CEMENTING

Halliburton Casing Equipment Differentiators

Halliburton is the only oilfield services provider to offer both

cementing services and casing equipment globally. This

integrated approach allows operators to gain efficiency and reduce

operating costs by running and landing casing to depth and

achieving long-term zonal isolation.

Super Seal II® (SS-II) Float Valve

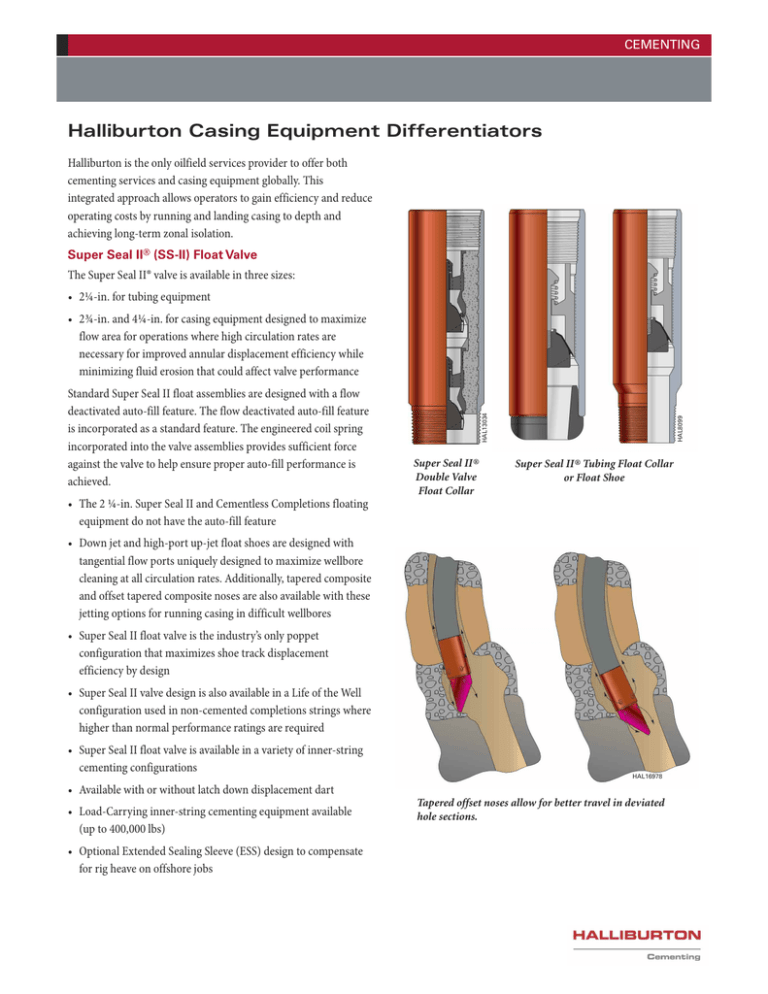

The Super Seal II® valve is available in three sizes:

• 2¼-in. for tubing equipment

Super Seal II®

Double Valve

Float Collar

HAL8099

Standard Super Seal II float assemblies are designed with a flow

deactivated auto-fill feature. The flow deactivated auto-fill feature

is incorporated as a standard feature. The engineered coil spring

incorporated into the valve assemblies provides sufficient force

against the valve to help ensure proper auto-fill performance is

achieved.

HAL13034

• 2¾-in. and 4¼-in. for casing equipment designed to maximize

flow area for operations where high circulation rates are

necessary for improved annular displacement efficiency while

minimizing fluid erosion that could affect valve performance

Super Seal II® Tubing Float Collar

or Float Shoe

• The 2 ¼-in. Super Seal II and Cementless Completions floating

equipment do not have the auto-fill feature

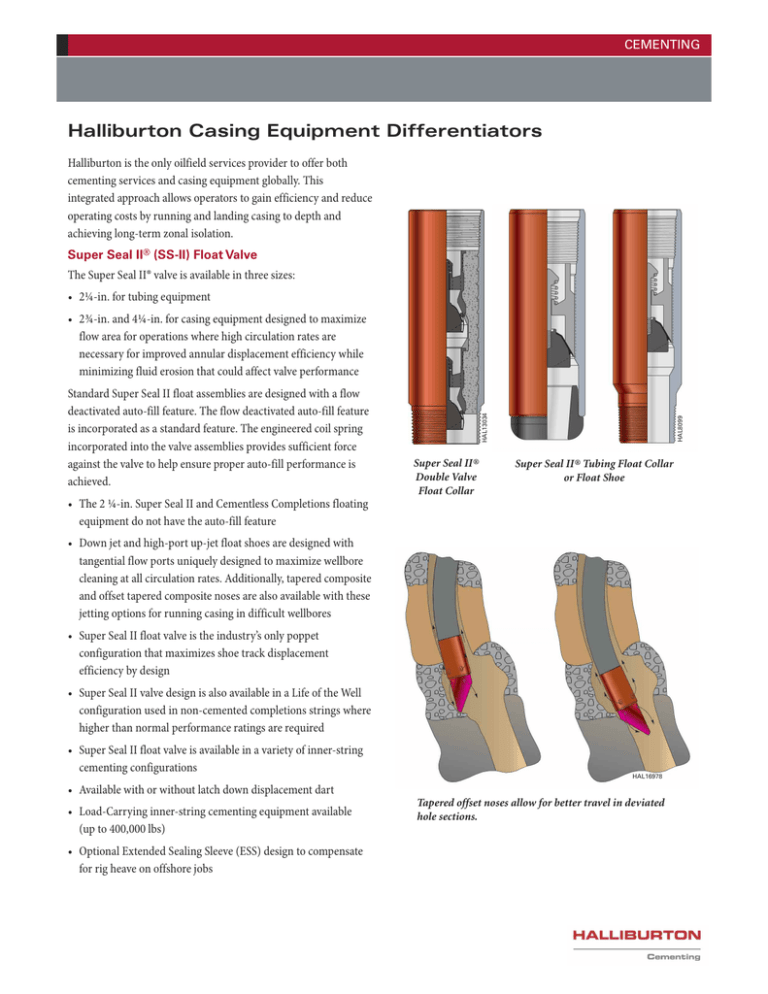

• Down jet and high-port up-jet float shoes are designed with

tangential flow ports uniquely designed to maximize wellbore

cleaning at all circulation rates. Additionally, tapered composite

and offset tapered composite noses are also available with these

jetting options for running casing in difficult wellbores

• Super Seal II float valve is the industry’s only poppet

configuration that maximizes shoe track displacement

efficiency by design

• Super Seal II valve design is also available in a Life of the Well

configuration used in non-cemented completions strings where

higher than normal performance ratings are required

• Super Seal II float valve is available in a variety of inner-string

cementing configurations

HAL16978

• Available with or without latch down displacement dart

• Load-Carrying inner-string cementing equipment available

(up to 400,000 lbs)

• Optional Extended Sealing Sleeve (ESS) design to compensate

for rig heave on offshore jobs

Tapered offset noses allow for better travel in deviated

hole sections.

High Wiping Efficiency (HWE®) Cementing Plugs

The Omega™ / HWE® Cementing Plugs

HWE® cementing plugs incorporate a patented deep cup wiper

configuration that provides measurable improvements over

conventional cementing plugs in three key areas.

• Reliable displacement under the most severe well conditions

• Efficient wiping of the casing ID

• Drill-ability for quick and easy drill out with roller cone and

fixed cutter PDC bits

Designed especially for the HWE bottom cementing plug, the

patented phenolic shear disk provides unique features not found

in conventional rupture mechanisms :

The Omega™ HWE® cementing plugs were designed to incorporate

two proven technologies for the purpose of providing superior

wiping efficiency and fluid separation for the most demanding

jobs.

• More consistent rupture pressures compared to rubber coated

fabric diaphragm.

• HWE cementing plugs are suitable for use with water-based

mud, oil-based mud, and synthetic-based mud and can be used

with most Halliburton cementing floating equipment that is de

signed with a flat landing seat

• Fine fragment pattern provides a full bore flow path to help im

prove flow performance with debris, lost circulation material or

other foreign materials that may be in the drilling fluid or

cement. Fine fragmented pieces easily pass through floating

equipment, thereby decreasing the possibility of material

plugging below the cementing plug

• Semi-spherical ball fits more tightly into the casing to provide

greater wiping efficiency and wear resistance for horizontal wells

where solids beds are common as compared to conventional

plug assemblies

• More drillable than previous higher pressure rupture discs

made of aluminum, brass or stainless steel

• Omega HWE cementing plugs are suitable for use with waterbased mud, oil-based mud, and synthetic-based mud and can be

used with most Halliburton cementing floating equipment that

is designed with a flat landing seat

• A 750 psi rating of the phenolic shear disk in the HWE plug is

higher than the industry average. It offers the following advan

tages over previous rubber coated fabric designs

• Also, Omega HWE cementing plugs are designed with phenolic

plastic, elastomer, and minimum aluminum to help ensure drill

ability with roller cone or fixed cutter polycrystalline diamond

compact (PDC) drill bits

– Reduces premature rupture in mixed strings when

encountering crossovers

– Reduces premature rupture associated with fill or sag

in extended length horizontal wells

• Differential pressure rating equal to standard HWE cementing

plugs when used with other Halliburton cementing floating

equipment

HWE cementing plugs are suitable for use with water-based mud,

oil-based mud, and synthetic-based mud and can be used with

most Halliburton cementing floating equipment that is designed

with a flat landing seat

Subsurface Release II (SSR-II) Cementing Plugs

Halliburton’s SSR® subsurface release cementing plug system

allows cementing operations to be performed from a floating

vessel or fixed platform that uses a subsea wellhead.

HAL809

History

• Halliburton was the first to use SSR® plug technology in

deepwater cementing in the 1970’s

• Halliburton SCRM (Single Collet Release Mechanism) was

introduced to the industry in the 1990’s, and is still the field

proven design choice of Halliburton sub surface release

equipment technology, and the basis of Halliburton SSR and

SSR-II plug sets

Properties

• Manufactured from a fiberglass resin matrix (composite) that

replaces metals commonly used in conventional SSR cementing

plugs. The composite materials are more easily drilled with PDC

bits compared to aluminum because it fragments into pieces

that can easily be displaced to the surface

• Industry average drill out time for conventional SSR Plugs has

been 94 minutes. With the SSR-II plug set, the average drill out

time has been 17 minutes average, that’s over an 80% savings

in time on drill out procedures

Protech DRB® Centralizers

• Protech DRB centralizers can be used for casing inside casing

applications and for drill pipe wear bands

• A composite material as hard as sapphire and with a low

coefficient of friction

• Centralizer blades are permanently bonded directly to the

drill pipe

Halliburton has Master Services Agreements (MSA) with the

following preferred vendors and alliance partners for centralizer

products.

• Designed with improved flow area that allows higher circulation

rates and reduced frictional pressure drop for applications where

surge/swab effects need to be minimized to improve surge

reduction and increase casing running speed

• Flow tested at 20 bpm for 24 hours with a 300°F (148.9°C)

temperature rating

• SSR-II plugs are available for casing sizes 9⅝ and larger

• Available in a three plug configuration (2 bottom plug option)

for applications where a first bottom plug can be launched for

displacement calibration while mud conditioning operations

are being performed

• Open cell foam matrix wiper plugs are used to wipe all drill pipe

sizes from 4½ to 6⅝. This enhanced foam technology design

offers the ability to wipe a broader range of multiple ID passages

singly or in combination drill strings

Centralizers

Protech CRB® Centralizers

• Patent rights owned by ENI with Halliburton as the exclusive

worldwide distributor

• More than 2000 applications worldwide

• Centralizer blades custom molded and bonded directly to casing

using a proprietary process

– Extremely high adhesion values mean that the blades are

integral to pipe

– Can be applied in any geometry and located anywhere on

the pipe

– Geometric shapes include button, pad, teardrop, straight,

spiraled, and staggered

• Titanium ceramics and carbon fiber composite material

provides a very low coefficient of friction

• Non-metallic inert composite material

• Low angle entry/exit blade design assists reaching total depth

• Can pass the smallest restrictions (for instance, Protech CRB

centralizers have been used on a 5-½-in. lateral liner in a

5-7/8-in. hole)

• Suitable for well temperatures up to 425°F (218.3°C)

Protech CRB® Centralizers –

blades bonded directly to casing

Antelope Oil Tools

• Bow spring, rigid, and customer centralizer designs

• Centralizer designs available in API and non-API designs and

specifications

• Other high-quality casing attachments include limit clamps,

cement baskets, scratchers, and wall cleaners in an array of sizes

– Custom build to non-API sizes in most cases

• Antelope close tolerance centralizers

– Alternative to running ICCS (Inter-Casing Centralizer Subs)

– Very low starting and running forces

– High restoring force

– Run with press-on limit clamps for maximum holding force

– Press-on limit clamps reduces tolerance stack of metal

components to allow for running under tight tolerance bow

spring centralizers to allow for the centralizer to be pulled in

either direction

Centek Centralizers

• Premium high-performance, semi-rigid, double-curvature bow

spring centralizer made of single-piece, laser-cut material

(non-weld construction)

• Zero starting force – exceptionally high load/deflection

performance enables the external diameter of the centralizer to

slide-fit into a gauge open hole

• Designed with flexibility to allow passage through under-gauge

hole sections

• Double curvature bow provides robust restoring force while

minimizing starting and running force

Ray Oil Tools

• Corrosion Resistant Alloy (CRA) centralizers

– Aluminum solid band straight blade and left/right spiral blade

positive stand-off

– Aluminum alloys are resistant to corrosion and provide high

impact and shock resistance along with high tensile strength

and yield strength

• A variety of blade lengths are available

• Solid centralizers may also be secured to the casing with

optional set screws where it is not desirable to rotate or

reciprocate the casing during cement operations

• Designed to provide a fixed casing standoff regardless of

lateral load

• The centralizers should be installed between two stop rings or

between a casing collar and a stop ring when casing rotation

reciprocation is desired

• Available in Type H or Type P version

– Type H is opened hydraulically once the first stage shut- off

cementing plug has landed

– Type P uses a free fall or displacement type opening plug

• Can be functioned with composite free-fall opening plugs that

are designed for improved drillability.

– Free-fall opening plugs are designed for improved operational

safety on location when loading into the casing or cementing

head

• Free-fall and displacement type plug sets are available to match

the selected stage tool type and specific application

• Incorporates dual lock rings located under the external sleeves

and protected from wellbore fluids and debris that can prevent

their ability to function properly

Downhole Products (DHP)

• Spir-o-lizer® Zinc solid band spiral blade positive stand-off

CRA centralizer

• Offers an extension of casing life by delaying the corrosion

cycle via the unique introduction of downhole cathodic

protection

• Unique non-sparking alloy recommended for safe use in

hazardous environments (aluminum or steel do not meet

this criterion)

• The BLADERUNNER patented friction-reducing Spir-o-lizer

centralizer performs equally well in open or cased holes

– Maximize drag reduction, minimize start up torque

– Cost effective alternative to roller type centralizers

• BACE™ collars are optimally placed through the use of

Landmark WELLPLAN™ software

• Single trip system deactivates with pressure disc and

cement plugs

• Design does not require holes extending through to the OD

of the casing

• Full bore ID after tool has functioned

• Available in many premium thread size and weights (the collet

design enables thread design by casing size rather than casing

wall thickness)

Buoyancy Assist Casing Equipment (BACE™)

for Extended Reach Wells

SuperFill System

SuperFill™ Surge Reduction Equipment (FV, FVB, and FVB Plus)

provides a reliable way for wellbore fluid to enter the casing or

liner ID while the casing is being run into the hole, helping to

reduce wellbore surge pressure and the volume of fluid lost to the

formation.

• High capacity fill opening

• Costly surface fill time is reduced or eliminated

• Some configurations allow for multiple circulations while

running in the hole

• Available in flow or pressure deactivated designs

• High LCM fluid systems compatible

• Available in float shoes and float collars in single or double

valve configurations

• For use in surface and subsurface release applications

• PDC Drillable

ES II™ Stage Cementers

HAL30079

Halliburton was the first company to bring

multi-stage cementing technology to the oilfield

industry. During the mid 1940’s, Halliburton

introduced the Diverter Valve multi-stage cementing

assembly. This tool became an industry standard

that is currently referred to as the DV™ tool, the

industry-adopted term for multi-stage cementing

equipment or jobs.

• ES II family of stage cementers is an external

closing sleeve stage cementer

– A single piece mandrel eliminates the need for

threaded or welded connections that can be a

leak path over the life of the well

– Provides a smooth bore drill out

Type P ES II Stage Cementer

Plug Setting Aids

Bottom Hole Kick-off Assembly (BHKA)

Allows for reliable placement of a competent cement plug for

kickoff, sidetrack, and plug-and-abandonment purposes

• Reduces the need for additional plug-back attempts

• Reliable tail pipe disconnect

• Open-ended work string after disconnect

• Eliminates swabbing from plug

• Reduces risk of differential sticking

• Dart activated

• Available with optional open hole packer

Tubing Release Tool (TRT)

A plug setting aid that helps enable placement of a competent,

uncontaminated cement plug downhole in an unbalanced hole

situation

• Similar to BHKA disconnect, but has a built-in fluid retention

device for function when desired after disconnect

• Reliable sacrificial tail pip disconnect (steel, aluminum or

fiberglass)

• Ball and foam wiper ball activated

CST™ Perigon Cement Support Tool

• Provides a displaceable fluid separator between fluids to help

mitigate the effects of gravity upon the cement plug (boycott,

spiral, or extrusion effects)

• Pumped to setting depth ahead of the spacer/cement or placed

before the pre-job circulation is started with a drill pipe wiper

dart

• Expands and fills the hole when exiting drill pipe or tubing

• Can be used for any off-bottom plugging operation as long as

there is no lost circulation problem below the CST

• Compatible with all known drilling fluids with well

environments up to 350°F (176.6°C)

• Tools available to work in wellbore with hole sizes 5½-in. to

45-in., as well as no angle limitation

• The CST™ tool is designed and manufactured by Perigon in

Norway. Halliburton is a distributor for this tool and its

technology.”

PSA (Plug Setting Aid) System

Halliburton combines previous field proven plug setting aids with

newly designed accessories to enhance effective plug setting

specifically for complicated wellbores. These tools eliminate the

need for conventional “pump and pull” plug setting techniques.

They also allow for increased plug lengths and decreased cement

contamination, while helping reduce wait-on-cement time.

The PSA system incorporates some or all of the following:

• BHKA (Bottom Hole Kick-off Assembly) Disconnect Tool with

activation dart

• Sacrificial Tailpipe

• Drillable Tailpipe Centralizer

• Drillable Tailpipe Diverter with Diverter Ball

– The new drillable tailpipe centralizer and diverter incorporate

multiple layers of flexible diffusers

– Can be assembled to fit many different work string and

annular configurations

– Adjustable flow path options

• Centralizer Diverter Shoe

– Guides tail pipe into well bore

– Provides base to eliminate annular fluid movement

due to gravity

– Centralizer assembly allows one way annular fluid movement

– Provides jetting action for hole cleaning and cement

placement

– Prevents slumping in horizontal wells

For more information on Halliburton Casing Equipment,

please call you local Halliburton representation or email us at cementing@halliburton.com.

© 2011 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale.

H08472 8/11

www.halliburton.com