White Paper

advertisement

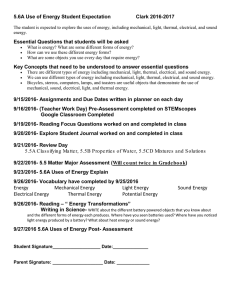

PASSIVE THERMAL MANAGEMENT OF LITHIUM-ION BATTERIES USING LATENT HEAT STORAGE MATERIALS WHITE PAPER | Joe Kelly - Materials Scientist, Outlast Technologies LLC | March 2015 | Rev: 2 INTRODUCTION As demand steadily grows for more powerful portable electronics, battery powered tools, and electric vehicles there is a desirable need for battery systems to effectively meet these necessary power and energy density requirements for operation. Because of their energy density, higher voltage, and negligible memory effects, lithium-ion batteries are the popular choice for a wide range of applications, especially in portable electronics. However, larger power demands and increasing cell density of lithium-ion battery packs result in higher operating temperatures, especially under peak loads. Because of the susceptibility of most commercial lithium-ion cell chemistries to degrade or age at or above 60°C, this leads to rapid loss of capacity over subsequent charge/discharge cycles as well as reduced overall power output (figure 1). In order to address these concerns, numerous studies into both active and passive thermal management systems for batteries have been undertaken for many applications which use lithium-ion batteries. An area of interest that shows great promise in reducing detrimental thermal effects is through the use of latent heat storage materials that absorb and store thermal heat during a change in material phase. The focus of this paper is on passive thermal management systems that use these phase change materials (PCMs) to effectively mitigate large temperature escalation during both discharge and charge, thereby relieving performance degradation over life of the battery and increasing the safety of the battery system. 1 J. Shim; R. Kostecki; T. Richardson; X. Song; K.A. Striebel, J. Power Sources, 112, 222-230 (2002) Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems FIGURE 1: CYCLING PERFORMANCE OF LITHIUM-ION POUCH CELLS AT 25°C AND 60°C. 1 1 THERMAL DEGRADATION MECHANISMS In order to understand how a thermal environment affects lithium-ion batteries it is necessary to recognize the major components of a battery, as each are a major player in the overall degradation mechanisms. A battery or a single cell is composed of two electrodes: anode and cathode, which are separated by a polymer membrane. Ionic conduction between the electrodes is achieved through an electrolyte, which can be liquid, solid, or polymeric. It is the interactions at the electrolyte/electrode interface that account for a large percentage of the thermal degradation of a battery. Anode Degradation Anode/electrolyte interactions at elevated temperatures, especially with carbon anodes have been widely studied to determine aging effects over battery lifetime. Typically, during the first discharge of a lithiumion cell, there is a certain amount of electrolyte decomposition and irreversible lithium ion loss at the anode/electrolyte interface due to unstable operating voltages at the anode. The decomposition of the electrolyte forms a protective solid-electrolyte interphase (SEI) layer on the electrode surface that is permeable to lithium ions but inhibits further electrolyte decomposition and electrode corrosion. The formation, composition, and morphology of the SEI layer are critical for effective anode performance. Change in any of these aspects can negatively affect battery capacity and life. Elevated temperatures greatly favor both SEI formation and growth, which can result in morphological and compositional changes. This can negatively impact porosity of the layer, enhancing irreversible reactions with lithium ions and leading to increased cell impedance, mobile lithium loss, resulting in power and capacity fade. Cathode Degradation Typically lithium-ion cathodes are composites containing a lithiated metal oxide as an active material, conductive additive(s) to increase overall electrical interconnectivity and binders coated together on an aluminum current collector. Therefore, degradation mechanisms of these cathodes are complex and are highly material dependent. Elevated temperatures can adversely affect the inactive components of the cathode, such as increase decomposition reactions of the binder, enhance oxidation of conductive additives, and intensify corrosion of the current collector from the electrolyte. Depending on the composition of both the metal oxide active material and electrolyte, elevated temperatures can drastically increase decomposition and facilitate structural changes, adversely affecting phase changes during lithiation/delithiation processes. These degradation pathways result in overall loss of capacity, increasing cell impedance, and power fade. 2 J. Vetter; P. Novak; M.R. Wagner; C. Veit; K.-C. Moller; J.O. Besenhard; M. Winter; M. Wohlfahrt-Mehrens; C. Vogler; A. Hammouche, J. Power Sources, 147, 269-281 (2005) Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems 2 This summary of the major thermal degradation mechanisms in lithium-ion batteries shows that such processes are complex and decidedly material dependent. In order to achieve thermal stability of one or all components of the battery system requires intensive material research and development that is both costly and time consuming. Passive thermal management of cells and battery packs shows promise in being able to maintain thermal stability of current commercial cell chemistries, circumventing extensive material development and reducing expensive new product lines. PASSIVE THERMAL MANAGEMENT Thermal management systems rely on thermal transfer of heat away from the cell surface, thereby inhibiting core temperature rise and limiting material degradation. The effectiveness of regulating core temperatures is both a function of the ability to efficiently transfer heat away from the cell’s surface and the inherent thermal properties of the battery materials. The decision in using active or passive thermal management systems at the cell level or in a pack is application dependent. While active cooling methods are effective in shuttling heat away from a surface, their size and complexity are prohibitive in applications such as portable electronics and battery-power tools. Passive systems offer simplicity in design that eliminates the need for mechanical equipment and additional capacity to power them. One of the most promising passive systems for managing heat dissipation involves the use of latent heat storage materials. Latent Heat Storage Materials (LHS) Latent heat storage materials depend on changing states of matter or phase changes in order to absorb and release heat while maintaining a constant temperature. Latent heat, otherwise called enthalpy of fusion, is defined as the amount of thermal energy required for a certain mass of material to undergo a change in phase, typically quantified as joules per gram (J/g). These phase change materials (PCMs) can have solid-solid, solid-liquid, or liquid-gas phase transitions and can be organic, inorganic, or eutectic compounds. When a phase change temperature is reached, the energy absorbed is utilized in transforming the material to another phase, thereby keeping the temperature relatively constant (figure 2). At a constant thermal flux the length of the temperature plateau (phase change) is directly related to both the latent heat properties of the PCM and its applied mass. Most PCM type materials considered for managing of thermal stress for battery systems are either organic or inorganic complexes. While inorganic PCMs such as salt hydrates exhibit high latent heat and high thermal conductivity, they suffer from limited melt/freeze cycles, are corrosive, electrically conductive, 3 Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems and are prone to supercool. Organic PCMs, such as paraffin waxes, are more appropriate Sensible Heat as they are able to achieve >1,000 melt/freeze cycles without serious degradation-similar to Latent Heat Sensible Heat for current batteries. Organic PCMs also exhibit high latent heat values and can be “tuned” for specific temperature ranges by modifying alkyl TEMP (ºC) the necessary charge/discharge cycles needed chain lengths to match appropriate melting Melting Time Melt Temperature point temperatures. They are chemically stable, non-reactive, and compatible with many polymer and resins used in packaging and construction. Conversely, they suffer from low TIME (MIN) FIGURE 2 thermal conductivity and need to be properly contained. However, with proper formulation to address these issues, organic PCMs have shown great success in being able to mitigate surface temperature escalation during high current discharges with commercial lithium-ion batteries. Thermal Performance of LHS Materials with Li-ion Batteries Studies using commercial 18650 (1.95Ah) format lithium-ion cells encased in polymer sleeves containing Outlast’s Latent Heat Storage (LHS) materials have shown a remarkable ability to maintain cell surface temperature below 50°C during high current discharges compared to control cells (figure 3). Specifically, during discharge currents of 20A Outlast observed that the surface temperature for the LHS-sleeved cells were on average 18.5°C lower than control cells across >600 charge/discharge cycles (figure 4 and 5) . This ability to maintain optimal thermal management effectiveness across the lifetime of the cells highlights FIGURE 3: LHS SLEEVES (LEFT) FOR 18650 LI-ION CELLS. IR IMAGES OF A) CONTROL AND B) LHS SLEEVE AFTER 15 MIN. DISCHARGE AT 20A. 4 Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems the inherent reliability of the LHS material’s energy storage and dissipation capabilities. Also demonstrated is the LHS material’s excellent ability to resist mechanical deformation during thermal cycling thereby maintaining intimate contact between the sleeve and cell surface throughout the calendar life of the battery. This minimizes interface thermal resistance and preserves thermal storage potency of the LHS sleeves. Significantly, LHS-sleeved cells remained above 75% of the rated cell capacity for greater than 150 cycles when compared to control cells (figure 6). Through repeatedly efficient thermal absorption at the cell surface during discharge and effective dissipation of this heat away from the cell while charging, the LHSsleeves are able to drastically minimize thermal stress experience by the cell. Consequently, LHS-sleeved cells are able to operate at higher discharge rates for approximately 40% longer, enhancing capacity and power capabilities of commercial cells. In order to facilitate a better understanding of the LHS sleeve/battery system, Outlast developed a finite difference, lump parameter thermal model using SINDA/FLUINT software. Comparisons between the average experimental temperature profiles and the thermal model show strikingly similar behavior with an average data point discrepancy of 0.61°C (figure 7). FIGURE 4: SURFACE TEMPERATURE COMPARISON BETWEEN LHS AND CONTROL 18650 CELLS FOR FIRST 3 CYCLES OF 1.95A CHARGE/ 20A DISCHARGES. 5 Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems FIGURE 5: COMPARISON OF HIGHEST CELL SURFACE TEMPERATURES AFTER EACH DISCHARGE CYCLE BETWEEN LHS-SLEEVED 18650 CELLS AND CONTROL CELLS. FIGURE 6: COMPARISON OF DISCHARGE CAPACITY RETENTION BETWEEN LHS-SLEEVED 18650 CELLS AND CONTROL CELLS. 6 Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems FIGURE 7: GRAPHICAL COMPARISON BETWEEN OUTLAST’S THERMAL MODEL WITH EMPIRICAL DATA FOR LHS-MODIFIED 18650 CELLS (1.96AH) BEING DISCHARGE AT 20A. SUMMARY Outlast LHS Battery Sleeves have been specifically engineered to meet critical thermal management needs for devices utilizing 18650 Li-ion cells by moderating cell surface temperatures during high current charge and discharge operations in order to enhance capacity and power performance while reducing potential thermal runaway issues. With this simple passive thermal management system utilizing LHS sleeves, 18650 cell surface temperatures can be reduced by approximately 19°C compared to unmodified cells depending on the discharge regime. Consequently, LHS-modified cells experienced notable increases of approximately 40% in charge/discharge cycles before reaching 75% of rated capacity compared to control cells, suggesting substantial decrease in thermal stress. Extensive cycling of the LHS sleeves show that they can operate over 600 cycles or greater without loss of thermal absorption properties while also maintaining mechanical integrity. Overall, these LHS materials demonstrate promise in preventing escalating capacity and power fade over operational lifetimes or a variety of Li-ion functions in which thermal stability is critical to device performance. The availability of a wide range of latent heat PCMs and the ability to modify their content permit more effective balancing between pack design versus application centered thermal management, especially for large thermal dissipative systems such as battery backup units. With their relative abundance, high latent heat, and ease of processability, PCM materials are becoming the forerunner in effective, simple, and cost conscious thermal management designs for power intensive lithium-ion battery applications. 7 Outlast Technologies LLC 831 Pine Ridge Road Golden Colorado 80403 P: 303.581.0801 F: 303.581.9029 thermalsystems@outlast.com outlast.com/thermalsystems