Technical Note

Various Schemes for Strengthening Concrete Structures

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

guin, Ph.D., F.ASCE.1

Gilbert H. Be

Abstract: Increased traffic loads and the creation of passages and openings in buildings by cutting a piece of slab or a portion of a wall require

the strengthening of the weak or impaired member. Means are various: addition of a supporting beam, prestressing the section with external

tendons, attaching steel plates or carbon-fiber-reinforced plastic (CFRP) strips to the weak face of a slab or wall. Adding a steel beam with the

purpose of creating a composite action between the beam and slab was critically examined. Strength as well as rigidities of the modified structure were affected. DOI: 10.1061/(ASCE)SC.1943-5576.0000377. © 2018 American Society of Civil Engineers.

Author keywords: Structural upgrading; Slabs; Arch bridge; Extra-supporting members; Postcomposite action; Posttensioning; Glued

reinforcement.

Strengthening a Bridge Deck

Introduction

Increased traffic loads demand the assessment of the load capacity

of urban structures, and in the case of deficiencies, a strengthening

of the deficient elements is required. In buildings, the cutting of

openings in slabs and in walls often requires a strengthening of the

regions adjacent to the opening.

Strengthening by Adding Concrete

This is the first solution that comes to mind. This method has to

cope with two basic problems: (1) the bond between new and older

concrete, and (2) the effect of shrinkage and creep in the new concrete on this bond. In Europe, where the concrete of roadways is often protected by an impervious membrane topped by a thickness of

bituminous material, the removal and replacement of such cover

prevents the application of this method.

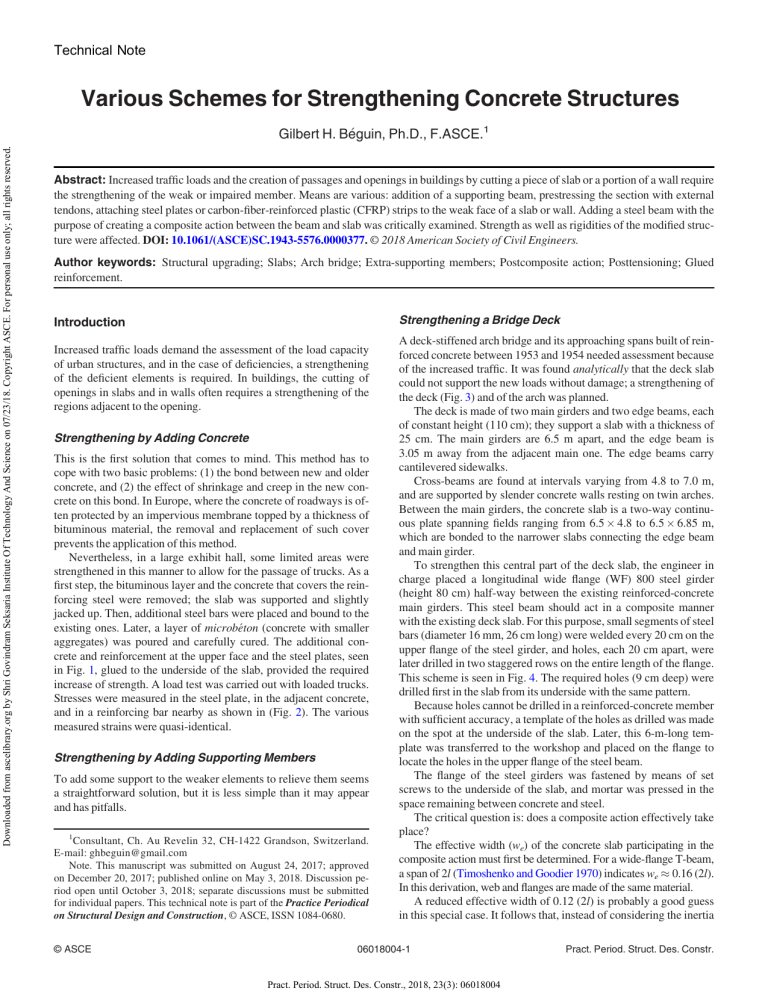

Nevertheless, in a large exhibit hall, some limited areas were

strengthened in this manner to allow for the passage of trucks. As a

first step, the bituminous layer and the concrete that covers the reinforcing steel were removed; the slab was supported and slightly

jacked up. Then, additional steel bars were placed and bound to the

existing ones. Later, a layer of microbeton (concrete with smaller

aggregates) was poured and carefully cured. The additional concrete and reinforcement at the upper face and the steel plates, seen

in Fig. 1, glued to the underside of the slab, provided the required

increase of strength. A load test was carried out with loaded trucks.

Stresses were measured in the steel plate, in the adjacent concrete,

and in a reinforcing bar nearby as shown in (Fig. 2). The various

measured strains were quasi-identical.

Strengthening by Adding Supporting Members

To add some support to the weaker elements to relieve them seems

a straightforward solution, but it is less simple than it may appear

and has pitfalls.

1

Consultant, Ch. Au Revelin 32, CH-1422 Grandson, Switzerland.

E-mail: ghbeguin@gmail.com

Note. This manuscript was submitted on August 24, 2017; approved

on December 20, 2017; published online on May 3, 2018. Discussion period open until October 3, 2018; separate discussions must be submitted

for individual papers. This technical note is part of the Practice Periodical

on Structural Design and Construction, © ASCE, ISSN 1084-0680.

© ASCE

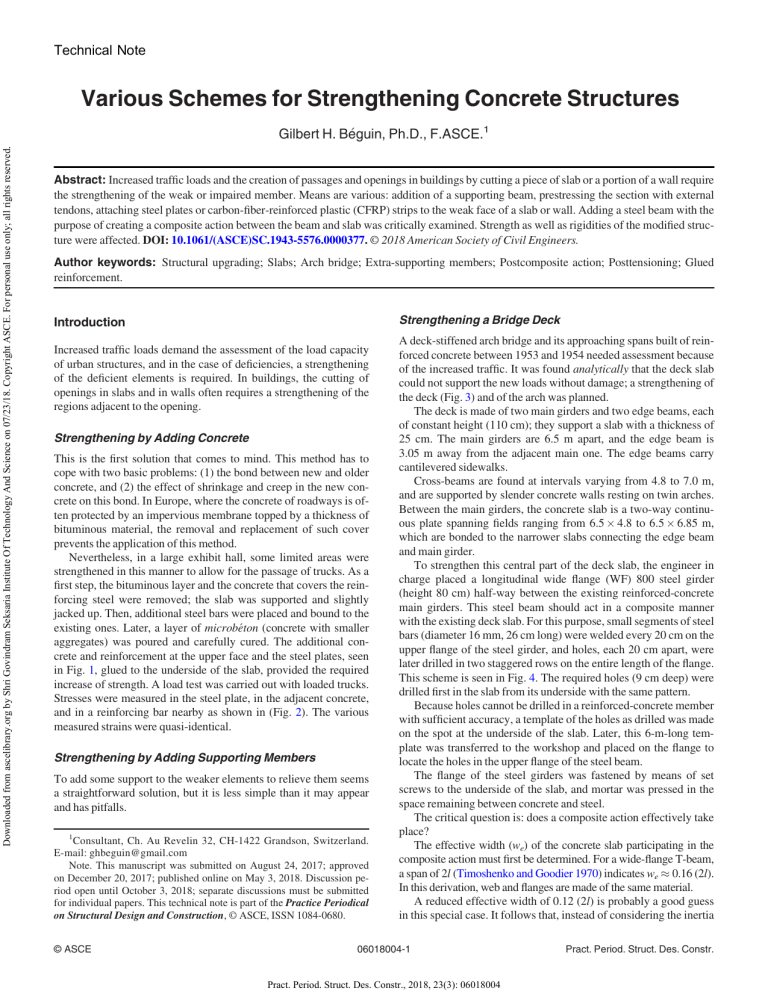

A deck-stiffened arch bridge and its approaching spans built of reinforced concrete between 1953 and 1954 needed assessment because

of the increased traffic. It was found analytically that the deck slab

could not support the new loads without damage; a strengthening of

the deck (Fig. 3) and of the arch was planned.

The deck is made of two main girders and two edge beams, each

of constant height (110 cm); they support a slab with a thickness of

25 cm. The main girders are 6.5 m apart, and the edge beam is

3.05 m away from the adjacent main one. The edge beams carry

cantilevered sidewalks.

Cross-beams are found at intervals varying from 4.8 to 7.0 m,

and are supported by slender concrete walls resting on twin arches.

Between the main girders, the concrete slab is a two-way continuous plate spanning fields ranging from 6.5 4.8 to 6.5 6.85 m,

which are bonded to the narrower slabs connecting the edge beam

and main girder.

To strengthen this central part of the deck slab, the engineer in

charge placed a longitudinal wide flange (WF) 800 steel girder

(height 80 cm) half-way between the existing reinforced-concrete

main girders. This steel beam should act in a composite manner

with the existing deck slab. For this purpose, small segments of steel

bars (diameter 16 mm, 26 cm long) were welded every 20 cm on the

upper flange of the steel girder, and holes, each 20 cm apart, were

later drilled in two staggered rows on the entire length of the flange.

This scheme is seen in Fig. 4. The required holes (9 cm deep) were

drilled first in the slab from its underside with the same pattern.

Because holes cannot be drilled in a reinforced-concrete member

with sufficient accuracy, a template of the holes as drilled was made

on the spot at the underside of the slab. Later, this 6-m-long template was transferred to the workshop and placed on the flange to

locate the holes in the upper flange of the steel beam.

The flange of the steel girders was fastened by means of set

screws to the underside of the slab, and mortar was pressed in the

space remaining between concrete and steel.

The critical question is: does a composite action effectively take

place?

The effective width (we) of the concrete slab participating in the

composite action must first be determined. For a wide-flange T-beam,

a span of 2l (Timoshenko and Goodier 1970) indicates we 0.16 (2l).

In this derivation, web and flanges are made of the same material.

A reduced effective width of 0.12 (2l) is probably a good guess

in this special case. It follows that, instead of considering the inertia

06018004-1

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

of the sole steel profile (35.91 dm4), a greater inertia (73.14 dm4)

must be taken into account, the geometrical parameters of the concrete section being reduced by a factor 10. The designer intended

the reinforcing beam to act as a continuous member; the extremities

of adjacent beams were tied with two high-stress bolted ties

26.5 mm in diameter placed in the upper part of the end plate of

each WF 800 profile. In the area where negative moment acts in the

WF 800, the concrete layer adjoining steel was stressed in tension;

positive bending moment in the longitudinal direction was found in

only approximately 27% of the span on each side of the midspan.

Fig. 1. Steel plates at the underside of slab (Image by author)

The condition of equal deflection of slab and beam, say at midspan, under two loads of 100 kN some 1.2 m apart in a 6-m

clamped square slab yielded a force of 127.2 kN acting between

slab and WF 800. The compressive stress at midspan at the upper

face of the steel section was 398 N/cm2 (i.e., 40 N/cm2 in the

adjacent concrete). These computations postulated a perfect bond

between steel flange and adjoining concrete. But between concrete and steel, there was a 2–3-cm layer of mortar with a modulus

of elasticity close to 2 106 N/cm2.

The maximum strain at the base of the layer of mortar was equal

to « max = 40/2 106 = 0.2 10−4, but the drying shrinkage of a

mortar, which can hardly be properly cured, was approximately

0.4 10−4; this reduced the postulated composite action. Moreover,

the shear deformation of the layer of mortar—examined in the appendix—further limited a perfect binding of steel beam and concrete slab.

Thus, it appears that there was a lower limit to the ratio

span=height of girder, under which one cannot expect a composite

action between steel and concrete. In composite bridges, this ratio is

close to 20, whereas in the case at hand, it was equal to 7.5.

This manner of strengthening the deck with a stiff beam has a

drawback: it causes negative bending moment in the slab at the top of

the WF 800 girder in the transverse direction, at midspan, where

most steel lies near the bottom of the slab. To stiffen the weak part of

the deck, one could place three or more longitudinal steel beams

instead of one. The spacing and rigidities of these beams would be

chosen to minimize the negative transverse bending in the deck at the

top of the beams. To reduce the stressing of the main longitudinal

reinforcing steel, one could attach a few steel plates or carbon-fiberreinforced plastic (CFRP) strips to the underside of the concrete slab.

In short, a few well-distributed stiffening beams are better than one.

Strengthening Arches of a Deck-Stiffened Arch Bridge

Fig. 2. Measurement of strains (Image by author)

The engineer in charge of the rehabilitation of this bridge (Fig. 5)

found by analysis that the twin arches were too weak to carry the

increased traffic loads; the engineer planned a strengthening scheme

in which the first two bays, on each side of the arch bridge, were

stiffened with a pair of hollow steel profiles (diameter 245 mm)

placed diagonally in each bay. The connection of the additional

members at the junctions of arch and cross wall is shown in Fig. 6.

Concrete blocks were poured at the joints and were anchored by

means of four longs bolts provided with a large square head. The

bolts were set in holes previously drilled in the arch. A plastic sleeve

drawn over the length of the bolt allowed the later stressing of the

long bolts. At the opposite side, two large U-bolts, later embedded

in the block, fastened the end plate welded at the extremities of the

tubular members. After the six bolts were in place, the concreting of

the blocks began.

Fig. 3. Bridge cross section; WF = Wide Flange

© ASCE

06018004-2

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

Fig. 4. Connection of steel flange to concrete slab; WF = wide flange

to a central part acting as a stiffened arch. Axial forces appeared in

the deck, and the cross walls suffered increased stressing. At the

junction of the truss to the remains of the original structure, unexpected bending moment appeared in the arch and in the deck, too.

This alteration of the original system was said to increase the

buckling load of the twin arches, although the buckling length and

the rigidity of the members of the arch were left unchanged.

Aesthetically, this solution is hardly satisfactory (Fig. 8).

Originally, the vertical loads transmitted by the cross walls were

taken up almost entirely by the arch, whose axial rigidity was

approximately 10 times that of the added steel diagonals.

Observations (deflections, stress measurements) were never made

either before rehabilitation or afterward. This absolute reliance on

computations is miles away from Maillart’s thinking, for he

designed a first version of this project (Bill 1949).

Fig. 5. Original arch bridge (Reprinted from Bill 1949)

Strengthening with the Help of Unbonded

Prestressed Tendons

For traffic load, the behavior of the deck-stiffened arch was

altered; the static scheme was a hybrid: two end quarters of the

bridge were transformed in a truss (Fig. 7) of variable height joined

© ASCE

This method has already been applied successfully in several cases.

Two specific applications for reinforcing concrete slabs are indicated here.

06018004-3

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

Fig. 6. Diagonal attached to the arch

Fig. 7. Arch bridge strengthened with diagonals

© ASCE

06018004-4

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

Fig. 9. Ribbed slab to strengthen (Image by author)

Fig. 8. Strengthened bridge (Image by author)

Ribbed Slab

The underside of the slab seen in Fig. 9 allows the easy placing of a

steel tendon between the ribs. In this building, the floor made of a

ribbed slab with a span of 5.5 m was designed for a load of 1,500 N/m2;

the owner wanted to increase the allowable live load to 2,800 N/m2. An

unbonded steel tendon set at the proper height between the ribs

(Fig. 10) and running from the end beam, which closed the profile

to the opposite one, was stressed with an appropriate jack

(Fig. 11); this provided the required strength increase.

Buried Service Gallery

At a large airport, the increased traffic load required the strengthening, over some 250 m, of the roof of a buried service gallery subjected to heavier wheel loads. This rectangular box structure, 4.0 m

wide and 2.6 m high with an upper slab 28 cm thick, was crowded

with a number of ducts and electrical lines; little space was left for

additional supporting members. A solution was adopted in which

unbonded steel tendons were placed in the transverse direction every meter over the entire 250-m-long gallery, near the bottom of the

roof slab. The tendons were stressed at 250 kN each.

Strengthening of Slabs with Steel Plates or CFRP Strips

This method has been known since the work of L'Hermite and

Bresson (1967) in France. It requires a concrete of good quality

because the critical parameters are the adhesion of the additional

member to the concrete and the shear strength of the outer layer of

concrete. The tests by Bresson (1971) showed that for a concrete of

standard quality, a steel plate with a thickness up to 3 mm may

reach its elastic limit. For thicker plates, adhesion and shear strength

of concrete are critical (Beguin 1991, 1992). Steel plates require

temporary support during the hardening of the adhesive. Steel plates

have been superseded by CFRP. These strips are much lighter and

thus easier to apply; however, in both systems, the weak link lies in

the anchorage area.

Various schemes of anchoring the ends of the strips have been

tested (Zhang and Yan 2017). The quality of the anchorage dictates

the allowable stress in the reinforcing strip.

In the strengthening of members by means of steel plates or by

CFRP laminates glued to the concrete, uninformed engineers often

consider the steel plate or the CFRP strip as an additional reinforcing bar comparable to those embedded in the concrete, which is not

the case.

© ASCE

Fig. 10. Cross section of slab

In a mathematical study, Pflüger (1947) considered a 2-dimensional. half-plane subjected to a uniform tension and strengthened

at its upper edge by a strip firmly attached to its support. The strip

had a length b, a thickness t, and a modulus of elasticity EL; the material of the half-plane had an elastic modulus E. The condition of

equilibrium and the boundary condition led to an integral equation.

The author examined more precisely the condition at the end of the

strip: there, a linear transition over a length equal to a few times the

thickness (t) reduced the shear stress to a finite value. However,

with such a linear transition, the stress (s x ) perpendicular to the

strip still grew to infinity at its end. The author showed that a transition zone in which the strip thickness has at its end a tangent parallel

to the edge of the half-plane leads to a finite shear stress (t ) and to a

finite value for s x only when the shear stress is t ¼ 0 at this point.

Forming the end of a strengthening strip in such a shape is not

practical. However, the CFRP laminates can be shaped to form an

anchorage, as shown by Orton et al. (2008). By designing a specified geometrical anchorage, described by Kim et al. (2014), the

weakness appearing at the end of the laminate was obviated. In the

practice, this has not yet found a large application.

Discussion

The various solutions adopted for strengthening reinforced-concrete

urban structures reflect the designer’s understanding of the play of

forces in the structure.

By modifying the path of forces within the structure, one runs

the risk of causing some deficiencies elsewhere. Therefore, the

engineer should attempt to retain the original system; if some rigidities must be modified, the rigidities of the connected members

should also be modified in a proportionate manner. Unfortunately,

the advent of limit design (Wood 1961) has blurred the intimate

relationship between strength and deformation.

06018004-5

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

Fig. 12. Layer of mortar between steel and concrete

Fig. 11. Jack for stressing the tendon (Image by author)

Two examples are given here. In a large office building, part of

the wall of the underground bank safe deposit had to be removed

over a length of approximately 4 m; this wall supported a

reinforced-concrete slab with a thickness of 45 cm. Fearing some

deflections, the engineer in charge requested steel plates to be glued

to the underside of the thick slab. To take up any stress, the steel

plates have to undergo some stretching through a curvature of the

slab. Given the thickness of the slab and the limited span, it is doubtful that the steel plates will serve their intended purpose.

In an underground structure, a wall had to be cut between two

rooms, leaving an opening 5 m wide. Above the planned opening,

the portion of reinforced-concrete wall left in place had a height of

120 cm and a thickness of 60 cm. The engineer in charge planned

the setting of three steel columns to support the open span, columns

simply fitted in the opening. A simple computation showed that the

deflection of the wall portion left in place was, at the location of the

columns, a small fraction of the shortening of the steel columns

under loads. Of course, in the thinking of limit design, the columns

take up large loads.

Regarding the reinforcing of slabs, it must be recalled that many

slabs have a reserve in strength (Bakht and Jaeger 1990; Das and

Sen 1979) that does not appear in the usual design computations.

Fig. 13. Infinite strip under shear stress

respect to the lower one is given by E u ¼ t o fð4 sh2 a tÞ=½a ð2 a t sh 2 a tÞg cos a x, with a ¼ p =l.

(t) is a small fraction of l, one can write Eu ¼

When the height

t 0 ð3l2 Þ=ðp 2 tÞ cos ax, where E is the modulus of elasticity of the

mortar. In the case examined here, with l = 300 cm and

2 t ¼ 3 cm,

umax = 0.06 cm, and an average strain of 0:06 2=ðp 300Þ ¼

1:26 104 .

Notation

Conclusion

The solutions shown—two of which did not originate in the

author’s office—reflect the variety of approaches to the problem of

strengthening an existing structure, or part of a structure. The engineer should strive to modify as little as possible the original static

system, for in this type of work, one often finds oneself in a dilemma: what is best? An estimate of the corresponding rigidities of

support and supported member, of reinforcement, and member to

be reinforced is necessary to judge the efficiency of the planned

measures.

Appendix: Analysis of Composite Action

The layer of mortar is inserted between steel flange and the underside of the slab. It is subjected mainly to a shear stress (Fig. 12).

Consider an infinite strip of rectangular section with thickness 2t

subjected to a distributed shear force (t o cos Ax) acting on the two

opposite faces of the strip seen in Fig. 13. In the plane stress theory

of elasticity, the displacement [u ða xÞ] of the upper face with

© ASCE

The following symbols are used in this paper:

E ¼ modulus of elasticity;

l ¼ span;

t ¼ thickness;

u ¼ displacement;

s ¼ normal stress; and

t ¼ shear stress.

References

Bakht, B., and Jaeger, L. G. (1990). “Bridge testing—A surprise every time.” J.

Struct. Eng., 10.1061/(ASCE)0733-9445(1990)116:5(1370), 1370–1383.

Beguin, G. H. (1991). “Discussion of ‘Debonding of steel plate–strengthened concrete beams’ by S. A. Hamoush and S. H. Ahmad (February,

1990, Vol. 116, No. 2).” J. Struct. Eng., 10.1061/(ASCE)0733

-9445(1991)117:11(3549.3), 3549–3551.

Beguin, G. H. (1992). “Discussion of ‘Premature failure of externally plated

reinforced concrete beams’ by Deric John Oehlers and John Paul Moran

(April, 1990, Vol. 116, No. 4).” J. Struct. Eng., 10.1061/(ASCE)0733

-9445(1992)118:3(862.2), 862–864.

06018004-6

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.

Downloaded from ascelibrary.org by Shri Govindram Seksaria Institute Of Technology And Science on 07/23/18. Copyright ASCE. For personal use only; all rights reserved.

Bill, M. (1949). Robert Maillart, Verlag f. Architektur, Zürich,

Switzerland.

Bresson, J. (1971). “Nouvelles recherches et applications concernant l'utilisation des collages dans les structures–Beton plaque.” Annales Institut

Technique Bât. et Trav., 278, 21–55 (in French).

Das, P. C., and Sen, R. (1979). “Reserve strength of bridge decks–A preliminary investigation.” Proc. Inst. Civ. Eng., 67, 425–434.

Kim, Y., Quinn, K., Ghannoum, W. M., and Jirsa, J. O. (2014).

“Strengthening of reinforced concrete T-beams using anchored CFRP

materials.” ACI Struct. J., 111(5), 1027–1035.

L'Hermite, R., and Bresson, J. (1967). “Beton arme d'armatures collees.”

Colloque RILEM: Recherches Experimentales, Vol. 2, Ed. Eyrolles, Paris

(in French).

© ASCE

Orton, S. L., Jirsa, J. O., and Bayrak, O. (2008). “Design considerations of

carbon fiber anchors” J. Compos. Constr., 10.1061/(ASCE)1090

-0268(2008)12:6(608), 608–616.

Pflüger A. (1947). “Halbscheibe mit Randglied–Ein Spannungsgleichnis

zum Problem der tragende Linie.. Zeitschrift f. angew. Math. Mech.,

25/27(7), 177–185 (in German).

Timoshenko, S. P., and Goodier, J. N. (1970). Theory of elasticity (3rd ed.),

McGraw-Hill Book Cy, New York.

Wood, R. H. (1961). Plastic and elastic design of slabs and plates, Thames

and Hudson, London.

Zhang, W., and Yan, J.-B. (2017). “Bond properties of additional anchorage

schemes for CFRP plate-concrete externally bonded system.” ACI

Struct. J., 114(2), 511–522.

06018004-7

Pract. Period. Struct. Des. Constr., 2018, 23(3): 06018004

Pract. Period. Struct. Des. Constr.