fatigue and fracture testing of additive manufactured materials

advertisement

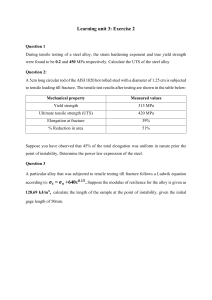

Fatigue and fracture testing of additively manufactured materials Chang Zhao 13484050 catalog What is additive manufacturing Why need tests What is Mechanical failure Failure forms of mechanical parts Causes of mechanical parts failure Type of test Test standard testing machine plan What is additive manufacturing Additive manufacturing technology, also known as 3D printing technology, is a combination of computer-aided design, material processing and molding technology. It is a kind of manufacturing technology based on digital model, by using software and control system, the special materials are stacked layer by layer according to extrusion, sintering, melting, UV curing, spraying, etc., to manufacture solid parts. Compared with the traditional processing mode of raw material removal cutting and assembly, it is a "bottom-up" manufacturing method through material accumulation. This makes it possible to manufacture complex structural parts which were constrained by traditional manufacturing methods and could not be realized in the past. This technology does not need traditional tools, fixtures and multiple processing procedures. It can quickly and accurately manufacture any complex shape parts on one equipment, thus realizing the "free manufacturing" of parts, solving the forming of many complex structural parts, greatly reducing the processing procedures and shortening the processing cycle. Moreover, the more complex the product structure, the more significant the effect of manufacturing speed. Why need tests Mechanical testing is a common testing used for explore the mechanical properties of materials. When using the materials, Material failure is a very common phenomenon, and often lead to very bad or even fatal results. Only when the mechanical properties are known, the failure of the material can be avoided in the process of use. This is the safe use of materials must know. Thus analysis in mechanical properties of applied materials is quite important and necessary. What is Mechanical failure The failure of mechanical parts refers to the partial or complete loss of design function of parts in the process of use. If the parts are completely damaged and can not continue to work; or the parts have been seriously damaged, if they continue to work, they will lose safety; or although they can work safely, but have lost the design accuracy, they are all failure. In order to prevent the failure of parts, it is necessary to analyze the failure of parts, that is, by judging the failure form of parts, determining the failure mechanism and causes, selecting materials pertinently, determining the reasonable processing route, and putting forward the measures to prevent failure. Failure forms of mechanical parts The common failure forms of mechanical parts can be divided into three types: excessive deformation failure, fracture failure and surface damage failure. (1) Excessive deformation failure: Failure of parts due to excessive deformation exceeding the allowable range. It mainly includes excessive elastic deformation, plastic deformation and creep under high temperature. (2) Fracture failure: The phenomenon that parts are separated into two or more parts which are not connected with each other due to excessive bearing capacity or fatigue damage. Fracture is the most serious failure mode, which includes ductile fracture failure, low temperature brittle fracture failure, fatigue fracture failure, creep fracture failure and environmental fracture failure. (3) Surface damage failure: The failure caused by surface relative friction or corrosion by environmental media on the surface of the part caused by damage or size change. It mainly includes surface wear failure, corrosion failure and surface fatigue failure. It should be noted that parts often have more than one failure when they are working. However, there is always a type of failure that plays a leading role. In this project we focus on excessive deformation failure and fracture failure. Mechanical failure cases Causes of mechanical parts failure There are many and complex factors that cause the failure of mechanical parts, involving the structural design, material selection, material processing and manufacturing, product assembly, use and maintenance, etc. (1) Unreasonable design: It mainly refers to the incorrect or unreasonable structure and shape of parts, such as the existence of gaps, small arc corners, transition areas of different shapes, etc. On the other hand, it refers to the insufficient estimation of the working conditions and overload conditions of the parts, resulting in the insufficient actual working capacity of the parts, resulting in the early failure of the parts. (2) Unreasonable material selection: Wrong judgment on the failure form of parts in the design, the performance of the selected material can not meet the needs of working conditions; the performance index based on which the material selection is based can not reflect the resistance of the material to the actual failure form, and the wrong material is selected; the quality of the selected material is too poor, and the composition or performance of the material can not meet the design requirements. (3) Unreasonable processing technology: Improper processing technology of parts may produce various defects, leading to early failure of parts in the use process. For example, overheat, overburnt and banded structure appear in hot working process; decarburization, deformation and cracking appear in heat treatment process; deep tool marks and grinding cracks appear in cold working process. (4) Improper installation and use: The assembly and installation process does not meet the technical requirements, such as too tight, too loose, inaccurate alignment, unstable fixation, etc., may lead to the parts can not work normally or fail prematurely; in addition, illegal operation, overload, overspeed, untimely repair and maintenance in the process of use will also cause premature failure of parts. Type of test Bending test: Bending test is one of the basic methods to measure the mechanical properties of materials under bending load. In bending test, one side of the specimen is uniaxial tension, the other side is uniaxial compression. The maximum normal stress appears on the surface of the sample, which is sensitive to surface defects. Therefore, bending test is often used to inspect the surface defects of materials, such as carburizing or surface quenching layer quality. Tensile test: Tensile test is a test method to determine material properties under axial tensile load. The elastic limit, elongation, elastic modulus, proportional limit, area reduction, tensile strength, yield point, yield strength and other tensile properties can be determined by using the data obtained from tensile test. Test standard This experiment strictly follows a series of test standards. ISO 13003:2003 Fibre-reinforced plastics — Determination of fatigue properties under cyclic loading conditions ISO 527 Plastics — Determination of tensile properties — Part 1: General principles ISO 14125 Fibre-reinforced plastic composites — Determination of flexural properties ISO 178 Plastics — Determination of flexural properties ISO 1268 Fibre-reinforced plastics — Methods of producing test plates ISO 291 Plastics — Standard atmospheres for conditioning and testing Standard for specimen preparation (ISO 527 & ISO 14125) Create CAD model of specimens Tensile test bending test Testing machine INSTRON Universal testing machine All test items in this project need to be carried out on Instron universal testing machine. So far After determining the project topic, collect relevant literature, discuss the content to be tested, and select the literature that meets the needs Literature review Research proposal Looking for test standards Create the CAD model of the specimen meeting the test standard. Determine some test parameters. Future plan The next semester will start to carry out the experiment, because the experimental variables are numerous and complex, so it will take a long time. Estimate: February: Getting ready for the experiment. March: Start tensile test, including fatigue and failure, test repeatedly to meet the specified standard, and sort out the data. April: Start bending test, including fatigue and failure, test repeatedly to meet the specified standard, and sort out the data. May: Sort out test data, prepare presentation, write report and PPT. Thank you Additive manufacturing equipment Markforged X7 The software can be quickly and seamlessly integrated into the manufacturing ecosystem. Obtaining industrial-grade parts in hand in hours, not weeks — the X7 enables engineers and designers to fundamentally improve their manufacturing operation at light speed. Product features Carbon Fiber Strength The X7 3D prints Continuous Carbon Fiber reinforced parts in hours that are as strong as — and capable of replacing — machined aluminum. Functional Parts of All Types Whatever your functional requirements are — flame resistant, chemical resistant, energy absorbent, high resolution, draft parts — the X7 has an industrial material or print mode capable of fabricating a functional part for you. Industrial Reliability and Accuracy Precision-machined hardware, advanced sensors, and unique software drive industry leading accuracy and reliability. Only Markforged industrial 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with 50 μm repeatability and industry-leading surface finish. Software Eiger What is Eiger A software suitable for Markforged X7 and dovetails into workflow It is basically a digital part repository It is a simple part library that enables users to dynamically manage engineering projects of any size — complete with versioning, permissioning, and advanced security It is a powerful prep and print software. Effortlessly print metal, continuous fiber, and composite base parts on a single cloud-based interface. features. Processing mode Different processing methods also have certain influence on the properties of the materials. The mechanical properties can be obviously changed by adding method, quantity, layer number and arrangement position, which needs many experiments.