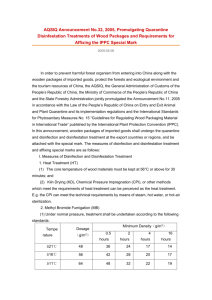

NSPM 11 Quarantine Treatment (MB) Standard

advertisement