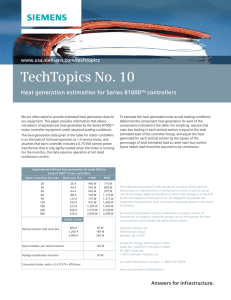

SINAMICS S110 servo drives 0.12 kW to 90 kW (0.16 hp to 125 hp)

advertisement