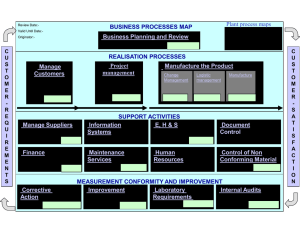

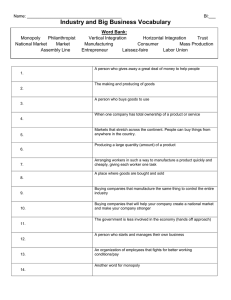

MEE 863 Advanced Manufacturing Technology (3 Units) Basic metal removal processes. Introduction to the mechanics of the processes. Economics of simple processes. Introduction to machine selection, flexibility, and automation. Organization of manufacturing, process planning, group technology, facilities layout, and production scheduling. Question 3 (a) and (c) 3a) In conventional metal cutting process, tool wear is inevitable. Discuss the most significant factors that cause tool wear. 3c) a steel ring of outside diameter 600mm and inside diameter 200mm is being faced on a vertical CNC lathe. The machine is capable of maintaining a constant surface speed, as the face of the ring is being machined and the feed-rate is set to 0.25mm/rev. From Tests, when v=50n/min, Tool life is 60min n=0.3. Given Taylor empirical tool life relationship, VT=C. Determine the number of components that can be machined per tool for a tool life of 50mins. Pages 20 to 32 Page 24 (Machining) Question One a) Differentiate between milling and turning operations. b) A lathe performs a turning operation on a work piece of 6in diameter. The shear strength of the work=40,000lb/in2. The rake angle of the tool =10o. The machine settings are: rotational speed=500rev/min, feed=0.0075in/rev. and depth=0.075in. The chip thickness after the cut is 0.015in. Determine: (a) the horsepower required (b) the unit horsepower for this material, (c) the unit horsepower with the correction factor (1 for to=0.01in.) Use the orthogonal model. Question Two a) What is “manufacturing” in the context of engineering production? Also, define manufacturing system. Manufacturing could be defined as the making of products from raw materials using various processes, equipment, operations and manpower according to a detailed plan that is cost-effective and generates income through sales, while manufacturing system is a system in which raw materials are processed from one form into another, known as a product, gaining a higher or added value in the process and thus creating wealth in the form of a profit. Or it could be seen as an integrated combination of processes, machine systems, people, organizational structures, information flows, control systems and computers whose purpose is to achieve economic product manufacture and internationally competitive performance. Basic Manufacturing system b) List four common characteristics of manufacturing systems. Four common characteristics of manufacturing systems are: 1. All systems will have specific business objectives to meet in the most cost-effective manner. 2. All systems consist of an integrated set of sub-systems, usually based on functions, which have to be linked according to the material processing. 3. All systems must have some means of controlling the sub-systems and the overall system. 4. To operate properly, all systems need a flow of information and a decision-making process. c) As a manufacturing engineer, what skills and knowledge must one possess in order to be successful as a process planner? In order to be effective in the role of a process planner, the manufacturing engineer must possess a variety of skills and knowledge. These have been identified as: (i) an ability to interpret engineering drawings; (ii) knowledge of materials for manufacture; (iii) knowledge of manufacturing processes; (iv) knowledge of jigs and fixtures; (v) an ability to use reference material, for example, manufacturers, machining data, tooling data, etc.; (vi) knowledge of the relative costs of materials, processes and tooling; (vii) an ability to calculate manufacturing parameters and costs; (viii) knowledge of inspection/QA procedures and specifications. d) List ten (10) conventional metal removal processes known to you. Question a) What role does “process planning” play in the manufacture of a given product? For an organization to manufacture a product that meets the design specification, the manufacture of each component part of the product must be thoroughly planned. However, merely ensuring that the product meets the design specification and is of the required quality is not enough. The manufacture of the product must be cost-effective, that is, maximize the added value, and meet the agreed deadlines, that is, be completed on time. Therefore, through process planning the manufacturing engineer is responsible for ensuring that the product is manufactured to the correct specification, at the lowest possible cost and completed on time. b) Graphically illustrate the processes involved in the design and manufacture life cycle. Question a) During turning a ductile alloy by a tool of γ0= 10o, it was found that Pz= 1000 N, Px = 400 N, PY= 300 N and ζ = 2.5. Evaluate, using MCD, the values of F, N and μ as well as Ps and Pn for the above machining. Force Pxy= Pz= 1000N Px