Breakdown mechanism in AlGaN/GaN HEMTs on Si substrate

advertisement

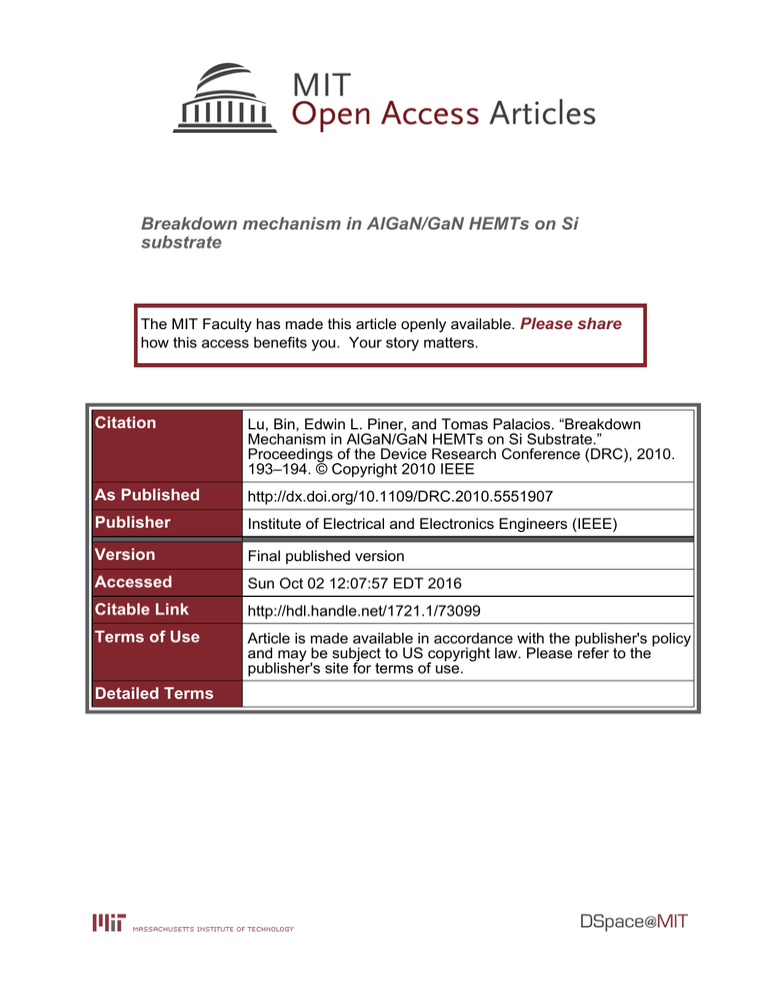

Breakdown mechanism in AlGaN/GaN HEMTs on Si substrate The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Lu, Bin, Edwin L. Piner, and Tomas Palacios. “Breakdown Mechanism in AlGaN/GaN HEMTs on Si Substrate.” Proceedings of the Device Research Conference (DRC), 2010. 193–194. © Copyright 2010 IEEE As Published http://dx.doi.org/10.1109/DRC.2010.5551907 Publisher Institute of Electrical and Electronics Engineers (IEEE) Version Final published version Accessed Sun Oct 02 12:07:57 EDT 2016 Citable Link http://hdl.handle.net/1721.1/73099 Terms of Use Article is made available in accordance with the publisher's policy and may be subject to US copyright law. Please refer to the publisher's site for terms of use. Detailed Terms Breakdown Mechanism in AlGaN/GaN HEMTs on Si Substrate Bin Lu1, Edwin L. Piner2* and Tomás Palacios1 1 Department of Electrical Engineering and Computer Science, Massachusetts Institute of Technology, Cambridge, MA, 02139 2 Nitronex Corporation, Durham, NC, 27703 Email: binlu@mit.edu Phone: 617-253-0715 AlGaN/GaN high electron mobility transistors (HEMTs) grown on Si substrates have attracted a great interest for power electronics applications. Despite the low cost of the Si substrate, the breakdown voltage (Vbk) of AlGaN/GaN HEMTs grown on Si (less than 600 V for 2 μm total nitride epilayer [1, 4]) is much lower than that grown on SiC (1.9 kV for 2 μm total epi-layer [2]). Although several approaches have been reported to improve Vbk [1, 3 and 4], the breakdown mechanism in these transistors is still not well understood. This paper studies for the first time the breakdown mechanism in AlGaN/GaN HEMTs on Si substrates. In addition, by transferring the AlGaN/GaN HEMTs grown on Si to a glass wafer, we have achieved devices with Vbk in excess of 1.45 kV and specific on-resistance of 5.3 mΩ.cm2. The devices analyzed in this paper were fabricated using our standard fabrication technology [4] on Al0.26Ga0.74N/GaN structures grown on intrinsic Si(111) by Nitronex Corporation. The device structure had a 2 nm GaN cap, 20 nm Al0.26Ga0.74N barrier and a 2 μm thick GaN/AlGaN buffer. The devices have a gate width of 100 μm, a 2 μm gate length, and varying gate-to-drain distances. It is suggested in [4] that the GaN-to-Si substrate vertical leakage limits the maximum breakdown of the AlGaN/GaN HEMTs on Si. To study this phenomena we measured the vertical leakage current between an ohmic contact on the GaN surface and the Si substrate (Fig.1). The leakage current shows a strong asymmetry on the polarity of the bias voltage. The leakage current starts to increase at a positive bias of 100 V between the GaN and the substrate, while a negative bias of 290 V is needed for the same amount of leakage. This asymmetry of the ohmic contact results in an unbalanced voltage distribution in AlGaN/GaN power transistors, as shown in the lateral buffer breakdown measurement in Fig.2. In this measurement, the Si substrate potential is recorded using a high impedance (20 MΩ) voltage meter while increasing the drain-to-source voltage. As shown in Fig. 2, more voltage is dropped at the substrate-to-source region than at the drain-to-substrate region. The leakage mechanism is different in the forward biased drain-to-substrate and in the reverse biased source-to-substrate regions. 1) At forward drain-to-substrate bias, accumulation of holes is observed at a bias voltage of ~ 150V as shown in the increase of capacitance in Fig. 3(b). At higher bias voltages, electrons are injected into the buffer from the Si substrate and annihilate with the holes, which reduces the capacitance as shown in Fig. 3(b) and causes light emission (Fig.3(c)). As shown in the band diagram in Fig.3(c), both the holes (generated in GaN through Schottky-Read-Hall generation) and the injected electrons from the Si substrate are thermally activated. The leakage current in forward drain-to-substrate bias is therefore increased with higher temperature as shown in Fig.1. 2) At reverse source-to-substrate bias (flat C-V in Fig.3(a)), electrons are injected from the source contact into the buffer and are trapped in the buffer, where they form a space charge region. The space charge region creates a nonuniform electric field distribution and eventually causes impact ionization in the buffer (positive temperature coefficient as shown in Fig. 1) for voltages between 300 V and 350 V. Assuming a uniform distribution of trapped electrons in the buffer, the calculated critical electric field is 3~3.5 MV/cm. To eliminate the vertical breakdown of the AlGaN/GaN HEMTs on Si, we removed the Si substrate and transferred the AlGaN/GaN HEMTs to a glass wafer through wafer bonding. The device maximum current (Fig.4) is lower after bonding to the glass substrate due to increased self-heating. A device with Lgd = 18 μm shows breakdown of 1370 V and on-resistance of 4.3 mΩ·cm2 with very low leakage current (< 10 μA/mm) (Fig.5). Three terminal breakdown voltage as a function of gate-to-drain spacing (Lgd) is shown in Fig.6. More than 1450 V * Currrent affiliation: Department of Physics, Texas State University, San Marcos, TX 78666 978-1-4244-7870-5/10/$26.00 ©2010 IEEE 193 breakdown and an on-resistance of 5.3 mΩ·cm2 is achieved on devices with Lgd = 20 μm, which is beyond our power supply maximum output voltage. In summary, in this work we have identified two different mechanisms in the buffer breakdown of AlGaN/GaN HEMTs on Si substrates. First, the drain-to-substrate forward bias leakage is due to hole generation in the buffer and electron injection from the Si substrate into the buffer. Second, the source-to-substrate reverse bias breakdown is due to impact ionization. By removing the Si substrate the breakdown voltage of AlGaN/GaN HEMTs can be improved significantly. Acknowledgements: This work has been partially funded by the MIT Energy Initiative, M/A-COM and the DOE-sponsored GIGA Project. [1] S.L. Selvaraj, T. Suzue, and T. Egawa, IEEE Electron Device Lett., vol. 30, no. 6, pp. 587-589, June 2009. [2] Y. Dora, A. Chakraborty, L. McCarthy, S. Keller, S. P. Denbaars, and U. K. Mishra, IEEE Electron Device Lett., vol. 27, no. 9, pp. 713-715, Sep. 2006. [3] Y.C. Choi, M. Pophristic, H.-Y. Cha, B. Peres, M.G. Spencer, L.F. Eastman, IEEE Tran. Electron Devices, vol. 53, no. 12, pp. 2926-2931, Dec. 2006 [4] B. Lu, E.L. Piner, T. Palacios, IEEE Electron Device Lett., vol. 31, no. 4, pp. 302-304, Apr. 2010 Fig. 1. Measurement of the vertical leakage current between an ohmic contact and the Si substrate at 10 oC and 100 oC. Fig. 2: Substrate-to-source and drain-to-substrate voltages as a function of source leakage current for two isolated ohmic contacts with a separation of 24 μm. The measurement setup is shown to the right. Fig. 3. C-V measurement of ohmic contact-2μm buffer-Si substrate capacitor (a) reverse bias (b) forward bias (c) Electroluminescence at forward bias of 200 V and the associated band diagram. AlGaN/GaN on Si Vg = 1V ΔVg = 1V AlGaN/GaN on glass 300 200 d I (mA/mm) 400 100 0 0 2 4 6 8 10 V (V) ds Fig. 4. I-V characteristics of an AlGaN/GaN HEMT before and after transferring it to a glass substrate 978-1-4244-7870-5/10/$26.00 ©2010 IEEE Fig. 5. Three terminal breakdown of an AlGaN/GaN device on glass with Lgd = 18 μm and Vgs = - 8 V. 194 Fig. 6. Three terminal breakdown of AlGaN/GaN HEMTs with different Lgd transferred to a glass substrate