EECE488: Analog CMOS Integrated Circuit Design Set 7 Opamp

advertisement

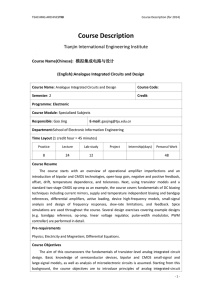

EECE488: Analog CMOS Integrated Circuit Design

Set 7

Opamp Design

References: “Analog Integrated Circuit Design” by D. Johns and K. Martin

and “Design of Analog CMOS Integrated Circuits” by B. Razavi

All figures in this set of slides are taken from the above books

Shahriar Mirabbasi

Department of Electrical and Computer Engineering

University of British Columbia

shahriar@ece.ubc.ca

SM

EECE488 Set 7 - Opamp Design

1

General Considerations

•

•

•

•

•

•

•

•

SM

Gain

Small-signal bandwidth

Large-signal performance

Output swing

Input common-mode range

Linearity

Noise/offset

Supply rejection

EECE488 Set 7 - Opamp Design

2

1

One-Stage Op Amps

SM

EECE488 Set 7 - Opamp Design

3

One-Stage Op Amp in Unity Gain

Configuration

SM

EECE488 Set 7 - Opamp Design

4

2

Cascode Op Amps

SM

EECE488 Set 7 - Opamp Design

5

Unity Gain One Stage Cascode

SM

EECE488 Set 7 - Opamp Design

6

3

Folded Cascode Op Amps

SM

EECE488 Set 7 - Opamp Design

7

Folded Cascode Stages

SM

EECE488 Set 7 - Opamp Design

8

4

Folded Cascode (cont.)

SM

EECE488 Set 7 - Opamp Design

9

Folded Cascode (cont.)

| Av |≈ gm1 {[(gm 3 + gmb3 )ro3 (ro1 || ro5 )]||[(gm 7 + gmb 7 )ro7 ro9 ]}

SM

EECE488 Set 7 - Opamp Design

10

5

Telescopic versus Folded Cascode

SM

EECE488 Set 7 - Opamp Design

11

Example Folded-Cascode Op Amp

SM

EECE488 Set 7 - Opamp Design

12

6

Single-Ended Output Cascode Op Amps

SM

13

EECE488 Set 7 - Opamp Design

Triple Cascode

Av app. (gmro)3/2

Limited Output Swing

Complex biasing

SM

EECE488 Set 7 - Opamp Design

14

7

Output Impedance Enhancement

Rout = A1 g m 2 ro 2 ro1

SM

EECE488 Set 7 - Opamp Design

15

Gain Boosting in Cascode Stage

SM

EECE488 Set 7 - Opamp Design

16

8

Differential Gain Boosting

SM

EECE488 Set 7 - Opamp Design

17

Differential Gain Boosting

SM

EECE488 Set 7 - Opamp Design

18

9

Differential Gain Boosting

SM

EECE488 Set 7 - Opamp Design

19

Two-Stage Op Amps

SM

EECE488 Set 7 - Opamp Design

20

10

Single-Ended Output Two-Stage Op Amp

SM

21

EECE488 Set 7 - Opamp Design

Two-Stage CMOS Opamp

•

•

•

•

Popular opamp design approach

A good example to review many important design concepts

Output buffer is typically used to drive resistive loads

For capacitive loads (typical case in CMOS) buffer is not

required.

Cc

V in

A1

Differential

input stage

SM

– A2

Second

gain stage

EECE488 Set 7 - Opamp Design

1

V out

Output

buffer

22

11

Two-Stage CMOS Opamp Example

SM

EECE488 Set 7 - Opamp Design

23

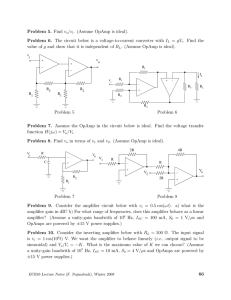

Gain of the Opamp

•

First Stage

Differential to single-ended

•

Second Stage

Common-source stage

•

SM

Output buffer is not required when driving capacitive loads

EECE488 Set 7 - Opamp Design

24

12

Gain of the Opamp

Third Stage

•

Source follower

•

•

•

Typical gain: between 0.7 to1

Note: go=1/ro and GL=1/RL

gmb is body-effect conductance (is zero if source can be tied to

substrate)

SM

25

EECE488 Set 7 - Opamp Design

Frequency Response

Q5

Vbias

300

vin+

Q1

300

vin–

Q2

300

v1

CC

v2

A3 ≅ 1

150

vout

i = g m1 vin

150

Q3

SM

A3

–A2

Ceq = CC ( 1 + A 2 )

Q4

EECE488 Set 7 - Opamp Design

26

13

Frequency Response

Simplifying assumptions:

• CC dominates

• Ignore Q16 for the time being (it is used for lead compensation)

Miller effect results in

•

SM

At midband frequencies

EECE488 Set 7 - Opamp Design

27

Frequency Response

•

Overall gain (assuming A3 ≈1)

which results in a unity-gain frequency of

•

SM

Note: ωta is directly proportional to gm1 and inversely

proportional to CC.

EECE488 Set 7 - Opamp Design

28

14

Frequency Response

•

First-order model

20 log ( A1 A 2 )

– 20 dB/decade

Gain

(dB)

ω ta ≅ g m 1 ⁄ CC

Freq

0

ω ta

ωp 1

(log)

ωp 1

0

Freq

ω ta

Phase

(log)

(degrees)

– 90

– 180

SM

29

EECE488 Set 7 - Opamp Design

Slew Rate

•

Maximum rate of output change when input signal is large.

Q5

Vbias

300

vin+

Q1

300

vin–

Q2

300

v1

CC

v2

A3 ≅ 1

–A2

150

Q3

SM

vout

i = g m1 vin

150

•

A3

Q4

All the bias current of Q5 goes either into Q1 or Q2.

EECE488 Set 7 - Opamp Design

30

15

Slew Rate

SM

EECE488 Set 7 - Opamp Design

31

Slew Rate

•

Normally, the designer has not much control over ωta

•

Slew-rate can be increased by increasing Veff1

•

This is one of the reasons for using p-channel input stage:

higher slew-rate

SM

EECE488 Set 7 - Opamp Design

32

16

Systematic Offset Voltage

•

To ensure inherent (systematic) offset voltage does not exist,

nominal current through Q7 should equal to that of Q6 when the

differential input is zero.

Q5

VDD

300

Vbias

Q6

300

I b ia s

Q1

Vin –

Q2

300

Vin +

300

Vo ut

300

150

150

Q3

SM

Q4

VSS

Q7

EECE488 Set 7 - Opamp Design

33

Systematic Offset Voltage

•

Avoid systematic offset by choosing:

•

Found by noting

and

then setting

SM

EECE488 Set 7 - Opamp Design

34

17

N-Channel versus P-Channel Input Stage

•

Complimentary opamp can be designed with an n-channel input

differential pair and p-channel second-stage

• Overall gain would be roughly the same in both designs

P-channel Advantages

• Higher slew-rate: for fixed bias current, Veff is larger (assuming

similar widths used for maximum gain)

• Higher frequency of operation: higher transconductance of

second stage which results in higher unity-gain frequency

• Lower 1/f noise: holes less likely to be trapped; p-channel

transistors have lower 1/f noise

• N-channel source follower is preferable (less voltage drop and

higher gm)

N-channel Advantage

• Lower thermal noise — thermal noise is lowered by high

transconductance of first stage

SM

35

EECE488 Set 7 - Opamp Design

Feedback and Opamp Compensation

Y

H (s)

(s) =

X

1 + βH (s)

•

Feedback systems may oscillate

•

The following two are the oscillation conditions:

| β H ( jω ) |= 1

∠β H ( jω ) = −180

SM

EECE488 Set 7 - Opamp Design

36

18

Stable and Unstable Systems

SM

EECE488 Set 7 - Opamp Design

37

Time-domain response of a feedback system

SM

EECE488 Set 7 - Opamp Design

38

19

One-pole system

H ( s) =

Y

( s) =

X

A0

1+ s

ω0

A0

1 + βA0

s

1+

ω 0 (1 + βA0 )

S p = −ω 0 (1 + β A0 )

Bode plot of the Loop gain

SM

EECE488 Set 7 - Opamp Design

39

Multi-pole system

0.1ω p 2 > 10ω p1

Bode plot of the Loop gain

SM

EECE488 Set 7 - Opamp Design

40

20

Phase Margin

-20 dB/decade

Loop Gain

(dB)

20 log (LG (j ω))

0

ωt

ωp 1

Freq

(log)

GM

(gain margin)

ωp 1

Phase

ωt

Freq

(log)

0

Loop Gain

(degrees)

–90

–180

SM

PM

(phase margin)

EECE488 Set 7 - Opamp Design

41

Phase Margin

β H ( ω1 ) = 1× e − j175

Y

11.5

(s) =

X

β

Closed loop frequency response

SM

EECE488 Set 7 - Opamp Design

42

21

Phase Margin (Cont.)

PM = 180 + ∠βH ( ωGX )

Phase Margin = 45°

SM

EECE488 Set 7 - Opamp Design

43

Phase Margin (Cont.)

Phase Margin = 45°

SM

EECE488 Set 7 - Opamp Design

44

22

Phase Margin (Cont.)

•

•

SM

At PM = 60o results in a small overshoot in the step response.

If we increase PM, the system will be more stable but the time

response slows down.

EECE488 Set 7 - Opamp Design

45

Frequency Compensation

•

•

SM

Push phase crossing point out

Push gain crossing point in

EECE488 Set 7 - Opamp Design

46

23

Telescopic Opamp (single-ended) -example

SM

EECE488 Set 7 - Opamp Design

47

Compensation (Cont.)

• Assume we need a phase margin of 45o (usually

inadequate) and other non-dominant poles are at high

frequency.

SM

EECE488 Set 7 - Opamp Design

48

24

Compensation of a two-stage opamp

Miller Effect

f pE =

Ceq = CE + (1+ Av 2 )CC

1

2πRout [CE + (1+ Av 2 )CC ]

SM

49

EECE488 Set 7 - Opamp Design

Compensating Two-Stage Opamps

Q5

Vbias1

300

Q1

300

Q2

300

Vin-

Q6

VDD

Vin+

300

Vout2

Vbias2

Q16

Cc

300

150

150

Q3

SM

Q4

EECE488 Set 7 - Opamp Design

Q7

50

25

Compensating Two-Stage Opamps

v

gm1 v

in

R1

1

C1

RC

CC

g

v

m7 1

R

2

C2

•

Q16 has VDS16 = 0 therefore it is hard in the triode region.

•

Small signal analysis: without RC, a right-half plane zero occurs

and worsens the phase-margin.

SM

EECE488 Set 7 - Opamp Design

51

Compensating Two-Stage Opamps

•

Using RC (through Q16) places zero at

•

•

Zero moved to left-half plane to aid compensation

Good practical choice is

•

satisfied by letting

SM

EECE488 Set 7 - Opamp Design

52

26

Design Procedure

Design example: Find CC with RC=0 for a 55o phase margin

– Arbitrarily choose C’C=1pF and set RC=0

– Using SPICE, find frequency ωt where a –125° phase shift

exists, define gain as A’

– Choose new CC so ωt becomes unity-gain frequency of the

loop gain, resulting in a 55o phase margin.

Achieved by setting CC=CCA’

– Might need to iterate on CC a couple of times using SPICE

SM

EECE488 Set 7 - Opamp Design

53

Design Procedure

Next: Choose RC according to

– Increasing ωt by about 20 percent, leaves zero near final ωt

– Check that gain continues to decrease at frequencies above the

new ωt

Next: If phase margin is not adequate, increase CC while leaving

RC constant.

SM

EECE488 Set 7 - Opamp Design

54

27

Design Procedure

Next: Replace RC by a transistor

SPICE can be used for iteration to fine-tune the device

dimensions and optimize the phase margin.

SM

EECE488 Set 7 - Opamp Design

55

Process and Temperature Independence

•

Can show non-dominant pole is roughly given by

•

Recall zero given by

•

If RC tracks inverse of gm7 then zero will track ωp2:

SM

EECE488 Set 7 - Opamp Design

56

28

Process and Temperature Independence

•

Need to ensure Veff16/Veff7 is

temperature variations

Q11

Vbias

Q12

independent of process and

Q6

25

300

25

V

a

25

CC

Q16

Q13

300

Vb

V

•

SM

Q7

b

First set Veff13=Veff7 which makes Va=Vb

EECE488 Set 7 - Opamp Design

57

Process and Temperature Independence

SM

EECE488 Set 7 - Opamp Design

58

29

Stable Transconductance Biasing

SM

EECE488 Set 7 - Opamp Design

59

Stable Transconductance Biasing

•

•

•

Transconductance of Q13 (to the first order) is determined by

geometric ratios only.

Independent of power-supply voltages, process parameters,

temperature, etc.

For special case (W/L)15=4(W/L)13

gm13=1/RB

•

•

•

SM

Note that high-temperature will decrease mobility and hence

increase effective gate-source voltages.

Roughly 25% increase for 100 degree increase

Requires a start-up circuit (might have all 0 currents)

EECE488 Set 7 - Opamp Design

60

30