Preliminary Structural Analysis

advertisement

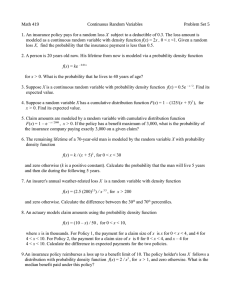

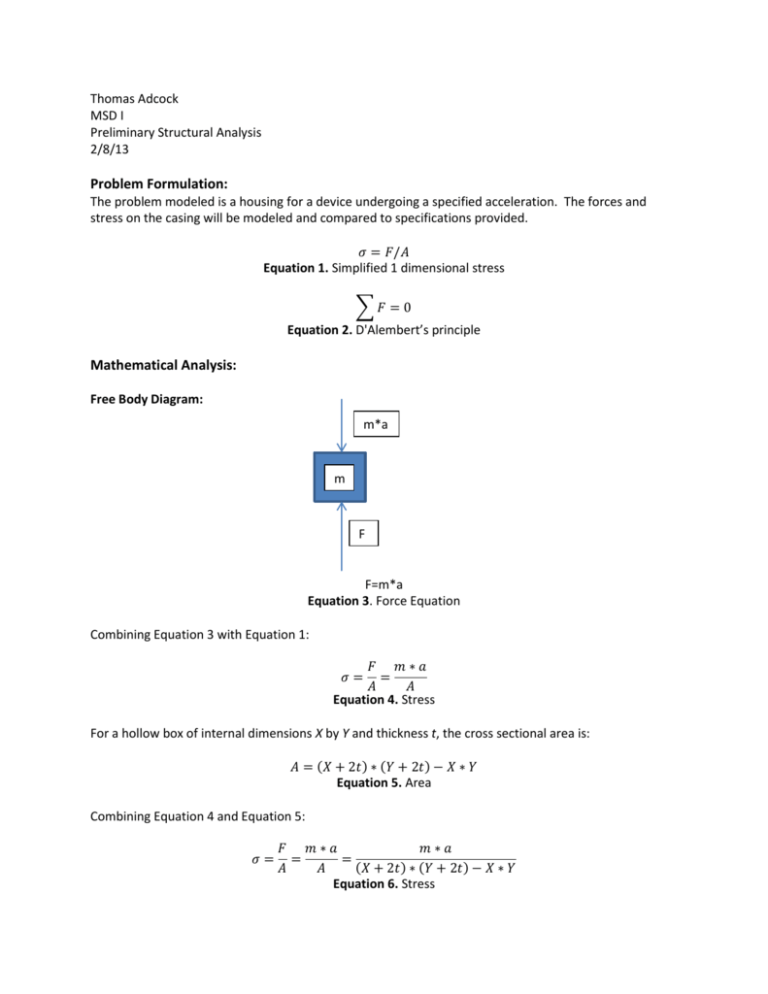

Thomas Adcock MSD I Preliminary Structural Analysis 2/8/13 Problem Formulation: The problem modeled is a housing for a device undergoing a specified acceleration. The forces and stress on the casing will be modeled and compared to specifications provided. 𝜎 = 𝐹/𝐴 Equation 1. Simplified 1 dimensional stress ∑𝐹 = 0 Equation 2. D'Alembert’s principle Mathematical Analysis: Free Body Diagram: m*a m F F=m*a Equation 3. Force Equation Combining Equation 3 with Equation 1: 𝐹 𝑚∗𝑎 = 𝐴 𝐴 Equation 4. Stress 𝜎= For a hollow box of internal dimensions X by Y and thickness t, the cross sectional area is: 𝐴 = (𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌 Equation 5. Area Combining Equation 4 and Equation 5: 𝜎= 𝐹 𝑚∗𝑎 𝑚∗𝑎 = = (𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌 𝐴 𝐴 Equation 6. Stress The specifies acceleration is 20G. Substituting this in to Equation 6 gives: 𝜎= 𝐹 𝑚∗𝑎 𝑚∗𝑎 𝑚 ∗ 20 ∗ 𝑔 = = = (𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌 (𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌 𝐴 𝐴 Equation 7. Stress Because the mass is unknown, a maximum mass will be solved for using the yield stress of the plastic as the stress 𝜎. Solving for mass: 𝜎 ∗ [(𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌]/[20 ∗ 𝑔] = 𝑚 Equation 8. Mass Assumed Key Parameters: 𝜎 = 6500 𝑃𝑆𝐼 = 44.82𝑀𝑃𝑎 = 44.82 ∗ 106 𝑃𝑎 X=70mm=.07m Y=65mm=.065m t=3mm=.003m g=9.81m/s2 Quantitative Outcome of Model: 𝜎∗ [(𝑋 + 2𝑡) ∗ (𝑌 + 2𝑡) − 𝑋 ∗ 𝑌] [20 ∗ 𝑔] = 44.82 ∗ 106 𝑃𝑎 ∗ = 193𝑘𝑔 Stress Strain Curves: Conclusion: [(. 07𝑚 + 2 ∗ .003𝑚) ∗ (. 065 + 2 ∗ .003𝑚) − .07𝑚 ∗ .065𝑚] =𝑚 𝑚 [20 ∗ 9.81 2 ] 𝑠 The maximum mass that can be accelerated safely by the casing far exceeds a reasonable mass for the product indicating that structural failure is extremely unlikely. The linear elastic region is around 15% of the UTS. This corresponds to 10% of the calculated mass or 19.3kg. http://www.azom.com/work/kWfiTWyN68bIo815M9HJ_files/image003.gif http://www.machinist-materials.com/comparison_table_for_plastics.htm