Alco Catalog

advertisement

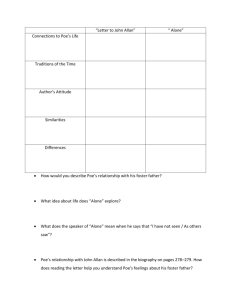

OIL CONTROLS OMA TRAXOIL A PPLICATION ¶ Compressor crankcase oil level protective control ¶ Warranty requirement for Copeland ZF, ZB and ZS refrigeration scroll compressors ¶ Recommended for Copeland, Carlyle, Bitzer and other semi-hermetic compressors F EATURES ¶ Self contained unit with oil level sensor and integral solenoid to manage oil level supply ¶ Hall-effect sensor for precise measurement of oil level ¶ Alarm and status indication by LEDs ¶ SPDT output contact for compressor shutdown or alarming ¶ Easy installation by sightglass replacement ¶ Adapters suitable for various types of compressors including conventional and scroll compressors ¶ Signal generated by gravity based float - not prone to errors from foaming like optical sensors ¶ Debris retention magnet for reliable operation ¶ UL recognized S PECIFICATIONS ¶Maximum Working Pressure: ¶Solenoid MOPD: ¶Supply Voltage: ¶Solenoid Coil: ¶Current Consumption: ¶Time delay for Low Level Signalling: ¶Time Delay After Setpoint Recovery ¶Alarm Delay Time (including alarm contact) ¶Alarm Switch: ¶Alarm Contact Rating: NOMENCLATURE Example: OMA JB1S/T ASC2 24 50/60 OMA JB Alco Oil JB - Junction Box Management MA - Stress Control Relief Connector 1 1 - TraxOil 2 - Oil Watch ORDERING INFORMATION PCN* 064340 064341 063678 063520 063521 048638 064811 064812 FOR S/T Oil Inlet FTG 1/4 SAE S/T - Straight ANG - Angle ASC2 24 50/60 Solenoid Coil Model Number, Voltage, Frequency (Included) OMA TRAXOIL DESCRIPTION T R A X OI L OMA-JB1 S/T ASC 2 24/50-60 - STD OMA-MO1 ANG ASC 2 24/50-60 - Hussmann Protocol A DAPTERS ( TO ATTACH T RAX O I L TO COMPRESSOR FOR NEW INSTALLATIONS ONLY - S E E T ABLE ON P AGE 258) OMA-ACB ADAPTER (Copeland Scroll ZF, ZS, ZB) - KS30349 OMA-ACA ADAPTER (Copeland Scroll ZF, ZS, ZB) - KS30350 OMA-AUA ADAPTER (Semi Hermetic Universal) - KS30348 S ERVICE P ARTS Inlet Flare Screen - X11176-7 Sight Glass and O-Ring - KS30367 O-Rings (3 pieces) - KS30368 7 1/2 - 15 HP 6 HP and smaller Standard Product Offering ¶Refrigerant Compatibility: (not for use with flammable refrigerants or ammonia) ¶Refrigerant Temp.: ¶Storage and Transpor t Temp.: ¶Ambient Temp. (Housing): ¶Oil Supply Fitting: 500psig 300 psi 24 V AC, 50/60 Hz Alco AMF or ASC2 24 V AC, 50/60 Hz 0.6A 10 seconds 10 seconds 120 seconds SPDT 1.2A @ 125VAC 50/60 0.6A @ 250VAC 50/60 HFC,HCFC, CFC 180oF Maximum 120oF Maximum 120oF Maximum 1/4" Male SAE D IMENSIONAL D ATA 4.76 3.1 *Product Code Number NOTE: An adapter kit is required for new installations. ALCO CONTROLS TraxOil unit must be mounted horizontally for correct operation. 257 OMA ADAPTERS OMA - AUA - 063521 Includes: (3) O-Rings, 3 Bolts, 3 Washers and 3 Nuts Flange Adapter 3/4 2.36 .98 3 holes (.26) 4 holes (.26) O-ring seal (1.3 x 1) 1.65 S EMI -H ERMETIC U NIVERSAL A DAPTER C OPELAND S CROLL ZS, ZB (2-6 HP) Thread NPTF male ZF, Teflon seal Additional flange ring for adapter/base unit connection (included) 1.6 OMA - ACA - 063520 Includes: Sight Glass, (2) O-Rings and 3 Bolts Screw Adapter 3/4-14 NPTF 1.83 OMA - ACB - 063678 Includes: Sight Glass, (2) O-Rings and 3 Bolts Screw Adapter 1-1/8-12 UNF Thread UNF C OPELAND S CROLL O-ring seal (.86 x 1) ZF, ZS, ZB (7 1/2 Additional flange ring for adapter/base unit connection (included) 1.13 1.57 OIL CONTROLS TRAXO IL OIL MANAGEMENT SYSTEM - 15 HP) 1.57 1.22 NOTE: Sight Glass PCN 064811 required for Bitzer 4-hole pattern compressor. OMA OIL WATCH The Alco OMA-JB2 Oil Watch is designed to monitor a compressors oil level and signal an alarm if the oil level is not adequate. The OMA-JB2 can be used to shut-down the compressor in addition to its alarm capability. For use on single compressor applications without oil separators. F EATURES ¶ Self contained unit ¶ SPDT alarm output ¶ Installs directly over compressor sight glass ¶ Junction box standard ¶ UL recognized 258 ORDERING INFORMATION FOR OMA OIL WATCH PCN 063841 ALCO CONTROLS DESCRIPTION OMA-JB2 OIL CONTROLS A-W & A-F OIL SEPARATORS APPLICATION ¶ Multiple compressor racks for supermarkets and air conditioning ¶ Systems with long refrigerant lines ¶ Systems with inherent oil return problems ¶ Ultra-low temperature systems ¶ For use with HCFCs, HFCs and their lubricants FEATURES ¶ Hermetic welded or accessible bolted flange construction ¶ Solid copper connections ¶ Corrosion resistant paint NOMENCLATURE Example: AW 5582 4 A W Alco 5582 W = Welded F = Flanged S PECIFICATIONS 4 Competitive Cross Reference ¶ Maximum working pressure: 450 psig ¶ U.L listed (file #5168) ¶ C.S.A. Listed (LR100624) Connection Size (in 1/8) ORDERING INFORMATION AND CAPACITY TABLE MODEL NO. R22/R407C R502 -40F/C 40F (14C) -40F/C 40F (14C) Tons k W Tons k W Tons k W Tons kW R134a -40F/C 40F (14C) Tons k W Tons k W R-404A/R-507 -40F/C 40F (14C) Tons k W Tons k W PCN* A-F 58824 060877 A-W 55824 060933 1 3.54 1.5 5.31 1.5 5.31 2 7.08 1.5 5.31 2 7.08 1 3.54 1.75 6.2 1.5 5.31 2 7.0 A-F 58855 060878 A-W 55855 060934 3 10.62 4 14.2 4.5 15.9 5.5 19.5 4.75 16.8 5.75 20.36 3.25 11.5 4.5 15.9 4 14.16 5.5 19.0 A-F 58877 060879 A-W 55877 060931 4.5 15.93 5.5 19.5 7 24.8 8 28.3 7.5 26.6 8.5 30.09 4.75 16.8 6.5 23 6.5 23.01 8.5 30.0 A-F 58889 060759 A-W 55889 060974 6 21.24 7.5 26.6 9 31.9 11 37.2 9.5 33.6 11.5 40.71 6.5 23 8.5 30.1 8.5 30.09 11 38.0 A-F 589011 060760 A-W 559011 060930 7.5 26.55 10 35.4 11.5 40.7 14 47.8 12 42.5 14.5 51.33 8 28.3 11.5 40.7 10.5 37.17 14 49.0 A-F 589213 060761 A-W 559213 060975 9 31.86 11.5 40.7 14 49.6 18 62 16 56.6 17.5 61.95 9.5 33.6 13.25 46.9 14 49.56 17 60.0 A-W 569011 060978 9 31.69 12 42.25 13 45.77 14 49.8 15 52.8 20 70.4 9.5 33.4 13.7 48.2 11 38.7 19 66.9 A-F 579213 060875 A-W 569213 060979 11 38.94 14 49.6 16 56.6 18 63.7 20 70.8 24 84.96 11.8 41.6 16 56.6 17.5 61.95 23 81 A-F 579417 060876 A-W 569417 060980 17 60.18 22 77.9 25 88.5 30 106 30 106 35 123.9 18 63.7 25.25 89.4 26 92.04 34 121.0 PCN* 40F (14C) Tons kW FLANGED SEALED R12 -40 F/C Tons kW Standard Product Offering *Product Code Number SEALED UNITS: A-W MODEL NO. A-W 55824 A-W 55855 A-W 55877 A-W 55889 A-W 559011 A-W 569011 A-W 569213 A-W 569417 DIMENSIONAL DATA STYLE NO. 1 1 1 1 1 1 1 1 CONNECTION SIZE 1/2 ODF 5/8 ODF 7/8 ODF 1-1/8 ODF 1-3/8 ODF 1-3/8 ODF 1-5/8 ODF 2-1/8 ODF DIMENSIONS (inches) A B 4.00 10.75 4.00 14.25 4.00 17.75 4.00 21.00 4.00 21.25 6.00 15.75 6.00 19.00 6.00 19.50 FLANGED UNITS: A-F MODEL NO. A-F 58824 A-F 58855 A-F 58877 A-F 58889 A-F 589011 A-F 589213 A-F 579213 A-F 579417 ALCO CONTROLS STYLE NO. 3 3 3 3 3 3 2 2 CONNECTION SIZE 1/2 ODF 5/8 ODF 7/8 ODF 1 1/8 ODF 1 3/8 ODF 1 5/8 ODF 1 5/8 ODF 2 1/8 ODF A 4.00 4.00 4.00 4.00 4.00 4.00 6.00 6.00 DIMENSIONS B 10.25 14.25 17.75 21.00 21.25 21.63 20.25 20.31 C 5.50 5.50 5.50 5.50 5.50 5.50 4.25 4.50 259 OIL CONTROLS AOFD 553 OIL FILTER-DRIER ALCOs AOFD is designed specifically for refrigerant systems that use POE oil. POE oil is hygroscopic in nature, which means that it attracts and absorbs water. Moisture in a closed system can produce acid and will harm the compressor. ALCOs AOFD protects compressors by removing moisture and trapping contaminants. F EATURES ¶ Designed to clean and dry POE Oil ¶ 3/8 male flare connections for easy replacement ¶ Large filter surface area to provide maximum filtration ¶ Contains 100% molecular sieve XH-9 Desiccant for moisture removal ¶ Designed to operate at a very low pressure drop ¶ 10 micron filtration for optimum oil cleaning (Replaces AC&R S-4005) AOFD W ATER C APACITY T ABLE DIMENSIONAL DATA REFRIGERANT TYPE R-22 R-134a R-404A R-407C 3 7 1/2 DROPS @ 125 O F 497 518 518 435 ORDERING INFORMATION FOR AOFD FILTER-DRIER 9 5/8 PCN 062829 DESCRIPTION AOFD 553 OIL FILTER DRIER ASF 45 F 3-VV OIL FILTER APPLICATION ¶The ASF 45F3-VV effectively removes debris from oil lines FEATURES ¶Specifically designed to protect the compressor from dirt and all solid contaminants ¶Full flow fittings minimizes pressure drop ¶Dual access valves ¶3/8 SAE connections for easy installation on oil lines ¶Filtration to 10 microns for maximum compressor protection ¶Corrosion resistant epoxy powder paint finish SPECIFICATIONS ¶Maximum working pressure: ¶UL file number: ¶CSA file number: 260 ORDERING INFORMATION FOR ASF PCN 059999 DESCRIPTION ASF 45 F 3-VV * Product Code Number Standard Product Offering 500 psig SA 3124 LR 32462 SEE PAGE 237 FOR DIMENSIONAL DATA. ALCO CONTROLS OIL CONTROLS AOF HIGH EFFICIENCY OIL FILTER DED MEN M O EC LL LY R HIGH FOR SCRO ORS! SS PRE M O C 3.06 APPLICATION ¶ Specifically designed to protect the compressor from dirt and all solid contaminants including metallic magnetic particles 7.50 9.63 F EATURES ¶ Corrosion resistant epoxy powder paint finish ¶ 3/8 SAE connections for easy installation on oil lines ¶ 98% efficient to 4 micron par ticles ¶ Compatible with all oils SPECIFICATIONS ¶ Maximum working pressure: 500 psig ¶ UL/CUL: SA 3124 O RDERING I NFORMATION PCN* DESCRIPTION 064952 AOF 303 * Product Code Number AOF HIGH EFFICIENCY TAKE-APART OIL FILTER APPLICATION 3.75 ¶ Specifically designed to protect the compressor from dirt and all solid contaminants including metallic magnetic particles 7.38 5.31 F EATURES ¶ Compatible with all oils ¶ Solid copper fittings ¶ Quick change filter cartridge ¶ Corrosion resistant epoxy paint finish ¶ 98% efficient to 4 micron particles ¶ 3/8 ODF connections AOF 023 S Take-Apar t Oil Filter ORDERING INFORMATION PCN* 062784 064799 DESCRIPTION AOF 023S F023 Car tridge SPECIFICATIONS F 023 Replaceable Filter Car tridge ¶ Maximum working pressure: ¶ UL/CUL: * Product Code Number Standard Product Offering ALCO CONTROLS 500 psig SA7175 261 OIL CONTROLS UNIVERSAL ACID TEST Kit H BOT ITH W E ND US FOR INERAL A S! M OI L POE A PPLICATION The Universal Acid Alert Test Kit provides a positive indication of whether the acid level of the refrigeration oil is safe or unsafe. F EATURES ¶Quick and easy test kit ¶Universal acid test kit for use with all refrigeration lubricants ¶By changing the percentage of oil sample taken, the acid number of the oil can be accurately determined ¶Phase separation of the chemicals in the kit provide a positive color change regardless of the color and condition of the oil 262 O RDERING I NFORMATION PCN* DESCRIPTION 064427 AA Kit Universal * Product Code Number ALCO CONTROLS OIL CONTROLS HFC REFRIGERANTS AND POE LUBRICANTS Moisture is the major problem causing contaminate for HFC/ POE oil systems just as it was for CFC and HCFC systems using Mineral oil. Many HFCs can hold much more water than their CFC counterparts but the oil differences are much worse than those of the refrigerant. POE oil can hold as much as 10 times more water than Mineral oils. In addition, evacuation has proven ineffective at removing this moisture so a filter-drier is required to perform this function. 1800 Water Content (ppm) 1600 1400 1200 1000 800 600 400 200 0 Mineral POE Oil Oil R-12 R-134a R-22 R-502 R-404A Water poses a new problem for POE oils above and beyond those experienced with Mineral oil. POE oil will react with water to form organic acids at normal operating conditions in refrigerating and air-conditioning systems. This reaction starts at water levels as low as 75 ppm. These acids attack system components including motor insulation and metallic components reducing system life. To combat the detrimental effects of water in HFC and POE oil systems it is imperative to hold moisture levels as low as possible. It is generally accepted that water level must be maintained less than 50 ppm in the refrigerant and the same for the oil. In order to monitor system water level a moisture indicator must be used that can sense changes in moisture in this ppm range. 0.2 Total Acid Number The use of HFC refrigerants and Polyolester (POE) lubricants for air-conditioning and refrigeration have generated new system chemistry related problems. New and redesigned system protectors have been developed to counteract these problems and provide a long, reliable life for the operating refrigeration system. 0.15 0.1 0.05 0 0 100 200 300 400 500 600 700 Refrigerant Water Concentration (ppm) Figure 2 Acid Generation in a 1.5 Ton R-134a Air-conditioning System Many commercial sightglasses cannot indicate a change at this level in liquid lines that exceed 100°F. This means that harmful organic acids may be attacking system components while the indicator is showing dry. The AMI has a unique element that has the ability to change color at low ppm levels so that proper action can be taken before any system components are damaged. It was necessary to redesign standard filter-driers for increased water removal capacity to achieve these low moisture levels. However, since no system is entirely devoid of water upon startup some organic acids will be generated and must be removed. The desiccant formulation for the EK and UDK series of filter-driers was designed to provide the optimal mix of water capacity and acid capacity to ensure that both harmful contaminates are effectively removed. This desiccant mixture contains both molecular sieve and activated alumina. The molecular sieve is specifically designed to provide maximum drying in todays systems. The activated alumina is ideal for capturing the large organic acids that the molecular sieve cannot. Another aspect of POE oil is the ability to keep more solid particles in suspension than Mineral oil. This is particularly important in retrofitted systems where pockets of solid contamination are now flushed from low flow areas and need to be removed before moving parts in the system are damaged. The filter-drier for POE oils needs to have increased solid particle holding capacity with minimal impact to refrigerant flow capacity or pressure drop. ALCO CONTROLS 263 OIL CONTROLS The filter-drier should also have improved contaminate removal efficiency as well to ensure that all particles are captured the first time they enter the filter-drier. The ability to remove smaller particles is also advantageous. The EK series filter-driers provide a unique combination of these characteristics to provide outstanding filtration as shown in Figure 3. Flow Restriction HFC REFRIGERANTS AND POE LUBRICANTS EK Typical drier Moisture Level (ppm) Solid Contamination Captured 125 Figure 4 Filtration Capability of Filter-driers Typical Sightglass 100 75 AMI 50 25 0 75 100 125 R-134a Refrigerant Temperature Figure 3 Dry Indication Water Level The filter-driers for use in HFC and POE oil systems must maintain the system dry and free of any acids that may have been generated. However, since water capacity is of primary importance the filter-drier should contain a higher percentage of molecular sieve than was required for CFC and HCFC systems. But molecular sieve alone is insufficient since it has virtually no organic acid capacity. An organic acid removal desiccant must be used such as activated alumina to ensure low acid levels are maintained. In addition, the filter-drier should also have increased filtration capacity and efficiency. The EK series of filter-driers provides the optimal combination of these properties to ensure the long, trouble-free life of any air-conditioning or refrigeration system. 264 The moisture indicating sightglass must also indicate moisture level in the range of less than 50 ppm moisture. Also, it must be able to perform this function at the temperature of the liquid line on which it is placed. Many sightglasses cannot perform this function at all liquid line temperatures. This low level indication ability is necessary to ensure that the system moisture never exceeds the level at which organic acid formation starts. The AMI moisture indicating sightglass provides this low level detection ability. ALCO CONTROLS