LVDT Principle of Operation

Page 1 of 2

LVDT PRINCIPLE OF OPERATION

COLLINS

TECHNOLOGIES

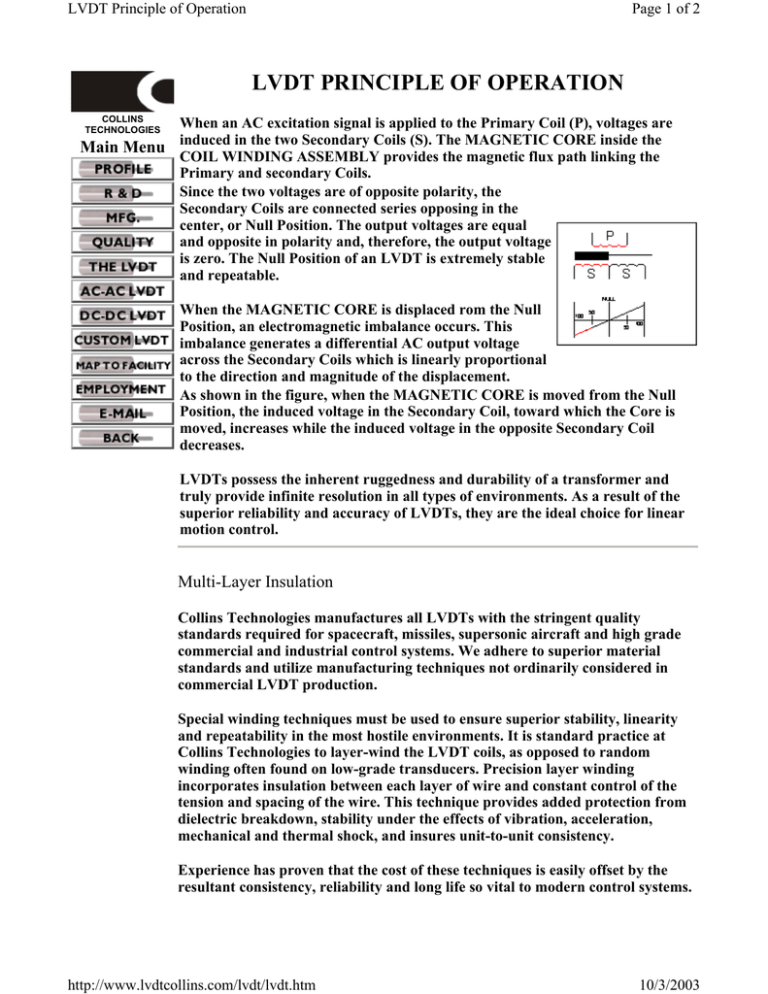

When an AC excitation signal is applied to the Primary Coil (P), voltages are

Main Menu induced in the two Secondary Coils (S). The MAGNETIC CORE inside the

COIL WINDING ASSEMBLY provides the magnetic flux path linking the

Primary and secondary Coils.

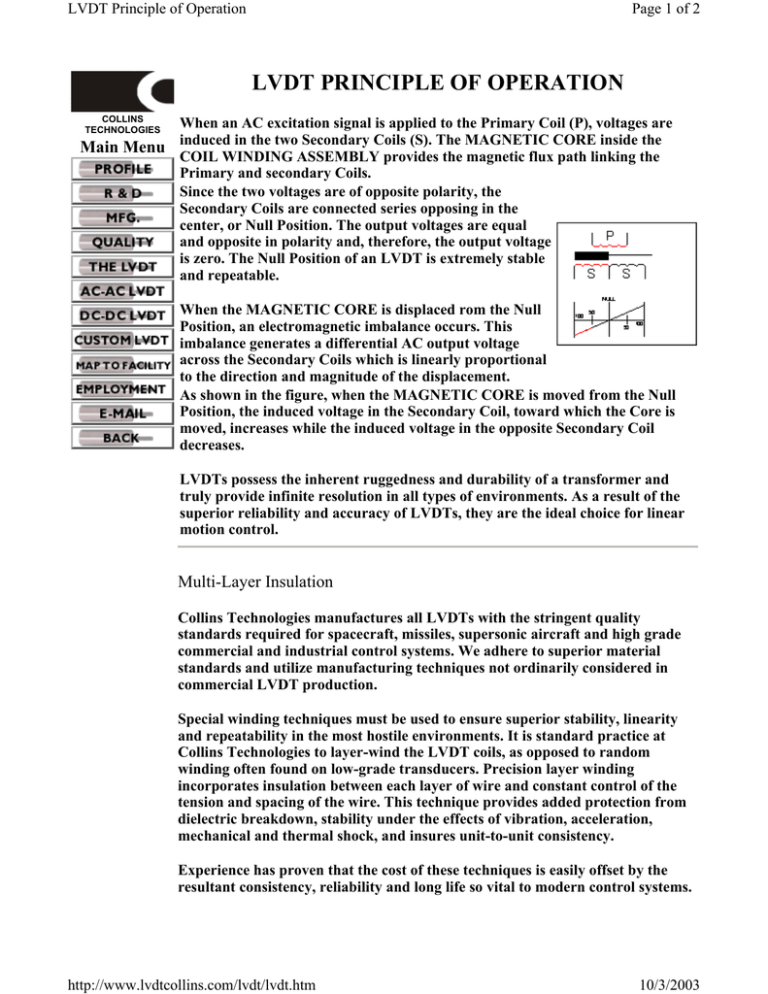

Since the two voltages are of opposite polarity, the

Secondary Coils are connected series opposing in the

center, or Null Position. The output voltages are equal

and opposite in polarity and, therefore, the output voltage

is zero. The Null Position of an LVDT is extremely stable

and repeatable.

When the MAGNETIC CORE is displaced rom the Null

Position, an electromagnetic imbalance occurs. This

imbalance generates a differential AC output voltage

across the Secondary Coils which is linearly proportional

to the direction and magnitude of the displacement.

As shown in the figure, when the MAGNETIC CORE is moved from the Null

Position, the induced voltage in the Secondary Coil, toward which the Core is

moved, increases while the induced voltage in the opposite Secondary Coil

decreases.

LVDTs possess the inherent ruggedness and durability of a transformer and

truly provide infinite resolution in all types of environments. As a result of the

superior reliability and accuracy of LVDTs, they are the ideal choice for linear

motion control.

Multi-Layer Insulation

Collins Technologies manufactures all LVDTs with the stringent quality

standards required for spacecraft, missiles, supersonic aircraft and high grade

commercial and industrial control systems. We adhere to superior material

standards and utilize manufacturing techniques not ordinarily considered in

commercial LVDT production.

Special winding techniques must be used to ensure superior stability, linearity

and repeatability in the most hostile environments. It is standard practice at

Collins Technologies to layer-wind the LVDT coils, as opposed to random

winding often found on low-grade transducers. Precision layer winding

incorporates insulation between each layer of wire and constant control of the

tension and spacing of the wire. This technique provides added protection from

dielectric breakdown, stability under the effects of vibration, acceleration,

mechanical and thermal shock, and insures unit-to-unit consistency.

Experience has proven that the cost of these techniques is easily offset by the

resultant consistency, reliability and long life so vital to modern control systems.

http://www.lvdtcollins.com/lvdt/lvdt.htm

10/3/2003

LVDT Principle of Operation

Page 2 of 2

The LVDT (Linear Variable

Differential Transformer) is an

electrometic device that produces an

electrical voltage proportional to the

displacement of a movable Magnetic

Core. The LVDT is composed of these

basic components:

A COIL WINDING ASSEMBLY

consisting of a Primary Coil and two

Secondary Coils symmetrically spaced

on a tubular center.

A CYLINDRICAL CASE which

encloses and protects the Coil Winding

Assembly.

A rod shaped MAGNETIC CORE

which is free to move axially within the

Coil Winding Assembly.

A separate shield is used for

ELECTROMAGNETIC SHIELDING.

Helpful Terms

a CURTISS-WRIGHT company

5875 Obispo Avenue, Long Beach, CA 90805 | (562) 531-6500 Fax: (562) 6339030

Copyright © Collins Technologies 2003, All rights reserved

This website designed and maintained by Townbiz

http://www.lvdtcollins.com/lvdt/lvdt.htm

10/3/2003