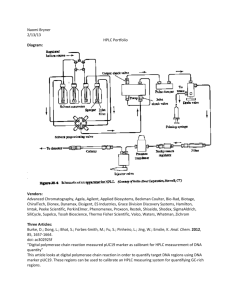

ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 2005 © The Japan Society for Analytical Chemistry 1401 Reviews Mechanism of Volatile Hydride Formation and Their Atomization in Hydride Generation Atomic Absorption Spectrometry A. RAMESH KUMAR* and P. RIYAZUDDIN**† *Chemical Laboratory, Central Ground Water Board, South Eastern Coastal Region, E1, Rajaji Bhavan, Besant Nager, Chennai 600090, India **Department of Analytical Chemistry, University of Madras, Guindy Campus, Chennai 600025, India The mechanism of volatile hydride generation (HG) and the formation of analyte atoms in the quartz cell atomizer used in the determination of hydride-forming elements (As, Bi, Ge, Pb, Sb, Sn, Te etc.) by atomic absorption spectrometry (AAS), have been critically reviewed. The nascent hydrogen mechanism failed to explain hydride generation under different experimental conditions when tetrahydroborate (THB), amineboreanes (AB) and cyanotrihydroborate (CBH) were used as reductants. Various experimental evidence suggested a non-nascent hydrogen mechanism, in which the transfer of hydrogen directly bonded to boron to an analyte takes place. In electrochemical hydride generation (EcHG), the reduction of the analyte species and subsequent hydrogenation was proposed. The mechanism of analyte atom formation in a quartz tube atomizer has been explained by the following hypotheses: thermal decomposition, oxidation by O2 and collisions by hydrogen free radicals. The free-radical mechanism satisfactorily explains most of the analytical implications. The significant variation in the experimental conditions required to generate different analyte hydrides makes it difficult to arrive at a generalized mechanism of hydride formation. (Received December 15, 2004; Accepted May 16, 2005) 1 2 3 4 Introduction 1401 Historical Development of Hydride Generation 1401 Generation of Volatile Hydrides 1402 Hypotheses Concerning the Hydride Generation Process 1402 4·1 The nascent hydrogen mechanism 4·2 Formation of hydroboran intermediates 4·3 Role of pH in hydride generation 4·4 Studies carried out with deuterated reagents 1 Introduction Volatile hydride generation (HG) combined with atomic absorption spectrometric (AAS) determination is a sensitive analytical method for the elements As, Bi, Ge, Pb, Sb, Sn and Te.1 The basic design of a hydride generation system with subsequent detection by atomic absorption may be classified as four steps. First, generation of the hydride; second, collection of the hydride (if necessary); third, transfer of the hydride to the atomizer; and fourth, decomposition of the hydride to the gasphase elemental form within the optical axis of the detection system. Various designs and techniques were developed during the last three decades to achieve these goals, which led to better sensitivity and lower detection limits. Because of the less interference, better selectivity and sensitivity, HG-coupled with AAS detection is the better choice for quantification of the † To whom correspondence should be addressed. E-mail: riyazdr@yahoo.co.uk 4·5 Electrochemical hydride generation 5 Effect of the Reaction Matrix and Thiols 5·1 Effect of halide ions 6 Atomization of Volatile Hydrides in the Quartz Cell 6·1 Atomization via thermal decomposition 6·2 Oxidation of the hydride 6·3 Free radical mechanism 7 References 1405 1406 1408 hydride-forming elements. Though the principle of this technique seems to be simple, the generation of volatile hydrides and their subsequent reduction to the atomic state, is still not completely understood.2 Many studies have been reported on the determination of As, Bi, Hg, Sb, Se etc. in natural water samples,3–12 geologic materials,13,14 flora and fauna,15–18 but, relatively few studies have been reported on the process of hydride generation and their detection in a quartz cell atomizer. 2 Historical Development of Hydride Generation The conventional flame atomization of hydride-forming elements results in poor sensitivity, since the resonance lines of these elements lie in the far-ultraviolet region of the spectrum. With the application of an Ar–H2 flame to AAS in 1967, a much improved sensitivity was obtained. This flame absorbs about 15% of the available light, compared with 62% for air–acetylene flame at the 193.7 nm line of arsenic.19 1402 ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 Holak20 first determined As by converting to AsH3, collected it in liquid-nitrogen trap, which was then warmed, and the evolved AsH3 was swept into the flame with a flow of N2. This greatly minimized the matrix interference. Madsan21 collected AsH3 in dilute AgNO3 and aspirated the resulting solution directly into the flame as described by Khan and Schallis.19 Dalton and Malanoski22 were the first to report on the direct aspiration of AsH3 into a flame, and attained a detection limit of 0.1 µg. A further improvement in the sensitivity was obtained by Fernandez and Manning,23 by collecting the AsH3 in a balloon reservoir and subsequent introduction into the flame. Manning24 was the first to introduce an accessory commercially with AAS for determining As. Pollock and West25 extended it to Sb and Bi. In 1972 the use of sodium tetrahydroborate (THB) was reported by Braman et al.,26 who employed an emission in a D.C. arc-discharge method. In 1973, Schmidt and Royar27 reported on the use of THB for the determination of As and Se; it was extended to Ge,28 Sn29 and Te29 by others. All of these methods continued to use an Ar–H2 flame. In 1974, Thomson and Thomerson30 reported the use of THB with a flame-heated quartz tube as the atomizer for As and Pb. The use of THB dramatically increased the popularity of HG as an analytical tool, exclusively for hydride-forming elements; recently, its use has been extended to the generation of volatile species of Cd,31,32 In,33 Tl,34 Cu,35 Ni,36 Zn,37–39 Au,40 Ag,37,38 and Pt.41 Various application methodologies did appear in the literature describing improved analytical performances.42–46 However, unfortunately the mechanism of hydride production and its atomization in a quartz cell atomiser is not fully understood, and the studies attempted so far to explain these phenomena form the basis of this review article. space of an electrolytic cell; and the process is considered to take place in at least two sequential events:49–51 3 Generation of Volatile Hydrides Various reducing agents and sources of nascent hydrogen have been suggested in order to convert the element to its hydride. These include Zn/HCl, SnCl2/HCl–KI, Mg/HCl–TiCl3 and THB.47 The reactions leading to the formation of hydrides with metal/acid reductant can be written as: Zn + 2H3O+ → Zn2+ + 2H2O + 2H·, Am+ + (m + n)H· → AHn + mH+, where Am+ is an analyte. THB is a particularly versatile reagent, which has become widely used for its reducing and hydride transfer properties.48 Assuming the evolution of nascent hydrogen from the acid hydrolysis of THB, the generation of hydrides is represented as m+ → H3BO3 + NaCl + 8H· A → AHn + H2 ↑. NaBH4 + 3H2O + HCl However, studies supporting the non-nascent hydrogen hypothesis propose that the hydride is formed by the action of hydrogen bonded directly to boron through the formation of some hydroboron intermediates. According to this, the derivatization process may be written as → Intermediates → H3BO3 + H2, THB + H3O+ + 2H2O THB/Intermediates + Analyte → Hydride. Hydrides have also been generated electrochemically (EcHG).49–55 In EcHG the hydride is formed in the cathodic Am+ + me– → A0. The formation metal/metalloid, of the hydride from the deposited A0 + nH· → AHn, where H represent the hydrogen atom, from the adsorbed H atom, reduced H3O+ or reduced H2O. Recently, D’Ulivo et al.56 generated hydrides using amine boranes (AB) of the type L-BH3 (where L = NH3, tert-BuNH2, Me2NH-, Me3N-) and sodium cyanotrihydroborate (CBH) (NaBH3CN) as derivatizing agents. Though a variety of reductants were suggested, THB is the most popular reductant used in analytical applications.48 4 Hypotheses Concerning the Hydride Generation Process According to Dedina,57 the mechanism of the reaction leading to the formation of hydrides is a matter of debate, and the different hypotheses of mechanisms can be classified into two categories. The first is based on the assumption that hydrides are formed by the action of “atomic hydrogen” or “nascent hydrogen”. The second includes all those mechanisms proposed by various workers who disagreed with the nascent hydrogen mechanism; it is called the “non-nascent hydrogen mechanism.” Based on the published literature up to 1995, Dedina et al.57 concluded that there was no convincing evidence for either of the two classes of mechanisms. 4·1 The nascent hydrogen mechanism From the time that Marsh58 conducted a test for As proposed in 1836 and subsequent stibine generation by Bloxam59 in 1861, untill recently this mechanism has been proposed by several authors. Robbins and Caruso60 in 1979 suggested that the acid decomposition of THB produces nascent hydrogen. Recently, Carrero et al.61 reported this mechanism to explain aciddependant hydride generation. Indirect support for the nascent hydrogen mechanism could be derived from studies of Wang and Barnes.62 They described a mathematical model for the pH dependency of hydride generation. Their theoretical predictions agreed well with the experimental results, and it was concluded that the efficiency of HG could be improved by the in situ generation of nascent hydrogen. Laborda et al.63 strongly objected to the nascent hydrogen mechanism, mainly concerning the formation of nascent hydrogen and the reduction of metal/metalloid, as indicated by a change of the oxidation state. Considering that the estimated standard potential for the H+/H couple is E0(H+/H) = –2.016 V, neither THB [E0(H3BO3)/BH4–) = –0.482 V], nor Zinc [E0(Zn2+/Zn) = –0.763 V] would be able to perform the reduction of protons to atomic hydrogen. He further pointed out that hydrides could also be generated in basic solutions64–67 and in an electrochemical process.49–55 In the case of EcHG, the hydrogen involved in the generation process does not have any special reducing property, because the electrons provided at a sufficient negative potential to the electrode are a reducing agent. In addition, there is a lack of agreement in assigning the oxidation number to the analyte/hydride, and hence knowing what is actually reduced, the analyte or the hydrogen, becomes ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 doubtful. According to Laborda et al.,63 the mechanism of HG could be written as Am+ + (m + n)/8 BH4– + 3(m + n)/8H2O → AHn + (m + n)/H3BO3 + 7(m – n)/8H+, where m represents the oxidation state of the analyte and n the coordination number of the hydride. The reaction would be analytically expressed as a hydrogenation reaction of the type A m+ + nH + (m + n)e → AHn. + – 1403 Table 1 Hydrolysis rate constants for hydroboran species formed during acid hydrolysis (0.1 – 1.1 H+) of THB in an 88% methanol–12% water solution Hydroboran species Khyda = –(d ln[hydroboron])/ dt Temperature/ ˚C H-BH3 (THB) H2O-BH3 K1 = Too fast to be measured K2 = 1.5 × 10–3 s–1 + 1.6 × 10–3 [H+]l mol–1 s–1 K3 ≈ 0 K3 = 1.7 × 10–2 s–1 K4 = 3.3 × 10–4 s–1 –78 –78 (H2O)2-BH2+ H2O-BH2-OH H2O-BH-(OH)2 –36 –36 The fact that hydrides could also be generated under basic conditions was sometimes put forth as evidence for a nonnascent hydrogen mechanism, since it is not compatible with the metal/acid system. However, Dedina et al.2 stated that, after the analyte is reduced in alkaline media, acidification generates the analyte hydride, which is still compatible with the nascent hydrogen mechanism. Qiu et al.67 generated stannane by mixing an acidic analyte soluition with alkaline THB and observed stannane up to pH 12. Their conclusion is that stannane generation proceeds via a non-nascent hydrogen mechanism, and stannane that generation and neutralization are synchronous reactions. This statement, according to D’Ulivo et al.,68 has led to the uncertainty of the reaction rate, and to the objection that it could be possible that nascent hydrogen is formed during the neutralization reaction, which thus poses some doubts about the fact that the findings of Qiu et al.67 can be considered as experimental evidence of the non-nascent hydrogen mechanism. D’Ulivo et al.68 generated stannane, stibine and bimuthine using THB and AB complexes in the pH range of 4.3 to 12.7. Based on kinetic calculations, they concluded that the nascent hydrogen mechanism failed to explain the generation of hydrides. According to them, under these pH values, the undecomposed borane complexes of AB are the only available species for hydride formation, and hence the transfer of hydrogen bonded to boron most probably forms the hydride. where L could be one or more groups among H2O, OH– and Cl– and n is charge, which could be –1, 0 or +1, depending on L. Under the unusual acidity employed in HG, the rate of acid hydrolysis of the hydroboran species appears to follow K1>K2>K3>K4. The rate constants of hydroboran species formed during the acid hydrolysis (0.1 – 1.1 H+) of THB in an 88% methanol–12% water solution, as reported by Wang and Jolly,74 is given in Table 1. According to them, the analyte elements differ in their selectivity to react with different hydroboran intermediates. In aqueous HCl media, Hg2+ and Sb3+ are very reactive and unselective towards all intermediates, implying that all three are equally reactive. Te4+ reacts preferentially with the hydroboran species formed in strong acid media, but Sn4+ is completely unreactive towards the same species. The analyte substrate of As3+, Se4+ and Bi3+ reacts selectively with some hydroboran species. Thus, the effectiveness of the derivatization processes depends on both the nature of the substrate containing the analyte and the nature of the hydroboran intermediate. 4·2 Formation of hydroboran intermediates Narsito et al.69 calculated the rate of formation (Kf) of hydrides as a function of the THB concentration. The results showed that, for Se, the values found for Kf were independent of the THB concentration up to 0.1% of THB; for As3+ and As5+, a slight dependency was noticed; and for Sb the dependency was considerable. Based on these findings, Narsito et al.69 proposed that hydride formation is not necessarily caused by decomposition of the THB reagent, but by some intermediate formed from its decomposition. The presence of these types of intermediates has been suggested by various workers.70,71 Studies of Krevoy and Hutchins72 supported the existence of an intermediate of the type H2-BH3 during the hydrolysis of THB. According to D’Ulivo,73 this intermediate and the precursor (BH4–) are the same independent of the pH, and loss of the first hydrogen of BH4– is the rate-determining step. Studies of Wang and Jolly74 on the decomposition of THB in a water–methanol solution indicated the existence of mono-, diand tri-hydroboran intermediates [H2O-BH(OH)2, (H2O)2-BH2+, Though the formation of such a type of H2O-BH3]. intermediates was stated during the early sixties,71,75 their role in the hydride derivatisation reaction has been suggested recently. D’Ulivo et al.76 in a recent study attempted to generate volatile hydrides from these hydroboran intermediates. According to them, the decomposition of THB in aqueous media follows a similar pattern as that of in a water–methanol 4·3 Role of pH in hydride generation The role played by the hydrogen ion concentration in analytical HG is two fold. First, it activates the analyte substrate to suitable chemical form; second, the hydrolysis of THB. Wang and Barnes62 described the theoretical pH dependence of hydride generation. A theoretical modeling and experimental study of As5+ and As3+ indicate that both reactions are pH dependent. However, As5+ reduction occurs in a lower pH region, which is restricted mainly by the dissociation of the borohydride. The reaction condition of As3+ is relatively broad, as has been verified in many experiments.77,78 Only a little dissociation of BH4– is necessary for As3+ hydride generation.57 Several authors studied the formation of arsine from As5+ and As3+ under different pH and THB concentrations.79–85 The determination of arsenic species, exploiting pH-dependant arsine generation is of interest to study by many authors.86–95 It was stressed by many authors that the analyte species must be fully protonated in order to generate arsine. Carrero et al.61 supposed that the reaction mechanism could be modified under different acid concentrations. They suggested that the protonation of analyte-thiolate complexes is necessary to permit its reaction with THB. The importance of the pH in activating the analyte precursor can be easily understood from the work of Bell and Kelly96 concerning the acid-catalysed reduction of nitrite to N2O by a weak reducing agent, Me3N–BH3 (KH+ = 1.2 × 10–4 l mol–1 S–1). They found that the rate of formation of N2O solution.74 Hence, by analogy, the stepwise decomposition of THB in a strongly acidic solution at room temperature could be K→ K→ K→ K→ 1 2 3 4 [BH3] or L-BH3n L2BH2n L3BHn B(OH)3, BH4– 1404 ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 increased by ~109 times by decreasing the pH from 5.85 to 0.3. It was concluded that the rate-determining step is a hydride attack to protonated nitrous acid, H2ONO+, or free NO+; this produces the nitrosyl hydride, HNO, which is rapidly converted into N2O by reaction with THB. The other, leading to the formation of SbD3, resulted from its reaction with B2D6, which was formed by a reaction of THB and H2SO4, followed by deuterium exchange. Pergnatis et al.,103 in their studies on arsine generation using duterated reagents and mass spectroscopy, observed that the reaction of As3+ and As5+ with NaBD4 in HCl and H2O produced AsD3 as the main product. When the reactions were performed in NaBH4, DCl and D2O, the main product was AsH3. If nascent hydrogen was involved in the above processes, all of the possible arsines randomly deuterated of type AsHnD3–n should have been formed. The findings of Pergnatis et al.103 strongly support the non-nascent hydrogen mechanism; particularly, the direct transfer of hydrogen atoms from boron to analyte species takes place. 2HNO → H2O + N2O. HONO + H+ ↔ H2ONO+ ↔ NO+ + H2O D’Ulivo et al.73 stated that considering HNO2 is a weak inorganic acid, a similar mechanism would also take place for the weak inorganic oxoacids of these metalloids, which are precursors in the analytical HG technique. In the case of Sb3+, by increasing the pH, the substrate would evolve into the following species: Sb3+ → SbO+ → SbO(OH) → SbO2–. Because SbO(OH) is insoluble, the antimonite SbO2– that is formed in alkaline solution is not reactive towards a THB attack. This indicates that the role of the pH in analytical HG could also be the formation of suitable analyte precursors. D’Ulivo et al.56 reported that suitable analyte precursors are obtained by increasing the acidity for Sb3+, As3+, Se4+ and Te4+, while the opposite behavior is observed for Bi3+. They also showed that the change in the efficiency of hydride generation was correlated to the variation in the structure of molecular species containing the analyte. Unsuccessful hydride generation in alkaline media mostly results from the loss of reactive species of the analyte, rather than from an inefficient degree of decomposition of the borane complex.68 4·4 Studies carried out with deuterated reagents The inconsistency of nascent hydrogen formation upon the decomposition of THB under acid medium has been demonstrated by various studies. Among these, studies carried out with deuterated reagents are important. The existence of the intermediate H2-BH3 indicates72 that molecular hydrogen, and not atomic hydrogen, is evolved during THB decomposition. Mesmer and Jolly97 carried out experiments on THB decomposition with deuterated reagents. The acid decomposition of KBD4 in 3 mol l–1 H2SO4 yielded HD as the main product (>90%), with 3 – 5% of D2 and H2. The hydrolysis of NaBH4 in D2O, resulted HD as the main product which represent a fraction >90%98 and 95%99 of the total hydrogen evolved. LiAlH4, the homologous compound of THB, has been used to prepare high-purity HD (99%) by the controlled hydrolysis of LiAlH4 with D2O at low temperature,100 indicating a similar mechanism as that described above. These studies indicate that the formation of nascent hydrogen is incompatible with the hydrolysis of THB, since it would have produced D2 and H2 as the main product in the above experiments. Craig et al.101 successfully derivatized methyl mercury (CH3Hg+) to its hydride, CH3HgH, at pH 4 with NaBH4 and to its deutrated form, CH3HgD, by a reaction with NaBD4. Freund102 prepared stibine by slowly adding an alkaline solution of Sb3+ (0.5 mol l–1) and KBH4 (0.4 mol l–1) to a solution of D2SO4 (2 mol l–1) prepared in D2O. The products were continuously stripped by nitrogen, trapped and purified. The main products identified were SbH3 (>93%) and SbD3 (∼7%), even though the total exchangeable hydrogen was 97% deuterium. The author proposed that there should be two pathways. One leading to the formation of SbH3, involves a 4·5 Electrochemical hydride generation Electrochemical hydride generation (EcHG) is an alternative to wet chemical methods, and has been studied in detail during the last 10 years.104–110 EcHG has recently been reviewed by Denkhaus et al.111 In EcHG the generation of hydrides is a three-step reaction on the cathode surface; deposition of the hydride forming elements onto the surface of the cathode and their reduction; formation of the hydrides and subsequent desorption of the hydrides. The deposition is connected with the reduction of the analyte, which depends on the nature of the cathode material. A detailed mechanistic electrolytic hydride generation was summarized by Denkhaus et al.112 The generation of hydrides follows two different mechanisms; electrocatalytic and electrochemical mechanisms, depending on the hydrogen overvoltage of the cathode material.113–116 In both mechanisms, the hydride-forming element must be reduced first and deposited on the cathode surface. Me + Xy+ + ye– → Me-X (Me, cathode surface; X, analyte) The electrocatalytic reaction mechanism is involved in the production of hydrogen atoms adsorbed on the surface of the cathodes with a low hydrogen overvoltage, whereby the discharge of hydronium ions to adsorbed H· atoms is facilitated and is characterized by the Volmer equation,117–119 Me + H3O+ + e– → Me-H + H2O (Volmer reaction; Me, cathode surface). The recombination of the adsorbed hydrogen atoms to form H2 follows the Tafel reaction,120 Me-H + Me-H → 2Me + H2 (Tafel reaction). To produce elemental hydrides, the adsorbed hydrogen atoms must recombine with the hydride-forming element adsorbed. This recombination reaction occurs stepwise, followed by desorption of the element hydride from the cathode surface: Me-H + Me-X → Me + Me-XH, → (n + 1) Me + XHn+1 Me-XH + nMe-H → nMe+ + Me-XHn+1 (Me, cathode surface; X, hydride forming element). The recombination to H2 competes with hydride formation. In electrochemical mechanism, the first step is the discharge of H3O+ ions on the cathode surface (Volmer reaction). The second step is the reaction of the deposited hydrogen atoms with ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 1405 the hydronium ions of the catholyte solution and subsequent electron transfer within the cathode surface. This reaction is called the Heyrowski reaction:121–123 probably due to electron release from the sulfur group, by analogy with alkoxy-borane and hydroxy boranes (RO-BH3–, HO-BH3–). On the other hand, the formation of analyte-cysteine complex was suggested by many authors48,132,134–136 in which the –OH group of protonated oxyacids of the hydride-forming element is replaced by the (–SR) group, which subsequently reacts with the BH4– and generates the hydrides: Me + H3O+ + e– → Me-H + H2O (Volmer reaction; Me, cathode surface), Me-H + H3O+ → Me-H2+ + H2O, Me-H2+ + e– → Me + H2 (Heyrowski reaction; Me, cathode surface). 2R-SH + RnAsO(OH)3–n → RS-SR + RnAs(OH)3–n + H2O, RnAs(OH)3–n + (3–n)R-SH → RnAs(SR)3–n + 2H2O, The formation of hydrides ensues from the surface of the cathode to the deposited hydride-forming element by charge transfer and a subsequent reaction with the hydronium ions of the electrolyte solution. It is possible that electron-charge-transfer proceeds simultaneously from the cathode surface to the adsorbed analyte, whereas the reaction of the adsorbed analyte with the hydronium ions runs stepwise.112 The overall reaction may be written as Me-X + me– + mH3O+ → XHm + mH2O + Me. Salzberg et al.50 proposed a similar mechanism for AsH3, where water molecules are reduced to H2, which is chemisorbed on elemental arsenic, forming a covalent hydride. 5 Effect of the Reaction Matrix and Thiols In HGAAS it is found that reaction matrix, type of acid, buffers and the addition of certain reagents enhances the analyte signal to a considerable extent. Such a signal enhancement in the HGAAS was first reported by Boampong et al.124 Brindle et al.125 reported the use of L-cysteine in the determination of arsenic in HG-DCP-AES as a signal enhancer. A similar effect was also reported for Sn126 and Ge.127,128 According to Chen et al.129 L-cysteine can speed up the rate of reduction by THB, thereby increasing the sensitivity. Anderson et al.130,131 suggested that the sulfur containing ligand was important in the reaction, and that the same effect was produced by thioglycerol, thiourea and thioacetic acid. It has also been reported that L-cysteine reduces the transition metal interference and acts as acid-base buffer, enhancing better stability of the hydrides.132 Brindle et al.125 showed that there is a compound formed between NaBH4 and the SH group of L-cysteine, which may be the reagent, which is a more potent reducing agent than NaBH4 alone. BH4– + RSH → RS-BH3– + H2 The formation of the above type of complex was assumed because it may be generated by the reduction of the disulfide:124 R-S-S-R + BH4– → RSH + R-S-BH3– (R-CH2CH(NH2)COOH) In another study, Brindle and Le133 found that in an aqueous solution of L-cysteine, pencicillamine and thioglycerol gave thiolotrihydroborate(III) anions. The formation of thiolotrihydroborate(III) was confirmed by 11B NMR at thiol/THB in the range of 0.66 to 0.83 M. The authors proposed that the thiol ligand competes with the solvent for forming the complex with BH3. D’Ulivo73 suggested that the enhanced reactivity of thiol-borane complex with respect to THB is RnAs(SR)3–n + BH4– → RnAsH3–n + (3–n)BH3 + (3–n)RS–, BH3 + 3H2O → H3BO3 + 3H2 ↑. These authors commented that the THB-thiol reaction did not explain the fact that the arsine yield depends on the prereaction between the analyte species and cysteine, prior to the addition of THB. Lee et al.137 reported that, though intermediate As-S compounds are formed, the final product, does not, incorporate the thiol group. According to Howard et al.,134 the thus-formed complexes are less sterically hindered with respect to the THB attack than the parent attack. Jolly138 in his work on the preparation of hydrides of As, Ge, Sb and Sn discussed the importance of accessibility of the hydride-forming atom to a THB attack. However, Carrero et al.61 suggested that the protonation of thiolate complexes is necessary to permit the reaction with BH4–. An important conclusion, which could be drawn from the studies reported by various authors, is that suitable substrate precursors are essential to facilitate a BH4– attack. This seems to be reasonable. The two reaction pathways supported by various studies seem to be acceptable, at least with the current status of knowledge. The specific role played by the thiol-analyte and thiol-THB interaction in the derivatization process of As needs to be studied further. However, the thiol modified reaction does not produce any appreciable signal enhancement in the generation of stibine139 and bismuthine140 in a continuous-flow system. D’Ulivo73 suggested that the lack of a detectable effect on stibine and bismuthine generation should not necessarily be ascribed to the lack of an interaction between the analyte and the thiols. On the other hand, Sb3+, Bi3+ present a more pronounced cationic character compared to As3+, and it is likely that their analyte substrates (SbO+, Sb(OH)2+, BiO+) already present a suitable reactivity towards a hydride attack of an unmodified hydroboran species. For As3+, the species As(OH)3 is probably not reactive enough for a hydride attack, and thiols modifies the analyte substrates reactivity towards THB. In the case of stannane generation, L-cysteine increases the signal only at higher acidity values.141,142 However, L-cysteine suppresses the signal during SeH2 and TeH2 generation, and must be considered in some cases as interfering species.143 This may probably be due to the formation of a much less reactive analyte substrate of the type RS-Se-SR and RS-Te-SR. 5·1 Effect of halide ions Agterdenbos et al.144 reported that halide ions (Cl–, Br– and I–) have a beneficial effect on the generation of SeH2 by THB in a continuous-flow reaction system. The authors studied the effect of HCl, HNO3 and H2SO4 on SeH2 generation, and found that with HNO3 and H2SO4 the addition of Cl– and Br– to the reaction system produced a signal equivalent to that generated by HCl. 1406 ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 The authors called it as a “catalytic effect”. The addition of I– to the reaction mixture reduced the signal, which was ascribed to the preferential reduction of Se4+ to Se. Interestingly, if I– was added to BH4–, it enhanced the signal more than that produced by other halide ions. D’Ulivo et al.73 stated that the effect of I– could be due to the formation of the iodide–THB interaction, which produced hydroboran species that were more resistant to acid hydrolysis. Another possible explanation stated by D’Ulivo et al.76 is that the additive–analyte interaction could lead to the formation of a halogenated species, such as SeOX2, SeX4 or SeX62–, in which the analyte substrate is more reactive towards THB than the simple H2SeO3 species. combination of the enthalpy values used for the calculation of Kd is correct. However, there are some inconsistencies that cause doubt concerning this mechanism, one of which is the temperature, itself. Whereas in heated quartz tubes, typically temperatures of around 800 – 900˚C are found to be optimum for the atomization of arsine,159,160 the same hydrides are atomized at 1700 – 1800˚C in a graphite-tube furnace.161,162 The second fact was that the addition of oxygen or air to the purge gas increased the sensitivity,163,164 and the highest sensitivities were found for extremely fuel-rich hydrogen–oxygen flames burning inside unheated quartz tube atomizers,165,166 with an optimum H:O ratio of 5:1; the third fact was a pronounced influence of the quartz cell surface on the analyte signal.167–169 6 Atomization of Volatile Hydrides in the Quartz Cell The first reference to using a quartz tube atomiser, in this instance electrically heated (EHQT) as an alternative to an Ar–H2 flame, appeared in a report of Chau et al.145 in 1972. In 1974, Thompson and Thomerson30 published a report on the use of THB and a flame-heated silica tube as the atomizer. Similar externally heated quartz tube atomizers were reported by various authors.146–149 An internal flame, or flame-in tube (FIT), which utilized the hydrogen-oxygen, was introduced by Simer and Hageman.150 It does not need to be heated. Of the several quartz tube atomizers reported, the most popular one is the flame heated quartz tube (FHQT), because of its excellent sensitivity, low cost and easy operation.2 The question of the atomization mechanism of gaseous, covalent hydrides in heated quartz tubes, as frequently used in the HGAAS technique, is not fully understood. It has been found that various instrumental and experimental parameters have a profound influence on the atomization mechanism. In addition, there are some inconsistencies that arise in the atomization among different hydrides, e.g. arsine and selenium hydride require different temperatures and carrier gas composition for obtaining the maximum signal. 6·1 Atomization via thermal decomposition Soon after introducing quartz tube atomizers, the general opinion, however appeared to be that the hydrides are atomized by thermal decomposition. Thomson and Thorsby,151 for example, referred to an “electrothermal atomization” of arsine in a heated quartz tube. This opinion was probably due to the similarity of electrically heated quartz tube atomizers and flame-heated quartz tubes reported by various workers.152–156 The increased analytical sensitivity with increasing temperature up to a maximum,156–158 as reported by various workers, might led to this conclusion as being the atomization mechanism. The thermal decomposition of hydrides are generally written as AHn(g) → A(g) + n/2H2(g). (1) Agterdenbos et al.158 made a thermodynamic calculation of the equilibrium constant values, Kd, for the decomposition of SeH2 in the temperature range of 600˚C to 2000˚C. SeH2 → Se + H2 ↑ (2) The theoretical calculations predicted the decomposition to occur at 800˚C and by experiment it was found that maximum atomization occurred at 700˚C. This fairly good agreement suggests that Eq. (2) governs the decomposition of SeH2 in the heated quartz tube. This conclusion is correct only if the 6·2 Oxidation of the hydride Bax et al.169 calculated the equilibrium constant of Eq. (1) for the atomization of AsH3 from the free energies of the various possible analyte species. Their results showed that: the decomposition occurs at a temperature of 1200˚C if only As and AsH3 are considered and at a temperature of 1500˚C if polymeric species are included in the calculation. Practically, however, appreciable atomization already occurs at 700˚C, which suggests that arsine is not atomized according to Eq. (1). Narsito et al.168 supposed that the decomposition reaction of the type in Eq. (1) could be reversed by the addition of excess hydrogen; instead atomization was efficient with an increase of extra hydrogen for AsH3. However, increasing the amount of hydrogen in selenium hydride atomization decreased the signal, which the authors supposed to be due to a reversal of the reaction in Eq. (2). For this reason, Bax et al.170 concluded that arsenic behaves differently from selenium. Bax et al.170 experimentally calculated the Kd values for the decomposition of selenium hydride (Kd = 0.26 atm), and found fairly good agreement with the Kd value calculated from thermodynamic data (Kd = 0.18 atm) by Agterdenbos et al.158 However, the experimental value of Kd remains constant for higher temperatures against the expectations of higher values. This discrepancy did not support Eq. (2) as the atomization process. The authors169 assumed that oxygen in the carrier gas oxidizes the hydrides to atoms, as given by 4AsH3 + 3O2 → 4As + 6H2O. Narsito et al.69 also suggested that the atomization of arsenic and other elements, like Antimony hydrides, follows a similar mechanism, as proposed by Bax et al.:169 AHn(g) + n/4O2(g) → A(g) + n/2H2O. (3) Narsito et al.69 made similar thermodynamic calculations for the decomposition of SbH3, and found that SbH3 dissociated at 400˚C if only Sb and SbH3 were considered, and at about 900˚C if the dimerization reaction was also included. The experimental atomization occurs at about 500 – 600˚C, which did not agree with the theoretical calculations, like arsenic. Several authors69,168–171 confirmed an increase of the analytical signal by the addition of extra hydrogen and oxygen, which led to an inference that these gases play a role during the atomization process. According to Narsito et al.,69 the lowest temperature at which the hydrides are decomposed or oxidized to atoms is about the same for the three elements, i.e. As, Sb and Se (about 700˚C). They assumed that some common factor initiates the atom formation. According to them, the role of oxygen is to oxidize the analyte hydride into the atom, as per ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 1407 Eq. (3), and the excess of oxygen decreases the analyte signal, probably due to the reaction of the type may be reatomized, but only upon another contact with H· radicals. Welz and Melcher181 carried out in-depth studies on the atomization mechanism of arsine in an electrically heated quartz tube atomizer. They found that purging the sample with nitrogen, or boiling the solution for 15 min before the reaction with THB, caused a decrease in the analytical signal. This led to the conclusion that the oxygen in dissolved air favored atomization. In another study,181 the authors reported that the introduction of pure arsine into the quartz tube produced no signal at all. The signal was resumed if a blank reaction mixture having THB and HCl was injected simultaneously. This indicated the same degree of atomization for both cases. From these experiments, the authors concluded that the hydrogen evolved by the acid decomposition of THB was essential in the formation of analyte atoms. This was further confirmed by signal enhancement, if extra hydrogen was added with the stripping gas. The authors also reported that the quartz cell surface affects the analytical sensitivity considerably if not conditioned i.e. a treatment with HF. From these studies, Welz and Melcher181 concluded that: 1) hydrogen is essential and plays an active role in the atomization of gaseous hydride forming elements in quartz cell atomizers heated at 1000˚C; 2) oxygen supports atomization in the presence of hydrogen, at least at lower quartz cell temperatures; 3) in the presence of oxygen, the effective temperature of the vapor phase in the heated quartz cell is not higher than in pure argon; 4) the maximum sensitivity can be obtained only in the cleaner environment of a quartz cell conditioned with HF; and 5) in the absence of H2 arsine is decomposed, but not atomized in a quartz cell. Based on these observations, the authors proposed that the atomization of volatile hydrides in a heated quartz cell must be due to collisions with free hydrogen radicals, as follows: 2As + 3O2 → 2As2O3. The role of hydrogen is to prevent the analyte atoms from forming the oxide; moreover, the role of both gases may be to form radicals, which probably take part in arsine oxidation. 6·3 Free radical mechanism The effect of oxygen on the atomization of As and Sb hydrides in the heated quartz tubes was first reported by Gouldden et al.164 They reported that an increase in the sensitivity could be obtained if oxygen was added to the purge gas. Similarly, Siemer et al.172 based on their studies on the optimization of arsine generation in flame-in quartz tube atomizers, found that the sensitivity could be increased by using hydrogen for stripping the arsine, rather than using argon or nitrogen. According to Siemer et al.,172 carrier gases like Ar and N2 dilute the analyte atoms within the atomizer, but no reason was given for the observed sensitivity increase. Dedina et al.173 studied the atomization of SeH2 in a cool hydrogen-oxygen flame burning in an unheated quartz tube, and proposed that atomization is brought out by collisions of the analyte hydride with the hydrogen free radicals. The hydrogen generated from the acid decomposition of THB, or added to the reaction mixtures, is the source of hydrogen atoms, and is produced in the primary reaction zone of the diffusion flame according to the following equations: → OH· + O, H· + O2 ← (4a) O· + H2 ← → OH· + H·, (4b) → H2O + H·. OH· + H2 ← (4c) MHx + H → MHx–1 + H2, McCrum174 has stated that the equilibrium constant of Eq. (4c) is very high and the hydrogen concentration is much higher than the water concentration. Thus atomization is via a two step mechanism with the predominating H· radicals: SeH2 + H· → SeH + H2 ∆H = –189 kJ/mol, (5a) SeH + H· → Se + H2 ∆H = –131 kJ/mol. (5b) A further reaction that should be taken into account is recombination, Se + H· → SeH ∆H = ±305 kJ/mol. (5c) By taking into account Eqs. (5a) – (5c), equilibrium is attained after a sufficiently large number of collisions with H-radicals. With increasing atomic weight (e.g. As-Sb-Bi), fewer free radicals are required for atomization, due to the higher efficiency of the larger and less stable hydride molecules. Dedina et al.173 made extensive studies on the atomization mechanism of AsH3, SeH2 in various types of quartz tube atomizers, i.e. EHQT,175 flame-in-gas-shield (FIGS),176,177 miniature diffusion flame (MDF),178 and a multiple microflame quartz tube atomizer (MMQT).179 He speculated that the radical mechanism of atomization appears to be identical to all types of quartz-tube atomizers,180 and it proceeds only in a small part of the atomizer volume. After that, the free atoms disappear from the observation volume by forced convection and by chemical reactions (free atom population decay). Once reacted, species MH + H → M + H2. The hydrogen radicals were probably formed by the same reactions with oxygen as proposed by Dedina et al.173 for the fuel rich oxygen-hydrogen flame. The proposed mechanism satisfactorily explains the observations made by several authors, that the need of hydrogen for atomization and oxygen enhances the sensitivity of the analyte signal. The authors suggested that in the absence of hydrogen, AsH3 is decomposed, but not atomized until a temperature of 1700˚C is reached, which is the typical temperature used in graphite-furnace atomizers. The temperatures of quartz-tube atomizers favor the decomposition of arsine with the formation of the tetramer or the dimmer, as follows: → 2As2 ←→ 4As. As4 ← The authors did not rule out the possibility of oxide formation in the absence of hydrogen. The conclusions made by Welz and Melcher181 were supported by Akman et al.182 They studied the atom formation mechanisms in GFAAS with the direct introduction of arsenic and arsine. In the direct injection method at a furnace temperature of about 1700˚C, it was found that arsenic is vaporized into AsO and atomized by dissociation of the oxide. However, in the direct injection of arsine, AsH3 is decomposed on the graphite surface before the atomization temperature is 1408 ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 reached, and the metallic arsenic is vaporized as As4, which is then decomposed to As2 dimers, and finally atomized by gasphase dissociation. However, there were some objections to the free-radical mechanism. Bax et al.169 raised the question that the reaction requires the presence of H· radicals in at least twice as high as the pressure of SeH2 molecules (approximately 10–7 atm). However, at temperatures of around 650 – 700˚C, decomposition of SeH2 already occurs, and at this temperature the equilibrium concentration for H, calculated from thermodynamic data for the H2 ↔ 2H· equilibrium, is about 100 or 1000-times lower. The same authors criticized the conclusions of Welz and Melcher181 that hydrogen radicals are required for the decomposition, since no absorbance signal was found if the absorption cell was not conditioned. Bax et al.170 reported that the amount of H· radicals present is probably by far not sufficient for these reactions. Agterdenbos et al.183 reported that OH· radicals may play a role in the decomposition reaction, since H2 and O2 gases are needed for atomization. However, Welz and Melcher181 stated that such a role was improbable, since the concentrations of OH· radicals are much lower than H· radicals. However, the authors183 assumed that the catalyst acts at even very low concentrations. In contrast, Welz and Melcher181 speculated that in the heated quartz cell the number of H radicals should increase with increasing temperature as well as increasing oxygen concentration, up to a certain optimum. Moreover, because radical recombination is a considerably slower process than their formation, a concentration well above the equilibrium values can be expected in a heated quartz cell, in the absence of any radical scavengers. The hydrogen free-radical mechanism is strongly supported by various studies, mainly interference studies made by Dedina184 on the atomization of AsH3 and SeH2. According to him, inside the quartz tube the interferent may reduce the population of H· radicals by accelerating their decay, thereby reducing the fraction of atomized analyte hydrides. These types of interferences mostly depend on the design of the quartz cell and the gas flow. In addition, the interferent may accelerate the decay of the free analyte atoms in the quartz tube, which is called self-interference by D’Ulivo and Dedina.185 This type of self-interference or analyte decay interference probably decides the fate of free atoms. The mechanism proposed by Dedina et al.173 and Welz and Melcher,181 satisfactorily explains the need of hydrogen and oxygen and their role in the atomization process. According to them, oxygen enhances the formation of H free radicals. Welz and Melcher181 explained the temperature-dependant sensitivity by stating that quartz has a strong catalytic effect at temperatures of around 1000˚C and that hydrogen radicals are formed by the decomposition of H2 molecules at the quartz surface. The concentration of H· free radicals will be maintained above the equilibrium concentration, since the competing process i.e. radical recombination is comparatively a slow process. 4. M. Eva Moreno and C. Perez-Conde, Anal. Bioanal. Chem., 2003, 375, 666. 5. H. W. Sun, J. Ha, J. M. Sun, D. Q. Zhang, and L. L. Yang, Anal. Bioanal. Chem., 2002, 374, 526. 6. I. Ipolyi and P. Fodor, Anal. Chim. Acta, 2000, 413, 13. 7. M. O. Andreae, Anal. Chem., 1977, 49(6), 820. 8. J. Morda-Pineiro, M. Luisa Cervera, and Miguel de La Guardia, J. Anal. At. Spectrom., 1997, 12, 1377. 9. M. L. Kokot, At. Absorption Newsl., 1976, 15, 105. 10. W. M. Mok and C. M. Wai, Water Res., 1989, 23, 7. 11. W. M. Mok, J. A. Riley, and C. M. Wai, Water Res., 1998, 22, 769. 12. J. Y. Cabon and N. Cabon, Anal. Chim. Acta, 2000, 418, 19. 13. J. Guimont, M. Pichelte, and N. Rheaume, At. Absorption Newsl., 1977, 16, 53. 14. A. Kuldvere, Analyst, 1989, 114, 125. 15. A. Takatsa and A. Uchiumi, Analyst, 1998, 123, 73. 16. M. Burguera and J. L. Burgurea, Talanta, 1997, 44, 1581. 17. Z. Stejkovvec, J. T. Van Elteren, and U. D. Woroniccka, Anal. Chim. Acta, 2001, 443, 277. 18. M. E. Moreno, C. Perez-Conde, and C. Camera, J. Anal. At. Spectrom., 2000, 15, 680. 19. H. L. Kahn and J. E. Schallis, At. Absorption Newsl., 1968, 7, 5. 20. W. Holak, Anal. Chem., 1969, 41, 1712. 21. R. E. Madsen, At. Absorption Newsl., 1971, 10, 57. 22. E. F. Dalton and A. J. Malanoski, At. Absorption Newsl., 1971, 10, 92. 23. F. J. Fernandez and D. C. Manning, At. Absorption Newsl., 1971, 10, 86. 24. D. C. Manning, At. Absorption Newsl., 1971, 10, 123. 25. E. N. Pollock and S. J. West, At. Absorption Newsl., 1971, 11, 104. 26. R. S. Braman, L. L. Justen, and C. C. Foreback, Anal. Chem., 1972, 44, 2195. 27. F. J. Schmidt and J. L. Royer, Anal. Lett., 1973, 6, 17. 28. E. N. Pollock and S. J. West, At. Absorption Newsl., 1973, 12, 6. 29. F. J. Fernandez, At. Absorption Newsl., 1973, 12, 93. 30. K. C. Thompson and D. R. Thomerson, Analyst, 1974, 99, 595. 31. A. Sanz-Medal, Y. Valdes-Hevia, M. C. Temprano, N. B. Gracia, and M. R. F. De La Campa, Anal. Chem., 1995, 67, 2216. 32. X. W. Guo and X. M. Guo, J. Anal. At. Spectrom., 1995, 10, 987. 33. J. S. Busheina and J. B. Headridge, Talanta, 1982, 29, 519. 34. D. Yan, Z. Yan, G. S. Cheng, and A. M. Li, Talanta, 1984, 31, 133. 35. L. Ebdon, P. Goodal, S. J. Hill, P. Stockwell, and K. C. Thompson, J. Anal. At. Spectrom., 1995, 10, 317. 36. R. E. Sturgeon, J. Liu, V. J. Boyko, and V. T. Luong, Anal. Chem., 1996, 68, 1883. 37. A. S. Luna, R. E. Sturgeon, and R. C. Campos, Anal. Chem., 2000, 72, 3523. 38. X. M. Guo, B. Huvang, Z. Sun, R. Ke, Q. Wang, and Z. B. Gong, Spectrochim. Acta, Part B, 2000, 55, 943. 39. T. Matousek, J. Dedina, and M. Vobecky, J. Anal. At. Spectrom., 2002, 17, 52. 40. H. Sun, R. Suo, and Y. Lu, Anal. Chim. Acta, 2002, 457, 305. 41. Y. L. Feng, J. W. Lam, and R. E. Sturgeon, Analyst, 2001, 126, 1833. 42. J. Y. Cabon and N. Cabon, Fresenius J. Anal. Chem., 2000, 7 References 1. S. J. Hill, J. B. Dawson, W. J. Price, I. L. Shuttler, C. M. M. Smith, and J. F. Tyson, J. Anal. At. Spectrom., 1999, 14, 1245. 2. J. Dedina and D. L. Tsalev, “Hydride Generation Atomic Absorption Spectroscopy”, 1995, Wiley, New York. 3. N. M. M. Coelho, A. Cosmen da Silva, and C. Moraes da Silva, Anal. Chim. Acta, 2002, 460, 227. ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 1409 368, 484. 43. H. Wen, S. J. Ha, J. M. Sun, and D. Q. Zhang, and L. L. Yang, Fresenius J. Anal. Chem., 2002, 374, 526. 44. J. F. Chapman and L. S. Dale, Anal. Chim. Acta, 1979, 111, 137. 45. H. Narasaki and M. Ikeda, Anal. Chem., 1984, 56, 2059. 46. S. A. Amankwah and J. L. Fasching, Talanta, 1985, 32(2), 111. 47. A. E. Smith, Analyst, 1975, 100, 300. 48. A. G. Howard, J. Anal. At. Spectrom., 1997, 12, 267. 49. L. Tolimson, J. Electrochem. Soc., 1964, 111, 592. 50. H. W. Salzberg and B. Goldschmidt, J. Electrochem. Soc., 1960, 107, 348. 51. A. M. Espinosa, M. L. Tascon, M. D. Varyquez, and P. S. Batanero, Electrochim. Acta, 1992, 37, 1165. 52. D. M. Heuber and J. D. Winefordner, Anal. Chim. Acta, 1995, 316, 129. 53. F. Laborda, E. Bolea, and J. R. Castillo, J. Anal. At. Spectrom., 2000, 15, 103. 54. W. W. Ding and R. E. Sturgeon, Spectrochim. Acta, Part B, 1996, 51, 1325. 55. W. W. Ding and R. E. Sturgeon, J. Anal. At. Spectrom., 1996, 11, 225. 56. A. D’Ulivo, V. Loreti, M. Onor, E. Pitzalis, and R. Zamboni, Anal. Chem., 2003, 75, 2591. 57. J. Dedina, “Flow Methods in Gas-liquid Separations” in A. Sanz-Medal (ed.), “Flow Analysis with Atomic Spectrometric Detection”, 1989, Elsevier, Amsterdam, 237 – 273. 58. J. Marsh, New Edinburgh Philos. J., 1836, 229. 59. C. L. Bloxam, Q. J. Chem. Soc., 1861, 13, 12. 60. W. B. Robbins and J. A. Caruso, Anal. Chem., 1979, 51, 889A. 61. P. Carrero, A. Malave, J. Luis, M. Buguera, and C. Rondon, Anal. Chim. Acta, 2001, 438, 195. 62. X. R. Wang and R. M. Barnes, Spectrochim. Acta, Part B, 1986, 41, 967. 63. F. Laborda, E. Bolea, M. T. Baranguan, and J. R. Castillo, Spectrochim. Acta, Part B, 2002, 57, 797. 64. T. Wickstrom, W. Lund, and R. Bye, Analyst, 1995, 120, 2695. 65. T. Wickstrom, W. Lund, and R. Bye, J. Anal. At. Spectrom., 1998, 10, 389. 66. R. Bye, J. Autom. Chem., 1989, 11, 156. 67. D. R. Qiu, C. Vandecasteelie, K. Vermeiren, and R. Dams, Spectrochim. Acta, Part B, 1990, 57, 439. 68. A. D’Ulivo, C. Baiocci, E. Pitzalis, M. Onor, and R. Zamboni, Spectrochim. Acta, Part B, 2004, 59, 471. 69. Narsito, J. Agterdenbos, and S. J. Santosa, Anal. Chim. Acta, 1990, 237, 189. 70. R. E. Mesmer and W. L. Jolly, Inorg. Chem., 1962, 1, 608. 71. R. E. Davis, E. Bromels, and C. L. Kibby, J. Am. Chem. Soc., 1962, 84, 885. 72. M. M. Kreevoy and J. E. C. Hutchins, J. Am. Chem. Soc., 1972, 94, 6371. 73. A. D’Ulivo, Spectrochim. Acta, Part B, 2004, 59, 793. 74. F. T. Wang and W. L. Jolly, Inorg. Chem., 1972, 11, 1933. 75. J. A. Gardiner and J. W. Collat, J. Am. Chem. Soc., 1965, 87, 1692. 76. A. D’Ulivo, M. Onor, and E. Pitzalis, Anal. Chem., 2004, 76(21), 6342. 77. M. H. Arabab-Zaver, Analyst, 1980, 105, 744. 78. A. V. Shaikh and D. E. Taliman, Anal. Chim. Acta, 1978, 98, 251. 79. P. D. Wentzell, N. G. Sundin, and C. Hogeboon, Analyst, 1994, 119, 1403. 80. T. R. Rude and H. Puchelt, Fresenius Z. J. Anal. Chem., 1994, 350, 44. 81. S. Nielsen and E. H. Hansen, Anal. Chim. Acta, 1997, 343, 5. 82. Y. Yano, T. Miyama, A. Ito, and T. Yasuda, Anal. Sci., 2000, 16, 939. 83. J. Aggett and A. C. Aspell, Analyst, 1976, 101, 341. 84. R. S. Braman, D. L. Johnson, C. C. Foreback, J. M. Ammins, and J. L. Bricher, Anal. Chem., 1977, 49, 621. 85. M. O. Andreae, Anal. Chem., 1977, 49, 820. 86. A. V. Shaikh and D. E. Tallman, Anal. Chim. Acta, 1978, 98, 251. 87. C. Felsman, Anal. Chem., 1979, 51, 664. 88. M. Verlinden, J. Barrt, and H. Deelstra, Talanta, 1980, 27, 633. 89. A. G. Howard and M. H. Arab-Zavar, Analyst, 1981, 106, 213. 90. T. A. Hinners, Analyst, 1980, 105, 751. 91. M. Yamamoto, K. Urata, K. Murashige, and Y. Yamamoto, Spectrochim. Acta, Part B, 1981, 36, 671. 92. S. Nakashima, Analyst, 1979, 104, 172. 93. Y. Yamamoto and T. Kumamaru, Fresenius Z. J. Anal. Chem., 1976, 282, 355. 94. P. W. Vijan and G. D. Wood, Analyst, 1976, 101, 966. 95. H. D. Fleming and R. G. Ide, Anal. Chim. Acta, 1976, 83, 67. 96. K. E. Bell and H. C. Kelly, Inorg. Chem., 1996, 35, 7225. 97. R. E. Mesmer and W. L. Jolly, J. Am. Chem. Soc., 1962, 84, 2039. 98. T. Freund, J. Inorg. Nucl. Chem., 1959, 9, 246. 99. W. L. Jolly and E. Mesmer, J. Am. Chem. Soc., 1961, 83, 4470. 100.I. Wender, R. A. Friedel, and M. Orchin, J. Am. Chem. Soc., 1949, 71, 1140. 101.P. J. Craig, D. Mennie, N. Ostah, O. F. X. Donard, and F. Martin, Analyst, 1992, 117, 823. 102.T. Freund, J. Am. Chem. Soc., 1991, 83, 2279. 103.S. A. Pergantis, W. Winnik, E. M. Heitmar, and W. R. Cullen, Talanta, 1997, 44, 1941. 104.X. O. Wang, Z. X. Zhuang, P. Y. Yang, and B. L. Huang, Microchem. J., 1995, 316, 88. 105.W. W. Ding and R. E. Sturgeon, Spectrochim. Acta, Part B, 1996, 51, 1325. 106.W. W. Ding and R. E. Sturgeon, J. Anal. At. Spectrom., 1996, 11, 225. 107.W. W. Ding and R. E. Sturgeon, J. Anal. At. Spectrom., 1996, 11, 421. 108.D. Schaumloffel and B. Neidhart, Fresenius Z. J. Anal. Chem., 1996, 354, 866. 109.E. Bolea, F. Laborda, M. A. Bellara, and Y. R. Castillo, Spectrochim. Acta, Part B, 2001, 56, 2347. 110.J. Sima, P. Rychlovsky, and J. Dedina, Spectrochim. Acta, Part B, 2004, 59, 125. 111.E. Denkhaus, A. Golloch, X-M. Guo, and B. Huang, J. Anal. At. Spectrom., 2001, 16, 870. 112.E. Denkhaus, F. Beck, P. Bueschler, R. Gerhard, and A. Gollach, Fresenius J. Anal. Chem., 2001, 370, 735. 113.F. Beck, Chem. Ing. Tech., 1976, 48, 1096. 114.W. M. Lestie and J. A. V. Butler, Trans. Faraday. Soc., 1936, 32, 989. 115.S. V. N. Szabo, Z. Phys. Chem., 1938, 181, 367. 116.K. F. Bonhoeffer, Z. Phys. Chem., 1924, 113, 199. 117.M. Volmer and H. Wick, Z. Phys. Chem., 1932, 172, 429. 118.J. Tafel, Z. Phys. Chem., 1905, 50, 641. 1410 ANALYTICAL SCIENCES DECEMBER 2005, VOL. 21 119.J. Tafel and K. Naumann, Z. Phys. Chem., 1905, 50, 713. 120.P. Rutschi and P. Delahay, J. Chem. Phys., 1955, 23, 195. 121.I. J. Heyrowski, Rec. Trav. Chim., 1927, 46, 582. 122.J. Horiuti and M. Ikusima, Proc. Imp. Acad., 1939, 15, 39. 123.G. Okamoto, J. Horiuti, and K. Hirota, Sci. Papers Inst. Chem. Res., 1936, 29, 223. 124.C. Boampong, I. D. Brindle, X.-C. Le, L. Pidwerbesky, and C. M. C. Ponzoni, Anal. Chem., 1988, 60, 1185. 125.I. D. Brindle and X.-C. Le, Anal. Chem., 1989, 61, 1175. 126.I. D. Brindle, X.-C. Le, and X.-F. Li, Analyst, 1988, 113, 1377. 127.I. D. Brindle and X.-C. Le, J. Anal. At. Spectrom., 1989, 4, 227. 128.I. D. Brindle and X.-C. Le, Anal. Chim. Acta, 1990, 229, 239. 129.H. Chen, I. D. Brindle, and X.-C. Le, Anal. Chem., 1992, 64, 667. 130.R. Anderson, M. Thompson, and E. Culbard, Analyst, 1986, 111, 1143. 131.R. Anderson, M. Thompson, and E. Culbard, Analyst, 1986, 111, 1153. 132.D. L. Tsalev, A. D’Ulivo, L. Lampugnai, M. Di Marco, and R. Zamboni, J. Anal. At. Spectrom., 1996, 11, 989. 133.I. D. Brindle and X.-C. Le, Anal. Chim. Acta, 1990, 229, 239. 134.A. G. Howard and C. Salou, Anal. Chim. Acta, 1996, 333, 89. 135.B. Welz and M. Sucmanova, Analyst, 1993, 118, 1425. 136.A. Shraim, B. Chiswell, and H. Olszoay, Talanta, 1999, 50, 1109. 137.X. C. Le, W. R. Cullen, and K. J. Reimer, Anal. Chim. Acta, 1994, 285, 277. 138.W. L. Jolly, J. Am. Chem. Soc., 1961, 83, 335. 139.A. D’Ulivo, L. Lampugnai, G. Pelligrini, and R. Zamboni, J. Anal. At. Spectrom., 1995, 10, 969. 140.A. D’Ulivo, E. Bramanti, L. Lampugnai, and R. Zamboni, Spectrochim. Acta, Part B, 2001, 56, 1893. 141.H. W. Chen, W. Yao, D. X. Wu, and I. D. Brindle, Spectrochim. Acta, Part B, 1996, 51, 1829. 142.A. D’Ulivo, E. Bramanti, L. Lampugnai, and R. Zamboni, Spectrochim. Acta, Part B, 2001, 56, 1893. 143.K. Marcucci, R. Zamboni, and A. D’Ulivo, Spectrochim. Acta, Part B, 2001, 56, 393. 144.J. Agterdenbos, J. T. M. Van Elteren, D. Bax, and J. P. Ter Heege, Spectrochim. Acta, Part B, 1986, 41, 303. 145.R. C. Chau, G. P. Barron, and P. A. W. Baumgarner, Anal. Chem., 1972, 44, 1476. 146.D. L. Collett, D. E. Fleming, and G. A. Taylor, Analyst, 1978, 103, 1074. 147.D. E. Fleming and G. A. Taylor, Analyst, 1978, 103, 101. 148.J. W. Robinson, R. Gracia, G. Hindman, and P. Selvin, Anal. Chim. Acta, 1974, 69, 203. 149.W. H. Evans, F. J. Jackson, and D. Dellar, Analyst, 1979, 104, 16. 150.D. D. Siemer and L. Hagemann, Anal. Lett., 1975, 8, 323. 151.A. J. Thomson and P. A. Thoresby, Analyst, 1977, 102, 9. 152.M. Verlinden, H. Deelstra, and E. Adriaenssens, Talanta, 1981, 28, 637. 153.D. Booke Hatfield, Anal. Chem., 1987, 59, 1887. 154.F. D. Pierce, T. C. Lamoreaux, H. R. Brown, and R. S. Frazer, Appl. Spectrosc., 1976, 30, 38. 155.F. D. Pierce and H. R. Brown, Anal. Chem., 1977, 49, 1417. 156.R. D. Wauchope, At. Absorption Newsl., 1976, 15, 64. 157.B. Welz and M. Melcher, Anal. Chim. Acta, 1981, 46, 17. 158.J. Agterdenbos, J. P. M. Van Noort, F. F. Peters, D. Bax, and J. P. Ter Heege, Spectrochim. Acta, Part B, 1985, 40(3), 501. 159.M. Fishman and R. Spencer, Anal. Chem., 1977, 49, 1599. 160.B. Welz and M. Melcher, Spectrochim. Acta, Part B, 1981, 36, 439. 161.W. A. Maher, Anal. Chim. Acta, 1981, 126, 157. 162.M. M. McDaniel, A. D. Shendrikar, K. D. Reiszner, and P. W. West, Anal. Chem., 1976, 48, 2240. 163.P. N. Vijan and G. R. Wood, Talanta, 1976, 23, 89. 164.P. D. Goulden and P. Brooksbank, Anal. Chem., 1974, 46, 1431. 165.J. Dedina and I. Rubeska, Spectrochim. Acta, Part B, 1980, 35, 119. 166.A. Mayer, C. Hofer, G. Tolg, S. Raptis, and G. Knapp, Fresenius Z. J. Anal. Chem., 1979, 296, 337. 167.D. C. Reamer, C. Veillon, and P. T. Tokousbalides, Anal. Chem., 1981, 53, 245. 168.Narsito and J. Agterdenbos, Anal. Chim. Acta, 1987, 197, 315. 169.D. Bax, J. T. VanElteren, and J. Agterdenbos, Spectrochim. Acta, Part B, 1986, 41, 1007. 170.D. Bax, F. F. Peters, J. P. M. Van Noort, and J. Agterdenbos, Spectrochim. Acta, Part B, 1986, 41, 275. 171.B. Welz and M. Melcher, Anal. Chim. Acta, 1981, 46, 17. 172.D. D. Siemer, P. Koteel, and V. Jariwala, Anal. Chem., 1976, 48, 836. 173.J. Dedina and I. Rubeska, Spectrochim. Acta, Part B, 1985, 35, 119. 174.M. McCrum, “Principles of Atomic Absorption Spectrometry”, 1999, GBC Scientific Equipment, Australia, 44 – 45. 175.J. Dedina and B. Welz, J. Anal. At. Spectrom., 1992, 7, 307. 176.J. Dedina and A. D’Ulivo, Spectrochim. Acta, Part B, 1997, 52, 1737. 177.A. D’Ulivo and J. Dedina, Spectrochim. Acta, Part B, 1996, 51, 481. 178.J. Dedina, A. D’Ulivo, L. Lampugnani, T. Matousek, and R. Zamboni, Spectrochim. Acta, Part B, 1998, 53, 1777. 179.T. Matousek, J. Dedina, and A. Selecka, Spectrochim. Acta, Part B, 2002, 57, 451. 180.T. Matousek, J. Dedina, M. Johansson, and W. Frech, Spectrochim. Acta, Part B, 2000, 55, 151. 181.B. Welz and M. Melcher, Analyst, 1983, 108, 213. 182.S. Akman, O. Genc, and T. Balkis, Spectrochim. Acta, Part B, 1982, 37(10), 903. 183.J. Agterdenbos, J. P. Van Noort, F. F. Peters, and D. Bax, Spectrochim. Acta, Part B, 1986, 41, 283. 184.J. Dedina, Anal. Chem., 1982, 54, 2097. 185.A. D’Ulivo and J. Dedina, Spectrochim. Acta, Part B, 2002, 57, 2069.