgets and plans ▪ ▪ 3. Track performance effectively ▪ Business – Choose metrics and set targets Individual – Agree to performance contract Business – Create budgets and plans Individual – Build capability Business – Track unit business performance and health Individual – Track individual performance McKinsey & Company | 10 Printed 3/15/2012 9:53:42 AM ▪ 5. Ensure rewards, consequences and actions Business – Take corrective actions Individual– Ensure appropriate rewards and consequences Measure stakeholder value/delivery of outcomes Working Draft - Last Modified 22/05/2012 17:13:43 ▪ 1. Establish clear metrics, targets, and accountability Business Individual 3 Approach Quality and OE “systemically” Integrated Quality and Operations Management Systems (OMSs) are a natural evolution of Quality Management Systems, developed to drive long-term sustainable excellence in Operational Integrity (i.e., Safety. Reliability, Environmental Compliance), Quality, and Efficiency ▪ ▪ Targeted levels of operational performance ▪ ▪ Internal and external best practices ▪ Create a common language and culture of operatingl discipline and excellence Common standards, guidelines, processes and practices, organizational capabilities, methods and tools in all company areas Printed 3/15/2012 9:53:42 AM SOURCE: McKinsey Working Draft - Last Modified 22/05/2012 17:13:43 Operations Management Systems (OMSs) are the response of industry leaders to stakeholder, competitive, and regulatory demands for dramatic, reliable, and sustained improvements in operational performance Operations Management Systems (OMSs) are deliberately designed to provide or promote A holistic, systemic framework for sustaining and continuously improving performance McKinsey & Company | 11 3 Approach Quality and OE “systemically” Operations Management Systems can be viewed as a layered “elements”, deliberately designed, integrated, and implemented to align, drive and sustain targeted performance, processes, and practices at all levels Working Draft - Last Modified 22/05/2012 17:13:43 Operations Objectives Operations Performance Priorities OMS Design & Implementation Core Support Enablers Processes Processes Printed 3/15/2012 9:53:42 AM Expectations & Standards Detailed Operating Processes, Procedures & Practices Day to Day Line Operations Expectations & Standards McKinsey & Company | 12 3 Approach Quality and OE “systemically” Integrated Operations Management Systems can be viewed as a hierarchical structure of interdependent elements or subsystems Different levels of elements Level 2 Basic elements, e.g. - Performance Priorities – e.g., HSE, Efficiency, Optim - Key enablers – e.g., People, Plant, Processes, Tech - Operating Principles – e.g., Lean, Continuous Impro Level 3 Functional and technical elements, e.g. • Core Business • Supporting Elements Elements (e.g., (e.g., Training, Perf. HSSE, Mgt, Asset Mgt., Procurement, Integrity Mgt, Asset Supply Chain Mgt., Reliability Mgt, IT & Document Mgt, Energy Mgt, Control Performance Mgt.) of Work, Production Optimization, Capital Project development) Level 4 Specification of Technical Standards associated with Level 3 Elements Level 5 Formal and informal Procedures and Practices on Level 3 and 4 Elements McKinsey & Company | 13 Printed 3/15/2012 9:53:42 AM Source: McKinsey Aspirations/ objectives (linked to vision), e.g., • Continuous • Recognition for Improvement Excellence Culture • Premier company • Efficiency • Risk Mgt Discipline Working Draft - Last Modified 22/05/2012 17:13:43 Element – A subsystem or a combination of Management, Organizational, and Technical Infrastructure components and capabilities (i.e., processes, practices, competencies, mindsets, behaviors, systems, etc.) which deliver business results in a particular area of the system Level 1 3 Approach Quality and OE “systemically” There are a few important principles to understand with regard to Quality and Operations Management System design and implementation Management System Design By nature, management systems need to cover all company processes (“elements”), in one holistic system; they are therefore complex, with many interdependencies ▪ Management systems in the oil & gas arena look different on the highest level but in reality they are very similar in terms of scope and many common elements 3B 3C ▪ Having a management system that drives sustainable, competitive advantage, beyond compliance to e.g. safety standards requires that “you go deep” to address the required elements ▪ Implementation on an element-level needs to be holistic, i.e. to 3D cover 1) the technical system, 2) the management structure around it as well as 3) the mindsets & capabilities to be sustainable Printed 3/15/2012 9:53:42 AM Management System Implementation Working Draft - Last Modified 22/05/2012 17:13:43 ▪ 3A ▪ Such implementation therefore require a well-architected 3E programmatic approach over a longer period of time (3 years to build internal capability) Source: McKinsey McKinsey & Company | 14 3 Approach Quality and OE “systemically” The Benefits of Formalized, Structured Quality and Operations Management Systems 100% 91% 90% 79% 80% Working Draft - Last Modified 22/05/2012 17:13:43 Firms with Structured OE Control Firms 69% 70% 60% 50% 43% 40% 30% 37% Printed 3/15/2012 9:53:42 AM 32% 23% 20% 7% 10% 9% 8% 0% 6% 0% Operating Income Sales Total Assets Employees Return On Sales Return on Asset Ref: Kevin B. Hendricks, Vinod R. Singhal, 2000 15 | 15 McKinsey & Company 3 Approach Quality and OE “systemically” Quality Management System Framework Illustration - EFQM Balancing Enablers and Performance Results (i.e., keys to reliability and sustainability) and Performance People Results People Partnerships & Resources Processes Customer Results Key Performance Results Printed 3/15/2012 9:53:42 AM Leadership Policy & Strategy Working Draft - Last Modified 22/05/2012 17:13:43 Results Enablers Society Results Innovation & Learning McKinsey & Company | 16 3 Approach Quality and OE “systemically” Quality Management System Illustration - EFQM Objective: Create a continuously reinforcing system of performance drivers and enablers leading to sustained high levels of operational excellence Working Draft - Last Modified 22/05/2012 17:13:43 Results Orientation Corporate Social Responsibility Customer Focus Continuous Learning & Improvement Printed 3/15/2012 9:53:42 AM Leadership & Constancy of Purpose Partnership Development Fact-based Management People Development & Engagement McKinsey & Company | 17 3 Approach Quality and OE “systemically” The importance of Systems Analysis and Systems Thinking --addressing complex interdependencies SIMPLIFIED Improve System & Equipment Criticality Analysis Improve Operations Performance Raise Condition Monitoring Stds Raise Operating Standards Improve Tech Services Performance Increase OM&T Failure Intervention Increase Tech Services Capability Improve Cross Functional Design Review Improve Operations Training Improve Construct & Commission QA Improve Design Operability Increase Asset Reliability Raise Maintenance & Repair Standards Accelerate Reliability Continuously Improvement Improve Engineering Performance Source: McKinsey Improve Project Development Standards Improve ERS & EDMS Enablement Printed 3/15/2012 9:53:42 AM Improve Engineering Design Standards Improve Lifecycle Cost Analysis Improve Maintenance Performance Improve Failure Analysis Increase Inherent Design Reliability Raise Materials & Parts Standards Increase Tech Services Capacity Working Draft - Last Modified 22/05/2012 17:13:43 Improve Condition Monitoring Improve Condition Monitoring Technology Increase Cross Functional Reliability Teamwork Improve Reliability Knowledge Management McKinsey & Company | 18 3 OMS Framework – Oil and Gas Industry Illustration „Exxon Mobil‟s OIMS framework establishes common worldwide expectations for controlling operations integrity risks inherent in its business‟ Driver “Assurance of operations integrity requires management leadership and commitment visible to the organisation and accountability at all levels” Source: ExxonMobil • • • • • • • • • Risk assessment and management Facilities design and construction Information/documentation Personnel and training Operations and maintenance Management of change Third-party services Incident investigation and analysis Community awareness and emergency preparedness Supported by 64 “expectations”, 256 detailed guidelines on best practice implementation and 27 common systems Evaluation Operations integrity assessment and improvement Printed 3/15/2012 9:53:42 AM Management leadership, commitment and accountability Operations Working Draft - Last Modified 22/05/2012 17:13:43 „Each operating unit must have in place properly designed and documented management systems that address all the expectations set out in the OIMS framework‟ Annual internal assessments and 3–5 yearly external assessment of management system „status‟ (design and deployment) and „effectiveness‟ (conformance, execution, impact) McKinsey & Company | 19 3 Operations Management Systems often look different at the highest levels i.e. the “superstructure” Working Draft - Last Modified 22/05/2012 17:13:43 Printed 3/15/2012 9:53:42 AM McKinsey & Company | 20 3 However, overall system scope and content is very similar….. ILLUSTRATIVE, NOT EXHAUSTIVE XOM CVX X X X X X X X X X X X X X X X X • Ops Integrity Mgt X X X X • Asset Integrity & Reliability X X X X X X X X X X X X X X X • Leadership Behaviors • Competency Mgt • Continuous Improvement Working Draft - Last Modified 22/05/2012 17:13:43 Any variances linked to business performance imperatives, priorities, and context at the time of system design and implementation Basic Elements BP RDS • …. Core Business Elements • HSSE Printed 3/15/2012 9:53:42 AM • …. Support Elements • IT and Document Mgt • Supply Chain • Technical Services • …. McKinsey & Company | 21 3 … and at the lowest levels, they are even more similar Core Business Elements • Control of Work • Reliability Improvement Support Elements • IT and Document Mgt • Contractor Management BP RDS CVX X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X • Procurement Basic Elements • Any •variances linked to business Similarities reflect performance imperatives, priorities, and industry‟s inherent asset context at the time of system design and intensivity, technical implementation complexity and risk profile • MOC Leadership Review • Required Safety Training • Employee Feedback McKinsey & Company | 22 Printed 3/15/2012 9:53:42 AM XOM Working Draft - Last Modified 22/05/2012 17:13:43 • Process Hazard Analysis ILLUSTRATIVE, NOT EXHAUSTIVE 4 Go to “the work” to make the change Addressing OMS implementation at the lowest level is necessary to impact the actual work practices and behaviors ……. • Cascade company vision and targeted performance expectations (e.g., KPIs) to lowest levels "The Defined System“ that is put on paper as a central, formalized and maintained system "The actual dayto-day Work" • Drive standardization on internal and external best practices across McKinsey & Company | 23 Printed 3/15/2012 9:53:42 AM • Break down organizational silos and facilitate cross-functional collaboration Working Draft - Last Modified 22/05/2012 17:13:43 Implementing an OMS requires “going deep”, e.g. 4 Go to “the work” to make the change ….which has some implications related to implementation strategy and approach You want to… Implementing an OMS - Engage at the line level - Thorough and rigorous Change Management approach - Define and drive standard practices - Objective, application of best practices - Deeply collaborate across functions - breaking through organizational silos - Link efforts to top-level company performance - closed loop continuous performance improvement McKinsey & Company Printed 3/15/2012 9:53:42 AM - Leadership alignment and commitment on objectives and aspirations Working Draft - Last Modified 22/05/2012 17:13:43 - Cascade objectives and expectations "The Defined System " "The actual day-to-day Work" Which requires… | 24 4 Go to “the work” to make the change For each element “successful implementation” (i.e., sustained performance at the target level) requires a holistic, integrated approach Reliable and sustained delivery of the targeted business objectives and benefits requires Technical Components Working Draft - Last Modified 22/05/2012 17:13:43 Alignment with overall vision, strategy and objectives (KPIs) Management Infrastructure Components Printed 3/15/2012 9:53:42 AM Organizational Components Leadership Commitment and Support (Active, Visible, Engaged) McKinsey & Company | 25 4 Go to “the work” to make the change A holistic approach to an individual element illustrates the depth of integration and alignment required across elements to achieve sustained results E.g., “Asset Reliability Management” Related Technical components Technical Components Management Infrastructure Components • Asset Condition Monitoring • Inspection Management Alignment with overall vision, strategy and objectives (KPIs) Working Draft - Last Modified 22/05/2012 17:13:43 • Maintenance Management Organizational Components • Asset Reliabilty Improvement • …. Technical Components Management Infrastructure Components Organizational Components Related Management Infrastructure Components • Inspection and Maintenance Budgeting and Planning Printed 3/15/2012 9:53:42 AM • Reliability Performance Monitoring and Reporting • Reliability Continuous Improvement •… Leadership Commitment and Support (Active, Visible, Engaged) Technical Components Management Infrastructure Components Organizational Components • Reliability Management Principles and Practices Competency and Capability Building • Maintenance QA Training and Competency • Contractor Management •… McKinsey & Company | 26 5 Adults “learn by doing” Adult learning methods employ experiential, physical learning environments (model workplace) I see and I remember, I do and I understand" Confucius ▪ Realistic learning environment in which managers and change leaders are trained to lead operational transformations ▪ New tools and skills are presented and immediately applied in real-life settings of a work place ▪ Learning center designed for lean service operations and manufacturing, covering private and public sector institutions Hearing Seeing Doing 85% Recall after 3 weeks 72% 70% Recall after 3 months 32% 65% 10% SOURCE: McKinsey McKinsey & Company | 27 Printed 3/15/2012 9:53:42 AM Typical learning center Working Draft - Last Modified 22/05/2012 17:13:43 Learning by … "I hear and I forget, Adults “learn by doing” 5 ILLUSTRATIVE Capability-building must employ adult learning approaches (e.g., “field and forum“) ▪ Prepare for diagnostic phase ▪ Understand key issues and possible impact 1 Find solutions for key issues and prioritize 2 Diagnose ▪ Prepare for roll-out phase (incl. organizational changes) 3 Design ▪ 4 5 Plan Plan for implement Forum 4 ation of Impleimprove- menting ments Coaching Coaching Coaching Coaching 2 weeks 2 weeks 2 week 14 weeks Review Implement Forum 5 and optimize Refine/ improve- Sustain ments Continued cycles of improvement Printed 3/15/2012 9:53:42 AM Idea generation and Forum 3 problem Planning solving workshops Keep continuous improvement loop alive (do not revert to old situation) 6 Implement Forum 2 Applying Analysis lean and diagnostic problem tools solving 4 days ▪ Implement changes and engrain new way of working Working Draft - Last Modified 22/05/2012 17:13:43 Prepare Forum 1 Lean Basics and tools ▪ Continuous Example of forum Lead business Lead self Lead others Lead change ▪ ▪ ▪ ▪ ▪ ▪ ▪ HSE processes and standards Work permitting planning Maintenance policies Operating standards Time management ▪ ▪ SOURCE: McKinsey Problem-solving – 7-step problem solving – Root-cause problem solving – Value driver mapping Interviewing – Listening and asserting Workshop facilitation Creating and communicating story for change McKinsey & Company | 28 5 Adults “learn by doing” McKinsey Learning Center Darmstadt Example: Learning by experience in a real production environment with real products Objective A real production environment ... ▪ Learning of lean principles in a real-life production environment Working Draft - Last Modified 22/05/2012 17:13:43 ▪ Experience of significant change through application of lean tool in a realistic production environment Set-up ▪ End-to-end production of a pneumatic cylinder with a machining center and an assembly line with 8 work stations from raw material to quality tested product ▪ Up to 10 line technicians in operation (trained staffed of the Technical University) Printed 3/15/2012 9:53:42 AM Process ▪ Clients observe a non-optimized workflow at the beginning of the session ▪ Step-by-step teaching and immediate application of With real products … performance improvements measures in the work flow ▪ Final target state fully optimized with nearly 100% productivity increase and a reduction of 50% in inventory and required space SOURCE: CiP, McKinsey Pneumatic cylinders From industry partner Bosch Rexroth McKinsey & Company | 29 6 “Have a pre-flight checklist and flight plan….and follow it.” The need to “go deep” in each element and, at the same time, cover the full system a programmatic approach Management system concept Program concept Wave 3 Wave 1 Pilot IC Purchasing ▪ One element on ▪ Few elements to scale up the program and build the competences to replicate ▪ Complete the management system working on all the elements of QG Printed 3/15/2012 9:53:42 AM Best practices to build a management system is to work at business processes/element level which test the optimization/ improvement methodology PPE Working Draft - Last Modified 22/05/2012 17:13:43 Wave 2 Program Management Office Overall concept Development and implementation of QGMS means optimize/ improve every single element of Qatargas business process universe McKinsey & Company | 30 6 “Have a pre-flight checklist and flight plan….and follow it.” Change champion Programmatic Capability Building ensures sustainability by creating your Change Champions to lead the improvement initiatives and carry forward the design and implementation principles McKinsey & Company Printed 3/15/2012 9:53:42 AM SOURCE: McKinsey Working Draft - Last Modified 22/05/2012 17:13:43 Pilot ▪ Coaches lead the improvement efforts, client‟s Change Champions participate in initial pilot with peers and supervisors Wave 3 ▪ Change Champions Wave 1 and 2 support multiple ▪ Change Champions improvement areas, move into leading role for supervising team leaders increasingly significant and front-line staff improvement areas ▪ Coaches provide ▪ Coaches support and feedback provide feedback | 31 “Have a pre-flight checklist and flight plan….and follow it.” 6 Formalized Program Management methods and tools are required … existing and resolved issues … Explicit tracking of program quality & risks … Issue matrix Risk Factor Low: Keep in mind 4a RISK MATRIX Progress Reports Risk Factor Low: Keep in mind 5b ISSUE MATRIX Medium: Action required Medium: Action required High: Urgent measures required D B C E Proposed measures Date Responsible Overall project leader High(4) Workstream leaders Sales and Distribution Technical Wokrstream Project Office Red Status Issue A Software delivery Deadline Deadline (new) Responsible Description Proposed measures Date • Delivery of • Continue test on alpha 10/20/06 10/21/06 11/04/06/ J. Westin release 1.0 delayed by two weeks release Low(1) • Set up contingency plan • Allocate additional High(4) Impact resources to testing (Importance = Impact x Probability) Source: Team 23 B Promotor allocation •BVA-262309-758-20061107-GE1-client Allocation • Launch internal of qualified promotors difficult 10/14/06 10/25/06 - T. Cochran 10/01/06 11/25/06 - L. Hersh campagin for promotor recruiting • Reach out for outsource partners C Product booking performance Source: McKinsey Source: McKinsey 21 22 BVA-262309-758-20061107-GE1-client • Average time to book a product is to high (>10 min) • Assess process speedup potential within IT and process description • Transfer tasks to Back Office BVA-262309-758-20061107-GE1-client ▪ Compiled and tracked optimally ▪ Compiled and tracked by the by the PMO Ongoing numbering to ensure consistency and ability to reference PMO Covers only main issues "Traffic light" logic to trigger necessary action ▪ SOURCE: McKinsey ▪ ▪ Resource Reports Printed 3/15/2012 9:53:42 AM D Description Regu• Product Roadmap • Set up meetings with regulatory 10/30/06 latory interferes with new board Environgovernmental ment regulation plans Low(1) Project • Insufficient project • Review project plans/milestones 10/31/06 Importance manage- management and (Importance = Impact x Probability) ment progress control PoSSource: Team • Legal danger to • Revise contracts and set up a 11/15/06 BVA-262309-758-20061107-GE1-client 21 contracts product sales by task force for negotiations with loopholes in distributor distribution channels contract for Points of Sale Construc- • Cities obstruct cable • Initiate talks with political leaders 12/15/06 tion Perconstruction works by • Check project plans for speed-up missions delaying permissions potential First • Integration of • Launch marketing campaigns ongoing mover employees advan• Competitors are tage pushing quickly to market B 5a Issue report Working Draft - Last Modified 11/22/2006 11:52:45 AMPrinted 11.10.2006 17:11:35 A Working Draft - Last Modified 11/22/2006 12:21:47 PMPrinted 11.10.2006 17:11:35 Issue Low (1) E proposed measures 4a Risk report – project risks and C Issue report Yellow B Green Urgency C A Working Draft - Last Modified 11/22/2006 11:52:45 AMPrinted 11.10.2006 17:11:35 Quality and Risk reports Working Draft - Last Modified 11/22/2006 11:52:45 AMPrinted 11.10.2006 17:11:35 High(4) High: Urgent measures required A Working Draft - Last Modified 22/05/2012 17:13:43 Risk matrices … and project-wide resources ▪ Regular tracking of project ▪ progress via estimate completion time Consistent, transparent tracking of budget allocation to work streams is key McKinsey & Company | 32 7 Leaders must “LEAD” John Kotter‟s Critical Success Factors to Sustained Performance Transformation 5 Empower others to act on the vision ▪ Get rid of obstacles to change ▪ Change structures that seriously undermine the vision ▪ Encourage risk taking and non-traditional ideas, activities, and action 2 Form a powerful guiding coalition ▪ Assemble a group with enough power to lead the change effort ▪ Encourage the group to work together 6 Plan for, and create, short-term wins ▪ Plan for visible performance improvements ▪ Create those improvements ▪ Recognize and reward those involved in improvements 3 Create a vision ▪ Create a vision to help direct the change effort ▪ Develop strategies to achieve that vision 7 4 Communicate the vision ▪ Use every vehicle possible to communicate the new vision and strategy ▪ Teach new behaviors by the example of the guiding coalition Consolidate improvements and produce still more change ▪ Use increased credibility to change systems, structures, and policies that don‟t fit the vision ▪ Hire, promote, and develop employees who can implement the vision ▪ Reinvigorate the process with new projects, themes, and change agents 8 Institutionalize new approaches ▪ Articulate the connection between the new behaviours and corporate success ▪ Develop the means to ensure leadership development and succession McKinsey & Company | 33 Printed 3/15/2012 9:53:42 AM Establish a sense of urgency ▪ Examine market and competitive realties ▪ Identify and discuss crises, potential crises, or major opportunities Working Draft - Last Modified 22/05/2012 17:13:43 1 7 Leaders must “LEAD” Leadership dimensions Working Draft - Last Modified 22/05/2012 17:13:43 ▪ Understand your value needs and system of beliefs and how it influences your behavior ▪ Take accountability and regulate behaviors to create change ▪ Manage energy and attention ▪ Develop strong support network ▪ Leave one‟s comfort zone and commit to opportunities ▪ Use personal vision to motivate self Lead self strategy Effective leadership ▪ Examine operational implications ▪ Align the BU strategies with the ▪ Inspire and motivate to action ▪ Turn difficult situations into overall corporate strategy ▪ Create environment for higher performance ▪ Communicate inspiring vision through stories ▪ Define leadership strategies to shift the broader dynamics Lead business Lead others learning moments ▪ Build relationships and networks ▪ Foster collaborative leadership and decision making ▪ Engage organizational support ▪ Create energy to sustain change McKinsey & Company | 34 Printed 3/15/2012 9:53:42 AM ▪ Develop the business vision and 7 Leaders must “LEAD” Required Leadership behaviors Fostering understanding and conviction “I know what is expected of me – I agree with it, and it is meaningful” ▪ Align management processes (including Mindsets and behaviors Reinforcing with formal mechanisms “The structures, processes, and systems reinforce the change in behavior I am being asked to make” McKinsey & Company | 35 Printed 3/15/2012 9:53:42 AM Developing talent and skills “I have the skills and competencies to behave in the new way” strategic, operational, and people planning and review, 360° feedback, performance dialogues, and personal development plans) and systems with the desired leadership behavior ▪ Set up individual and organizationwide performance goals necessary to reach or exceed aspirations ▪ Motivate individual and group performance and align employee interest with the organization‟s objectives, through financial and nonfinancial incentives and consequence management ▪ Other specific interventions tailored to the client‟s context Working Draft - Last Modified 22/05/2012 17:13:43 Role modeling “I see superiors, peers, and subordinates behaving in the new way” 7 Leaders must “LEAD” Companies with top quartile leadership characteristics have measurably better performance 59 ▪ The likelihood that a company with top1.8x 33 Top quartile 1 Leadership measured as an element in the Organizational Health Index database Source: Organizational Health Index database mining effort (N = 60,000) McKinsey & Company | 36 Printed 3/15/2012 9:53:42 AM Bottom quartile ▪ quartile leadership has above-median EBITDA margin is 59%, suggesting it is a key contributor to financial performance Companies with top-quartile leadership are 1.8 times more likely to outperform on EBITDA margin, compared with companies with bottom-quartile leadership Working Draft - Last Modified 22/05/2012 17:13:43 Likelihood that top quartile leadership1 has above-median EBITDA margin performance % 7 Leaders must “LEAD” Organizations that invest in developing leaders through business transformations are ~2.5 times more likely to succeed Degree of transformation success Extremely successful Very successful Somewhat successful Unsuccessful A great deal 1 Somewhat 36 3 7 Not at all 15 53 65 59 39 5 26 23 11 Printed 3/15/2012 9:53:42 AM A little 52 Working Draft - Last Modified 22/05/2012 17:13:43 To what extent, if at all, did your company invest in developing leaders through the transformation? %, N = 2,0471 3 3 x 2.4 1 Unweighted data Note: Because of rounding off, totals might not add exactly to 100%; data weighted by proportion of world GDP, following McKinsey Quarterly weighting standards Source: McKinsey Quarterly transformational change survey, January 2010 McKinsey & Company | 37 7 Leaders must “LEAD” Successful approaches to Cultural Change (i.e., values, mindsets, and behaviors) are fact-based and link aspirations to Program Architecture Organizational Health Assessment Cultural Change Engineering J Area of focus Architect Programmatic Cultural Change Use the influence model to design interventions that address FROM TO shifts along the four levers Understanding & Conviction “... I understand what is being asked of me and it makes sense.” Working Draft - Last Modified 3/10/2011 7:46:57 PM “…I see my leaders, colleagues, and staff behaving differently.” “I will change my mindset and behavior if . . .” Skills required for change “…I see that our structures, processes, and systems support the changes I am being asked to make.” Reinforcement mechanisms ▪ Diagnose organizational health outcomes and practices ▪ Analyze relative emphasis of practices ▪ Focus efforts on most critical practices for a given archetype Identify current activities to address critical practices and highlight activity gaps McKinsey & Company | 13 ▪ Use influence model to design interventions ▪ Construct portfolio of initiatives to “move the needle” on practices McKinsey & Company | 38 Printed 3/15/2012 9:53:42 AM SOURCE: Scott Keller and Colin Price, ‘Performance and Health: An evidence-based approach to transforming your organization’, 2010. ▪ Printed 3/4/2011 4:36:04 PM “…I have the skills and opportunities to behave in the new way.” Working Draft - Last Modified 22/05/2012 17:13:43 Role modeling “Laws of Physics” for Sustained Quality and Operations Excellence (OE) 1. Be clear and aligned on “the destination” (i.e., with meticulous alignment to enterprise vision, mission, strategic objectives, targeted performance and practices) 3. Approach Quality and OE “systemically” (i.e., based on thorough accounting for interdependencies in related processes and systems) 4. Go to “the work” to make the change (i.e., the only change that matters -- “go deep”, to the line level) 6. “Have a pre-flight checklist and flight plan….and follow it.” (i.e., Design and implement programmatically -- with attention to key enablers and key success factors) 7. Leaders must “LEAD” (i.e., with active, visible support and role modeling) McKinsey & Company | 39 Printed 3/15/2012 9:53:42 AM 5. Adults “learn by doing” (i.e., Employ adult learning principles and concepts in training and capability-building.) Working Draft - Last Modified 22/05/2012 17:13:43 2. It‟s a “Transformation” -- Design and implement “holistically” (i.e., with balanced and complete attention to the technical processes and systems, management systems, Text and organizational capabilities and behaviors) Working Draft - Last Modified 22/05/2012 17:13:43 Thank You. Printed 3/15/2012 9:53:42 AM | 40 McKinsey & Company