Frost Control Strategies

advertisement

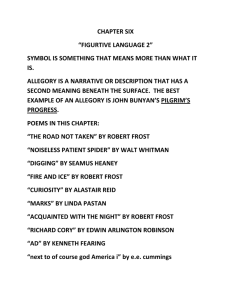

Frost Control Strategies Engineering Bulletin Order No. VCES-DEF-EB-1 Date July 2015 Rev. No. 1 (July 2015) Frost control must be considered when specifying an energy recovery unit for climates with severe winter conditions. Frost buildup on the energy recovery device results in reduced airflow through the heat exchanger, reduced energy savings and potential damage to the device. This bulletin describes the need for frost control and provides both simple and more complex frost control strategies that will allow continuous ventilation and prevent frost formation. At a Glance • Why do we need frost control? –– Flat plate heat exchangers –– Heat pipe heat exchangers –– Energy recovery wheels • Frost control strategies –– Exhaust only –– Recirculation –– Face and bypass –– Traversing –– Variable frequency drive –– Preheat ©2015 Nortek Air Solutions, LLC Why Do We Need Frost Control? Supply air inlet (Entering) X4 Air-to-air heat exchanger X1 Supply air outlet (Leaving) Exhaust air outlet (Leaving) X2 X3 Exhaust air inlet (Entering) Figure 1: Airflow diagram Frost control must be considered when specifying an energy recovery unit for climates with severe winter conditions. This is true whether you are using a flat late or heat pipe heat exchanger or you are using an energy recovery wheel. Frost buildup on the energy recovery device results in reduced airflow through the exchanger, reduced energy savings and potential damage to the device. Determining or measuring frost threshold is not an easy task and different approaches can be used. These include measuring temperature, humidity, or pressure drop variation. In general, frost buildup becomes a problem when outdoor air temperatures reach −5°F [−15°C]. Figure 1 illustrates the flow of air through an air-to-air heat exchanger. Frost formation can occur at Station X4 as the exhaust air temperature drops below the frost threshold while at saturation. This is due to the energy transfer to the supply side. Venmar CES typically monitors air temperature and/or relative humidity at Station X4 to ensure that the air temperature remains above frost threshold values and/ or the humidity remains below them. In addition, to maximize effectiveness, the outdoor air temperature at Station X1 may also be monitored to start or modify the frost control sequence. Figure 2: Flat plate heat exchanger Figure 3: Heat pipe heat exchanger Requirement for Frost Control on Flat Plate Heat Exchangers In flat plate heat exchangers, warm return air cools as it passes through the heat exchanger. See Figure 2. Moisture from the warm air condenses and creates water droplets on the media. As cool outdoor air enters the heat exchanger, the water droplets start to freeze, creating ice on the cold corner of the core. If the ice keeps building, it will eventually block the flow of air through the heat exchanger. A defrost cycle is required to warm up the cold side of the core, to melt the ice and to maintain airflow and heat transfer through the heat exchanger. Requirement for Frost Control on Heat Pipe Heat Exchangers In heat pipe heat exchangers, warm return air cools as it passes through the heat exchanger. See Figure 3. Moisture from the warm air condenses and creates water droplets on the heat pipe. As cool outdoor air enters the heat exchanger, the water droplets start to freeze, creating ice on the cold side of the heat pipe. If the ice keeps building, it will eventually block the flow of air through the heat exchanger. A defrost cycle is required to warm up the cold side of the heat pipe, to melt the ice and to maintain airflow and heat transfer through the heat exchanger. Requirement for Frost Control on Energy Recovery Wheels In energy recovery wheels, warm return air cools as it passes through the rotating wheel. See Figure 4. Moisture from the warm air condenses and creates water droplets on the sensible wheel. The water molecules are then absorbed by the desiccant on the enthalpy wheel. As the wheel rotates through the cold supply air, the water can start to freeze and form ice before the water droplets can be cleared on the sensible wheel and before the water molecules can be desorbed on the enthalpy wheel. The ice typically forms on the internal surface of the wheel, near the outdoor air entrance. Figure 4: Energy recovery wheel Frost Control Strategies VCES-DEF-EB-1 July 2015 Page 2 of 6 Frost Control Strategies Simple strategies can be used to defrost ice formation in both flat plate and heat pipe heat exchangers. These include exhaust-only and recirculation frost control. There are also more complex frost control strategies that allow continuous ventilation and prevent frost formation on flat plate and heat pipe heat exchangers and on energy recovery wheel units. Examples include face and bypass, traversing, variable frequency drive (VFD) and pre-heat frost control. If supply air temperature is critical, post-heating must be included or applied to trim the supply air temperature to the desired setpoint, as some frost control strategies can drop the supply air temperature below freezing. These strategies are discussed in more detail on the following pages, along with some guidelines to keep in mind when evaluating frost control options. The selection of frost control should take into consideration energy savings and the operating sequence for cooling, heating, occupied, unoccupied and economizer operation. Exhaust Only Frost Control Flat plate or heat pipe heat exchangers only Exhaust Only Defrost 1 OA EA 3 4 RA 2 SA When the unit goes into a defrost cycle, the exhaust fan continues to operate, the supply fan is de-energized and the outdoor air damper closes. This method can be used with flat plate or heat pipe heat exchangers only and is ideal for source control applications where continuous exhaust is required. Figure 5: Exhaust only frost control – flat plate heat exchanger Exhaust Only Defrost EA OA 4 3 1 RA 2 Figure 6: Exhaust only frost control – heat pipe heat exchanger Exhaust only frost control is a simple, cost-effective method, which periodically defrosts ice formation on the heat exchanger by shutting down the supply fan to remove the source of cold air. See Figures 5 and 6. SA Since the building is under a negative pressure during the defrost cycle, there is the potential for combustion appliances or equipment to backdraft into the mechanical room where the unit is installed. Pressure relief should be provided through the use of fresh air dampers as part of the building ventilation system. A drawback of this method is that ventilation is interrupted when the supply fan shuts down during the defrost cycle. This may not be acceptable in all applications and may not meet indoor air quality (IAQ) requirements as set out in ASHRAE Standard 62. Shutting down the supply fan may also be an issue if the unit has high thermal inertia heating devices, such as electric heating coils or an indirect gas-fired heater.CFM spikes may cause overheating, potential operation faults and supply temperature variations. Exhaust only frost control has two temperature-initiated, time-based cycles of defrost to ventilation: 1. At an initiating outdoor air temperature, duration is a linear, time-versustemperature variant in minutes of defrost to minutes of ventilation until a lower outdoor air temperature is reached. 2. Below the lower outdoor air temperature, duration and cycle time is a constant in minutes of defrost to minutes of ventilation. Frost Control Strategies VCES-DEF-EB-1 July 2015 Page 3 of 6 Recirculation Frost Control Standard: Flat plate or heat pipe heat exchanger units only Recirculation Defrost 3 OA EA RA 2 SA Figure 7: Recirculation frost control – flat plate heat exchanger Recirculation Defrost EA 4 OA 3 1 RA 2 SA Figure 8: Recirculation frost control – heat pipe heat exchanger Recirculation frost control is another low cost method of frost control. Ice formation on the heat exchanger is periodically defrosted by shutting down the exhaust fan, by closing the outdoor and exhaust air dampers and by opening a recirculation air damper to remove the source of cold air. When the unit goes into a defrost cycle, the supply fan remains on to recirculate building exhaust air back into the occupied space. The exhaust air goes through the heat exchanger and provides defrosting in the absence of cold outdoor air. See Figures 7 and 8. A drawback of this method is that ventilation is interrupted when the exhaust fan shuts down during the defrost cycle. This may not be acceptable in all applications and may not meet indoor air quality (IAQ) requirements as set out in ASHRAE Standard 62. Standard recirculation frost control has two temperature-initiated, time-based cycles of defrost to ventilation: 1. At an initiating outdoor temperature, duration is a linear, time-versustemperature variant in minutes of defrost to minutes of ventilation until a lower outdoor temperature is reached. 2. Below the lower outdoor temperature, duration and cycle time is constant in minutes of defrost to minutes of ventilation. Modulating: Energy recovery wheel units only Recirculation Defrost EA OA 4 3 1 RA 2 Figure 9: Recirculation frost control – energy recovery wheel SA In energy recovery wheel units, recirculation frost control prevents frost buildup inside the wheel by mixing building exhaust air with outdoor air through modulating recirculation. See Figure 9. The outdoor and exhaust air dampers reduce the cold air entering the wheel, thereby increasing the exhaust air temperature above the frost threshold. A recirculation air damper, located downstream of the exhaust fan, is used to remove the source of cold air. Both supply and exhaust fans continue operating but at a reduced ventilation rate. A plenum or FANWALL® exhaust fan is required to keep the increase in unit length to a minimum and for best performance. Recirculation frost control for energy recovery wheel units with modulating dampers has the following advantages over 100% fixed ventilation. • Frost prevention is used instead of defrost, eliminating possible heat wheel damage. • Exhaust air temperature and humidity sensors are used instead of an outdoor air temperature sensor. The result is a lower leaving exhaust air temperature and, hence, higher efficiencies and lower reheat requirements. • Exhaust and ventilation operation continues during defrost, though at a reduced rate, versus shutting down. A drawback of this method is that a percentage of exhaust air is recirculated to the supply air and the actual ventilation rate is reduced. Modulating recirculation frost control starts when the exhaust air temperature drops below the frost threshold value and will modulate the mixing dampers to maintain the exhaust air humidity below the frost threshold. Extensive testing has shown that the exhaust temperature can drop well below the starting exhaust temperature before frost crystals appear on the wheel. Frost Control Strategies VCES-DEF-EB-1 July 2015 Page 4 of 6 Face and Bypass Frost Control 1 OA EA Flat plate or heat pipe heat exchanger units only 3 4 RA 2 SA Exchanger Side View Face and bypass is a preventative strategy for flat plate or heat pipe heat exchangers, with the objective of preventing frost formation while maintaining 100% ventilation. See Figures 10 and 11. As the outdoor air becomes colder, face and bypass dampers upstream of the heat exchanger modulate to reduce the amount of outdoor air flowing through the heat exchanger. This reduces the amount of energy recovered and keeps the exhaust temperature above the frost threshold. The supply and exhaust fans, as well as the outdoor air and exhaust air dampers, continue to operate during the frost control cycle. Thus there is no interruption to ventilation, making this strategy ideal for harsher environments or source control applications like laboratories. Figure 10: Face and bypass frost control – flat plate heat exchanger As both fans remain running, there is no depressurization of the building, eliminating the potential for combustion appliance backdraft into the occupied space. The face and bypass dampers can also be used for free cooling (economizer) and/ or supply air temperature control in different modes of operation, if required. Face and bypass frost control starts when the exhaust air temperature drops below the frost threshold value. The face and bypass dampers will modulate to maintain the exhaust air temperature above the frost threshold. This method is proportionally controlled, meaning the face and bypass dampers will be modulated linearly to maintain the exhaust air temperature setpoint. Figure 11: Face and bypass frost control – heat pipe heat exchanger Traversing Frost Control 1 OA EA 4 Flat plate heat exchanger units only 3 RA 2 Exchanger Side View SA Traversing frost control is similar to face and bypass control, but uses several motorized face dampers in series upstream of the heat exchanger. The dampers periodically block a portion of the outdoor air from flowing through the heat exchanger to defrost ice formation on the exhaust portion of the heat exchanger while maintaining 100% ventilation. There are typically five motorized dampers so that, at any given time, four out of five dampers are open and one is closed. See Figure 12. The advantages of this strategy are similar to face and bypass except for free cooling, where the addition of an outdoor air bypassing section and motorized damper is required. Figure 12: Traversing frost control – flat plate heat exchanger Traversing frost control has two temperature-initiated, time-based cycles of frost control: 1. At an initiating outdoor air temperature, the first damper of the set closes to defrost while all of others are open and exchanging heat. Then the first damper of the set re-opens and the second closes, and so on. A cycle is finished when all of the dampers in the set have closed once. If, after the cycle is complete, the outdoor air temperature is still lower than the set point, a new cycle starts. The duration of closure of each damper in the set is a linear, time-versus-temperature variant in minutes of defrost to minutes of ventilation until a lower outdoor temperature is reached. 2. Below the lower outdoor temperature, duration and closing time for each damper of the set remains constant in minutes of defrost to minutes of ventilation until a cycle is completed. Frost Control Strategies VCES-DEF-EB-1 July 2015 Page 5 of 6 Variable Frequency Drive (VFD) Frost Control Energy recovery wheel units only The objective of VFD frost control is to prevent frost formation within the energy recovery wheel and maintain 100% ventilation. At the normal running rpm of the wheel, as the outdoor air temperature becomes colder, the exhaust temperature also becomes colder and the exhaust relative humidity rises. With this frost control strategy, the VFD slows down the rpm of the energy recovery wheel drive motor. This reduces the sensible and latent effectiveness of the wheel, thereby reducing the risk of frost crystals forming on the internal media. VFD frost control starts when the exhaust air temperature drops below the frost threshold value. Then the VFD will vary the speed of the wheel drive motor to maintain the exhaust air humidity below the frost threshold. Extensive testing has shown that the exhaust temperature can drop well below the starting exhaust temperature before frost crystals appear on the enthalpy wheel, making it the most efficient frost control strategy and requiring the lowest reheat. Preheat Frost Control Flat plate or heat pipe heat exchangers and energy recovery wheel units OA −22ºF [−30ºC] EA 23ºF [−5ºC] Pre-heat Figure 13: Preheat frost control – energy wheel or heat pipe heat exchanger 4 1 3 RA SA 2 Figure 14: Preheat frost control – flat plate heat exchanger Pre-heat frost control is a preventative strategy for flat plate or heat pipe heat exchanger and for energy recovery wheel units. See Figures 13 and 14. The objective is preventing frost from occurring within the heat exchanger while maintaining 100% or continuous ventilation. The benefit is efficiency as energy recovery operates at full capacity. Heating coils (electric, steam or hot water) are duct-mounted or integrated into the unit in the outdoor airstream so that the entering outdoor air temperature is pre-conditioned to a temperature above the frost threshold for the technology being used. Because there is no interruption to fan operation, this strategy provides continuous ventilation, making it ideal for harsh environments or source control applications. While pre-heat typically has higher up-front costs than other strategies, it can result in significant operating savings in climates where frost control is required for a long period of time (more than a few hours). The pre-heater should be sized for the coldest outdoor air design temperature and to the appropriate outdoor air temperature where the exhaust air frost threshold is reached based on the design conditions and airflows for the type of heat exchanger in the selection report. Nortek Air Solutions has a policy of continuous product improvement and reserves the right to change design and specifications without notice. Nortek Air Solutions is a leader in innovative custom and engineered HVAC solutions for commercial, industrial and critical environments through our brands Governair, Huntair, Mammoth, Temtrol, Venmar CES, Ventrol and Webco. Nortek Air Solutions, LLC is a subsidiary of Nortek, Inc., a global, diversified company whose many market leading brands deliver broad capabilities and a wide array of innovative, technology-driven products and solutions for lifestyle improvement at home and at work. nortekair.com R ©2015 Nortek Air Solutions, LLC VCES-DEF-EB-1 July 2015