H. Kristiansen, Z. L. Zhang and J. Liu, Characterization of

advertisement

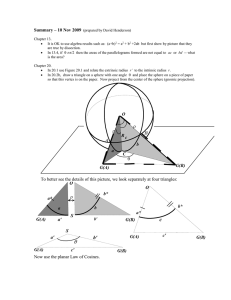

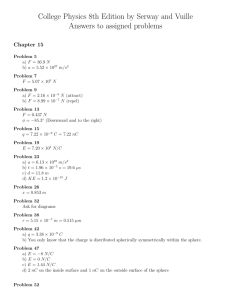

H. Kristiansen, Z. L. Zhang and J. Liu, Characterization of mechanical properties of metal-coated polymer spheres for anisotropic conductive adhesive, Proceedings of 10th Int. Symposium on Advanced Packaging Materials: Processes, Properties and Interfaces, 2005, p 209-213 Characterization of Mechanical Properties of Metalcoated Polymer Spheres for Anisotropic Conductive Adhesive H. Kristiansen1, Z. L. Zhang2 and J. Liu3 1: Conpart A.S, , N-2027 Kjeller, Norway, E-mail: helge@conpart.no 2: Faculty of Engineering Science and Technology, Norwegian University of Science and Technology, N-7491 Trondheim, Norway 3: Sino-Swedish Microsystem Integration Technology (SMIT) Center, Shanghai University, Shanghai China / Department of Microtechnology and Nanoscience (MC2), Chalmers University of Technology, Se 412 96, Göteborg, Sweden Abstract- Metal coated small (micron sized) polymer particles are used in developing anisotropic conductive adhesives (ACA). The mechanical properties of polymer particles are of crucial importance both to assembly process and the reliability of ACA. In this paper we present a method to determine the mechanical properties of polymer sphere particles by using inverse indentation test – soft elastic sphere against rigid flat. Finite element analyses have been carried out to study the large deformation contact between the sphere particle and a rigid flat. The classical Hertz solution works only for small sphere deformation. A modification has been made to the Hertz contact force-displacement solution and an approximate equation is presented. A capacitance based experimental setup for particle indentation has been built. The proposed method has been applied to determine the elastic properties of typical polymer particles used for conductive adhesives. For the metal plated polymer particles tested, it has been found that a linear elastic model seems to hold for a large range of deformation. Chip Substrate Fig. 1. Schematic plot of flip-chip connection using anisotropic conductive adhesives. I. INTRODUCTION Anisotropic conductive adhesives are an enabling technology for a growing number of electronic packaging applications, in particular in flip chip packaging applications. Fig. 1 illustrates the the principal of flip-chip connections using ACA [1]. In general, ACA materials are prepared by dispensing electrically conductive particles in an adhesive matrix. These particles can be pure metals such as gold, silver or nickel, or metal-coated particles typically with polymer cores. The volume fraction of particles is well below the percolation threshold (typically between 5 and 10 %), and the particles mostly range from 3 to 10 Pm in diameter. Due to the low volume fraction, there are no continuous conductive paths among the particles in the x-y plane of the film. The adhesive therefore conducts electricity in only z direction - anisotropic conductive adhesives. The reliability of ACA assembly strongly depends on the thermomechanical properties of the conductive particles. A detailed knowledge of the mechanical properties and failure mechanisms is required in order to ensure good process yield and reliable products, and provide accurate inputs to finite element simulations of package performance. Due to temperature and mechanical induced loading, various failure mechanisms such as deformation, delamination, cracking and fracture, thermal fatigue, creep can occur during production and service. Fig. 2 shows different failure mechanisms which are observed in compression tests [2]. Because of small size scale nature (particle diameter under 10Pm), there is no well established method to characterize the mechanical behaviour of conductive particles. One of the feasible approaches to determine the mechanical properties of single particles is to perform inverse indentation test, Fig. 3 by using nanoindenter. To distinguish with the common sense indentation where a rigid sphere is pressed against a deformable half space, here the inverse indentation is meant the opposite – contact of rigid flats against a deformable sphere. This method is still under development. Similar methods for contact test of larger scale spheres (about 300 Pm) can be found in [3]. It should be noted that significant amount of research has been carried out recently in the research community on the indentation problem of a half space by a rigid sphere or sharp tip. However, the inverse indentation of a soft sphere with a rigid flat is different to the common indentation problem. In the common indentation the indenter tip radius remains constant while the curvature of the deformable sphere in the inverse indentation is changing. 0-7803-9085-7/05/$20.00 ©2005 IEEE II. CLASSICAL HERTZ SOLUTION Hertz’s solution considers the contact of two elastic spheres with radii R1 and R2 in the absence of adhesion and friction. Define the contact curvature 1/RC and elastic contact modulus KC as 1 1 1 (1) R C R1 R 2 and 4 ª 1 Q12 1 Q 22 º « » 3 ¬« E1 E 2 ¼» KC Fig. 2. Different particle failure modes observed; a) cracking and delamination of metal layer, b) fracture in polymer particle and c) complete disintegration. The initial diameter of these particles are about 10µm. [Ref] The paper is organized as follows. Section 2 describes the classical Hertz solution. The finite element analysis and the new explicit large contact deformation equation are reported in section 3. In section 3, both spheres made of single material and two materials have been studied. The inverse indentation test setup, application of the proposed large deformation contact equation and elastic properties of the tested polymer spheres are presented in section 4. The paper is concluded with discussions and summary. F 1 (2) where E1 , Q1 and E 2 , Q 2 are the Young’s modulus and Poisson’s ratio of sphere 1 and 2, respectively. By assuming that the contact area is much smaller than the size of the spheres, Hertz theory provides the following relation between the contact deformation h C h1 h 2 and the contact force F, 1.5 F K C R 0.5 (3) C hC The Hertz’s solution states that the contact force is proportional to the power 1.5 of the sphere deformation. For an elastic sphere and rigid flat contact problem considered in this paper, Fig. 3, the contact modulus, contact radius of curvature and contact deformation can be written as 4 E KC K and R C R , respectively. 3 1 Q2 Denote h C h1 h . Substitute these into (3), the Hertz contact equation for the inverse indentation problem becomes KR 0.5 h1.5 F (4) Equation (4) can be re-written as 3 F SR 2 K § h ·2 S ¨© R ¸¹ (5) or VS K h F 1 HS 1,5 S (6) where VS and HS are defined as sphere contact stress and strain. It can be observed from (6) that Hertz theory states that the contact stress in an elastic sphere is proportional to the power of 1.5 of the sphere contact strain. A number of modifications have been made to extend the Hertz theory to large deformations. Yoffe [4] modified Hertz solution with a first-order correction for the errors which are introduced when relatively large contact areas are present. Later, by invoking a non-linear elastic response Tatara [5] presented a large deformation formulation for predicting the compressive behaviour of elastomeric spheres up to a value of 60% deformation. However, Tatara’s theory is complicated and does not present explicit solutions. Fig. 3. Schematic plot of the large deformation contact problem between an elastic sphere and rigid flat 0-7803-9085-7/05/$20.00 ©2005 IEEE III. FINITE ELEMENT ANALYSIS The success of Hertz theory has been well established. However, the limitation of the Hertz theory to the inverse indentation is not clearly understood. In the following large deformation finite element analyses has been carried out to study the mechanical behaviour of single polymer particles. Sphere made of a single material is studied. The effect of elastic coating properties on the indentation curve has also studied by using a bi-material sphere model. ABAQUS was used to study the inverse indentation problem. The finite element mesh used in the analyses is shown in Fig. 4. ¼ of the sphere has been modelled. The model consists of about 3700 4-node axisymmetric elements and 4000 nodes. A convergence study has been performed to ensure that the mesh applied is sufficiently accurate. Very fine mesh was used in the contact region. The mesh has also been deigned in such a way that the same model can be applied to study the coating effect. The minimum element size in the model is about 0.1% of the initial sphere radius. VS K 1 HS 1,519 2, 6 (7) for sphere strain HS 10%. It can be seen from (7) that for large deformation contact the contact force is proportional to the power of about 1.52 of the sphere strain. Note that this is on the similar form as the Hertz equation. For even larger contact deformation (10% < HS 35%), the above equation is not accurate and following equation can be used to describe the contact force and sphere strain relation: VS K 0.0667HS 0.5105HS2 0.5724HS3 (8) Once an experimental inverse indentation curve is obtained, (7)-(8) can be applied to determine the contact modulus K by dividing the contact stress by the power equation or the polynomial equation. 0,0003 FEM Hertz Shpere stress/K A. Sphere of homogenous material Fig. 5a compares the finite element results with the Hertz solution. The contact stress has been normalized by the contact modulus K. Fig. 5a shows a very good agreement between the finite element results and the Hertz solution when the sphere strain is small. Depending on the accuracy requirement apparent deviation from the Hertz solution occurs when the sphere deformation is larger than, for example 1%. It can be seen from Fig. 5b that the Hertz solution underestimates the sphere contact stress more than 40% when the sphere strain has reached 35%. It must be noted that the finite element solution presented in Fig. 5b is universal as long as the material behaves linear elastically. The finite element solution can be fitted by the following power law equation 0,0002 0,0001 0,0000 0 0,002 0,004 0,006 0,008 0,01 Sphere strain 0,12 FEM Shpere stress/K 0,10 Hertz 0,08 0,06 0,04 0,02 0,00 0 0,05 0,1 0,15 0,2 0,25 0,3 0,35 Sphere strain Fig. 4 Finite element mesh (1/4 model) used for the analyses. The model consists of about 4000 nodes and 3700 elements. Fig. 5 Comparison of the Hertz solution and the finite element solution for small and larger deformation. Respectively. 0-7803-9085-7/05/$20.00 ©2005 IEEE EXPERIMENTAL STUDIES An experimental setup has been developed [7] to perform the inverse indentation test, Fig. 6. Two double side polished silicon chips were taken as the rigid flat. One side of the opposing chips was coated with aluminium, while the other side was oxidised. The distance between the two silicon chips was measured by measuring the capacitance between them by an LCR meter. The use of silicon as sample holders was beneficial for several reasons. The chips were cut from a low resistivity wafer, which means that the electrical impedance through the chip is controlled by the resistivity at the test frequency of 100 kHz. The silicon oxide layer on the other hand which is of the order of 0.5 mm thick electrically insulates the particles from the electrodes. The polished silicon surface is very flat, and makes a near ideal surface for the small spheres. The high E-modulus and hardness means that the surface undergoes only negligible deformations compared to the polymer particles during the test. A controlled compressive force is obtained by mounting the lower chip onto an electromagnetic device, where a current was used to control the force. A number of particles with a truly uniform size distribution are tested in parallel. The force per particle was obtained by didiving the total force by the number of particles. Two types of metal-coated polymer particles, A and B have been tested. Both particles have same diameter 10 Pm but differ in elastic properties. Particle A has been tested to about 7% deformation while particle B was tested up to about 20% deformation. Fig. 7 compares the experimental sphere stress versus strain results with the finite element solution Eq. (7) using an average effective contact modulus. It is interesting to note that the obtained contact modulus appears to be independent of the sphere deformation up to 7%. The average measured contact modulus is 1175 MPa. 10 EXP 8 Sphere stress [MPa] IV Eq.(7) 6 4 2 0 0,00 0,02 0,04 0,06 0,08 Sphe re s train Fig. 7 Mechanical properties of particle type A: a) indentation curves The results of large deformation contact of particle B are shown in Fig. 8. The deformation range of particle B is about three times that of particle A. The minimum contact modulus, 1380 MPa appeared at a sphere deformation about 3% while the maximum contact modulus, 1948 MPa occurred at 15% deformation. The average contact modulus is 1731 MPa. V DISCUSSIONS AND CONCLUDING REMARKS Mechanical properties of conductive particles are an important part of the ACA technology. In order to provide reliable data for design and reliability assessment of packaging it is essential to develop complete understanding of their failure mechanisms and methodology to characterize their mechanical behavior. In this study a so-called inverse indentation method has been introduced to characterize the elastic properties of micron sized polymer particles. 70 Sphere stress [MPa] 60 Exp (8) Eq. (9) 50 40 C 30 20 10 0 0,00 0,05 0,10 0,15 Sphere strain 0,20 0,25 Fig. 6. Experimental setup for testing the mechanical properties of polymer particles. Fig. 8. Indentation curves showing mechanical properties of particle type B 0-7803-9085-7/05/$20.00 ©2005 IEEE Finite element analysis of large deformation contact shows Hertz solution works only in a small deformation range (less 1%). An approximate but universal sphere stress versus sphere strain equation has been proposed. With the proposed sphere stress-strain relation, the elastic contact modulus can be estimated from the experimental inverse indentation results. It is an open question whether linear elasticity exists in large deformation contact of polymer spheres. The present investigation indicates that estimated elastic contact modulus is relatively constant. The experimental work has shown clear indications of hysteresis during loading and de-loading of the particles. It is at the moment not clear whether this is cased by material properties or interfacial forces. The experimental work will also include new measurements with more advanced instruments. Further FEM work will include adhesion forces between particle and indenter as well as non elastic material properties. REFERENCES [1] Kristiansen, H, et al, “Electrical and Mechanical Properties of Metal-coated Polymer Spheres for Anisotropic Conductive Adhesive”, Proc, PEP 99; Gothenburg Oct. 99, pp 63 – 71 [2] Kristiansen, H, et al, “Characterisation of Electrical and Mechanical Properties of Metal-coated Polymer Spheres for Anisotropic Conductive Adhesive”, Proc, IMAPS Nordic 04; Helsingør Oct. 99, pp 63 – 71 [3] K K Liu et al, “The large deformation of a single microelastiomeric sphere”, 1998 J. Phys. D: Appl. Phys. 31 294303. [4] E. H. Yoffe, “Modified hertz theory for spherical indentation”, Philosophical Magazine A: Physics of Condensed Matter, Defects and Mechanical Properties, 50, n 6, Dec, 1984, p 813-828. [5] Y. Tatara , S. Shima and J. C. Lucero, J. Engng Mater Tech. ASME 1991, 113, 292-295. [6] H. D. Espinosa, B. C. Prorok, Size effects on the mechanical behaviour of gold thin films, Journal of Materials Science 38 (2003) 4125 – 4128. [7] Kristiansen, H, Liu, J, “Behaviour and Properties of Conductive Particles in Anisotropic Conductive Adhesive”, High Density Electronics Packaging 2002, Shanghai, July 2002 0-7803-9085-7/05/$20.00 ©2005 IEEE