FANUC-OPERATOR’S MANUAL FOR LATHE 63344EN 02

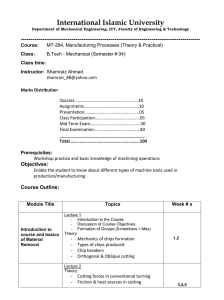

advertisement