08PR005C Guidelines in Conducting a JHA

advertisement

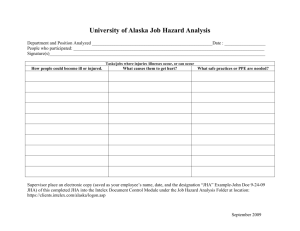

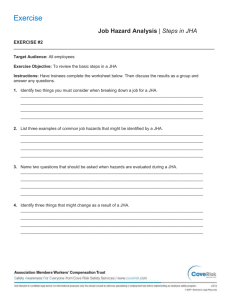

SAFETY MANAGEMENT SYSTEM PROCEDURE 08PR005C GUIDELINES IN CONDUCTING A JHA Brierty Ltd ABN 65 095 459 448 72 Melville Parade South Perth WA 6151 Locked Bag 2001 South Perth WA 6951 Telephone (08) 9267 8000 Facsimile 1300 735 152 info@brierty.com.au GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE CONTENTS 1 Purpose ...................................................................................................................................................... 4 2 Responsibilities ........................................................................................................................................... 4 3 Procedure Details ....................................................................................................................................... 4 3.1 When to Conduct a JHA .................................................................................................................... 4 3.2 Description of the JHA Technique ..................................................................................................... 4 3.3 Breaking the Job into Basic Steps ..................................................................................................... 5 3.4 Identifying the Potential Hazards ....................................................................................................... 5 3.5 Recording the Risk ............................................................................................................................ 5 3.6 Determining the Preventive Measures or Controls ............................................................................ 7 3.6.1 Elimination by:................................................................................................................................ 7 3.6.2 Substitution by: .............................................................................................................................. 7 3.6.3 Redesigning the Work Method by:................................................................................................. 7 3.6.4 Separating Exposures by: .............................................................................................................. 8 3.6.5 Administrative Exposures by: ........................................................................................................ 8 3.6.6 Personnel Protective Equipment: .................................................................................................. 8 3.6.7 Follow-up ....................................................................................................................................... 8 3.6.8 Recording....................................................................................................................................... 8 3.6.9 Reviewing JHA............................................................................................................................... 8 3.6.10 Expiry of JHA ............................................................................................................................. 8 3.6.11 JHA at Work Site........................................................................................................................ 8 3.6.12 Compact Cards or Procedures .................................................................................................. 9 ДОКУМЕНТ1 10-JAN-19 2 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE DOCUMENT CONTROL Document ID 08PR005C Date 15/09/08 20/03/09 31/07/09 23/09/09 27/10/09 29/01/10 22/06/10 19/07/10 11/4/12 02/05/12 16/06/13 Document Name Guidelines in conducting a JHA Version 1 2 3 4 5 6 7 8 9 10 11 Description Safe Work Procedure Safe Work Procedure Upgrade Safe Work Procedure Upgrade Safe Work Procedure Upgrade Safe Work Procedure Upgrade Safe Work Procedure Upgrade Safe Work Procedure Upgrade New Document Control Guidelines Reviewed grammar and spelling details Amended JHA Review process Added new “simplified” risk matrix option for applicable sites Comment Originator S. Hart S. Hart S. Hart S. Hart S. Hart S Hart S Hart K Berridge S Hart S Hart S Hart Reviewer S. Hart S. Hart S. Hart S. Hart T. Thompson E Kelman T. Thompson S. Hart Jennifer Graham Approver T. Abrahams Stuart Crofts Stuart Crofts Stuart Crofts Stuart Crofts S Hart Stuart Crofts Stuart Crofts T Thompson T Thompson B Bryan B Bryan DEFINITIONS AND ABBREVIATIONS Term Abbreviation Comment Job Hazard Analysis JHA Hazard Identification Process of the Task ДОКУМЕНТ1 10-JAN-19 3 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE 1 PURPOSE The purpose of this procedure is to provide guidance and instruction to personnel that will be involved with the following: Confine Space Vessel Entry Any job that is out of the ordinary Any change of work method Any change of procedures & works instruction Any client or regulatory mandatory requirement. Any “High Risk Work” as defined in the National Standard for Construction Work This procedure shall apply to Brierty employees and contractors working at any of their locations. 2 RESPONSIBILITIES The responsibility of issuing and reviewing the Job Hazard Analysis rests with the Brierty Area Supervisor or their designated nominee. It is the responsibility of the site Supervisor to ensure that the above safe systems of work as well as any site requirements for hazard recognition is complied with and undertaken before the task is started. It is the responsibility of the workers or their Safety Representative to be involved in the development of JHAs. 3 PROCEDURE DETAILS 3.1 WHEN TO CONDUCT A JHA It is the responsibility of the Supervisor directly in charge of the job to ensure a JHA is completed when required by the system. The workers (Including subcontractors) or their Safety Representative must be involved in the development of the site specific JHAs. All jobs are subject to a JHA, however due to the practical constraints of the time and effort required, a job to be analysed shall be identified and given priority on the following basis: 3.2 When frequency and severity of incidents require that analysis to be conducted. When the consequences of an incident are potentially severe. When a new job is established. When a new Safe Work Instruction or Procedure is created. When an existing Safe Work Instruction or Procedure is modified. As per Clients request or Works Contract Guidelines Any client or regulatory mandatory requirement. Conducting any “High Risk Work” as defined in the National Standard for Construction Work DESCRIPTION OF THE JHA TECHNIQUE A JHA is prepared to ensure that each basic step of the job is examined to identify potential hazards and to determine the safe method to undertake the job. The basic stages in conducting a JHA are: ДОКУМЕНТ1 10-JAN-19 4 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE 3.3 Selecting the job to be analysed. Breaking the job down into a sequence of steps. Identifying potential hazards. Determining preventive methods to overcome these hazards. Documenting the results. Approval and sign-off and implementation BREAKING THE JOB INTO BASIC STEPS Having identified the job to be analysed, it should then be broken down into its component steps. Most jobs can be described in less than ten steps. The steps are to be recorded in the correct sequence otherwise the analysis may be invalid, due to missing potential hazards or by introducing hazards which don’t exist. A JHA work sheet is provided to assist with recording the steps. Record each step in sequence, noting WHAT is to be done, not HOW by observing the usual worker doing the job under normal conditions where possible. This may indicate that you can do the job. Commence the recording of each step with a verb, e.g. lift, turn, open, close, etc. Record the steps in the left-hand column of the work sheet and when complete validate the sequence of steps by checking the steps with other workers who are familiar with the job. 3.4 IDENTIFYING THE POTENTIAL HAZARDS The potential hazards can now be identified for each step of the job and entered in the centre column of the work sheet. For each step, ask the following questions and any others you can think of, and if the answer is YES or PROBABLY or POSSIBLY a hazard or potential hazard has been identified and must be recorded. 3.5 CAN any part of the body get caught in or between an object? DO tools, machines or equipment used for the job present any hazards? CAN objects / machinery contact the worker? CAN the worker slip, trip or fall? CAN the worker suffer strain from lifting, pushing or pulling? IS the worker exposed to extreme heat or cold? IS excessive noise or vibration a problem? IS there a lighting problem? CAN weather conditions affect the worker? IS harmful radiation a possibility? ARE flammable or explosive substances present? CAN contact be made with hot, toxic, acidic or caustic substances? ARE there dusts, fumes, mists or vapours in the air? If work is carried out can Energy be released? Is the atmosphere healthy or can it become dangerous? ARE there particular skills or is special training required? RECORDING THE RISK The risk recording is to be documented as per the Risk Matrix. The process includes the following factors; injury and disease, environmental impact, social or cultural heritage, community, government, media or reputation, legal, operational impact and cost. The Likelihood should be determined first, followed by the Consequence, where these meet on the matrix will be the Risk Rating, as shown on the next page. (E.g. Possible + Minor = M18 or Be Alert) ДОКУМЕНТ1 10-JAN-19 5 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE Brierty’s preference is to use the risk matrix shown below (where Client approval can be obtained) as it is more intuitive and easier to understand for personnel new to the industry. ДОКУМЕНТ1 10-JAN-19 6 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE 3.6 DETERMINING THE PREVENTIVE MEASURES OR CONTROLS The preventive measures will now have to be determined to eliminate or control the identified hazards; they should be listed in order of preference by adopting the hierarchy of control, as illustrated below. The HIERARCHY OF CONTROLS should be applied in the following order :ELIMINATE : The complete elimination of the hazard. REDESIGN : Redesign the equipment or work processes. SEPARATE : Isolating the hazard by guarding or enclosing it. A number of these options may be considered and applied individually, or in combination. ADMINISTRATE : Providing control such as training, procedures etc. of nce tions p fere Pre ent O atm Tre SUBSTITUTE : Replacing the material or process with a less hazardous one. PERSONAL PROTECTIVE EQUIPMENT : Use properly fitted PPE where other controls are not practical; impact minimisation equipment such as spill clean up material or dust suppression measures. When identifying and selecting controls and preventative measures, it is preferred to place hard controls such as Eliminate, Substitute, Redesign and Separate, as these are physical barriers for improvement. Soft controls such as Administration and PPE are the last resort. 3.6.1 3.6.2 3.6.3 Elimination by: Eliminate the necessity for the job. Choose a different work method. Modify the existing work method. Improve environment (e.g. forced ventilation/heating/cooling). Modify or change tools or equipment. Substitution by: Ordering a safer chemical than the more hazardous one. Substituting that heavier tool for a lighter one. Use a lighter sling Substitute a heavier SWL shackle for the lighter SWL. Substitute a forklift for the pallet jack Redesigning the Work Method by: Change the steps, which are hazardous. Change the sequence of steps. Add additional steps/manual assistance/mechanical assistance. Add spotters/warning signage/warning devices/monitors. Relocate the job to a safer area. Change timing of job to eliminate or reduce hazards. Enclosures/screens/barricades. ДОКУМЕНТ1 10-JAN-19 7 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE 3.6.4 3.6.5 3.6.6 3.6.7 Separating Exposures by: Separate the employee from the task Guarding/shielding/insulating Worker booths or similar devices. Administrative Exposures by: Implementing Procedures Implementing Inspections Quality Control Auditing Personnel Protective Equipment: Hard Hat Safety Glasses, Goggles etc Respirators, Face masks Clothing Steel cap boots Encapsulated Suits Spray suits Follow-up Once the JHA is completed and all identified hazards have been considered and controls determined, the designated nominee who conducted the JHA shall forward it to the Supervisor for review and approval. The Supervisor can then determine whether the JHA has captured the appropriate information or not. If the Supervisor is satisfied the JHA meets the criteria, they are to sign off the JHA in the appropriate section. The Supervisor shall be responsible for ensuring the implementation is on a consultative basis with employees, and where appropriate, with the site OH&S Representative or Safety Department. 3.6.8 Recording The Project Manager or Nominee shall ensure that all approved JHA’s are filed and are to be maintained by the site. 3.6.9 Reviewing JHA A sample of JHA’s shall be reviewed on a monthly basis using the JHA Review Checklist; once the checklist has been completed it shall be attached to the back of the JHA. ALL Subcontractor JHAs must be reviewed using the checklist and signed off. 3.6.10 Expiry of JHA A JHA is valid for a maximum of one (1) month and must be signed on to by every person accessing that work area. After this point a new JHA shall be completed and signed on by the team conducting the task. 3.6.11 JHA at Work Site Where practicable the Supervisor shall ensure a JHA or Copy of the JHA shall be located at the work area for the following reasons: Can be easily referred to when needed; Visitors visiting the site can sign onto the JHA; If there is a change of conditions or work method the team can change the JHA then and there to reflect it; Regulators visiting can see the correlation between the works and the JHA to ensure compliance; Adopting best practice as well as a client requirement in some cases; ДОКУМЕНТ1 10-JAN-19 8 OF 9 GUIDELINES IN CONDUCTING A JHA SAFETY MANAGEMENT SYSTEM PROCEDURE The Supervisor can ensure that the work method is being under taken as per the JHA by inspecting the work areas and referring to the JHA for compliance; this will assist with the Safe Acts Observation Process. 3.6.12 Compact Cards or Procedures Compact Cards are an abbreviated version of Brierty Limited’s Safe Work Procedures that are available through the Brierty intranet, located on B-Online. The intention of these Compact Cards is to make available a quick and easy reference to assist all personnel capturing the ‘Key Points’ of the Safe Work Procedures. It is highly recommended that the full procedures are read by Management and any personnel performing the task covered by the Compact Card if there are any discrepancies. Compact Cards shall be utilised when compiling JHA’s as the relevant compact card can then be attached to the JHA to assist personnel in complying with Brierty Limited’s Procedures. ДОКУМЕНТ1 10-JAN-19 9 OF 9