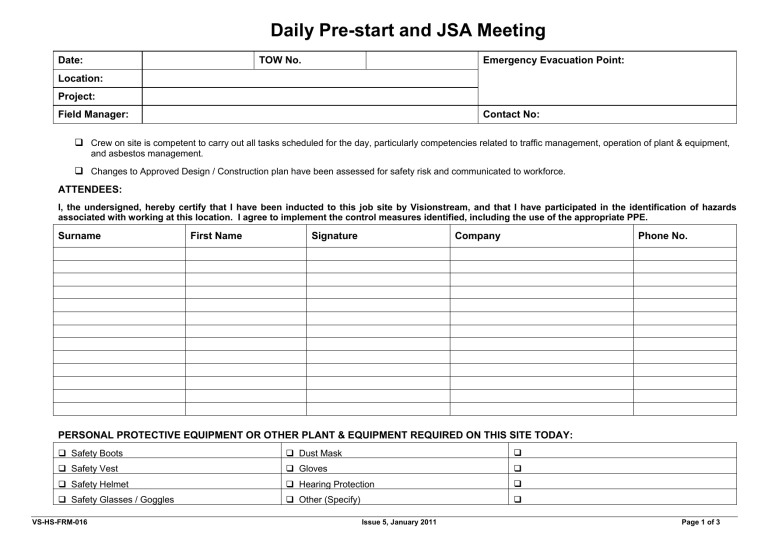

Daily Pre-start and JSA Meeting Date: TOW No. Emergency Evacuation Point: Location: Project: Field Manager: Contact No: Crew on site is competent to carry out all tasks scheduled for the day, particularly competencies related to traffic management, operation of plant & equipment, and asbestos management. Changes to Approved Design / Construction plan have been assessed for safety risk and communicated to workforce. ATTENDEES: I, the undersigned, hereby certify that I have been inducted to this job site by Visionstream, and that I have participated in the identification of hazards associated with working at this location. I agree to implement the control measures identified, including the use of the appropriate PPE. Surname First Name Signature Company Phone No. PERSONAL PROTECTIVE EQUIPMENT OR OTHER PLANT & EQUIPMENT REQUIRED ON THIS SITE TODAY: Safety Boots Dust Mask Safety Vest Gloves Safety Helmet Hearing Protection Safety Glasses / Goggles Other (Specify) VS-HS-FRM-016 Issue 5, January 2011 Page 1 of 3 REFER TO GUIDANCE NOTE & ENVIRONMENT INSTRUCTION NO. Alpine Conditions Asbestos Backhoe Bees and Wasps Bobcat Boring Machine Bulldozer Cable Plough Ceilings and Under Floors Chain Trencher Chemicals Concrete Saw Confined Spaces Contaminated Soil Contaminated Water Crane Cyclones & Natural Disasters Disturbance of Soil Dogs Driver Fatigue Dust Electrical - EPR Zones Electrical - Live Comms Racks Electrical - Overhead Electrical - Tools Electrical Wiring– Cavity Walls Electrical - Underground Electromagnetic Radiation Excavator Fire Fire Ants (QLD Only) Forklift Gas Gas Cylinders Glass Fibres Grader Grundamat Heat PRESENT ON THIS JOB RISK PRESENT ON THIS JOB PLEASE PLACE A TICK BESIDE ANY HEALTH, SAFTEY OR ENVIRONMENTAL RISK POSSIBLY ENCOUNTERED DURING THIS JOB RISK Heights - EWPs Heights - Ladders Heights - Masts & Towers Heights - Poles Heights - Roofs Heights - Scaffolds Horizontal Directional Drill Hot Work Humans Lasers Lightning Manual Handling Noise Overhead Hazards (falling objects) Polychlorinated Biphenyls(PCBs) Rock Saw Self-Loading Trailer Sharps Skid Steer Loader Snakes Spiders Static Plant Traffic Management Trains Trees Track Trencher Trenching & Shoring Underground Services Vehicles Vibratory Plough Waste Management Winches Winches – Optical Fibre Working Hours Other: Other: Other: DAILY TASK REVIEW (To be completed when tasks are recurring or in the same areas as previous shift): What are we doing today that is different from yesterday or last shift? Discuss any safety incidents or hazards from last shift? Discuss any safety initiatives or positive events from previous shift? Page 2 of 3 JOB SAFETY ANALYSIS: Determine Effective Controls What are we doing? What are the hazards? How can we prevent harm? Are the Controls In Place / Working? Controls in Place (Y/N) Certification: Controls Working (Y/N) NOTE: IF CONTROLS ARE NOT WORKING – STOP WORK AND DETERMINE NEW ACTION. Discuss the Potential Hazards NOTE: IF CONTROLS ARE NOT IN PLACE – STOP WORK AND IMPLEMENT IMMEDIATELY. Review the planned activities for shift I certify that this risk assessment and job safety analysis was completed prior to commencing work on this site, and that all appropriate risk controls were implemented as per the Guidance Notes and Environmental Instructions referenced on Page 2 of this document. Signature: __________________________________ Name: ___________________________________ Position: __________________________________ Date: SAFE WORK METHOD STATEMENTS IN USE (list reference no.) _______ / _______ / ______ Page 3 of 3