ADDENDUM NO. 1 DATE: April 20,1994

advertisement

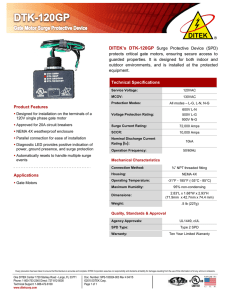

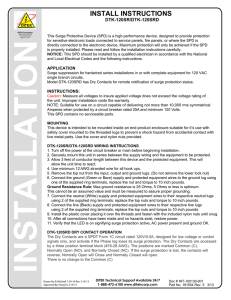

WEST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL ADDENDUM NO. 1 DATE: JANUARY 5, 2016 Project: West Aurora School District #129 Addition, Improvements, & Geothermal Installation Jefferson Middle School Architect: StudioGC architecture + interiors 223 W. Jackson Blvd. Suite 1200 Chicago, Illinois 60606 Project No.: 15049 1.1 PROJ. NO. 15049 SUMMARY A. The Bidding Documents and Project Manual dated December 15, 2015 and Drawings dated December 15, 2015 for the above referenced project are hereby modified and revised as follows. B. The information contained within this Addendum modifies, supplements or replaces information contained in the Project Manual and the Contract Drawings and is hereby made a part of the Contract Documents. C. Acknowledge receipt of this Addendum on the Bid Form. FAILURE TO DO SO MAY SUBJECT THE BIDDER TO DISQUALIFICATION. D. The Bidding Documents include the Project Manual dated December 15, 2015, the Drawings dated December 15, 2015, and Addenda issued prior to the receipt of bids. 1.2 PROJECT MANUAL A. Section 003132 – Geotechnical Data 1. ADD the following new Article 1.4: "1.4 A. B. UNCONTAMINATED SOIL CERTIFICATION The IEPA Uncontaminated Soil Certification is included at the end of this Section for the Contractor’s convenience. Section 084113 – Aluminum Entrances and Storefronts 1. Article 2.3, subparagraph A.3, CHANGE glazing plane to "Front." 2. REPLACE Article 2.4 with the following new Article 2.4: “2.4 A. VENTING WINDOWS Aluminum Windows: Manufacturer's standard units, complying with AAMA/WDMA/CSA 101/I.S.2/A440, with self-flashing mounting fins, and as follows: 1. 2. 3. Window Type: Hopper. Minimum Performance Class: AW. Minimum Performance Grade: 40. 009113.1 - 1 WEST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL 4. Aluminum Extrusions: ASTM B 221, alloy and temper recommended by manufacturer for strength, corrosion resistance, and application of required finish, but not less than 0.064-inch thickness at any location for main frame and sash members. a. 5. 8. Cam-action sweep sash lock and keeper at meeting rails. Spring-loaded, snap-type lock at jambs. Steel or bronze operating arms. Weather Stripping: Woven-pile weather stripping of wool, polypropylene, or nylon pile and resin-impregnated backing fabric; complying with AAMA 701/702. Insect Screens: Provide removable insect screen with wickets as required on each operable exterior sash, with screen frame finished to match window unit, complying with SMA 1004 or SMA 1201, and as follows: a. C. Reinforcement: Where fasteners screw-anchor into aluminum less than 0.128 inch thick, reinforce interior with aluminum or nonmagnetic stainless steel to receive screw threads, or provide standard, noncorrosive, pressed-in, spline grommet nuts. Hardware: Manufacturer's standard; of aluminum, stainless steel, die-cast steel, malleable iron, or bronze; including the following: a. b. c. 7. Thermally Improved Construction: Fabricate window units with an integral, concealed, low-conductance thermal barrier; located between exterior materials and window members exposed on interior side; in a manner that eliminates direct metal-to-metal contact. Fasteners, Anchors, and Clips: Nonmagnetic stainless steel, aluminum, or other noncorrosive material, compatible with aluminum window members, trim, hardware, anchors, and other components of window units. Fasteners shall not be exposed, except for attaching hardware. a. 6. PROJ. NO. 15049 Fabric: Manufacturer's standard aluminum wire fabric or glass-fiber mesh fabric. B. Glazing: Same as adjacent aluminum-framed entrances and storefront glazing. C. Finish: Match adjacent aluminum-framed entrances and storefront finish.” Section 084523 – Fiberglass Sandwich Panel Assemblies 1. Article 2.4, REPLACE subparagraph E.3 with the following new subparagraph E.3: "3. Grid Pattern: "Verti-Kal" 8 inch wide pattern." D. Section 262413 – Switchboards 1. ADD new Section 262413 to the Project Manual as issued with this addendum. Modify Table of Contents accordingly. E. Section 264313 – Surge Protective Devices 1. ADD new Section 264313 to the Project Manual as issued with this addendum. Modify Table of Contents accordingly. 009113.1 - 2 WEST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL 1.3 PROJ. NO. 15049 DRAWINGS A. T1.00 – Title Sheet 1. REVISE Alternate 8 to read: “… north of column B.3. Revise …” B. Sheet G2.00 – Partition Types and Mounting Heights 1. DELETE small triangle in partition notes. C. Sheet G3.00 - Geothermal Well Drawings 1. REVISE well field pipe transition point to match location shown on HV1.11 D. Sheet CX5 - Site Plan 1. REVISE well field pipe transition point to match location shown on HV1.11 E. Sheet S3-1 – Foundation Sections and Details 1. CHANGE Detail 4 as indicated on the attached sketch SSK-3.00. F. Sheet S3-2 – Foundation Sections and Details 1. CHANGE Detail 1A as indicated on the attached sketch SSK-3.01. G. All AD sheets 1. REVISE Demolition Sheet Note 16 to read: “… existing window mechanical unit…” H. Sheet A1.00 - Crawl Space Plan – Existing 1. DELETE elevation tag 7.11. I. Sheet AD1.11 - Demolition First Floor – Area “C & C1” 1. ADD Demolition Sheet Note 32 to read: “Contractor to demolish vent opening and vent areaway walls.” 2. ADD Demolition Sheet Note 32 to two locations along the East wall along the match line to Area G. J. Sheet A3.00 – Roof Plan – Area "G" 1. K. L. CHANGE plan and ADD section indicator at column center line "B" as indicated on the attached sketch ASK-1.00. Sheet A3.10 - Roof Details 1. REVISE detail 7 note that reads 6” concrete masonry unit to read “12” concrete masonry unit.” Sheet 3.11 – Roof Details 1. ADD Detail 8 as indicated on the attached sketch ASK-1.01. M. Sheet A4.00 - Building Elevations 1. DELETE note stating “For Reference” 2. REVISE note at B.3 to indicate Alternate 8 in lieu of Alternate 7. 3. REVISE Window type A to eliminate operable panels, provide fixed lites in lieu. N. Sheet A5.20 – Wall Details 1. ADD note to read: “For clear glazing only. Provide opaque film at heat pump unit.” to detail 4/A5.20. O. Sheet A8.11 - Storefront and Translucent Panel Schedule 1. REVISE Detail 5 – Storefront Window “A” to eliminate operable panel, provide fixed lite in lieu. 009113.1 - 3 WEST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL P. PROJ. NO. 15049 Sheet 8.13 – Door, Window, and Translucent Panel Schedule 1. REPLACE Detail 9 with revised detail (as indicated on the attached sketch ASK-2.00). Q. Sheet DV1.14 – First Floor HVAC Demolition Plans – Area “F” 1. ADD note at south boiler concrete pad on Plan 3 as follows: “Conc. Pad To Remain”. R. Sheet HV1.13 – First Floor HVAC Plans – Area E 1. REPLACE this sheet with revised Sheet HV1.13 as issued with this addendum. S. Sheet E1.13 – First Floor Power Plan – Area E 1. REPLACE this sheet with revised Sheet E1.13 as issued with this addendum. T. Sheet E4.00 – Electrical Riser Diagram 1. REPLACE this sheet with revised Sheet E4.00 as issued with this addendum. U. Sheet E5.00 – Electrical Panel Schedules 1. CHANGE panel rating for “MP-A” to be 42 kAIC in lieu of 22 kAIC. V. Sheet E6.01 – Electrical Details 1. REPLACE this sheet with revised Sheet E6.01 as issued with this addendum. 1.4 CLARIFICATIONS A. The plan view areas on CX5 are correct. There is a total of 3,705 SF of new sidewalk to the north of the building addition and a total of 376 HMA pavement for the new fire lane. The alternates clarify what is base bid and what is to be included in the alternate. In essence the North sidewalk that runs east west is in the base bid and removed in the alternate. The fire lane and associated sidewalk adjustments to the west are added in the alternate, there is no work in the base bid for this scope of work. B. At all classroom locations the Geothermal Heat Pump will obstruct clear glazing contractors are to provide opaque (decorative) film on the interior of the glass lite per detail 1/A5.20. C. Contractors shall field verify all existing conditions for removal of the stair, ramp, foundations, and other wooden structures that remain after the removal of the mobile classrooms by the District. D. A clarification request was received in regards to access control. Rough-in only is to be provided by the Contractor. All wiring, hardware, and equipment will be provided and installed by the District. E. Temperature control rough ins are shown on the E and HV drawings. No separate temperature control location/ rough in drawings will be issued. F. We do not anticipate that any temporary exits/stairs/hallways will need to be constructed to maintain code required egress. All contractors are to coordinate construction sequencing and efforts with all authorities having jurisdiction to maintain all egress requirements during construction. G. Precast contract has not accommodated for leaving a panel out for GC and their subcontractor convenience. If the GC finds that it will be economically advantageous to coordinate this with the precast contractor please incorporate costs or credits associated with doing so in the GC base bid. 009113.1 - 4 WEST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 H. Moisture mitigation in Slabs on Grade: Intent of the documents is that under the Base Bid, Concure admixture is included in the concrete for all interior slabs on grade. In the event that moisture levels in either new or existing slabs are still unacceptable for floor covering installation, installation of topical moisture mitigation system specified in Section 096990 will be authorized under the provisions of the "Unit Costs" as specified and included on the bid form I. The sanitary sewer that is noted on CX5 will need be in the over dig area for the foundations for the elevator. Contractor is responsible for either supporting it or relocating it out of the work area at the contractor’s discretion. End Addendum 009113.1 This Addendum consists of 5 pages. Attachments: Project Manual: IEPA Uncontaminated Soil Certification, Section 262413, Section 264313 Sheets: HV1.13, E1.13, E4.00, E6.01 Sketches: ASK-1.00, ASK-1.01, ASK-2.00, SSK-3.00, SSK-3.01 009113.1 - 5 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 SECTION 262413 - SW ITCHBOARDS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section Includes: 1. 2. 1.3 Switchboards. Switchboard Accessories. RELATED SECTIONS A. Section 26 05 00 - Common W ork Results for Electrical. B. Section 26 05 53 - Identification for Electrical Systems. C. Section 26 28 13 - Fuses. 1.4 REFERENCES A. NEMA AB 1 - Molded Case Circuit Breakers. B. NEMA KS 1 - Enclosed and Miscellaneous Distribution Equipment Switches (600 Volts Maximum). C. NEMA PB 2 - Dead Front Distribution Switchboards. D. NEMA PB 2.1 - Instructions for Safe Handling, Installation, Operation and Maintenance of Deadfront Switchboards Rated 600 Volts or Less. E. NETA ATS (International Electrical Testing Association) - Acceptance Testing Specifications for Electrical Power Distribution Equipment and Systems. F. NFPA 70 - National Electrical Code. 1.5 SUBMITTALS A. Section 01 33 00 - Submittal Procedures: Submittal procedures. B. Product Data: Provide electrical characteristics including voltage, frame size and trip ratings, fault current withstand ratings, and time-current curves of all equipment and components. SW ITCHBOARDS 262413 - 1 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL C. 1.6 PROJ. NO. 15049 Shop Drawings: Indicate front and side views of enclosures with overall dimensions shown; conduit entrance locations and requirements; nameplate legends; size and number of bus bars per phase, neutral, and ground; and switchboard instrument details. CLOSEOUT SUBMITTALS A. Section 01 70 00 - Execution and Closeout Requirements: Closeout procedures. B. Project Record Documents: Record actual locations, configurations, and ratings of switchboards and their components on single line diagrams and plan layouts. C. Maintenance Data: Include spare parts listing; source and current prices of replacement parts and supplies; and recommended maintenance procedures and intervals. 1.7 QUALIFICATIONS A. 1.8 Manufacturer: Company specializing in manufacturing the products specified in this section with minimum five years experience. REGULATORY REQUIREMENTS A. Conform to the 2010 Health/Life Safety Code for Public Schools, 23 Illinois Administrative Code 180. B. Conform to the 2009 International Building Code (IBC). C. Conform to the 2009 International Existing Building Code (IEBC). D. Conform to the 2009 International Fuel Gas Code (IFGC). E. Conform to the 2009 International Property Maintenance Code (IPMC). F. Conform to the 2009 International Fire Code (IFC), excluding Chapter 4. G. Conform to the 2009 International Energy Conservation Code (IECC). H. Conform to the 1997 Illinois Accessibility Code, 71 Illinois Administrative Code 400. I. Conform to 2014 State of Illinois Plumbing Code, 77 Illinois Administrative Code 890. J. Conform to the 2010 Illinois State Fire Marshall Boiler and Pressure Vessel Safety Act, 41 Illinois Administrative Code 120. K. Conform to the 2009 International Mechanical Code (IMC). L. Conform to the 2009 ICC Electrical Code. M. Conform to 2008 NFPA 70, National Electrical Code. N. Conform to 2007 NFPA 72, National Fire Alarm Code. O. Products: Listed and classified by Underwriter's Laboratories, Inc. as suitable for the purpose specified and indicated. SW ITCHBOARDS 262413 - 2 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL 1.9 PROJ. NO. 15049 DELIVERY, STORAGE, AND HANDLING A. Section 01 60 00 - Product Requirements: Requirements for transporting, handling, storing, and protecting products. B. Deliver individually wrapped for protection and mounted on shipping skids. C. Store in a clean, dry space. Maintain factory wrapping or provide an additional heavy canvas or heavy plastic cover to protect units from dirt, water, construction debris, and traffic. D. Handle in accordance with NEMA PB 2.1 and manufacturer's written instructions. Lift only with lugs provided for the purpose. Handle carefully to avoid damage to switchboard internal components, enclosure, and finish. 1.10 FIELD MEASUREMENTS A. 1.11 Verify that field measurements are as required to suit installation. MAINTENANCE MATERIALS A. Section 01 70 00 - Execution and Closeout Requirements: Spare parts and maintenance products. B. Furnish two of each key. PART 2 - PRODUCTS 2.1 MANUFACTURERS 1. 2. 3. 4. 2.2 Eaton / Cutler-Hammer. Square D Company. Siemens. G.E. SWITCHBOARD A. Description: NEMA PB 2 switchboard with electrical ratings and configurations as indicated and specified. B. Ratings: Furnish voltage, configuration, main bus, and integrated equipment rating as indicated on the drawings. C. Main Section Devices: Individually mounted and compartmented. D. Distribution Section Devices: Individually mounted and compartmented. E. Bus Material: Copper, standard size. F. Bus Connections: Bolted, accessible from front for maintenance. G. Fully insulate load side bus bars. SW ITCHBOARDS 262413 - 3 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 H. Ground Bus: Extend length of switchboard. I. Fusible Switch Assemblies: NEMA KS 1, load interrupter enclosed knife switch with externally operable handle. Provide interlock to prevent opening front cover with switch in ON position. Handle lockable in OFF position. 1. J. Fusible Switch Assemblies, 800 Amperes and Larger: Bolted pressure contact switches. 1. K. Fuse clips: Designed to accommodate Class R fuses, type as specified. Fuse clips: Designed to accommodate Class L fuses. Molded Case Circuit Breakers with Current Limiters: NEMA AB1, molded case circuit breakers with replaceable current limiting elements, in addition to integral thermal and instantaneous magnetic trip in each pole. 1. Provide circuit breakers UL listed as Type HACR for air conditioning equipment branch circuits. L. Line and Load Terminations: Accessible from the front of the switchboard, suitable for the conductor materials and sizes indicated on drawings.. M. Utility Metering Compartment: Compartment size, bus spacing and drilling, door and locking and sealing requirements in accordance with Utility Company's requirements. N. Pull Section: Size as shown on drawings or as required to facilitate installation. O. Future Provisions: Fully equip spaces for future devices with bussing and bus connections, suitably insulated and braced for short circuit currents. Provide continuous current rating as indicated. P. Enclosure: Type 1 - General Purpose. 1. 2. 3. Align sections at front and rear. Switchboard Height: 90 inches, excluding floor sills, lifting members and pull boxes. Finish: Manufacturer's standard light gray enamel over external surfaces. Coat internal surfaces with minimum one coat corrosion-resisting paint, or plate with cadmium or zinc. PART 3 - EXECUTION 3.1 PREPARATION A. 3.2 Provide concrete housekeeping pad. INSTALLATION A. Install switchboard in locations shown on drawings in accordance with NEM A PB 2.1. B. Tighten accessible bus connections and mechanical fasteners after placing switchboard. C. Install fuses in each switch and coordinate sizes with connected load. D. Install engraved plastic nameplates in accordance with Section 26 05 53. SW ITCHBOARDS 262413 - 4 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL E. 3.3 PROJ. NO. 15049 Ground and bond switchboards in accordance with Section 26 05 26. FIELD QUALITY CONTROL A. Section 01 40 00 - Quality Requirements: Field inspecting, testing, adjusting, and balancing. B. Inspect and test in accordance with NETA ATS, except Section 4. C. Perform inspections and tests listed in NETA ATS, Section 7.1. 3.4 ADJUSTING A. Section 01 70 00 - Execution and Closeout Requirements: Testing, adjusting, and balancing. B. Adjust all operating mechanisms for free mechanical movement. C. Tighten bolted bus connections in accordance with manufacturer's instructions. 3.5 CLEANING A. Section 01 70 00 - Execution and Closeout Requirements: Final cleaning. B. Touch up scratched or marred surfaces to match original finish. END OF SECTION 262413 SW ITCHBOARDS 262413 - 5 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 SECTION 264313 - SURGE PROTECTIVE DEVICES PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section Includes: 1. 1.3 Surge Protective Devices. RELATED SECTIONS A. Section 26 24 13 - Switchboards. B. Section 26 24 16 - Panelboards. 1.4 DESCRIPTION A. This section describes the materials and installation requirements for surge protective devices (SPD) for the protection of all AC electrical circuits from the effects of lightning induced currents, substation switching transients and internally generated transients resulting from inductive and/or capacitive load switching. B. To maximize performance and reliability and to obtain the lowest possible let-through voltages, the ac surge protection shall be integrated into electrical distribution equipment such as switchgear, switchboards, panelboards, busway (integrated within bus plug), or motor control centers. 1.5 SUBMITTALS A. Section 01 33 00 - Submittal Procedures: Submittal procedures. B. Product Data: 1. 2. 3. Provide verification that the SPD complies with the required ANSI/UL 1449 3rd Edition listing by Underwriters Laboratories (UL). Compliance may be in the form of a file number that can be verified on UL's website, as long as the website contains the following information at a minimum: model number, SPD Type, system voltage, phases, modes of protection, Voltage Protection Rating (VPR), and Nominal Discharge Current (In). For sidemount mounting applications (SPD mounted external to electrical assembly), electrical/mechanical drawings showing unit dimensions, weights, installation instruction details, and wiring configuration. The following additional information shall be submitted: SURGE PROTECTIVE DEVICES 264313 - 1 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL a. b. 1.6 PROJ. NO. 15049 Descriptive bulletins Product sheets CLOSEOUT SUBMITTALS A. Section 01 70 00 - Execution and Closeout Requirements: Closeout procedures. B. Operation and Maintenance Manuals shall be provided with each SPD shipped. 1.7 QUALITY ASSURANCE A. Systems shall be designed, manufactured, tested and installed in accordance with the following standards: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Underwriters Laboratories (UL 1449 - 3rd Edition) ANSI/IEEE C62.1 and C62.11 Canadian Standards (CUL) Institute of Electrical and Electronic Engineers (C62.41 and C62.45) Military Standards (MIL-STD 220A) National Electrical Code (Article 280) Federal Information Processing Standards Publication (FIPS PUB 94) National Electrical Manufacturers Association (NEMA LS1-1992 Guidelines) National Fire Protection Association (NFPA 70 [NEC], 75, and 78) Underwriters Laboratories (UL 1449 - 3rd Edition and 1283) B. Electrical Component Standard: Components and installation shall comply with code. C. The system shall be UL 1449 - 3rd Edition listed system under the UL 1449 for Surge Protective Devices. Systems not UL 1449 listed are not acceptable. D. UL 3rd Edition Voltage Protection Rating (VPR) shall test using the combination wave generator at a setting of 6kV, 3kA. SPD shall pass UL 1449 3rd edition Nominal Discharge Current Rating (In) at 10kA or 20kA. 1.8 REGULATORY REQUIREMENTS A. Conform to the 2010 Health/Life Safety Code for Public Schools, 23 Illinois Administrative Code 180. B. Conform to the 2009 International Building Code (IBC). C. Conform to the 2009 International Existing Building Code (IEBC). D. Conform to the 2009 International Fuel Gas Code (IFGC). E. Conform to the 2009 International Property Maintenance Code (IPMC). F. Conform to the 2009 International Fire Code (IFC), excluding Chapter 4. G. Conform to the 2009 International Energy Conservation Code (IECC). H. Conform to the 1997 Illinois Accessibility Code, 71 Illinois Administrative Code 400. I. Conform to 2014 State of Illinois Plumbing Code, 77 Illinois Administrative Code 890. SURGE PROTECTIVE DEVICES 264313 - 2 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 J. Conform to the 2010 Illinois State Fire Marshall Boiler and Pressure Vessel Safety Act, 41 Illinois Administrative Code 120. K. Conform to the 2009 International Mechanical Code (IMC). L. Conform to the 2009 ICC Electrical Code. M. Conform to 2008 NFPA 70, National Electrical Code. N. Conform to 2007 NFPA 72, National Fire Alarm Code. O. Products: Listed and classified by Underwriter's Laboratories, Inc. as suitable for the purpose specified and indicated. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. 2.2 Surge protective devices shall be of the same manufacturer as the switchboard/panelboard. VOLTAGE SURGE SUPPRESSION - GENERAL A. Electrical Requirements 1. 2. 3. 4. Unit Operating Voltage - Refer to drawings for operating voltage and unit configuration. Maximum Continuous Operating Voltage (MCOV) - The MCOV shall not be less than 115% of the nominal system operating voltage. The suppression system shall incorporate thermally protected metal-oxide varistors (MOVs) as the core surge suppression component for the service entrance and all other distribution levels. The system shall not utilize silicon avalanche diodes, selenium cells, air gaps, or other components that may crowbar the system voltage leading to system upset or create any environmental hazards. Protection Modes - The SPD must protect all modes of the electrical system being utilized. The required protection modes are indicated by bullets in the following table: Protection Modes Configuration L-N L-G L-L N-G W ye C C C C Delta N/A C C N/A C C C C High Leg Delta 5. 6. Nominal Discharge Current (In) - All SPDs applied to the distribution system shall have a 20kA In rating regardless of their SPD Type (includes Types 1 and 2) or operating voltage. SPDs having an In less than 20kA shall be rejected. ANSI/UL 1449 3rd Edition Voltage Protection Rating (VPR) - The maximum ANSI/UL 1449 3rd Edition VPR for the device shall not exceed the following: SURGE PROTECTIVE DEVICES 264313 - 3 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL Modes B. PROJ. NO. 15049 208Y/120 480Y/277 L-N; L-G; N-G 700 1200 L-L 1200 2000 SPD Design 1. 2. 3. 4. 5. Maintenance Free Design - The SPD shall be maintenance free and shall not require any user intervention throughout its life. SPDs containing items such as replaceable modules, replaceable fuses, or replaceable batteries shall not be accepted. SPDs requiring any maintenance of any sort such as periodic tightening of connections shall not be accepted. SPDs requiring user intervention to test the unit via a diagnostic test kit or similar device shall not be accepted. Balanced Suppression Platform - The surge current shall be equally distributed to all MOV components to ensure equal stressing and maximum performance. The surge suppression platform must provide equal impedance paths to each matched MOV. Designs incorporating replaceable SPD modules shall not be accepted. Electrical Noise Filter - Each unit shall include a high-performance EMI/RFI noise rejection filter. Noise attenuation for electric line noise shall be up to 50 dB from 10 kHz to 100 MHz using the MIL-STD-220A insertion loss test method. Products unable able to meet this specification shall not be accepted. Internal Connections - No plug-in component modules or printed circuit boards shall be used as surge current conductors. All internal components shall be soldered, hardwired with connections utilizing low impedance conductors. Monitoring Diagnostics - Each SPD shall provide the following integral monitoring options: a. Protection Status Indicators - Each unit shall have a green / red solid-state indicator light that reports the status of the protection on each phase. 1.) 2.) 3.) b. c. For wye configured units, the indicator lights must report the status of all protection elements and circuitry in the L-N and L-G modes. Wye configured units shall also contain an additional green / red solid-state indicator light that reports the status of the protection elements and circuitry in the N-G mode. SPDs that indicate only the status of the L-N and L-G modes shall not be accepted. For delta configured units, the indicator lights must report the status of all protection elements and circuitry in the L-G and L-L modes. The absence of a green light and the presence of a red light shall indicate that damage has occurred on the respective phase or mode. All protection status indicators must indicate the actual status of the protection on each phase or mode. If power is removed from any one phase, the indicator lights must continue to indicate the status of the protection on all other phases and protection modes. Diagnostics packages that simply indicate whether power is present on a particular phase shall not be accepted. Remote Status Monitor - The SPD must include Form C dry contacts (one NO and one NC) for remote annunciation of its status. Both the NO and NC contacts shall change state under any fault condition. Audible Alarm and Silence Button - The SPD shall contain an audible alarm that will be activated under any fault condition. There shall also be an audible alarm silence button used to silence the audible alarm after it has been activated. SURGE PROTECTIVE DEVICES 264313 - 4 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL d. Surge Counter - The SPD shall be equipped with an LCD display that indicates to the user how many surges have occurred at the location. The surge counter shall trigger each time a surge event with a peak current magnitude of a minimum of 50 ± 20A occurs. A reset pushbutton shall also be standard, allowing the surge counter to be zeroed. The reset button shall contain a mechanism to prevent accidental resetting of the counter via a single, short-duration button press. In order to prevent accidental resetting, the surge counter reset button shall be depressed for a minimum of 2 seconds in order to clear the surge count total. 1.) 6. 8. The unit shall contain thermally protected MOVs. These thermally protected MOVs shall have a thermal protection element packaged together with the MOV in order to achieve overcurrent protection of the MOV. The thermal protection element shall disconnect the MOV(s) from the system in a fail-safe manner should a condition occur that would cause them to enter a thermal runaway condition. Fully Integrated Component Design - All of the SPD's components and diagnostics shall be contained within one discrete assembly. SPDs or individual SPD modules that must be ganged together in order to achieve higher surge current ratings or other functionality shall not be accepted. Safety Requirements a. b. c. 2.3 The ongoing surge count shall be stored in non-volatile memory. If power to the SPD is completely interrupted, the ongoing count indicated on the surge counter's display prior to the interruption shall be stored in non-volatile memory and displayed after power is restored. The surge counter's memory shall not require a backup battery in order to achieve this functionality. Overcurrent Protection a. 7. PROJ. NO. 15049 The SPD shall minimize potential arc flash hazards by containing no user serviceable / replaceable parts and shall be maintenance free. SPDs containing items such as replaceable modules, replaceable fuses, or replaceable batteries shall not be accepted. SPDs requiring any maintenance of any sort such as periodic tightening of connections shall not be accepted. SPDs requiring user intervention to test the unit via a diagnostic test kit or similar device shall not be accepted. SPDs designed to interface with the electrical assembly via conductors shall require no user contact with the inside of the unit. Such units shall have any required conductors be factory installed. Sidemount SPDs shall be factory sealed in order to prevent access to the inside of the unit. Sidemount SPDs shall have factory installed phase, neutral, ground and remote status contact conductors factory installed and shall have a pigtail of conductors protruding outside of the enclosure for field installation. SYSTEM APPLICATION A. The SPD applications covered under this section include distribution and branch panel locations, busway, motor control centers (MCC), switchgear, and switchboard assemblies. All SPDs shall be tested and demonstrate suitability for application within ANSI/IEEE C62.41 Category C, B, and A environments. B. Surge Current Capacity - The minimum surge current capacity the device is capable of withstanding shall be as shown in the following table: SURGE PROTECTIVE DEVICES 264313 - 5 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL PROJ. NO. 15049 Minimum surge current capacity based on ANSI / IEEE location category C. 2.4 Category Application Per Phase Per Mode C Switchboards 250 kA 125 kA B Distribution 160 kA 80 kA A Panelboards 120 kA 60 kA SPD Type - All SPDs installed on the line side of the service entrance disconnect shall be Type 1 SPDs. All SPDs installed on the load side of the service entrance disconnect shall be Type 1 or Type 2 SPDs. LIGHTING AND DISTRIBUTION PANELBOARD REQUIREMENTS A. The SPD application covered under this section includes lighting and distribution panelboards. The SPD units shall be tested and demonstrate suitability for application within ANSI/IEEE C62.41 Category B environments. 1. 2. 3. 4. 5. 6. 7. B. Sidemount Mounting Applications Installation (SPD mounted external to electrical assembly) 1. C. The SPD shall not limit the use of through-feed lugs, sub-feed lugs, and sub-feed breaker options. SPDs shall be installed immediately following the load side of the main breaker. SPDs installed in main lug only panelboards shall be installed immediately following the incoming main lugs. The panelboard shall be capable of re-energizing upon removal of the SPD. The SPD shall be interfaced to the panelboard via a direct bus bar connection. Alternately, an SPD connected to a 30A circuit breaker for disconnecting purposes may be installed using short lengths of conductors as long as the conductors originate integrally to the SPD. The SPD shall be located directly adjacent to the 30A circuit breaker. The SPD shall be included and mounted within the panelboard by the manufacturer of the panelboard. The SPD shall be of the same manufacturer as the panelboard. The complete panelboard including the SPD shall be UL67 listed. Lead length between the breaker and suppressor shall be kept as short as possible to ensure optimum performance. Any excess conductor length shall be trimmed in order to minimize let-through voltage. The installer shall comply with the manufacturer's recommended installation and wiring practices. Switchgear, Switchboard, MCC and Busway Requirements 1. 2. 3. 4. 5. 6. The SPD application covered under this section is for switchgear, switchboard, MCC, and busway locations. Service entrance located SPDs shall be tested and demonstrate suitability for application within ANSI/IEEE C62.41 Category C environments. The SPD shall be of the same manufacturer as the switchgear, switchboard, MCC, and busway The SPD shall be factory installed inside the switchgear, switchboard, MCC, and/or bus plug at the assembly point by the original equipment manufacturer Locate the SPD on the load side of the main disconnect device, as close as possible to the phase conductors and the ground/neutral bar. The SPD shall be connected through a disconnect (30A circuit breaker). The disconnect shall be located in immediate proximity to the SPD. Connection shall be made via bus, conductors, or other connections originating in the SPD and shall be kept as short as possible. The SPD shall be integral to switchgear, switchboard, MCC, and/or bus plug as a factory standardized design. SURGE PROTECTIVE DEVICES 264313 - 6 DECEM BER 15, 2015 W EST AURORA SCHOOL DISTRICT #129 ADDITION, IMPROVEMENTS, & GEOTHERMAL INSTALLATION JEFFERSON MIDDLE SCHOOL 7. 2.5 PROJ. NO. 15049 All monitoring and diagnostic features shall be visible from the front of the equipment. ENCLOSURES A. All enclosed equipment shall have NEM A 1 general purpose enclosures, unless otherwise noted. Provide enclosures suitable for locations as indicated on the drawings and as described below: 1. 2. 3. NEMA 1 - Constructed of a polymer (units integrated within electrical assemblies) or steel (sidemount units only), intended for indoor use to provide a degree of protection to personal access to hazardous parts and provide a degree of protection against the ingress of solid foreign objects (falling dirt). NEM A 4 - Constructed of steel intended for either indoor or outdoor use to provide a degree of protection against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (dirt and windblown dust); to provide a degree of protection with respect to the harmful effects on the equipment due to the ingress of water (rain, sleet, snow, splashing water, and hose directed water); and that will be undamaged by the external formation of ice on the enclosure. (sidemount units only) NEM A 4X - Constructed of stainless steel providing the same level of protection as the NEM A 4 enclosure with the addition of corrosion protection. (sidemount units only) PART 3 - EXECUTION 3.1 INSTALLATION A. 3.2 The Contractor shall install all equipment per the manufacturer's recommendations and the contract drawings. FACTORY TESTING A. 3.3 Standard factory tests shall be performed on the equipment under this section. All tests shall be in accordance with the latest version of NEMA and UL standards. W ARRANTY A. The manufacturer shall provide a full ten (10) year warranty from the date of shipment against any SPD part failure when installed in compliance with manufacturer's written instructions and any applicable national or local code. END OF SECTION 264313 SURGE PROTECTIVE DEVICES 264313 - 7 DECEM BER 15, 2015 223 West Jackson Boulevard Suite 1200 Chicago, IL 60606 ph: 312.253.3400 fx: 312.253.3401 Project: ADDITION, IMPROVEMENTS AND GEOTHERMAL INSTALLATION TO JEFFERSON MIDDLE SCHOOL Project No.: 15049 Subject: FLASHING DETAIL @ EXIST. ROOF Date: 01/05/16 Sheet: 1/A3.00 Sketch: ASK1.00 LINE OF EXIST. MASONRY WALL 8 ASK1.01 B 1 3 1 ROOF PLAN - ROOF AREA "G" 3/16" = 1'-0" 2.1 2 223 West Jackson Boulevard Suite 1200 Chicago, IL 60606 ph: 312.253.3400 fx: 312.253.3401 Project: ADDITION, IMPROVEMENTS AND GEOTHERMAL INSTALLATION TO JEFFERSON MIDDLE SCHOOL Project No.: 15049 Subject: FLASHING DETAIL @ EXIST. ROOF Date: 01/05/16 Sheet: A3.11 Sketch: ASK1.01 1 METAL REGLET - SET IN ROOF MASTIC IN PRECAST REVEAL PREFINISHED METAL COUNTERFLASHING PRE-MANUF EXPANSION JOINT 3/4" EXTERIOR GRADE PLYWOOD 2X BLOCKING COMPOSITE PRECAST WALL FLASHING MEMBRANE TO MATCH EXISTING EXISTING ROOF ASSEMBLY TO REMAIN EXISTING ROOF DECK TO REMAIN _t/ exist. roof deck 22' - 11 1/2" EXISTING WALL W/ FACE BRICK +/- 0' - 8" SET BACK 8 WALL FLASHING @ EXIST. ROOF 1 1/2" = 1'-0" 223 West Jackson Boulevard Suite 1200 Chicago, IL 60606 ph: 312.253.3400 fx: 312.253.3401 Project: ADDITION, IMPROVEMENTS AND GEOTHERMAL INSTALLATION TO JEFFERSON MIDDLE SCHOOL Project No.: 15049 Subject: STOREFRONT HEAD DETAIL Date: 01/05/16 Sheet: 9/A8.13 Sketch: ASK2.00 1 SAWCUT DRIP CUT - TYPICAL EACH HEAD OPENING (EXTERIOR CONDITIONS ONLY) 1/2" CHAMFER AT EXPOSED PANEL EDGES ALUMINUM WINDOW UNIT - AT LOCATIONS OF INTERIOR FRAMES, CENTER ON PRECAST WALL OPENING 9 STOREFRONT HEAD DETAIL - PANEL OPENING 1 1/2" = 1'-0"