ADD1 - City of Tampa

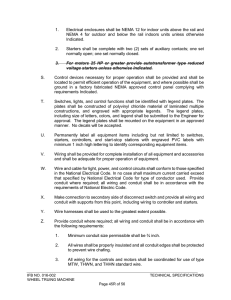

advertisement