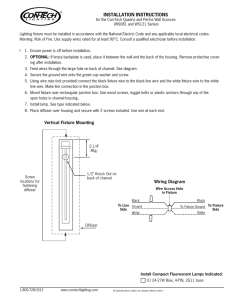

INSTALLATION INSTRUCTIONS

advertisement

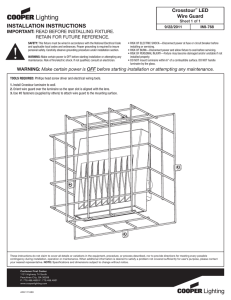

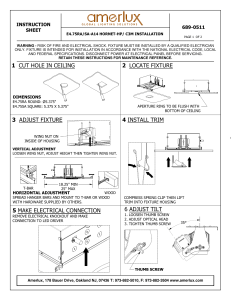

VS SERIES VAPORTIGHT CEILING MOUNT INSTALLATION INSTRUCTIONS PAGE 1 OF 2 11/1/06 IMI-661 IMPORTANT: Read carefully before installing fixture. Retain for future reference. Safety: This fixture must be wired in accordance with General: Upon receipt of fixture thoroughly inspect for any freight damage, which should be brought to the attention of the the National Electrical Code, National Electrical Safety Code and applicable local codes and ordinances. Proper grounding is delivery carrier. Compare the catalog description listed on the required to insure personal safety. Carefully observe grounding packing slip with the fixture label on the housing to be sure the procedure under installation section. This fixture is not suitable correct merchandise has been received. for Hazardous or Classified Locations. WARNING: Risk of Fire/Electric Shock. If not qualified, consult an electrician. Risk of Electric Shock. Disconnect power at fuse or circuit breaker panel or fuse box before installing or servicing. Risk of Burn. Allow fixture to cool before changing bulb or handling fixture. IMPORTANT: Dual voltage and multi-tap ballasts are factory wired for 277 Volt input. Before installation make certain power supply and ballast voltages are compatible. For use with other line voltages, remove wire nut splicing the black lead from the quick disconnect plug and 277V lead from ballast. Cap off lead with wirenut. Splice black lead from the quick disconnect plug with the desired voltage lead from ballast. APPLICATIONS: • 70W HID and 42W CFL fixtures are not suitable for operation in ambients exceeding 40°C. 100W HID fixtures are not suitable for operation in ambients exceeding 25°C. • Minimum supply wire conductor requirements 90°C in J-box. 150°C supply wire is required for through wire applications. • Thread sealing compound (not provided) must be applied to all unused plugs when used in wet location applications. • Caulking (not provided) must be used between ceiling and upper cover when used in wet location applications. TO ENSURE PROPER GROUNDING AND POLARITY: • Connect the fixture ground wire (Green) to the supply ground. • Connect the fixture neutral wire (White) to the supply neutral. • Connect the fixture line wire (Black) to the supply line. NOTE: If you are unsure which wires are ground, neutral or line, consult an electrician. J-Box (Not Provided) Upper Cover Quick Disconnect Receptacle (4) #10 Fasteners (Not Provided) Quick Disconnect Plug TOOLS REQUIRED: • Phillips screw driver • Slotted screw driver • 1/8” Allen wrench Lower Housing INSTALLATION INSTRUCTIONS: 1) Loosen Allen set screw and remove guard and globe. 2) Loosen (3) #12 Phillips pan head screws and remove lower ousing assembly. Disconnect plug and receptacle. 3) Knockout desired holes in upper cover. Make electrical splices, push leads into J-Box and install upper cover to ceiling or J-Box using appropriate fasteners (not provided). 4) Reconnect plug and receptacle and reassemble lower housing to upper cover. 5) Install lamp and reinstall globe and guard. Loosen Set Screw with 1/8” Allen Wrench to Remove Guard (3) #12 Philips Pan Head Screw NOTE: For Metal Halide application, a glass globe or lens must be used unless an open rated lamp is installed. Ø4.75 (120.6) Ceiling Apply Caulking between Ceiling and Fixture when used in Wet Location Applications Ø3.50 (88.9) (12) Ø.210 KO (5.33) Ø2.75 (69.8) These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every possible contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for user’s purpose, please contact your nearest Cooper Lighting representative. LUMARK 1121 HIGHWAY 74 SOUTH PEACHTREE CITY, GEORGIA 30269 11/1/06 IMI-661 ADH061573 VS SERIES VAPORTIGHT PENDANT MOUNT INSTALLATION INSTRUCTIONS PAGE 2 OF 2 11/1/06 IMI-661 IMPORTANT: Read carefully before installing fixture. Retain for future reference. Safety: This fixture must be wired in accordance with General: Upon receipt of fixture thoroughly inspect for any freight damage, which should be brought to the attention of the the National Electrical Code, National Electrical Safety Code and applicable local codes and ordinances. Proper grounding is delivery carrier. Compare the catalog description listed on the required to insure personal safety. Carefully observe grounding packing slip with the fixture label on the housing to be sure the procedure under installation section. This fixture is not suitable correct merchandise has been received. for Hazardous or Classified Locations. WARNING: Risk of Fire/Electric Shock. If not qualified, consult an electrician. Risk of Electric Shock. Disconnect power at fuse or circuit breaker panel or fuse box before installing or servicing. Risk of Burn. Allow fixture to cool before changing bulb or handling fixture. IMPORTANT: Dual voltage and multi-tap ballasts are factory wired for 277 Volt input. Before installation make certain power supply and ballast voltages are compatible. For use with other line voltages, remove wire nut splicing the black lead from the quick disconnect plug and 277V lead from ballast. Cap off lead with wirenut. Splice black lead from the quick disconnect plug with the desired voltage lead from ballast. APPLICATIONS: • 70W HID and 42W CFL fixtures are not suitable for operation in ambients exceeding 40°C. 100W HID fixtures are not suitable for operation in ambients exceeding 25°C. • Minimum supply wire conductor requirements 150°C. • Thread sealing compound (not provided) must be applied to all unused plugs when used in wet location applications. Upper Cover TO ENSURE PROPER GROUNDING AND POLARITY: • Connect the fixture ground wire (Green) to the supply ground. • Connect the fixture neutral wire (White) to the supply neutral. • Connect the fixture line wire (Black) to the supply line. NOTE: If you are unsure which wires are ground, neutral or line, consult an electrician. 3/14-14 Threaded Pendant Quick Disconnect Receptacle Quick Disconnect Plug TOOLS REQUIRED: • Phillips screw driver • Slotted screw driver • 1/8” Allen wrench • 5/64” Allen wrench INSTALLATION INSTRUCTIONS: 1) Loosen Allen set screw and remove guard and globe. 2) Loosen (3) #12 Phillips pan head screws and remove lower ousing assembly. Disconnect plug and receptacle. 3) Pull supply leads into upper cover and thread upper cover to pendant. To avoid pinched wires, only 6” of supply leads should extend into fixture. Use wire ties to bundle wires. Splice supply leads to quick disconnect leads. Note: See instructions in section “TO INSURE PROPER GROUNDING AND POLARITY”. 4) Reconnect plug and receptacle and reassemble lower housing to upper cover. Tighten Set Screw with 5) Install lamp and reinstall globe and guard. 5/64” Allen Wrench Lower Housing (3) #12 Philips Pan Head Screw Loosen Set Screw with 1/8” Allen Wrench to Remove Guard NOTE: For Metal Halide application, a glass globe or lens must be used unless an open rated lamp is installed. These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every possible contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for user’s purpose, please contact your nearest Cooper Lighting representative. LUMARK 1121 HIGHWAY 74 SOUTH PEACHTREE CITY, GEORGIA 30269 11/1/06 IMI-661 ADH061573