LG - AgriSETA

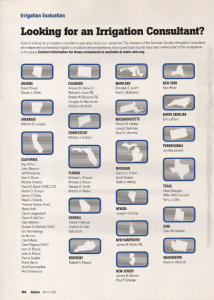

advertisement