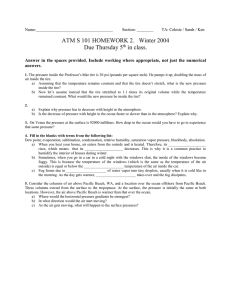

MOTOR Magazine - 21st Century Tire Service

advertisement

BY MIKE MAVRIGIAN Busting tires has served as an auto repair intro for many aspiring techs. Tires have now gone high-tech, and special tools and techniques are required to avoid busting something expensive, even during routine service. S hop owners and technicians may have always considered tire and wheel service to be the low-tech aspect of their workday. But there’s some new technology out there now that may make you reassess that notion. Tire Pressure Monitoring Systems A tire pressure monitoring system (TPMS) alerts a vehicle’s driver of lower-than-specified tire inflation pressure. If a vehicle is equipped with run-flat/zero-pressure tires, a TPMS is absolutely needed, since most drivers won’t feel the result of a low-pressure condition when a run-flat tire loses pressure. As of 2007, all OEMs will be required to feature a TPMS on their vehicles. This means that the aftermarket service industry must be able to handle these systems properly and diagnose system problems. Two types of tire pressure monitoring systems are currently in use—direct and indirect. A direct tire pressure monitoring system features an individ- 38 July 2006 ual sensor or monitor mounted inside each wheel’s inner well. This system is calibrated to alert the driver when one or more tires have lost at least 20% to 25% of the programmed or recommended inflation pressure. A receiver mounted in the vehicle receives individual wheel sensor signals, then sends this information to a central on-board computer (ECU), which in turn alerts the driver via an in-dash warning signal. Whenever a low-pressure signal is processed by the ECU, the in-dash tire pressure warning light will illuminate. In most cases, if a tire pressure problem is indicated, the warning light will remain on constantly. However, if the warning light blinks, this indicates a system fault that must be diagnosed. If wheel positions are changed on the vehicle (during the course of tire rotation, for example), individual sensors must be reprogrammed. If the sensors are not reprogrammed, the ECU will then assign the pressure data to an incorrect wheel location. Depending on vehicle make, model and year, one of two direct-type TPM Photoillustration: Harold A. Perry; photos: Mike Mavrigian and Wieck Media 21st CENTURY TIRE SERVICE sensor/transmitters may be present. These are the banded type and the stem type. Banded inflation sensors are attached to the wheel’s inner well area via both a peel-off positioning adhesive and a circumferential band clamp. Stem-type sensors mount at the valve stem location, with the valve stem an integral part of the sensor. Most OE tire pressure monitoring systems are the stem type, partly to aid in system diagnosis, since the sensor is much more accessible, in terms of distance, by a diagnostic or relearn tool. Band-mounted sensors are located deep inside the wheel, making it more difficult for the signal to pass to the diagnostic tool, whether the system uses an RF signal or a magnetic signal. Stem-type sensors weigh about an ounce, so this presents no extraordinary balancing issues. The OE-favored direct type pressure sensors are powered by a 10-year lithium battery. The expected battery life is realistic, since these sensors are designed to operate only during or after a 20-mph speed is reached. When a vehicle is parked, the sensors are designed to transmit pressure only once per hour or so. If a vehicle is equipped with an OE TPMS and the customer wants a set of aftermarket alloys, pay attention: Not all aftermarket wheels will accept the stem-type sensor. These sensors require a specific valve hole relief design. Most aftermarket wheels, which are designed to accept only standard snap-in rubber valves, do not allow the addition of the stem type transmitter. In this case, you’ll need to find aftermarket wheels that are designed to accept stem-type sensors. Instead of incorporating a stem-type direct system, some vehicles rely on information already monitored by the antilock braking system (ABS). This is referred to as an indirect TPMS. Since an insufficiently inflated tire will rotate at a different rate than a properly inflated tire, due to the resulting difference in rolling tire diameter, the difference in wheel rotation is sensed by the ABS. A signal is then sent to alert the driver via a warning light. It’s then up to the driver to check all four tires to determine which one is underinflated. However, if all four tires are equally July 2006 39 Photos: Mike Mavrigian 21st CENTURY TIRE SERVICE This is a typical stem-type tire pressure sensor/transmitter installation. It’s essential that the wheel’s inside well area is clean to prevent contamination of the sensor. underinflated, the ABS might not trigger the pressure warning, since all wheels would rotate at the same speed. Indirect TPMSs generally are designed to illuminate the warning light when a single tire’s pressure has dropped by about 30% in relation to its official recommended inflation pressure. Aftermarket Systems. The three commonly available aftermarket tire pressure monitoring systems are made by Doran, Smar Tire and Schrader. Doran’s PressurePro systems are available to suit a wide variety of applications, including passenger vehicles, lightto heavy-duty trucks, motorhomes, fifthwheel trailers and tag trailers. The PressurePro installation kits include a dashmounted 12-volt monitor and individual-wheel sensors that thread onto each wheel’s air valve. An audible alarm alerts the driver if any tire loses more than 12% of its programmed pressure. A simple programming procedure is outlined with the kit’s instructions. Smar Tire’s system includes four band-mounted wheel-mount pressure sensors and a dash-mounted receiver/ display unit. Each pressure sensor weighs a tad under 1.5 oz. These sensors are said to be accurate to ⫾1.5 psi. Sensor mounting band-straps accommodate 13- to 20-in.-diameter wheels. The band is clamped to the wheel’s inner well area. Each sensor features a motion detector that powers the sensor down when the vehicle is parked, conserving 40 July 2006 Be careful when dismounting or mounting tires on a wheel that’s equipped with a TPM sensor. Some OEMs recommend removing the retaining nut and dropping the sensor into the wheel before attempting bead-breaking or dismounting. the lithium sensor’s five-year battery life. The basic receiver display identifies each tire by a color-coded light. Each sensor is also color-coded, as is each tirevalve-mounted washer. The sensors are programmed to alert the driver if tire pressure drops to 22 psi. If pressure drops below that, a red LED on the display illuminates above the individual color-coded indicators. As an additional alert, if air pressure drops to 18 psi, a second-level warning activates an audible alarm, and the LED will flash red. Schrader’s Generation II Smart Valve RF TPMS is a direct system comparable to OE systems. Individual stem-type sensors mounted to each wheel transmit data to individual wheel-well-mounted detectors, which in turn send signals to the centrally mounted receiver. TPMS Initialization/Diagnostic Tools. A test tool is required to service any direct TPMS. For aftermarket use, easy-to-use hand-held testers are commonly available. The two most common uses for a diagnostic tool are to perform a system reset and to test system operation. About 75% of the tool’s use will be for resetting during routine tire or TPMS service. There is no industry standard regarding TPMSs. Some systems require resetting if primary vehicle battery power is interrupted, while this problem is not an issue in other systems. Depending on vehicle make, model and year, some systems’ data may be corrupted if the ignition key remote control is activated during a pressure sensor reset procedure. Currently, more than 40 different testing and resetting protocols are in use. Some aftermarket initializing and diagnostic tools are make/model/yearspecific, while others are designed to communicate universally with a broad spectrum of OE tire pressure monitoring systems. Sensor Replacement Caution. Before installing any direct (stem-type) TPMS sensor, and before mounting a tire onto a sensor-equipped wheel, you must note the sensor’s ID code (printed on the sensor body). This code will be required when programming or reprogramming the sensor. Remember to record this number before hiding the sensor from view. While specific procedures for initializing an indirect TPMS may vary among vehicle makes and models, a typical approach involves first adjusting each tire’s inflation pressure to the recommended level. With the vehicle stopped, turn the ignition switch to the ON position. Press and hold the tire pressure warning reset switch (typically located under the dash) until the tire pressure warning light blinks three times at 1-second intervals. Next, operate the vehicle at 19 mph or more to complete the initialization of the skid control ECU. If the tire pressure warning light blinks at .25-second intervals while the vehicle is in motion, the initialization may have failed. If this Photo: Mike Mavrigian Photo courtesy SPX/OTC 21st CENTURY TIRE SERVICE This hand-held initializing tool is being used to reprogram a sensor for wheel location. This procedure can be accomplished with the tire on or off with stem-type sensors. occurs, the initialization procedure must be repeated. After initialization is completed, the skid control ECU monitors tire pressure by using the ABS/traction control wheel speed sensors. The Cool Tools. Bartec, a manufacturer of TPMS tools for both the OE factory and dealership levels, offers a variety of hand-held TPMS service tools that are dedicated to specific makes and/or systems. In addition to their OE support, Bartec offers two hand-held tools specifically designed for the aftermarket—the DBL3 and the DEG. The DBL3 is an entry-level sensor “trigger” and test tool. The DEG is a heavy-duty trigger, test and diagnostic tool that features a large, easy-to-view display. These tools are able to test sensor condition (capturing sensor ID number, temperature, pressure and operating data from the sensor’s internal clock, and decoding this information while determining sensor status). Such higherend tools can “force” a sensor to transmit data, without the need to perform a driving loop. Bartec also offers three versions of diagnostic tools for both aftermarket and dealership use. Diagnostic tool leader OTC offers its Model 3833 Tire Pressure Monitor, a convenient hand-held device that provides total and universal monitoring of all OE stem-type TPMSs. Simply enter the vehicle make, model and year and the tool readies itself to diagnose or re- 42 July 2006 The diagnostic/relearn tool is placed adjacent to the tire pressure sensor, accommodating communications via either an RF or magnetic signal, depending on OE design. set any system. A comprehensive manual and CD are also available. When performing troubleshooting and diagnostics, the tool is able to activate the sensors and inspect all transmitted data, which is displayed on the monitor screen (ID number, pressure, last-vehicle history, etc.). The tool is easily updatable by connecting it to a PC for downloads from OTC. Also available is the T.I.P.S. (Tire Inflation Positioning Switch) tool from Spectrum Composites. This universal LED sensor resetting tool is designed only to reset/initiate system sensors. According to the maker, the tool is compatible with all current OE tire pressure sensors. A working relationship between OTC and Spectrum Composites was announced recently. TPMS Service Guidelines. Any good shop should have no trouble servicing a tire pressure monitoring system, so long as the following guidelines are adhered to: 1. Handle with care. When a system problem occurs, chances are a damaged or faulty sensor is the cause. Because of its location (close to the bead), the prospect for stem-type sensor damage is high as a result of curb hits or careless handling during tire changing. In the case of a band-mounted sensor, damage can easily occur during tire changing, especially if the technician isn’t aware of the sensor’s pres- ence. While some band-mounted sensor setups feature a color-coded valve stem washer or cap, some don’t. Play it safe and ask the customer if the wheels are equipped with a tire pressure monitor, since a band-type system may have been retrofitted to the wheels. The need for caution should be obvious, but we must stress the importance of exercising care during tire dismounting and mounting. A pressure sensor can be easily damaged by a tire iron, so avoid blindly jamming anything into the bead or well cavity. Most OEMs specify that the stem-type sensor be dislodged before attempting bead breaking. Deflate the tire first, then remove the sensor’s retaining nut. Gently allow the sensor to drop into the tire cavity. This moves the sensor out of danger during bead breaking and dismounting. As soon as the sensor is accessible, remove it from the tire and set it aside. Note: Before reinstalling a sensor, always record the ID number, as this may be needed during the initialization procedure (although some sensor tools are able to recognize the ID number automatically). Never tighten the retaining nut on a sensor by guessing at torque value. Take the time to reference the OE torque value specification, and follow this value in every case, since overtightening can damage the sensor. 2. Not just any replacement part will do. The advent of the TPMS changes several service procedures, and valve core replacement is one of them. Most stem-type pressure sensors feature alloy or plastic valve caps and nickel-plated cores. In many cases, the tip of valve stem may act as the sensor’s data-transmission antenna. Whenever replacing valve cores or caps, use only the type originally featured by the OEM. 3. Use precise pressure. Make sure your pressure gauges are accurate when checking inflation on any TPMS. The OE-level pressure sensors can be surprisingly sensitive (sometimes alerting the system when the tire is underinflated by only 2 psi or so). 4. Don’t ignore the remote. Depending on the vehicle make and model, the key fob remote control may be involved in resetting procedures. Be aware of this, to avoid inadvertent button-pushing on the remote, which may initiate a reset. 5. When to reset? Resetting a TPMS is required if certain procedures are performed, including tire pressure correction(s), tire/wheel rotation, tire or wheel replacement, TPMS sensor replacement, receiver antenna replacement, TPMS control unit replacement or loss of vehicle battery power. Photo courtesy RTI Technologies, Inc. 21st CENTURY TIRE SERVICE Depending on how much tire service your shop does, a nitrogen-generating station may make sense. After the initial cost of the unit is recovered, extra revenue can be “generated” from premium tire service that includes a nitrogen fill. The big news in the tire industry today seems to involve the use of compressed nitrogen to inflate tires. This inert, moisture-free gas has been used for decades by the racing community (as well as for aircraft, military and various industrial applications). The primary reason for using nitrogen is simple and twofold: It’s an attempt to maintain a consistent inflation pressure, because since a near-pure fill of nitrogen features “fatter” molecules than an air mixture, a nitrogen-filled tire will leak less. Nitrogen doesn’t contain or carry airborne moisture. Think about it: When moisture-laden air heats, it expands; when it cools, it contracts. On a warm day or when a tire is heated by use at high speeds, the inflation pressure rises. When the tire cools, inflation pressure drops. By using nitrogen instead of air, the initial inflation pressure is much more stable. This means that the tire On the PAX tire system, an inner liner is positioned onto the wheel’s inner well to provide tire-to-wheel integrity under low- or no-pressure conditions. Servicing this wheel and tire combination requires special tools and techniques. 44 July 2006 Photo courtesy Michelin Nitrogen Tire Filling contact patch remains more stable in spite of thermal influences. Some promotional material regarding nitrogen, while true, seems to exaggerate the issue. For instance, using nitrogen “increases tire life”; yes, because inflation pressure is more stable. Nitrogen provides “better handling and braking”; yes, because inflation pressure is more stable. Nitrogen “provides better fuel economy”; again, yes, because inflation pressure is more stable. Let’s keep things in perspective: Nitrogen doesn’t save tires; proper inflation pressure saves tires. Whether we accomplish this by the use of nitrogen or regular pressure monitoring is the real issue. Because, as we said, nitrogen molecules are larger than molecules that comprise air, nitrogen leakage is about one-sixth that of compressed air. Also, nitrogen runs about 20% cooler than compressed air, theoretically resulting in diminished tire degradation. Nitrogen is also a poor heat conductor, which is one of its benefits. It won’t cause inflation pressure changes due to temperature fluctuations. To achieve the maximum benefit of inflating tires with nitrogen, a charge should consist of at least 95% nitrogen. Compressed nitrogen is commonly available at any compressed gas supply facility. Nitrogen cylinders are available in five sizes, based on cubic foot capacity. From smallest to largest, these include sizes R, Q, S, K and T. One option is to visit your local gas supplier and rent the size and number of nitrogen cylinders you’d like. When the cylinder is depleted, exchange it for a full cylinder. The only other pieces of equipment you need are a regulator (which threads into the cylinder port and allows you to dial down the outgoing pressure to a manageable level—say, 100 psi) and one or more safety devices to prevent the regulator from being damaged. You can install a safety cage on the cylinder top (this houses the regulator, protecting it from damage). You can (and should) also secure the standing cylinder against a shop wall to prevent it from being knocked over. Compressed nitrogen cylinders are charged at 2200 to 2640 psi, so common sense should tell you that if the regulator is damaged and an open release is created, a nitrogen cylinder will become a missile that can shoot across the shop floor. Nitrogen is an inert gas, and as long as it’s regulated to a sensible pressure level, any quality serviceable hose and hose couplers will work just fine. If you want to follow the current trend in terms of color designations, you can buy green 21st CENTURY TIRE SERVICE Photo courtesy Hunter Engineering The tire and PAX inner liner shown here are being installed on a wheel. Special tire machine rollers prevent liner damage during tire removal and installation, and the inner bead must be installed by hand with PAX bead levers. hose. Green valve caps are a good idea as well, for no other reason than to readily identify a tire that has been inflated with nitrogen. Be aware that while most nitrogen-generating systems offer green valve stem washers and caps, some manufacturers may offer their own unique color. Purigen98, for example, uses blue. The only reason to color-code the valve caps is to alert a shop that the tire has been inflated with nitrogen. If a nitrogen-filled tire is topped off with compressed air, no damage will occur. You’ll simply diminish or lose the benefits that a near-pure nitrogen fill provides. So, you have a choice, depending on your mood. You can either purchase a nitrogen-generating system that allows you to “make” your own never-ending supply of nitrogen, or you can rent compressed nitrogen cylinders. Remember, if you rent cylinders and your anticipated use is relatively low, you’ll save money. If you purchase a nitrogen generator, you won’t need to worry about running out of the stuff. The PAX Tire System The PAX tire system, developed by Michelin, is a unique so-called run-flat tire and wheel system consisting of a special wheel, an inner liner, a specialdesign tire and a TPMS sensor. The intent is to provide tire-to-wheel integrity under low- or no-pressure conditions. This is accomplished by two basic features—how the tire “bead” seats and locks to the wheel rim and the presence of a reinforced polyurethane inner liner 46 July 2006 Tire Service Tool Sources Bartec Auto ID LTD (tools and info) U.S. Office: 586-685-1300 www.bartecautoid.com SPX/OTC 800-533-5338 www.otctools.com Spectrum Composites, Inc. 800-359-9855 www.tipstool.com that provides support in the event of pressure loss. This inner liner is positioned onto the wheel’s inner well, but is not affixed to the wheel. The wheel front (outboard) diameter is smaller than the inboard diameter, allowing removal of both the tire and support ring liner past the smaller-diameter outboard side of the wheel. The liner must then be removed from the tire in a separate procedure. The way in which the PAX tire seats onto the wheel provides a positive lock that prevents the bead from unseating even in a zero-pressure condition. Instead of the bead being held captive behind a rim flange (anchored only by relying on internal pressure), the PAX bead seats into a recessed groove in the wheel rim. As internal air pressure decreases, the vertical load between the bead and wheel actually creates a more secure bead-to-wheel anchor. The inner liner (also called a support ring) is somewhat flexible while creating a supportive gap-filler between the tire and the wheel well. This provides support and maneuvering control even after a complete loss of pressure. This highly advanced run-flat system is original equipment on late-model Honda Odysseys and a few high-end rides in Europe, and is employed on many high-risk armored/securityequipped executive and government vehicles. More applications are being added. To dismount or mount a PAX system package, specific equipment and procedures are required, involving two separate service issues—removal/installation of the tire from/to the wheel; and removal/installation of the inner liner from/to the tire. In other words, the PAX system requires two separate tasks involving either dismounting or mounting. Basically, mounting a PAX package is a four-step procedure: 1. Remove tire assembly from wheel. 2. Remove inner liner from tire. 3. Install inner liner to tire. 4. Mount tire to wheel. Regarding service equipment needed for dismounting and mounting a PAX tire/wheel assembly, you have a choice of buying a dedicated changer specifically designed for the task or an accessory kit that adapts your current changer to handle the PAX system. Considering the number of PAX jobs that your shop may encounter, the volume may not justify the price for a piece of equipment that can’t handle conventional wheels/tires. The sensible approach seems to be the adapter kit. Check with your equipment maker to see if they offer such kits for your shop’s tire changer. Will you see tons of PAX type systems roll into your shop? Probably not, at least not right now. However, you need to be aware of the service issues in order to avoid damaging these wheels and tires if conventional changer procedures are inadvertently followed. Visit www.motor.com to download a free copy of this article.