Single-Shell Synthetic Fiber Shotcrete Lining for SLAC Tunnels

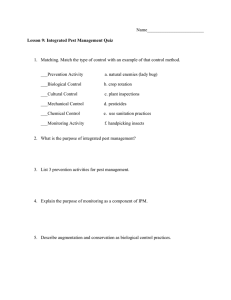

PART TITLE

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING

FOR SLAC TUNNELS

Wern-ping Nick Chen ■ Jacobs Engineering

Frederick (Rick) Vincent ■ Jacobs Associates

ABSTRACT

The application of macro synthetic fiber reinforced shotcrete in the US tunnel industry is slow in comparison to its steel fiber counterpart. Besides its potential cost saving over steel fiber, synthetic fiber has performance benefits over steel fiber in certain occasions. For example, its toughness performance after first crack in large deformation range is superior to steel fiber. This paper demystifies the rationales in designing the single shell synthetic fiber reinforced shotcrete for the LINAC Coherent Light Source tunnels at Standard Linear Accelerator Center (SLAC) that have been constructed.

Several US record features for these tunnels, design revisions, and lessons learned during construction phase are illustrated.

INTRODUCTION

The Stanford Linear Accelerator Center (SLAC) LINAC Coherent Light Source

(LCLS) Project, which is operated by Stanford University in Menlo Park, CA, just outside of San Francisco, completed construction of the LCLS facilities in mid-2008. Then and now, the LCLS represents the world’s most powerful X-Ray free electron laser, allowing researchers to watch the motion of the atomic and molecular world with unprecedented detail, and facilitating advances in scientific fields including materials science, biology and medicine, chemistry, physics, energy science and research, electronics, and environmental science. Today, hundreds of scientists from around the world are utilizing this one-of-a-kind facility to conduct a wide range of experiments, but even before the facility was fully operational, it had already proven to be a success of a different kind in the underground industry. The LCLS mined tunnels enjoy the distinction to be among the first to employ single-shell synthetic fiber reinforced shotcrete linings as both their initial and final linings.

The project consists of 800 m (½ mile) of underground construction, including

518 m (1,700 ft) of tunneling in rock 3 to 30 m (10 to 100 ft) deep, which was excavated using the New Austrian Tunneling Method (NATM), also called herein the Sequential

Excavation Method (SEM). Three 6 m (19.5 ft) tunnels, namely the Undulator Hall tunnel, X-Ray Tunnel and Access Tunnel, and one 14 m (46 ft) cavern, called the Far

Experimental Hall (FEH), make up the mined portion of the project. All of the initial and final linings are macro synthetic fiber reinforced shotcrete and plain shotcrete, with welded wire fabric and lattice girders. In the cavern, 5 or 6m (16 or 20 ft) galvanized cement grouted rock dowels were also installed. Figures 1 and 2 show a 3D rendering of the overall project, with mined tunnel and cavern indicated, and the project location and alignment plan, respectively.

1336

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1337

Figure 1. 3-D rendering of project site aerial view

Figure 2. Project location and alignment plan

PURPOSE OF THIS PAPER

The purpose of this paper is to document the success application of a cost effective and unique shingle shell hybrid SnFRS lining with plain shotcrete and welded wire fabric. This is the first application of this type of lining system in the world. This paper will address the development and the selection of this lining system. Comparisons are made between the traditional steel fiber reinforced shotcrete (SFRS) and the macro synthetic fiber reinforced shotcrete (SnFRS). It covers the following topics:

■

■

Regional geology

Selection of tunnel initial support and final lining

■ Fiber reinforced shotcrete

1338 SEM/NATM

Figure 3. Subsurface profile along tunnel alignment

■

■

Discussions

Conclusions

Engineer of Record

As SLAC’s primary consultant for the LCLS Project, Jacobs Engineering Group

(JEG) performed both the preliminary and final designs for the LCLS Project, and serve as the Engineer of Record for all above and below-ground facilities. JEG also provided engineering services during the construction phase, reviewing technical submittals, requests for information, and evaluating any Contractor or client proposed changes to the design.

REGIONAL GEOLOGY

As shown on the geologic profile of Figure 3, the tunnels and cavern were located within the Ladera Sandstone formation, which is a poorly graded, fine to medium grained sandstone. The rock is generally weathered and moderately cemented, with occasional zones or pockets of poorly cemented and un-cemented sands, which would tend to ravel when excavated. The average unconfined compressive strength of the rock, as measured by laboratory tests, was only approximately 1.1 MPa (160 psi), which is indicative of a soft or very weak rock, and sometimes can be classified as

Intermediate Geo Material (IGM—materials with strength in-between those typically of rocks and soils).

Geotechnical Design Parameters and Actual Ground Conditions Encountered

During Construction

The classification of the rock as an IGM made for a challenging rock mass classification process during the design phase, in order to find the most appropriate manner to characterize the rock mass conditions that would best reflect its behavior during the tunnel construction (Halim 2007). Traditional rock mechanics approaches were supplemented by engineering judgments to consider the very weak and sometimes uncemented nature of the rock. While Q and RMR indices, of which RQD is a component, were used with caution to analyze the rock mass behavior during the SEM tunneling process, other geologic considerations including observations of actual ground behavior during previous tunneling experience in the area became of the utmost importance.

Researching the past experience of tunnel excavations at the site, the ground was

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1339

Table 1. Summary of design rock properties

Ladera Sandstone Rock Properties:

Classification Ratings:

RMR

Q

GSI

Strength Criteria:

Typical/Average Rock:

Hoek-Brown

Equivalent Mohr-Coulomb

Low/Poor Rock:

Hoek-Brown

Equivalent Mohr-Coulomb

Modulus of Deformation:

Typical/Average Rock

Low/Poor Rock

In-Situ Stress/Ko

Poisson’s Ratio

30 to 50

0.04 to 0.5

15 to 50 mb = 1.65, sb = 0.0026, ab = 0.509

c = .05 MPa (7.5 psi), f = 31° m b

= 0.61, s b

= 0.0001, a b

= 0.553

c = 0.0276 MPa (4 psi), f = 23°

300 MPa (43.5 ksi)

140 MPa (20.3 ksi)

0.1 to 1.0

0.1 to 0.25

anticipated to behave more like fair to good rock with limited zones of poor to very poor rock.

This latter description proved to be the case during construction. With the exception of some looser material found in limited zones of the X-Ray tunnel, the rock in the project site proved to have very good standup time with no water inflows aside from some occasional dampness in the X-Ray Tunnel, and exhibited only minimal air slacking behavior (Doig, 2008). Also, very little movement was detected in the geotechnical instrumentation, which consisted of Multiple Position Borehole Extensometers

(MPBXs) installed prior to excavations, tunnel monitoring points within the cross sections, and surface survey points. Movement readings in the MPBX’s were less than

12.5 mm (½ inch), and there was very little convergence in the tunnels.

However, without the benefit of this information during design, Jacobs Engineering

Group (JEG) was required to establish geotechnical design parameters to be used for the SEM parameters as well as the initial and final lining designs. Ironically, one of the factors that led JEG to consider the use of synthetic fiber reinforced Shotcrete (in lieu of steel fibers) was that its toughness performance after first crack in large deformation range is superior to steel fiber, and due to the extremely weak nature of the rock, the anticipated deformations in the tunnel opening were predicted to be relatively large for a rock tunnel.

In addition to the Q and RMR systems, an alternate system recommended by

Hoek (Hoek and Marinos, 2000), the Geological Strength Index (GSI), was used for the final rock mass properties estimation. This index was used to bridge the apparent gap between the Q and RMR systems, as it can be directly related to the RMR for better quality rock masses, and has been extended for weak or poor quality rock masses where the RMR correlation does not normally work, such as in this case.

Table 1 presents the final design rock mass properties that were used during the design phase (Halim 2007).

1340 SEM/NATM

Figure 4. Excavation and support requirements for Undulator Hall tunnel.

SELECTION OF TUNNEL INITIAL SUPPORT AND FINAL LINING

Undulator Hall, X-Ray and Access Tunnels Excavation and Initial Support

Due to the anticipated weak nature of the on-site rock, it was correctly anticipated that the tunnel excavations would be performed using a roadheader, which would impose relatively minor disturbance to the rock surrounding the tunnel. It was further analyzed that the three tunnels would be excavated in a single heading and bench excavation sequence. For SEM designs, the ability of the surrounding rock to support itself during tunneling is balanced against the relatively flexible, passive support systems which are designed to allow controlled ground deformations until the ground mass reached a state of equilibrium. In this case, the predicted deformations at this site showed the need for an initial support system that could undergo significant ground deformation, and thus absorb significant amounts of energy. Also, during the design phase, it was predicted that the sequence of excavation and the timing of support installation would be of paramount importance and specified for construction. See

Figure 4 for an example of the Contract requirement for sequence of support installation in the Undulator Hall tunnel.

In areas with minimum or shallow covers such as near the tunnel portals, the amount of rock cover was not be adequate to maintain stability, and therefore pre- support systems by forepoling or spiling were used. In addition, a set of contingency measures or tool box was incorporated into the design to account for the varying ground conditions. They included several pre-support and face stability measures such as selfdrilled and grouted pipe spiling, flashcrete and fiberglass bolting at the tunnel face.

The application of these contingencies would be based on the actual ground behavior observed during construction, as described in the GBR. During construction, when the three tunnels were excavated, due to the better than expected ground behavior, no additional contingency measures were needed.

For the standard support case in average tunneling ground conditions, the ground was anticipated to be firm to slowly raveling, with pockets of weakly cemented or uncemented sandstone which could lead to local instability in the tunnel perimeter or heading. The standard initial tunnel support system consisted of a combination of

Synthetic Fiber Reinforced Shotcrete (SnFRS) and regularly spaced lattice steel girders with spot rock dowels. Due to the high susceptibility of the rock to slaking when subjected to a wetting and drying cycle, the initial shotcrete layer was recommended to be applied at or close to the tunnel heading to protect the rock surface against

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1341 deterioration. The very strict movement tolerance/criterion of the final invert slab in the

Undulator Hall tunnel required the slab subgrade to be stable and undisturbed at all times during construction. For this purpose and to minimize ground heave during construction, excavation for the Undulator Hall tunnel was specified with a slightly curved bottom (not required for the other tunnels). Furthermore, a minimum 1 m (3-foot) thick invert bench and immediate installation of mud slab (not required for the other tunnels) was also specified to stabilize and protect the final tunnel invert against construction traffic. Limits were placed on excavation equipment to be used for the bench, and the amount of bench excavation that could be performed before installing the mud slab.

Although the rock behavior during construction was better than expected, these measures for the Undulator Hall tunnel were largely followed. The sensitive instruments housed within this tunnel performed well within their tolerances without any adverse effects from tunnel invert slab movement.

Based on the subsurface information that was available during the design phase, the stand-up time in the typical tunnel opening was expected to range between several hours to several days. Therefore, the maximum length of unsupported excavation round and timing of support installation were specified as part of the support requirements in the Contract Documents. During construction, after the ground conditions were shown to be better than anticipated, these criteria were relaxed significantly, allowing the tunnel advance lengths for both the top heading and bench excavations in the three tunnels to be doubled from 1.2 m (4-ft) and 2.4 m (8-ft) in the top heading, and from 2.4 m (8-ft) to 4.8 m (16-ft) in the bench excavations.

Far Experimental Hall Excavation and Initial Support

The design approach for the Far Experimental Hall (FEH) cavern excavation and support was similar to the one for the tunnels described above. However, due to its relatively large size, the FEH would need to be excavated in multiple headings and benches, the size and sequence of which were specified to maintain the excavated openings stability, and also to facilitate construction and the initial support installation.

During construction, the suggested sequence presented in the design documents was altered by the Contractor (Sander, 2008); however, the alternate design was reviewed against the Contract requirements. The initial support for the cavern consisted of fully grouted dowels, synthetic fiber reinforced shotcrete, and lattice girders, which were installed immediately in conjunction with the staged excavations. The initial support system would be integrated into the final support system for the tunnels and cavern, as described in the following section.

Because of the very weak or soft nature of the sandstone rock, the failure mode in the tunnel excavations were controlled by the plastic failure or yielding of the rock mass surrounding the excavation opening, instead of rock discontinuities. Figure 5 shows a typical result of the final stress distribution around the cavern, and also the stresses and forces in the initial support system, using a continuum mechanics finite element method. The PHASE2, 2-dimensional program, by RocScience (2002) was used to perform the analyses in this project. The primary function of the dowels in this case is to “knit” the rock together and improve the rock mass quality as a whole, and therefore limit the plastic zone formation around the excavation opening.

In some areas, such as the tunnel portals and intersections, and where the rock is relatively good and its discontinuities are well defined, spiling bolts and spot bolting were specified as needed to stabilize potentially unstable blocks or wedges, and to prevent those rock blocks from falling out. Additional dowels were also specified for the areas where high stress concentrations were expected. Due to the nature of the rock and lack of joints definition, no formal wedge stability analysis could be performed in this project.

1342 SEM/NATM

Figure 5. Typical PHASE2 results of final stress distribution around FEH cavern

Final Lining Design for Tunnels and Cavern

The concept for the final lining for the three tunnels and the FEH cavern is a composite system including both the SnFRS initial support layers and lattice girders, and the additional layers of plain shotcrete placed after excavation and initial support is installed. The plain shotcrete is reinforced with welded wire fabric (WWF) for long-term static and seismic loadings. The 150 mm (6 in) SnFRS layers are combined with the plain shotcrete layers to achieve an overall minimum 300 mm (12 in) thick final lining in the tunnels and a 380 mm (15 in) thick final lining in the FEH cavern. The final support system in the FEH cavern also relies upon 25 mm (1 in) diameter cement grouted dowels for long-term support, which are installed as part of the initial support system.

All tunnels and cavern were also specified to have a reinforced cast-in-place invert slab that was tied through the linings to the rock, to be structurally integrated with the tunnel linings. While most slabs are flat, in the case of the Undulator Hall, where strict final slab movement criteria was required, the slab bottom is constructed with a minimum radius to divert upward ground movements to the undisturbed ground at the tunnel sidewalls, promoting the arching effect. Where the final tunnel linings met with cutand-cover cast-in-place concrete construction, special seismic connection details were developed to allow for the large predicted relative movements at this joint.

During design, other finished tunnel linings were considered, such as cast-in-place concrete; however, the shotcrete lining was chosen as the final lining for a number of reasons. First, there was a precedent of finished shotcrete linings working satisfactorily on the SLAC campus. The existing PEP and Stanford Linear Collider (SLC) tunnels were constructed using shotcrete. This latter fact is coupled with the fact that the optimum shape of the tunnels was a horseshoe shape with a flat top slab surface. This shape was needed to facilitate the mounting of the equipment to the invert slab, as well as the movement of rolling tables and other day-to-day scientific instrumentation that would be expected to be used by the personnel within the tunnels. Also, although these personnel would occasionally enter the tunnels between experiments, the operational requirements for the tunnels did not include full-time occupation by SLAC personnel.

Therefore, the aesthetics and other “human-factors,” which may have otherwise influenced the decision towards a smooth, CIP concrete surface, were not present in the case of the three tunnels. Given these reasons, the additional cost to build formwork

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1343 was seen as unnecessary. In the FEH cavern, due to its sheer size and cross section shape of approximately 10 m by 14 m ( 33-ft by 46-ft) wide horseshoe shape, the notion of a CIP lining was not practical, nor cost-effective. For this reason, coupled with the fact that it would be receiving an architectural fit-out, complete with numerous rooms and other internal components, a CIP lining was unnecessary.

Final Lining Loading Criteria

The design loading criteria for the final lining were based on the static (i.e., gravity) load of rock above the tunnels, the tunnel lining dead loads, and the seismic structural requirements governed by the project. Since the tunnels and cavern will be located above known groundwater table at the site, the hydrostatic load acting on the tunnel structure was expected to be insignificant, and therefore not considered during the design, although saturated unit weights for rock were used in all analyses. During construction, only isolated damp patches were observed on the shotcrete surface in the X-Ray tunnel, and no water inflows were ever present (Doig, 2008). The long-term gravity rock load was based on the anticipated ground behavior during excavation (as predicted by the analytical models), and widely accepted empirical formulas using the rock mass characteristics, but in no case greater than one tunnel width or diameter of rock load above the tunnel crown (from prior experience in similar tunneling ground conditions). As previously mentioned for the FEH cavern, the main function of the dowels was to improve the rock mass condition to reduce the long-term loading to an amenable amount.

The seismic performance criteria for the tunnel and cavern structures were based on the widely accepted methods of seismic design and analysis of underground structures, as well as all applicable codes and SLAC project specific seismic criteria (Halim,

2007).

Lining Materials

The minimum 28-day compressive strength of all shotcrete is 34 MPa (5,000 psi), and due to the weak nature of the rock, the average toughness absorption of the SnFRS at 28 days, per ASTM C1550, was 500 Joules using 40 mm central deflection. In addition to the 500 Joule requirement, the macro-synthetic fibers were also specified with a minimum dosage of 10.7 kg/M 3 (18 lb/CY); however, as a value engineering item, using newly established methods of quantitative correlation between design values and toughness performance level developed by Chen (2006), the dosage was allowed to be reduced to an amount that would satisfy only 400 Joules of energy absorption. The

Contractor was able to demonstrate that they could exceed this 400 Joule requirement with a dosage of 10.7 kg/M 3 (18 lb/ CY), using a macro-synthetic virgin copolymer/ polypropylene fiber by Forta Corporation, called Forta Ferro. The lattice girders were composed of smooth bars with minimum yield strength of 483 MPa (70 ksi), while the invert slabs contained grade 60 reinforcement and the WWF is in accordance with

ASTM A185. Final cavern rock dowels were ASTM A615 grade 75 minimum, hot-dip galvanized.

Lining Tolerances and Serviceability Concerns

Although not crucial for “human-factor” reasons, since the shotcrete lining will be the final surface in the manned tunnels and cavern walls, for serviceability purpose, such as hanging conduit, pipes, etc., strict surface tolerances were specified. The tolerances were set by SLAC to satisfy equipment operational tolerances and included both minimum and maximum final lining targets. The final tunnel and cavern lining had to fall within an annulus centered on the tunnel/cavern centerline that is 102 mm (4 in) in total

1344 SEM/NATM

Figure 6. Ranges of back-analyzed values of lining permeability k l

2001)

(m/s) (Celestino et al., thickness, with the actual inside surface that was no greater than 25 mm (1 in) inside or 75 mm (3 in) outside the theoretical inside tunnel profile. This tolerance was specified not only to permit proper placement of the high-energy physics equipment to be installed, but to facilitate the ventilation design, which established the controlled environment (temperature and air velocity) that the equipment and experiments required.

Groundwater Infiltration and Shotcrete Permeability

As mentioned previously, the invert of the tunnel is above the water table. However, as the tunnels and cavern will permit manned access and, in the case of the cavern, will be occupied during some experimentation periods, the use of low-permeability shotcrete was specified. During construction, as a value engineering item and with SLAC concurrence, the waterproofing admixture requirement in the shotcrete specification was relaxed, considering both the water table elevation and the requirement for 10% microsilica in the shotcrete mix, which shall, by itself, produce a fairly low permeability shotcrete lining. The verification of the low permeability shotcrete is based on back analysis data for infiltration in tunnels with different lining system by Celestino (2001), extending for lined tunnels a previous solution presented by El Tani (1999) for unlined tunnels:

Q = 2 π

; 1 − c r eq

2 h

− c m

2

E ln r eq h r

2 h eq m

2

− c r eq

2 h m

2 r eq

= r r i r e where r = tunnel radius (i: internal, e: external, eq: equivalent) k g

, k h

Q l

= depth of tunnel axis with respect to the water level

= permeability coefficients for ground mass and lining

= infiltration rate per unit length of tunnel

The calculated permeability for shotcrete are between 10 –11 and 10 –8 m/s, as shown on Figure 6.

Also, it was considered that if some perched water did seep into the areas, a drainage system consisting of sumps embedded within the final invert slabs is provided to

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1345

Figure 7. Finished Undulator Hall Tunnel with painted finish surfaces (Source: lcls.slac

.stanford.edu/Multimedia) carry water out of the facilities via pumps. SLAC had used similar methods to remove small amounts of water in their other underground facilities in the past. In the final condition, the shotcrete surfaces were painted with an epoxy to minimize dust and improve aesthetics and lighting. See Figure 7 for a picture of the finished Undulator Hall Tunnel.

Serviceability

Another major serviceability consideration that the designer was required to follow was the strict final movement tolerance criteria established for a facility whose laser will function only under the tightest operational tolerances, complicated by the fact that the site is only 4 km (2.5 miles) from the San Andreas Fault. This criterion was primarily focused upon very strict differential settlement limits for the invert slab of the

Undulator Hall Tunnel. As the most sensitive underground area, the Undulator Hall

(UH) will house a series of undulator magnets that a laser will pass through, and microscopic movements in the magnets will misalign the laser, so the criteria was required to prevent frequent adjustments to the magnets during experimentation. Based on the operational requirements and experience with the other similar tunnel facilities in the area (PEP and LINAC tunnels), it was determined that a vertical differential movement criterion of 2–3 microns per week over points at 10-m apart was both reasonable and feasible (Welch, 2004). It was decided that a similar approach to the existing PEP and

LINAC tunnels was the preferred approach to achieving this criterion, and that the instruments supported on the slab, rather than the slab itself, would be required to make up any differential movement that is experienced in the tunnel. To achieve a similar to or better movement performance in the proposed UH than the existing facilities, the cast-in-place (CIP) concrete invert slab is designed to obtain an equal or greater overall structural stiffness than the existing tunnel structures. Other structural details are incorporated that should allow for improved performance. For example, the concave shape of the tunnel invert was designed to potentially reduce the upward heaving of the final subgrade and bending movements in the floor slab, and the concrete mix for the invert floor slab has been specified as a low-shrink mix to assure that the invert slab will be in full contact with the shotcrete walls and thus provide the full shear transfer across that vertical joint (Figure 8). Today, the Undulator Hall tunnel is now fully operational, and to date, has had no adverse impacts from any differential movements.

1346 SEM/NATM

Figure 8. 6-m (19.5 ft) ID SLAC Undulator Hall (UH) Tunnel. Note the curved invert and reinforced invert slab.

Durability

Since the use of hybrid single shell SnFRS with plain shocrete and welded wire fabric system, the potential of chloride corrosion from the environment is much reduced.

In addition, the potential of macro cell corrosion, the corrosion from potential differential normally found with concrete structure with two lays of steel reinforcements, is eliminated.

FIBER REINFORCED SHOTCRETE

Fiber reinforced Shotcrete (FRS) has been widely used in underground constructions in the last three decades, including its applications to mining, underground facilities, and civil tunnels. This is because of its residual strength after crack. The ability of a FRS to continue function as a load carrying element, the residual strength, when it is loaded beyond its flexural capacity is because of the fibers in the shotcrete mix that provide bridging effect, acting as steel reinforcement, when tensile cracks of the FRS occur. Without fibers, a plain shotcrete would lose its load carrying capacity when its tensile strength is exceeded and tensile cracks formed. On the other hand, if the shotcrete will not experience tensile cracks from exerted loads, fiber is not needed.

The post-crack residual strength of a FRS is normally referred to by the term

“toughness,” which is a measure of its load carrying capacity, or energy absorption, beyond its elastic limit. In a simple term, toughness is a measure of the FRS’ load carry capacity after it is loaded to crack. Mathematically, this toughness is generally defined

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1347

(first crack)

A

X

B

G

C

O

E Deflection

Figure 9. Idealistic FRS load-deflection curve

F D as the area under the load-deflection curve. For example, the area within points O, A,

B, C, and D in Figure 9 is the toughness of an idealistic FRS.

Fibers used in shotcrete can be made of steel, glass, synthetic polymers, and natural materials. Only steel and synthetic fibers are considered for the SLAC tunnels because they are the most commonly used fibers for underground applications.

Figures 10 and 11 illustrate steel and macro synthetic fibers being used in shotcrete

(ACI 506.1R-3).

Macro Fibers

Macro fibers are fibers with equivalent diameters greater than 0.3 mm (0.012 in).

The majority of macro fibers used in shotcrete are either steel or synthetic fibers. Steel fibers used in shotcrete are generally between 19 to 35 mm (0.75 to 1.4 in.) in length and 0.4 to 0.8 mm (0.016 to 0.03 in.) in equivalent diameter. Synthetic macro fibers can be longer and vary between 40 to 50 mm (1.5 to 2 in.) long, with equivalent diameters similar to the steel fibers. The fibers should meet the requirements of ASTM C1436.

Micro Fibers

Micro fibers are normally polyolefin-based or nylon, and should meet the requirements of ASTM C1436. Micro fibers used to resist explosive spalling in fires are polypropylene, with equivalent diameters less than 0.033 mm (0.0013 in.) and less than

(0.5 in.) long. Since micro fibers are not for structural applications, they are not discussed hereafter in this paper.

Why Synthetic Fiber Reinforced Shotcrete

Debates exist for the effective use of Synthetic Fiber Reinforced Shotcrete (SnFRS) versus Steel Fiber Reinforced Shotcrete (SFRS). Arguments mostly lie on strength and deformation, creep, characteristics of their associated fibers.

Young’s Modulus

The ranges of Young’s modulus are about 200 GPa and 5 to 10 GPa for SFRS and SnFRS, respectively (for 35 MPa concrete, its Young’s modulus is about 28 GPa).

This means SFRS will pick up load in a much early crack width stage than SnFRS. As

1348 SEM/NATM

Figure 10. Examples of steel fibers, after ACI 506.1R-3

Figure 11. Examples of macro synthetic fibers, after ACI 506.1R-3

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1349

Figure 12. Typical load vs. deflection curve for 1% by volume of macro synthetic fiber, after Ratcliffe, 2007 shown on Figures 12 (Ratcliffe 2007), the SnFRS shows a strain softening behavior and its optimal post crack residual strength is achieved about at 3 mm deflection. While the SFRS shows, on Figure 13 (Ratcliffe 2007), a strain hardening behavior and its post crack residual strength is achieved immediately after crack occurs.

Creep

Creep is a phenomenon of a structure element when it deforms over time under a sustain load. Its benefit can be the advantage of load distribution under deformation. Its issue lies on the potential of excessive deformation and therefore impacts the serviceability requirement of the structure.

Though advocates for SFRS exist (Ratcliffe 2007, Allen 2009, Rossi 2011), who criticize SnFRS lacks the immediate optimal load carrying capacity and its potential of excessive post crack time dependent creep deformation, advocates for SnFRS exist as well, who claim certain type of SnFRS fibers exhibit similarly post crack creep behavior to that of SFRS when the exerting load is moderate (Bernard 2004), say approximately at 50% of the gravity load to static capacity ratio, which will be addressed again in the

“Discussion” section. MacKay and Trottier (2004) also indicated that under moderately loading conditions, the cracked SnFRS specimens showed to be no more likely to fail due to flexural creep than the cracked SFRS specimens.

Though Figure 14 indicates SnFRS have higher creep deflection than that of

SFRS, care must be made in the interpretation of this figure. Post crack creep deflection of SnFRS depends upon the type of fiber in the SnFRS and the magnitude of the load the shotcrete is experiencing. It is agreed, during the design of SLAC tunnels, that

SnFRS will experience more creep deflection after crack than SFRS and its residual strength should be able to be designed to support this type of ground. It is therefore made a conservative design decision by employing a composite lining of 150 mm (6 in)

SnFRS as initial support with additional 150 mm (6 in) plain shotcrete with welded wire fabric to resist seismic loadings. The selection of the plain shotcrete is to minimize the potential of excessive post crack deflection and the selection of the SnFRS over SFRS is because of the following reasons:

■ Minimize shotcrete equipment wearing

1350 SEM/NATM

Figure 13. Typical load vs. deflection curve for 0.5% by volume of hooked end steel fiber, after Ratcliffe, 2007

Figure 14. Creep deflection (in 1/100 mm) versus time (days), after Ratcliffe, 2007

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1351

■

■

■

Minimize hazard underground condition (the SFRS surface can be sharp resulting in hazard working environment to workers/users in the tunnel)

Lighter weight for transportation (it is our experience the dosage rate, with similar residual strength performance, of SnFRS to SFRS is about 1 to 4)

Durability—No corrosion potential in extreme environment condition. In fact,

SnFRS is required for sub-sea tunnels in Norway. In addition, the service life prediction of the SFRS can’t be quantified at today’s technology; the service life prediction model for concrete structures is based on the concrete cover over the steel reinforcement, the water cement ratio in the concrete mix, and the chloride concentration the concrete is exposed. With the use of steel fiber, the concrete cover over the SFRS can’t be quantified

■ In general, SnFRS is more cost effective than SFRS with similar strength performance

Lastly, it was also reported that during construction the shotcrete for initial lining with the synthetic fiber reinforcement was observed to have extremely low rebound, less than 5%. This is compared to the rebound observed with the plain shotcrete layers, which was more in the 15% range (Doig, 2008).

DISCUSSIONS

Though SnFRS has been used in Norway, United Kingdom, and Australia for tunnels in extreme conditions (high risk of chloride corrosion and carbonation corrosion), its use in the US is late, starting about early 2000. The primary reason for the delay of its usage in the US is the lack of understanding its post crack creep deflection behavior.

The other reason, which is in general for all fiber reinforced shotcrete, is the lack of unified design approach for fiber reinforced shotcrete.

Question may be asked whether decision in the selection of the type of tunnel lining system be changed, if we design the tunnels based on the latest technology we know today. The answer is likely to be “yes.”

FRS Post-Crack Creep Deflection Behavior Revisit

Bernard (2010) has investigated the influence of fiber type on creep deformation of cracked fiber reinforced shotcrete panels. His investigation is summarized in this section.

The experimental investigation was undertaken into the time-dependent flexural creep deformation of cracked and un-cracked FRS panels reinforced with either steel or macro synthetic fibers, including:

■

■

Dramix RC 65/35—steel fiber

Novotex 0730—steel fiber

■

■

Barchip Kyodo—synthetic fiber

Strux 85/50—synthetic fiber

■ S-152 HPP—synthetic fiber

The majority of tests were performed on C1550 panels that had been cracked in a servo-controlled test machine and subsequently moved to a gravity-based test rig and loaded in flexure for a period of 3 months. See Figure 15 for typical series of loaddeflection cycles.

The investigation indicated that post crack creep deflection is relatively insensitive to load ratio for SFRS, but the post-crack creep deformation of cracked macro SnFRS were sensitive to the load ratio. The load ratio is defined as the ratio between the gravity load and the residual load capacity as defined in Figure 16.

1352 SEM/NATM

Figure 15. Typical series of load-deflection curves sustained by each HPP-reinforced specimen, commencing with (1) initial cracking test, (2) creep test, and (3) final C1550 test (after Bernard 2010)

The creep deflection exhibited by un-cracked FRS panels was similar to that exhibited by cracked hooked-end SFRS panels, suggesting that the post crack flexural deformation of hooked-end SFRS was small.

The investigation also indicated that there is considerable variation in creep deflection behavior among SnFRS with different macro synthetic fibers. In addition, the total creep deflection at any given time varies with the load ratio experienced and is thus sensitive to the dosage rate of fiber , as shown on Figure 17.

The results for the three types of macro SnFRS investigated suggest that creep deflection is not a simple function of fiber composition. Other properties of the fibers and the associated concrete mix may also play significant roles in determining timedependent behavior of cracked SnFRS.

With the understanding that the post crack long term creep deflection of a SnFRS depends upon the type and dosage rate of the fiber being used, a performance specification can be used to specify the type of the fiber such that its post crack creep deflection is insignificant. Its design process can be couple with the approach suggested by

Chen (2006).

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1353

Figure 16. Definition of terms related to load-deflection response during initial cracking test in servo-hydraulic test rig, gravity loading in creep rig, and reloading in servohydraulic test rig for typical Strux-reinforced specimen, after Bernard 2010

In terms of the resisting of seismic loading, the SnFRS is expected to perform better than the SFRS, since its low modulus and optimal residual strength in wider crack width (larger deformation).

CONCLUSION

A unique and cost effective single shell hybrid composite SnFRS and plain shotcrete with welded wire fabric was used successfully for the SLAC tunnels. It does not employ the use of waterproofing membrane or waterproofing admixture because of the low permeability nature of the shotcrete and the tunnels are above groundwater table.

Technology has advanced since the design of the SLAC tunnels. With the understanding of its residual strength and post crack time dependent creep deflection,

SnFRS, if its type and dosage rate are specified appropriately, can be cost effectively used as single shell lining for underground structures and its durability performance is superior to that of the SFRS.

1354 SEM/NATM

Figure 17. Creep deflection at 100 days expressed as function of load ratio (based on load capacity at initial maximum deflection), after Bernard 2010

ACKNOWLEDGMENTS

The authors wish to acknowledge SLAC of the Stanford University as the Owner of the project described in this paper and Jacobs Engineering is the Engineer of Record for this project. This article represents the opinions and conclusions of the authors and not necessarily those of SLAC. This article shall not be used as evidence of design intent, design parameters or other conclusions that are contrary to the expressed provisions in contract documents for the project.

REFERENCES

ACI 506.1R-08, “Guide to fiber-reinforced shocrete,” American Concrete Institute,

Farmington Hills, MI, 2008.

Allen, C. 2009. “Fibre Decider,” Tunnels & Tunnelling International, October 2009.

ASTM C1436, “Specification for Materials for Shotcrete,” ASTM International, West

Conshohocken, PA, 2008.

ASTM C1550, “Standard Test Method for Flexural Toughness of Fiber Reinforced

Concrete (Using Centrally Loaded Round Panel),” ASTM International, West

Conshohocken, PA, 2005.

Bernard, E. S. 2004. “Creep of Cracked Fibre-Reinforced Shotcrete Panels,” Shotcrete:

More Engineering Developments, Proceeding of the second International

Conference on Engineering Development in Shotcrete, October 2004, Cairns,

Queensland, Australia.

SINGLE-SHELL SYNTHETIC FIBER SHOTCRETE LINING 1355

Bernard, E. S. 2010. “Influence of Fiber Type on Creep Deformation of Cracked Fiber-

Reinforced Shotcrete Panels,” ACI Material Journal, September-October 2010.

Celestino, T. B., Giambastiani, M. and Bortolucci, A. A. 2001. “Water Inflows in Tunnels:

Back-analysis and Role of Different Lining Systems,” ITA World Tunnel Congress,

2001, Milan.

Chen, W. 2006. “Design and specification of fiber reinforced shotcrete for underground supports,” North American Tunneling ’06, Chicago.

Doig, P.J. 2008. “NATM Tunnels at Stanford Linear Accelerator Center, Menlo Park,

California,” North American Tunneling ’08, San Francisco.

El Tani. M. 1999. “Water Inflows into Tunnels.” ITA World Tunnel Congress, Challenges for the 21st Century, 1999, Oslo.

Halim, I., Vincent, F., and Taylor, J. 2007. “NATM Design for Stanford Linac Coherent

Light Source Tunnels,” the Rapid Excavation and Tunneling Conference (RETC),

June 2007, Toronto.

Hoek, E. and Marinos, P. 2000. “GSI—A Geologically Friendly Tool for Rock Mass

Strength Estimation,” Proceeding of the GeoEng Conference, 2000, Melbourne.

MacKay, J. & Trottier, J-F. 2004. ”Post-crack Creep Behavior of Steel and Synthetic FRC under Flexural Loading,” Shotcrete: More Engineering Developments, Proceeding of the second International Conference on Engineering Development in Shotcrete,

October 2004, Cairns, Queensland, Australia.

Phase 2 V 5.0, 2002. “Two-dimensional Finite Element Program,” Rocscience Inc.

Ratcliffe, R. 2006. “Steel Versus Synthetic Fibre Reinforcement in Shotcrete,” Shotcrete for Underground Support X, September 2006, Whistler.

Rossi, P. 2011. “Steel or Synthetic Fibre Reinforcement?” Structure Magazine, January

2011.

Sander, H.J. 2008. “Stanford LCLS Project—Detailed Construction Design for the

Intersection between Access Tunnel and FEH Cavern, “ North American Tunneling

’08. San Francisco.

Welch, J. 2004. “Ground Motion Expectations for the LCLS Undulator Hall,”

LCLS-TN-04-14, November 2004.