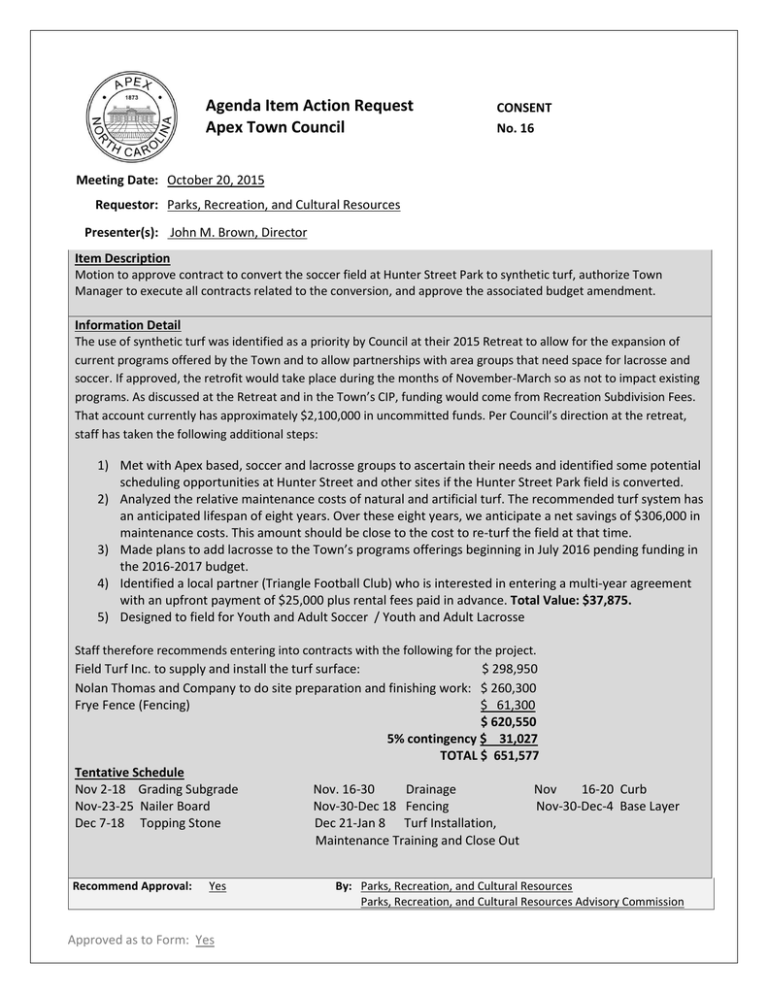

Agenda Item Action Request

Apex Town Council

CONSENT

No. 16

Meeting Date: October 20, 2015

Requestor: Parks, Recreation, and Cultural Resources

Presenter(s): John M. Brown, Director

Item Description

Motion to approve contract to convert the soccer field at Hunter Street Park to synthetic turf, authorize Town

Manager to execute all contracts related to the conversion, and approve the associated budget amendment.

Information Detail

The use of synthetic turf was identified as a priority by Council at their 2015 Retreat to allow for the expansion of

current programs offered by the Town and to allow partnerships with area groups that need space for lacrosse and

soccer. If approved, the retrofit would take place during the months of November-March so as not to impact existing

programs. As discussed at the Retreat and in the Town’s CIP, funding would come from Recreation Subdivision Fees.

That account currently has approximately $2,100,000 in uncommitted funds. Per Council’s direction at the retreat,

staff has taken the following additional steps:

1) Met with Apex based, soccer and lacrosse groups to ascertain their needs and identified some potential

scheduling opportunities at Hunter Street and other sites if the Hunter Street Park field is converted.

2) Analyzed the relative maintenance costs of natural and artificial turf. The recommended turf system has

an anticipated lifespan of eight years. Over these eight years, we anticipate a net savings of $306,000 in

maintenance costs. This amount should be close to the cost to re-turf the field at that time.

3) Made plans to add lacrosse to the Town’s programs offerings beginning in July 2016 pending funding in

the 2016-2017 budget.

4) Identified a local partner (Triangle Football Club) who is interested in entering a multi-year agreement

with an upfront payment of $25,000 plus rental fees paid in advance. Total Value: $37,875.

5) Designed to field for Youth and Adult Soccer / Youth and Adult Lacrosse

Staff therefore recommends entering into contracts with the following for the project.

Field Turf Inc. to supply and install the turf surface:

$ 298,950

Nolan Thomas and Company to do site preparation and finishing work: $ 260,300

Frye Fence (Fencing)

$ 61,300

$ 620,550

5% contingency $ 31,027

TOTAL $ 651,577

Tentative Schedule

Nov 2-18 Grading Subgrade

Nov. 16-30

Drainage

Nov

16-20 Curb

Nov-23-25 Nailer Board

Nov-30-Dec 18 Fencing

Nov-30-Dec-4 Base Layer

Dec 7-18 Topping Stone

Dec 21-Jan 8 Turf Installation,

Maintenance Training and Close Out

Recommend Approval:

Yes

Approved as to Form: Yes

By: Parks, Recreation, and Cultural Resources

Parks, Recreation, and Cultural Resources Advisory Commission

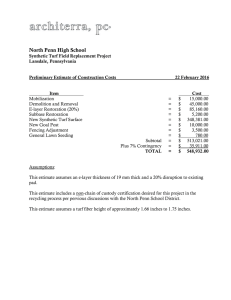

Attachments

1) Field Layout

2) Costing and Product Information

3) Budget Amendment

Approved as to Form: Yes

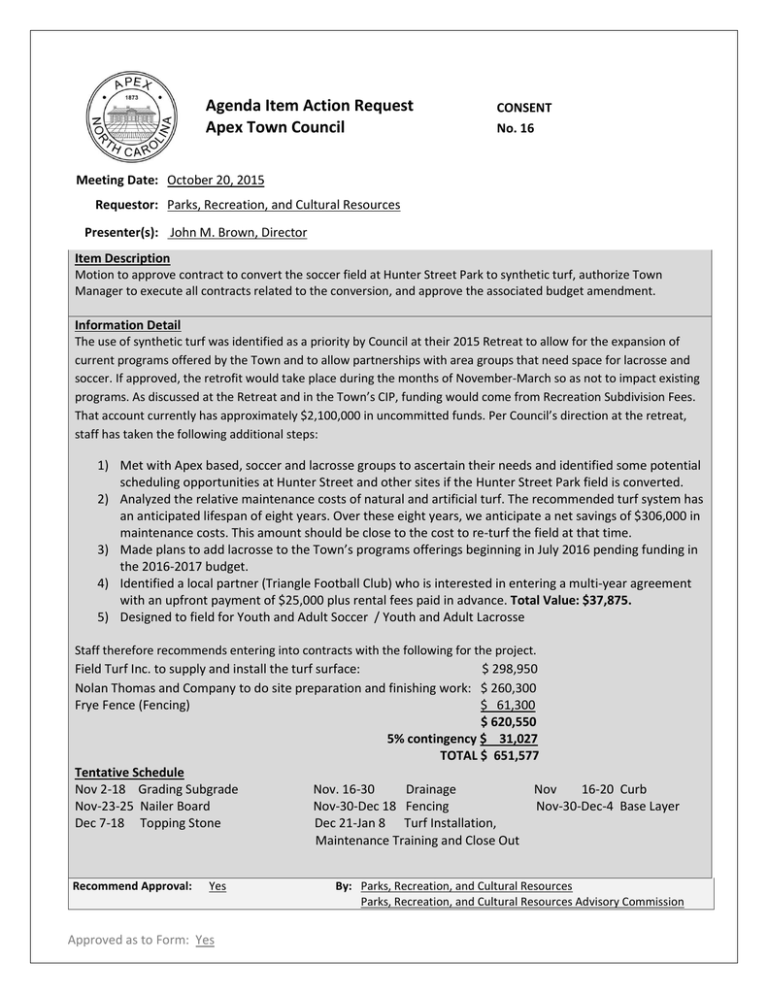

74,000 sq.ft.

1170' ln.ft.

PERIMETER:

1"=40'

SCALE:

FIELD AREA:

J.B.

CHECKED BY:

D.H.

400' FIELDTURF LIMIT

360' SOCCER FIELD (O/O)

20'

20'

105' MINI SOCCER FIELD (O/O)

105' MINI SOCCER FIELD (O/O)

GIRL'S LACROSSE

COMPLETE COLOR NAME: BLACK

PANTONE COLOR NUMBER:BLACK

SOCCER

COMPLETE COLOR NAME: RED

PANTONE COLOR NUMBER: 185C

FIELD LAYOUT NOTES (sports are in order of dominance) :

SIGNATURE:

PRINTED NAME:

LEGEND:

TITLE:

DATE:

GREEN FIELDTURF

74,000 sq.ft.

1. SOCCER MARKINGS ARE 4" WHITE NFHS STANDARDS.

2. BOY'S LACROSSE MARKINGS ARE 4" REFLEX BLUE.

3. GIRL'S LACROSSE MARKINGS ARE 4" RED.

4. MINI SOCCER MARKINGS ARE 4" RED.

COLOR DASHED CIRCLES ARE TO INDICATE PLACEMENT OF

THE 4" X 4" INLAID LACROSSE/FIELD HOCKEY TICK MARKS.

ALL DIMENSIONS TO BE VERIFIED BEFORE ANY CONSTRUCTION BEGINS.

ISSUE: PRESENTATION

COMPLETE COLOR NAME: BLACK

PANTONE COLOR NUMBER: BLACK

APPROVED BY:

DATE: OCTOBER 13, 2015

BOY'S LACROSSE

COMPLETE COLOR NAME: REFLEX BLUE

PANTONE COLOR NUMBER: RFXC

LOGO COLORS:

COMPLETE COLOR NAME: WHITE

PANTONE COLOR NUMBER: WHITE

APEX PARKS

SOCCER

APEX, NC

SPORT COLORS:

SOCCER

COMPLETE COLOR NAME: WHITE

PANTONE COLOR NUMBER: WHITE

SHEET: 1/1 FIELD LAYOUT

45'

175' MINI SOCCER FIELD (O/O)

175' BOY'S LACROSSE FIELD (I/I)

175' GIRL'S LACROSSE FIELD (I/I)

175' SOCCER FIELD (O/O)

5'

185' FIELDTURF LIMIT

5'

105' MINI SOCCER FIELD (O/O)

All Rights Reserved. Confidential Information: No portion of these drawings may be disclosed, used, reproduced, modified or shown, without prior written consent of FieldTurf.

330' BOY'S LACROSSE FIELD (I/I)

DRAWN BY:

360' GIRL'S LACROSSE FIELD (I/I)

QUOTATION

Client: Field Turf

Address:

Attn: Rich Stucky

Email: rich.stucky@fieldturf.com

Nolan Thomas & Company, Inc.

Sports Turf Contractors

PO Box 369

Stovall, NC 27582

Ph: 919-693-6478

Fax: 772-365-6129

Web: www.ntandcoinc.com

This Quotation, when properly executed, becomes a purchase order, subject to the terms, conditions, and

limitations appearing herewith. This quotation is subject to availability of necessary labor, materials, and supplies

to produce the items quoted.

Date: 9/30/2015

Project: Apex Park

Scope of Work:

Install construction entrance.

Install inlet protection around 7 inlets as shown on plans.

Demo existing irrigation valves.

Demo existing 12” HDPE and drainage structure as shown on plans.

o Note: All non organic items to demo shall be disposed by NT and Co at offsite location.

Remove hatched portion of sidewalks to meet new curb.

Excavate field to subgrade.

Haul only topsoil spoils to owner’s site approximately 2 miles from construction site.

Prep existing drainage structures to be covered with stone base.

Install 1 precast concrete yard inlet.

Supply and install approximately 1,100 linear feet of 8” collector line.

Backfill collector pipe with #57 stone.

Supply and install approximately 3,700 linear feet of 1”x12” flat pipe, 20’ on center.

Supply and install geotextile fabric over entire subgrade.

Provide and install new 8”x12” concrete curb.

Provide and install treated nailer boards.

Provide and install 4” of #57 or #67 stone base.

Provide and install 2” of #78 topping stone.

Compact stone base.

Laser grade stone base.

Nolan Thomas and Company, Inc. Confidential

Page 1

Remove inlet protection and construction entrance.

Clean site of all NT and Co construction debris.

Total Project: $260,300

Fencing

To add removal of 4’ fence: Add $1,400 to above base price

To add installation of 450’ of 4’ tall chain link fence per detail: Add $6,125 to above base price

To add installation of 800’ of 8’ tall chain link fence with 10’ tall lacrosse net above fence with

extended posts and cables per detail, 1-5’ wide walk gate, and 1-10’ double drive gate: Add

$76,025 to above base price

Fencing shall be installed outside of concrete curb with posts set in concrete per fencing details

on sheet C7.2. Fencing can be set in curb, however our quote would need to be adjusted

according to reflect a wider curb and more labor to work around the poles when the curb is

poured.

Unit Price

Undercut excavation and backfill with fill material: $85 C/Y

Exclusions/Exceptions:

Permits and/or engineering fees.

Fencing and netting not included in base price.

Tap or impact fees of any kind.

Soil Importing.

Locating, relocation, removal, and/or repair of any utilities.

Rock excavation or rock trenching.

Temporary power, water, and/or washroom facilities.

Construction and removal of any access road.

Supply and installation of electrical conduit.

Replacement of suitable soils/ABC stone on sub-grade.

Terms of Payment: Net 15

A service charge of 1 ½% per month (effective annual rate of 18%) will be charged on all accounts not

paid within thirty (30) days.

Expiration of Acceptance:

The prices quoted herein expire thirty (30) days from date of quote unless made effective as a purchase

order prior to expiration, by proper approval and signature.

Please print, sign, fax to (772) 365-6129

Accepted By: _____________________________

Date: ___________________________________

Company: _______________________________

Nolan Thomas and Company, Inc.

Submitted By:

Tim Grein

Nolan Thomas & Company, Inc.

Nolan Thomas and Company, Inc. Confidential

Page 2

Mobile: 336-803-1108

Fax: 772-365-6129

Email: tim.grein@ntandcoinc.com

Web: www.ntandcoinc.com

Nolan Thomas and Company, Inc. Confidential

Page 3

October 1, 2015

PRICING PROPOSAL FOR TOWN OF APEX

FieldTurf is pleased to offer to supply and install the following high performance artificial infilled

grass surface.

Field Name

Hunter Street Park Soccer Field

Turf System

FieldTurf Classic FTHD-2

Square Footage

Approx. 74,000

Field Markings

Soccer, U10-Soccer, Lacrosse Tick Marks,

Center Field Logo

Price

$ 298,950.00

*Price is based on above-mentioned dimensions

Product Details

______

FieldTurf, the worldwide leader in artificial turf, is pleased to offer the FieldTurf Classic FTHD-2

system, with the following product characteristics:

Pile Height:

Infill Weight:

Pile Weight:

Total System Weight:

2 Inches

6.25 lbs/ft2

30 oz/yd2

951 oz/yd2

The FieldTurf Quality Guarantee

To achieve unmatched quality and level of performance, we have invested heavily in

modernizing our plants with the latest fiber manufacturing, coating and tufting technologies

along with top manufacturing talent, and specialized installation equipment. Our dedicated

CAD-based design department supports customization for each client, and our experts ensure

timely delivery and installation on every project.

The world leader in artificial turf innovation is ISO 9001, ISO 14001 and OHSAS 18001 certified

for its leadership in quality, environment and safety management systems. FieldTurf’s Calhoun

7445 Côte-de-Liesse Road Suite 200, Montreal, QC, Canada H4T 1G2 • Toll Free: 1-800-724-2969 • Website: http://www.fieldturf.com

facility represents the only artificial turf manufacturing operation in North America to have

received these ISO certifications.

FieldTurf has taken the necessary steps to ensure that your project will run smoothly and that

the quality promised will be the quality delivered.

Price Includes:

a)

b)

c)

d)

e)

f)

g)

h)

Installation of the artificial in-filled grass surface upon a suitable base;

An 8 year 3rd party pre-paid insured warranty on the FieldTurf artificial grass surface;

Inlaid Soccer markings

Inlaid U-10 Soccer markings

Inlaid Boys Lacrosse Tick Marks

Inlaid Girls Lacrosse Tick Marks

Inlaid Center Logo (Standard, 2 colors, 30’ X 30’)

Maintenance equipment: 1 GroomRight + 1 SweepRight + 1 GroomRight Brush

Extension Wings.

Price does not Include:

a) The base upon which the FieldTurf field will be placed. FieldTurf shall not be responsible

for the planarity, the stability, the porosity, nor the approval of the base upon which the

FieldTurf surface will be installed, the drainage system, nor any construction or

modification of existing installations around the fields.

b) Any costs associated with necessary changes relating to delineation of the field.

c) The supply or installation of the field edging.

d) Unless otherwise specified, does not include any G-max testing.

e) The supply of manholes or clean-outs or grates, or supply of the manhole covers.

f) Any alteration or deviation from specifications involving extra costs, which alteration or

deviation will be provided only upon executed change orders, and will become an extra

charge over and above the offered price.

g) Site security.

h) Small vehicle to tow FieldTurf maintenance equipment.

i) All applicable taxes, bonding fees, prevailing wages, union labor or other labor law

levies.

The price is valid for a period of 90 days. The price is subject to increase if affected by an increase

in raw materials, freight, or other manufacturing costs, a tax increase, new taxes, levies or any

new legally binding imposition affecting the transaction.

7445 Côte-de-Liesse Road Suite 200, Montreal, QC, Canada H4T 1G2 • Toll Free: 1-800-724-2969 • Website: http://www.fieldturf.com

Please feel free to reach out to any member of our project team with questions about our offer:

Richard Leibl-Cote

Project Manager

241-375-2599

Richard.Leibl-Cote@fieldturf.com

Rich Stucky

Regional Sales Manager

704-849-9030

Rich.Stucky@fieldturf.com

Thank you again for your interest in FieldTurf, we look forward to working with you.

Per:

__________________________________________________________

Marie-Christine Raymond, Director of Project Management

FieldTurf USA, Inc. /FieldTurf, Inc.

7445 Côte-de-Liesse Road Suite 200, Montreal, QC, Canada H4T 1G2 • Toll Free: 1-800-724-2969 • Website: http://www.fieldturf.com

Conditions

Notwithstanding any other document or agreement entered into by FieldTurf in connection with

the supply and installation only of its product pursuant to the present bid proposal, the

following shall apply:

a) This bid proposal and its acceptance is subject to strikes, accidents, delays beyond our

control and force majeure;

b) Final payment shall be upon the substantial completion of FieldTurf’s obligations;

c) Accounts overdue beyond 30 days of invoice date will be charged at an interest rate of

10% per annum.

d) FieldTurf requires a minimum of 21 days after receiving final approvals on shop

drawings to manufacture, coordinate delivery and schedule arrival of installation crew.

Under typical field size and scenario, FieldTurf further requires 28 days per field to

install the Product subject to weather and force majeure.

e) FieldTurf requires a suitable staging area. Staging area must be square footage of field x

0.12, have a minimum access of 15 feet wide by 15 feet high, and, no more than 100ft

from the site. A 25 foot wide by 25 foot long hard or paved clean surface area located

within 50 feet of the playing surface shall be provided for purposes of proper mixing of

infill material. Access to any field will include suitable bridging over curbs from the

staging area to permit suitable access to the field by low clearance vehicles.

f) This proposal is based on a single mobilization. If the site is not ready and additional

mobilizations are necessary, additional charges will apply.

g) FieldTurf shall be accountable for its negligence but shall not be bound by any penalty

clauses.

h) FieldTurf shall be entitled to recover all costs and expenses, including attorney fees,

associated with collection procedures in the event that FieldTurf pursues collection of

payment of any past due invoice.

i) All colors are to be chosen from FieldTurf’s standard colors.

7445 Côte-de-Liesse Road Suite 200, Montreal, QC, Canada H4T 1G2 • Toll Free: 1-800-724-2969 • Website: http://www.fieldturf.com

Town of Apex

C/o Eric Battle

10/13/15

Hunter St. Park Soccer Field

Apex, NC

I. Furnish and install 441’ ft. of 4’ ft. tall vinyl coated chain link fencing.

9 gauge core chain link fabric

1-5/8” Sch 40 top rail

2” Sch 40 line posts

2 ½” Sch 40 terminal posts

7 gauge bottom tension wire

$5,300.00

*Deduct 1500.00 from Item I to take out and reinstall 300’ ft. of existing 4’ ft. tall black vinyl coated chain link fencing

(approximately 141’ of new and 300’ reinstalled – 2100.00 materials savings minus 600.00 to take out and haul away concrete).

II. Furnish and install 791’ ft. of 8’ ft. tall vinyl coated chain link fencing with 10’6” tall netting above.

9 gauge core chain link fabric

1-5/8” Sch 40 top, middle and bottom rail

2 ½” Sch 40 line posts

4” Sch 40 intermediate posts (40’ ft or less apart)

One 5’ ft. wide walk gate

One 10’ ft. wide double door gate

6-5/8” Sch 40 end and corner posts

$56,000.00

The World Leader In Artificial Turf

April 2012

FTNA Corp Brochure_2014.indd 1

1/6/2014 1:50 PM

THE GREATEST TURF ON EARTH.

How The Legend Was Born

FieldTurf comes from humble beginnings. Its debut in the sport surfacing industry was in 1988 with the introduction of a synthetic grass system for tennis courts and a synthetic grass surface used to minimize wear and tear

around golf practice tees. The company then began developing synthetic turf surfaces for other sports installations including soccer, lacrosse, football and baseball. FieldTurf focused on perfecting a sports field system with

a sand and rubber infill, which provided superior athlete safety, high performance and extreme durability. The

infilled artificial turf industry was born when, in 1994, FieldTurf installed its first full size soccer field.

The Installation That Changed The Industry

As the story goes, Tom Osborne, Nebraska Cornhuskers coaching legend, travelled to a high school installation in

Pennsylvania with a recently installed FieldTurf field and walked across the field to meet FieldTurf representatives.

“So, where is this stuff everyone’s talking about,” he asked. The truth was he had just walked across it. Osborne

thought he was walking on natural grass. Upon recommendation from Osborne, Nebraska’s athletic department

installed FieldTurf at one of their practice facilities in 1999. Husker players were so enthusiastic that the school

decided to install FieldTurf in its stadium a year early. The Huskers finished with an incredible 12-1 record and a

virtually injury-free season their first year on FieldTurf. It was the Nebraska installation that propelled FieldTurf

forward, as top teams from around the world began to play on FieldTurf.

University of Nebraska - Memorial Stadium

[2]

The Sports World Chooses FieldTurf

Since the installation at Nebraska, FieldTurf has grown exponentially. Throughout the last decade our engineered,

infilled artificial turf systems became the first to host two Super Bowls, the World Series, the World Baseball

Classic, a Major League Soccer Cup final and College Bowl games from coast to coast.

Today, FieldTurf continues to thrive as the global market leader in synthetic sports fields with more than 7,000

fields installed. Cities and schools have been benefitting from our ability to provide the very best value for the

short and long term, allowing organizations at all levels to be able to forecast the amount of money they will save

by installing FieldTurf, the safest, longest lasting and highest performing artificial turf system.

The Future Of Artificial Turf

With the best and most exclusive fiber manufacturing technology in the market today, FieldTurf has become

one of the most vertically integrated companies in the industry. All four of FieldTurf’s manufacturing facilities are

ISO certified and state-of-the-art. FieldTurf also has permanent R&D centers set up at Penn State University

and at each and every one of FieldTurf’s manufacturing plants across the globe. At FieldTurf Headquarters,

our Innovation & Performance Center has already led to some promising new discoveries that will once again

revolutionize the artificial turf industry.

Super Bowl XLVI on FieldTurf

Heritage

[3]

Premium Price. Best Value.

What Separates FieldTurf From All The Rest?

Here are the Top 10 Benefits:

1. FieldTurf has the most innovative product offering.

2. Independent testing has proven that FieldTurf is the safest turf system when compared to natural grass.

3. FieldTurf is one of the most vertically integrated companies in the world.

4. When it comes to playability and performance, FieldTurf is the clear market leader.

5. No other long pile, artificial turf system has lasted longer than FieldTurf.

6. FieldTurf may be priced higher, but it costs less.

7. For peace of mind, FieldTurf provides clients with the best insured warranty in the business.

8. FieldTurf is the clear choice of the pros.

9. FieldTurf offers First Class Customer Service.

10. When combining all these benefits it’s clear that FieldTurf is simply …the best investment.

These are not empty marketing claims, they are backed by science and facts.

Keep reading to find out more…

FieldTurf Is The Best Investment

When compared to natural grass and competing turf systems, FieldTurf has time and again proven to be the

better investment. It’s all about long term savings.

FieldTurf may be priced higher but it costs less

FieldTurf vs. Competing Artificial Systems: Best Value Analysis

Competition

FieldTurf

Base Preparation

$320,000

$320,000

Materials*

$4.00 per sq ft = $320,000

$4.75 per sq ft = $380,000

Maintenance**

$10,000 x 8 yrs = $80,000

$5,000 x 10 yrs = $50,000

Total Cost

$720,000

$750,000

Turf Life*

6-8 years

8-10 years

Average Cost Per Year

$90,000

$75,000

*Material per square foot price difference and turf life figures are

based on the last 10 years of industry data. For calculations, 8 years

was used for 6-8 yrs range and 10 years was used for 8-10 yrs range.

** Yearly maintenance cost is an average figure based on the last

10 years of industry data - cost difference mainly due to increased

infill work and repairs associated with competitor fields.

All figures based on average sized fields of 80,000 square feet.

A guaranteed return on your investment

FieldTurf vs. Natural Grass: Costs Over 10 Years

Natural Grass

FieldTurf

Base Preparation

$150,000

$320,000

Materials

$2.75 per sq ft = $220,000

$4.75 per sq ft = $380,000

Maintenance

$20,000 x 10 yrs = $200,000

$5,000 x 10 yrs = $50,000

Total

$570,000

$750,000

Scheduling Possibilities

25 hrs x 25 wks x 10 yrs = 6,250 hrs

68 hrs x 44 wks x 10 yrs = 29,920 hrs

Average Cost Per Hour of Use

$91.20

$25.07

Figures based on 80,000 square foot fields and average costs and usage rates across North America.

[4]

Did You Know?

A Positive Contribution

When it comes to carbon footprints, there’s simply no comparison between

natural grass and FieldTurf fields.

By choosing FieldTurf, you’re becoming part of an environmental movement

that not only saves clean drinking water, but also:

n

n

n

n

n

n

n

A typical full size FieldTurf

field saves 1 million

gallons of water per year,

utilizes 20,000 recycled

tires, and eliminates the

use of over 8,000 pounds

of chemicals per year.

Eliminates impact on water resources, saving billions of gallons of water each year

Eliminates the use of billions of pounds of chemicals

Removes millions of tires from landfill sites each year

Significantly lowers the use of natural gas and other fossil fuels

Eliminates fuel-powered mowing, aerating, and re-seeding

Eliminates grass clippings

Can contribute toward numerous Leadership in Energy and Environmental Design (LEED) credits

Largest artificial turf project in the world.

Golden Eagle Regional Park - Sparks, NV

1,400,000 sq ft

Costs Less

“We chose FieldTurf because of

the combination of value and

quality associated with the

FieldTurf product and company.

It was a 2-year evaluation process

of studying artificial turf products

and companies. We visited fields

all over the West Coast and spoke

with numerous Athletic Directors

and Parks & Recreation Directors.

It was a consensus among those

that we spoke with that FieldTurf

had the best product and the best

value.”

Stan Sherer

-Director of Parks &

Recreation, City of Sparks

[5]

The most innovative turf offering.

The FieldTurf Elite System Difference.

When it comes to safety, performance and durability,

nothing compares to the FieldTurf Elite system.

Patented Infill Layering System:

Often imitated, but never equaled, FieldTurf’s patented infill mixture delivers unmatched player

safety with published peer-reviewed studies to prove it!

Highest Quality Materials:

Not all materials are created equal. FieldTurf uses the best ingredients – round, clean and

durable silica sand coupled with the cleanest and roundest cryogenically processed rubber.

Heavyweight System:

Don’t be fooled by pile weight – focus on the total system weight. With FieldTurf’s heavyweight

infill system the total carpet weights of most Elite systems eclipse 1300 oz/sq yd.

Most Durable Fibers:

When it comes to durable fibers, FieldTurf’s Elite systems feature some of the most durable

fiber systems available in the market today. Just ask us for the testing!

Unmatched Drainage:

FieldTurf’s patented finger coating system provides 40% more porosity than competing

perforated turf systems.

[6]

THE FIBERS

The Most Durable Fibers – for Longest-Lasting Performance

The ideal turf fibers should provide grass-like aesthetics and unmatched durability.

FieldTurf’s systems have done just that. FieldTurf has the most innovative fiber options to

choose from. Here are the fiber options for the Elite system:

FieldTurf Revolution - Manufactured in FieldTurf’s own fiber plant, FieldTurf

Revolution features a proprietary polymer formulation that reduces splitting and

degradation and includes a leading ultraviolet inhibitor technology. A state-of-theart extrusion process provides intricate concave and ridged construction to eliminate

breaking points.

Classic HD - The gold standard in slit-film durability and technology, Classic HD is the

ideal combination of softness and stiffness, designed to be the most player-friendly and

resilient slit-film fiber in the marketplace. Its unique extrusion and inline precision cutter

eliminates excess splitting, for longer-lasting performance.

FieldTurf

Revolution

Classic HD

THE INFILL

A Patented Infill System - for Superior Playability

FieldTurf’s infill is installed in 3 layers – a base layer of sand for ballast, a middle layer

of silica sand / cryogenic rubber, and a top layer of larger sized cryogenically processed

rubber particles. This patented system is the secret behind the safety and playability of

FieldTurf. While fiber provides aesthetic value, it is the infill that delivers what the athlete

needs to perform. FieldTurf infill is made of the highest quality materials. Unlike ambient

rubber, FieldTurf uses only cryogenic rubber, the cleanest and highest grade of rubber

granule. Similarly sized particles of washed silica sand and rounded cryogenic rubber hold

each other in suspension - compress and expand to provide stability, long life resiliency

and proper energy restitution. A top layer of rubber particles provides athletes with a

non-abrasive cushion. FieldTurf’s Elite systems offer the heaviest infill systems in the

industry – with up to 9.2 lbs of infill per sq. ft.

Silica Sand

Cryogenic Rubber

THE BACKING

SureLock Coating - for the Most Durable Product

When designing the ideal turf backing three aspects must be considered – tuft bind

strength, stability, and drainage. FieldTurf’s SureLock Coating delivers the ultimate in

all 3 categories. Tuft bind is the strength of the attachment of the yarn to the backing

material. FieldTurf’s industry-leading tuft bind is achieved by using strong fibers secured

with the SureLock Coating System. The fibers are tufted into a backing of permeable

woven and non-woven polypropylene fabrics at a patented row width of 3/4” for optimal

cleat interaction. Our patented finger unit seals only the row of fibers, leaving the backing

40% porous, for unmatched drainage. Our competitors coat the entire backing, then burn

holes into the turf to allow drainage.

SureLock Coating

Technology

[7]

The most innovative turf offering.

FieldTurf Prestige Systems

FieldTurf’s world class technology

…with less of the cost.

THE FIBERS

Natural Aesthetics - for a Grass-Like Surface

FieldTurf XM6 - developed with strict adherence to the 3 pillars of

fiber development - Polymer, Process, and Geometry (PPG). The result

is a resilient fiber that has been designed to provide excellent long-term

durability.

FieldTurf XT - High performance slit-film fibers are fibrillated to

encapsulate infill and provide a dense fiber appearance.

THE INFILL

Two-Layered Infill System - for All Sports and Ages

XM6

This traditional two-layer infill is comprised of ballast layers of sand and

top layers of recycled ambient rubber granules for proper shock absorption

and world class performance. Prestige systems also include alternative infill

options such as Nike Grind, TPE, and Cork.

THE BACKING

Durable Coating - for Trustworthy Drainage

Ambient Rubber

Silica Sand

Prestige series systems feature a traditional two-layer, dimensionally stable

backing, coated and perforated at FieldTurf’s manufacturing facility.

The result is exceptional tuft bind strength along with excellent drainage.

Backing

[8]

XT

FieldTurf CoolPlay:

High Performance. Low Temperature.

-35°F

The CoolPlay system delivers the same

behavior and overall stability as FieldTurf’s

patented layered system.

CoolPlay takes nothing away from

performance …except the heat!

200

Temperature (°F)

FieldTurf’s exclusive cork top dressing

performs just like the very best FieldTurf

Elite system, found in the world’s most

famous stadiums.

Laboratory tested to be 35ºF

cooler than traditional sand/

rubber systems.

160

120

80

n CoolPlay

n Sand / Rubber Mix

40

0

0

5

10

15

20

25

30

35

40

45

50

55

60

Exposure time (minutes)

Alternative Infill Offering

In addition to our standard crumb rubber infill, FieldTurf also offers a complete

line of turf systems with the following alternative infill options: Nike Grind: Consists of recycled athletic shoes and Nike manufacturing scrap which are

ground up and turned into infill crumb. Nike Grind is also a non-marking rubber, leaving balls,

shoes and uniforms clean from any markings.

TPE: Produced by using prime raw materials which offer a stable shock absorption for synthetic

turf fields. FieldTurf offers an innovative high grade, high performance TPE option.

Nike Grind Rubber

TPE Granules

Cork: Cork, a totally organic product harvested from cork oak trees, is 100% recyclable with no

waste by-products. Due to its natural structure, cork’s low thermal conductivity will allow the

turf to remain cooler.

Cork

FieldTurf Fire Fighters

FieldTurf’s revolutionary fire retardant materials and

systems can meet and exceed any indoor or outdoor flame

test or building code. FieldTurf’s fire retardant offering

includes a fire retardant fiber (FieldTurf FR), along with

two infill options (FlameGuard and FlameGuard Green).

FlameGuard

FlameGuard Green

Did You Know?

Innovation

FieldTurf was one of the

first companies in the

world to use TPE infill

and has over 25 FIFA

recommended fields

using the material.

[9]

FTNA Corp Brochure_2014.indd 9

1/7/2014 9:09 AM

The safest turf system.

The Ultimate In Safety, Performance

And Durability

The most important attributes of a turf system are Safety, Performance, and Durability.

FieldTurf is proud to be at the top of the class in all 3 categories. Independent testing proves its

safety; player preference confirms its performance; and its durability is proven day in and day

out at thousands of installations around the world.

What makes FieldTurf the safest system?

The answer is simple. FieldTurf works just like natural grass.

On a natural grass field the athletes cut, plant and release in the earth – not in the blades

of grass. On an artificial turf field, the infill is the earth. FieldTurf’s infill provides the same

biomechanical properties as natural grass, as athletes cut, plant and release. Like in natural

grass, athletes play in the infill, not on the turf fibers.

FieldTurf’s infill system contains up to 9.2 lbs. per square foot. It’s the “heavyweight” in the turf

industry. All other turf systems contain a lightweight infill system, typically no more than 6 lbs.

per sq. ft.

Stitch “gauge” refers to the distance between the rows of fibers in a turf carpet. FieldTurf is

a “wide gauge” turf system. The rows of fiber are 3/4” apart for ideal cleat interaction. This

spacing allows for proper cleat penetration of the infill. Proper penetration enables the athlete

to plant, twist and release just like they do on natural grass - without undue torque transmitted

to the knees and ankles. As a result, chances of injuries are greatly reduced.

All other turf systems use a very “narrow gauge” usually 3/8” or 1/2”. This narrow gauge results in

turf that is overly dense, preventing the same penetration and positive biomechanical functions

found on FieldTurf and natural grass.

The result is that the athlete plays on or in the fibers - not in the infill. This causes the fibers to

wear faster and makes it more difficult for the athlete to get solid footing, causing slippage. We

call this “The Skate Effect.”

FieldTurf was built by athletes for athletes. Our team has taken the time to design and produce

a patented turf system that is engineered and quite unlike any other. The combination of our

heavyweight infill system and our wide gauge turf spacing are two unique inventions that set

FieldTurf apart from the rest. The result is proven player safety and performance that is simply

unmatched.

FieldTurf’s performance enhancing artificial turf provides a surface

that allows athletes to focus on skill and execution.

[10]

Did You Know?

FieldTurf’s heavyweight

infill system is constructed

using up to 9.2 lbs of

infill material per square

foot, which is quite

similar in weight to the

root zone of a high quality

natural grass field.

Playing In The Safety Zone

Long term study of FieldTurf fields provides evidence of the proven safety

of the heavyweight infill system.

Data collected from 11 FieldTurf fields located in California confirmed the long term safety of FieldTurf fields as it

relates to field hardness (Gmax).

FieldTurf fields with heavyweight infill systems maintain safe Gmax ratings over time, dispelling any myth of field

compaction. In accordance with MSP (Maximum Safety and Performance) fields must be within a Gmax range of

120-180 to be considered safe. All the FieldTurf fields analyzed were in this range. Published reports have indicated

that lightweight turf systems can achieve Gmax levels above 200.

Heavyweight infill systems have a minimum of 8 pounds of infill per sq. ft. while lightweight systems typically have a

high face weight (high fiber density) a term commonly described as “Fiber Loading” and only 3 to 6 pounds of infill

per square foot.

School

Field Age

Gmax

Francis Parker High School

7

127

Sycamore Valley Park

6

Mission Hill Middle School

6

Riverside Comm. College

6

Piner High School

Montgomery High School

School

Field Age

Gmax

Tamalpais High School

7

128

165

Granada High School

6

142

149

Andrew Hill High School

7

134

131.9

Piedmont Hills High School

7

143

7

136

Milpitas High School

7

163

7

122

Independent Testing Proves FieldTurf’s Safety

With FieldTurf, safety is not an empty claim or marketing jargon. We’ve put our product to the test in the most accurate

testing possible – real life epidemiological testing of athletes. Here are the highlights of two published, peer reviewed studies:

FieldTurf was proven safer than natural grass in a

5-year high school football safety study:

n

n

n

n

44% Fewer Concussions

33.4% Lower ACL Trauma

26.6% Fewer Severe Injuries

33.4% Fewer Ligament Tears

Source: American Journal of Sports Medicine

HIGH SCHOOL FOOTBALL SAFETY STUDY: FIELDTURF VS. NATURAL GRASS,

A 5-YEAR PROSPECTIVE STUDY

Safety

FieldTurf was proven safer than natural grass in

a 3-year college football safety study:

n

n

n

n

12% Fewer Concussions

40% Lower ACL Trauma

20.6% Fewer Severe Injuries

31.4% Fewer Ligament Tears

Source: American Journal of Sports Medicine

COLLEGE FOOTBALL SAFETY STUDY: FIELDTURF VS. NATURAL GRASS,

A 3-YEAR PROSPECTIVE STUDY

FieldTurf’s heavyweight infill

system and wide gauge design

result in fewer concussions and

reduced lower extremity injuries.

[11]

The longest lasting turf. Period.

Longest-Lasting Performance

Since its inception, FieldTurf has proven to be the most durable turf system in the world, with more fields that

are 8 years or older than all other competitors combined. All of FieldTurf’s components are made from the

highest quality materials. FieldTurf fields are manufactured and installed with a level of attention to quality

control that has changed the industry forever. No other artificial turf manufacturer in the world can measure up.

6+ yrs

5+ yrs

2442 fields

1072 fields

7+ yrs

1847 fields

8+ yrs

693 fields

9+ yrs

374 fields

249 fields

YEARS OF CONTINUOUS USE

10+ yrs

NUMBER OF FIELDS IN DAILY USE

Detroit Country Day School Selects FieldTurf Again,

After First Field Lasts Thirteen Years!

Detroit Country Day School also chose to install

FieldTurf in their impressive new indoor athletic

complex that will serve the football, boys and girls

soccer, boys and girls lacrosse and field hockey

teams.

“We looked at many different products in the industry and

the same holds true today as it did more than a decade ago

– nothing in the marketplace compares to what the FieldTurf

product offers in terms of safety and playability. When we

originally decided to install FieldTurf on our Stadium Field,

we expected an excellent level of service and product and that

is exactly what we experienced over the last 13 years. We are

excited to continue our longstanding relationship with the

world leader in artificial turf.”

Glen Shilling - Headmaster, Detroit Country Day School

[12]

Detroit Country Day School, MI

“For the last 8 years FieldTurf has been part of Wesley College athletics and we could not be more satisfied with our decision. Over this time, our 47-3 home record is not only a testament to our players and coaches, but also to the surface we play on – FieldTurf.”

Mike Drass - Athletic Director and Head Football Coach, Wesley College

Keys To A Long-Lasting Turf System

There are 4 keys to a long-lasting turf system – a durable fiber system, high quality infill materials,

proper infill depth and strong seam technology.

1

Durable Turf Fibers

2

High Quality Infill Materials

3

Proper Infill Depth

While an artificial turf system’s infill performs well for up to twenty years, it is the fiber system that wears first. Finding a

durable fiber system is key when selecting your turf system. Independent testing on the durability of various fiber types is

available at Penn State University. For more information on the study, contact your FieldTurf representative.

Low grade rubber materials can cause premature wear of a turf field. There are two types of rubber material – high grade

cryogenic rubber and low grade ambient rubber. Cryogenic rubber works to promote effective and consistent drainage by

eliminating the potential for migration caused by water. The cryogenic rubber’s smooth and rounded shape facilitates a

consistent flow of water through the infill without raising and displacing any rubber. The loose and jagged rubber strands

found in ambient rubber make it vulnerable to migration and floatation caused by the air bubbles in water.

Infill depth will ensure proper playability and longevity of the fiber, while also maintaining a

grass-like appearance. The infill is the athlete’s source for cutting, planting, shock absorption

and energy restitution. The critical mistake regardless of the type of infill used, is the under

filling or over filling of the turf system.

Proper Infill Level: Infill at approximately 2/3 (two-thirds) depth of the fiber height will

provide the necessary fiber support for a longer lasting field along with less maintenance and

a very minimal amount of infill displacement.

3/4”

2 1/2”

Proper Infill Level

Over Filled: Too much infill depth in a turf system leads to rooster tails following ball roll

and running, along with the potential for severe infill displacement.

Under Filled: An infill level that is too low can cause wrinkling and/or buckling of the turf

surface and fails to protect the turf fibers from premature wear and abrasion.

4

Over Filled

Under Filled

Strong Seam Technology

When it comes to the longevity of field seams, there is only one answer – FieldTurf’s

heavy duty sewn seams. Simply put, glued seams will not stand the test of time. The

number one maintenance problem associated with synthetic fields is that of loose

unglued turf seams. Glued seams may be easier to install and less expensive as they

require no special equipment or expertise. But sewn seams are the only way to ensure a

trouble-free seam and a long lasting, safe field. FieldTurf ’s panel seams are sewn with a

double lock stitch. FieldTurf fields do not experience seam problems because FieldTurf

settles for nothing less than the best materials and most thorough seam installation.

Durability

[13]

The #1 Choice For Football.

Designed For Football

FieldTurf is clearly the #1 choice of football. Whether it is at the professional level where 22

of 32 NFL teams have selected FieldTurf, or the NCAA where over 100 universities play their

home games on FieldTurf, or even at the high school level where dozens of state champions

have played on our surface.

FieldTurf’s safety, performance and durability levels are far superior to any other system. As

the world’s largest synthetic turf company, FieldTurf is installed in most major stadiums. But

there is no difference between a high profile FieldTurf field and one installed in a small town.

For every pro or college field we build, we install the same quality field at 150 schools and

municipal facilities.

NFL Players Prefer FieldTurf

When it comes to surface preference, NFL Players have voted FieldTurf as the top artificial

surface. Every two years, the NFL Players Association conducts a survey of its players where all

of the league’s playing surfaces are rated and ranked on many performance-based factors. In

2010, the NFL Players voted FieldTurf as the best artificial surface in the league - for the 10th

year in a row! A total of 1619 active NFL players from all 32 teams completed survey forms.

2010 Artificial Turf Surface Rankings

1. Indianapolis (FieldTurf)

2. New York Giants/Jets (FieldTurf)

4. Seattle (FieldTurf)

6. Atlanta (FieldTurf)

7. New England (FieldTurf)

8. Detroit (FieldTurf)

10. Cincinnati (FieldTurf)

Players perform with more confidence on FieldTurf - not only because

it is a safer surface - but because it is the most consistent, stable and

athlete friendly artificial turf system in the world.

FieldTurf is the Fastest Surface

In addition to its renowned safety benefits, the FieldTurf system has gained a reputation across

the industry for its high performance and speed.

At the 2008 NFL Combine, Chris Johnson ran a record 4.24 40-time on FieldTurf. Since 2000,

nine of the fastest twelve times at the NFL Combine have been on FieldTurf.

[14]

“I like it (FieldTurf) a lot… just because the footing is so good and you can really push off and

drive the ball, and the receivers can cut really well. I think everybody really likes the surface.”

Tom Brady - QB, New England Patriots

Below are just some of the teams that have chosen FieldTurf:

NFL

n

n

n

n

n

n

n

n

n

n

n

n

Atlanta Falcons

Denver Broncos

Detroit Lions

Green Bay Packers

Indianapolis Colts

New England Patriots

New York Giants

Oakland Raiders

San Diego Chargers

Seattle Seahawks

Tennessee Titans

Washington Redskins

NCAA n

n

n

n

n

n

n

n

n

n

n

n

n

n

High School

Air Force Falcons

Boise State Broncos

Cincinnati Bearcats

Fresno State Bulldogs

Illinois Fighting Illini

Kansas Jayhawks

Louisville Cardinals

Michigan Wolverines

Minnesota Gophers

Mississippi Rebels

Missouri Tigers

Navy Midshipmen

Nebraska Cornhuskers

Nevada Wolf Pack

n

n

n

n

n

n

n

n

n

n

n

n

n

n

Northern Illinois Huskies

Ohio State Buckeyes

Oregon Ducks

Oregon State Beavers

Rutgers Scarlet Knights

Syracuse Orange

Texas Longhorns

Texas Tech Red Raiders

Tulsa Golden Hurricane

Utah Utes

Washington Huskies

Washington State Cougars

West Virginia Mountaineers

Wisconsin Badgers

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

New England Patriots - Gillette Stadium

Seattle Seahawks - CenturyLink Field

Bergen Catholic (NJ)

Blue Springs South (MO)

Celina (TX)

Colerain (OH)

Don Bosco Prep (NJ)

Jenks (OK)

Lake Oswego (OR)

Loyola (CA)

Mater Dei (CA)

Memphis University (TN)

Plano (TX)

St. Peter’s Prep (NJ)

St. Thomas Aquinas (FL)

Torrey Pines (CA)

Valley Christian (CA)

Wayzata (MN)

Wheaton-Warrenville South (IL)

Wimberley (TX)

Xaverian Brothers (MA)

Atlanta Falcons - Georgia Dome

Detroit Lions - Ford Field

Did You Know?

Football

In 2012, Super Bowl XLVI

took place on FieldTurf.

This was only the second

time that a Super Bowl

has been played on a

heavyweight infilled

surface. The first one?

Super Bowl XL on FieldTurf

at Ford Field in Detroit.

[15]

THE WORLD CLASS SOCCER SURFACE.

Designed For Soccer

The FieldTurf product was designed for soccer by focusing on four key soccer-related

requirements: Ball Performance, Energy Restitution, Shock Absorption and Playability.

FieldTurf is ideal for soccer because of its fiber technology (ball performance), heavyweight

infill system (energy restitution and shock absorption) and wide gauge tufting (playability).

Why Is FieldTurf The Best Surface For Soccer?

most Grass-Like Playability

The 2012 study conducted by Prozone, an independent consulting firm specializing in soccer performance,

confirms that there are “No Major Differences” in playability on FieldTurf or natural grass.

Prozone installed a player tracking system on 2 fields – one at Luzhniki Stadium (FieldTurf) and the other at

Khimki Arena (natural grass). Since 2006 Luzhniki has had FieldTurf installed for their pitch and the results

in key playability categories indicate FieldTurf is equal to natural grass when it comes to playing soccer.

n

n

n

n

Distance run during match was 113.9 km on FieldTurf vs. 112.1 km on grass, indicating teams are confident

to play very similar styles on both surfaces.

Ball touches per player were 2.01 on FieldTurf vs. 2.06 on grass, indicating players are just as comfortable

with the possession of the ball on FieldTurf as on natural grass.

Passes played forward increased on FieldTurf, indicating more offense and more entertaining games are

played on it.

Tackles per player rose by 0.70 on FieldTurf, illustrating that players are just as comfortable defending on

FieldTurf and do not feel a greater risk of playing on the surface.

The Soccer Reference

With over 3,000 FieldTurf soccer installations, FieldTurf has the most

FIFA Recommended fields in the world! Some of the most prestigious

clubs worldwide practice or play on FieldTurf, including Real Madrid, FC

Barcelona, and Manchester United. In the U.S., FieldTurf is the choice

for 16 MLS teams for practice facilities, with New England Revolution,

Portland Timbers and Seattle Sounders picking FieldTurf for their

stadiums as well.

New England Revolution - Gillette Stadium

[16]

FTNA Corp Brochure_2014.indd 16

1/7/2014 9:10 AM

Did You Know?

Soccer-Smart System Design

Over 75% of all teams

in the English Premier

League, Spain’s ‘La Liga’

and France’s ‘Ligue de

Football Professionnel’

train on FieldTurf systems.

FieldTurf has invested in developing the ideal system for soccer

with the following soccer specific attributes:

The Most Natural Ball Performance: The knock on synthetic turf has been unrealistic ball roll. On competitors’ fields,

fibers have laid over or become matted within just 1 or 2 years, causing the ball to roll too rapidly - informally referred to as “quickroll”.

FieldTurf has solved this problem with the introduction of our FieldTurf Revolution fiber. With unmatched memory to return each fiber

to the upright position, ball roll remains natural, even over time.

Ball bounce on an artificial turf field is another concern that only FieldTurf has been able to properly address. Ball bounce is linked to the

infill composition of the turf system. FieldTurf’s patented layered infill system provides the right amount of softness to absorb the ball’s

impact in a natural way for the life of the field.

Optimal Energy Return: Energy restitution is the amount of energy that goes back into your legs when running on a surface.

FieldTurf’s layered system of sand and rubber provides the optimum level of energy restitution. Other all-rubber or lightweight surfaces

are spongier which accelerate fatigue and muscle / joint stress. This effect is magnified on fields that will be used for both training and

matches.

Proven Safety: During the Men’s 2007 FIFA U20 World Cup in Canada, where the majority of the matches on artificial turf were

played on FieldTurf, medical officer Dr. Rudy Gittens noted… “There were an average of 2.8 injuries per game through the first 48 games

- 3.3 per game on natural grass and 2.4 on artificial turf. From these particular figures it would appear that artificial turf might be safer.”

FIFA Preferred Producer: FieldTurf is a select member of the FIFA Preferred Producer Program having met the rigid obligations

and reporting requirements. A FIFA Preferred Producer goes beyond the traditional supplier / installer scenario by continually improving

the quality of their product and assuming responsibility for the production, installation and maintenance of the turf from inception to

completion.

Seattle Sounders - CenturyLink Field

Portland Timbers - Jeld Wen Field

Did You Know?

Soccer

FieldTurf surfaces have played

host to Champions League

matches, Euro Cup qualifiers,

MLS Cup finals, an MLS AllStar game, the Men’s and

Women’s FIFA U20 World Cup

final, UEFA Cup qualifiers,

World Cup qualifiers and

NCAA D-I League finals.

[17]

Baseball’s home run.

Did You Know?

The 2008 World Series

was played on FieldTurf

while over 25 NCAA

D-I teams continue to

play and / or practice

on FieldTurf baseball

systems.

Designed For Baseball

FieldTurf is far and away the industry leader in artificial turf systems designed specifically for baseball – at all

levels of competition. What better proof is there than the reduction of error rates? Many Division I baseball

programs have reported a reduction of up to 50% in fielding errors after switching to FieldTurf.

Why Is FieldTurf DoublePlay

The Best Surface For Baseball?

The launch of FieldTurf’s DoublePlay baseball systems signify the

greatest technological advancement in baseball surfacing in decades.

FieldTurf combines the beneficial biomechanical properties of natural

grass, with the best attributes of a durable synthetic system - all weather

playability, low maintenance, safety and high performance.

FieldTurf DoublePlay Systems

DOUBLEPLAY CLASSIC

n

n

n

n

Patented infill

Extremely durable slit-film fiber

Ball pace mimics the best real grass fields

Over 20 NCAA Division I installations

DOUBLEPLAY

n

n

n

n

SBR Rubber and Silica Sand infill mix

Extremely durable slit-film fiber

Fastest ball pace of any SBR Rubber/Silica Sand baseball system

Different pile heights for infield and outfield

DOUBLEPLAY LASER

n

n

n

n

[18]

SBR Rubber and exclusive Flexsand infill mix

Fiber is an extremely durable slit-film

Fastest ball pace of any baseball-specific infill system

Different pile heights for infield and outfield

DOUBLEPLAY

Tuning The Speed Of Play

FieldTurf offers its clients the ability to ‘tune’ the speed of play of the infield and outfield to slow, medium, or fast - depending on

preference. The speed of play is set through a combination of infill materials, infill depth and underlying base materials. Each of these

components are tailor-made to meet the pace of play required by each client.

Here are the five (5) pillars of FieldTurf baseball-specific product development:

1

2

Penn State Comparative Testing

Coefficient of Restitution (COR) is defined as a

ratio of two velocities: the velocity of a baseball after

impact with the surface divided by the velocity of the

ball prior to impact. The COR value is the only way to

accurately measure and compare ball speed levels on

different types of surfaces. The higher the COR value,

the faster the surface.

Penn State University tested over 20 different

surfaces, including natural grass and the top

competitive artificial turf surfaces. The objective was

to find which surfaces delivered slow, medium or fast

ball pace. Here is a snapshot of the results.

Coefficient of Restitution

.575

.572

.565

.563

.550

.516

.506

.491

.485

.316

s

y

ix

D

er

er

er

sic

nd

nd

ras

Pla

as

s3

bb

bb

as

sa

rM

Sa

eG

Cl

yL

ble

ras

%

Ru

Ru

be

lex

a

u

/

u

y

l

0

l

F

b

G

d

a

%

o

P

10

0

Pl

Ru

ay

yB

an

0%

fD

ble

10

d/

ck

xs

ble

10

eD

ur

ou

tu

an

Fle

ou

am

ldT

xs

en

fD

d

D

e

r

e

G

i

e

l

K

f

u

r

f

F

F

ur

ur

ye

er

ldT

ldT

La

oT

ay

Fie

str

Fie

3L

*A

Natural Grass Playability & Aesthetics

*Data taken from an NCAA Division I game field.

For DoublePlay and DoublePlay Laser systems, a taller

fiber blade height is used for the green-colored areas on the baseball field – outfield, foul areas, and green infield area. A slightly shorter

fiber blade height is used for all basepath areas. This small fiber height difference allows for a perfect replication of grass and clay area

transitions on natural ball fields. FieldTurf also offers its clients the option to use colored infill to match the color of a natural field and

the turf installed. In green areas, the infill will be dirt-colored. In rust areas, the infill will be rust-colored. Should the basepaths be a tan

color, the infill will be tan-colored.

3

Warning Track Technology

4

Coach Approved

5

Removable Bases

FieldTurf warning tracks are installed with a special, durable lavarock infill. This ensures there is a distinct difference in feel and sound,

for a player who is tracking a ball near the fence, without having to look down.

During a FieldTurf installation, coaches have a chance to validate the performance of the surface. This is our way of ensuring that the

field is tailored to the speed and performance that meets each customers’ needs.

Our ‘ExtraBase’ program ensures that high wear areas on a FieldTurf field are taken care of for the long-term. FieldTurf offers its clients

the option of having removable or serviced replacement home plate and base areas. The replacement of these high-traffic areas can

be done periodically as a simple ‘do-it-yourself’ option, with easy fastening and removal methods, or by one of FieldTurf’s experienced

local installation crews.

Baseball

University of Oregon - PK Park

University of Texas - Disch-Falk Field

[19]

The ultimate multi-use solution.

Turf For All-Reasons & All-Seasons

With over 2500 municipal and county installations, the FieldTurf system has proven to deliver the best value

when compared to all other artificial turf systems – and even to the very best natural grass fields. This is thanks

to FieldTurf’s ability to deliver a pro-caliber and world-class playing surface that provides many measurable

benefits to communities across the nation.

FieldTurf continues to transform previously inefficient municipal properties into long-lasting and lush playing

fields that make positive environmental contributions. FieldTurf fields help municipalities save enough money,

resources and time in order to re-invest in other areas of the community that are lacking.

Below are just some of the larger multi-field projects FieldTurf has completed:

Golden Eagle Regional Park - Sparks, NV

n 13 Fields - 1,400,000 sq. ft.

Medford Sports Park - Medford, OR

n 11 Fields - 968,000 sq. ft.

Starfire Sports Complex - Tukwila, WA

n 8 Fields - 632,000 sq. ft.

Ripken Experience Myrtle Beach - Myrtle Beach, SC

n 6 Fields - 630,000 sq. ft.

Chino Hills Community Park Field - Chino Hills, CA

n 6 Fields - 615,000 sq. ft.

City of Medford, OR

Regional Athletic Fields - Lacey, WA

n 6 Fields - 552,000 sq. ft.

Warhill Sports Complex - Williamsburg, VA

n 6 Fields - 510,000 sq. ft.

Mass Youth Soccer Association - Lancaster, MA

n 5 Fields - 445,000 sq. ft.

Warhill Sports Complex, VA

“A few of us went on trips to view turf fields in Southern California. We

went to college sites, a few parks, and some recreation sites. We knew

by our research that FieldTurf was considered to be the premier turf

on the market and we wanted the best turf available. As advertised,

FieldTurf was the best. The surfaces look great, and from other sites we

visited, FieldTurf held up under significant use. The athletes that use

our field love it, the city staff loves it, it drains well, it is generally low

maintenance, all while being environmentally sound. It’s a consistent

surface day in and day out compared to natural turf after heavy usage.”

Peter Rogers - Mayor, City of Chino Hills

[20]

Chino Hills, CA

Military Projects

FieldTurf is the turf of choice for the military. Among others, FieldTurf has numerous high profile installations for the U.S. Military

Academy, U.S. Naval Academy and U.S. Air Force Academy, making us the most trusted name in turf for military projects.

Below are just some of the larger military field projects FieldTurf has completed:

n

n

n

n

n

n

n

n

n

n

n

Fort Huachuca Army Base

Fort Lee Military Reserve

Fort Lewis Army Base

Great Lakes Navy Base - Constitution Field

Great Lakes Navy Base - Softball Field

Guantánamo Bay Naval Base - 3 Fields

Hanscom Air Force Base

Miramar Air Station - MCAS & MCRD

MWR Miramar Sports Complex (4 fields)

Sasebo Naval Base

U.S. Air Force Academy - Baseball Field

n

n

n

n

n

n

n

n

n

n

n

U.S. Air Force Academy - Football Stadium

U.S. Air Force Academy - Indoor Practice Field

U.S. Air Force Academy - Soccer Field

U.S. Merchant Marine Academy

U.S. Military Academy - Baseball Field

U.S. Military Academy - Howze Stadium

U.S. Military Academy - Michie Stadium-Blaik Field

U.S. Military Academy - Rugby Field

U.S. Naval Academy - Baseball Field

U.S. Naval Academy - Halsey Field House

U.S. Naval Academy - Jack Stephens Field

Organizations can now obtain FieldTurf through the federal government’s General Services Administration (GSA) program

without having to endure the lengthy and at times misleading bid process.

Visit www.gsaadvantage.gov and enter the FieldTurf contract holder number in the search box:

Guantánamo Bay Naval Base

Contract Holder

GS-07F-9631S

U.S. Naval Academy - Jack Stephens Field

“When we saw FieldTurf’s latest technology, FieldTurf

Revolution, we knew we had to have it on our stadium field.

We felt that upgrading to FieldTurf Revolution and having

the absolute best in turf technology was the right thing to do

for our program. This represents another first-class upgrade

for Navy athletics.”

Chet Gladchuk - Athletic Director, Naval Academy

Military

[21]

VERTICAL INTEGRATION = QUALITY ASSURANCE.

The Quality Standard

FieldTurf, the worldwide leader in quality, remains focused on

three pillars, all of which are supported by our triple ISO certification.

1 - Better Materials

2 - Manufacturing Excellence

3 - World Class Installations

Better Materials

Better materials make better fields. It’s that simple. The two main materials in a turf system are fiber and infill

and FieldTurf has invested heavily in selecting only the highest grade materials.

Fiber

For years, the belief throughout the industry has been that the shape of the fiber dictates its performance and

durability. While this is partly true, the real key to fiber performance is a combination of Polymer, Process, and

Geometry. This is FieldTurf’s PPG philosophy. FieldTurf has spared no expense in using the best – and now

exclusive – polymer and processing technology available on the market today.

Here are the three keys to producing high quality artificial turf fibers:

Polymer Proprietary polymer formulation to resist splitting and degradation, complete with an industry leading ultraviolet

inhibitor technology.

Process State-of-the-art extrusion process for precision manufacturing that ensures the production of an exceptionally strong fiber with

a radical reflection feature built into each artificial grass blade.

Geometry Intricate concave and ridged construction eliminates breaking points and provides the most natural looking fiber.

Infill

Cryogenic rubber is a rare grade of clean and finely rounded rubber. For improved safety and performance,

cryogenic rubber is the only grade of rubber that FieldTurf uses in its Elite system fields. Others use ambient

rubber, a cheaper grade of mass produced rubber. Ambient rubber is a jagged grade of particle and has the

propensity to migrate resulting in low filled areas which can be more dangerous to athletes and contribute to

premature fiber wear.

While most turf companies use low grade sand products, FieldTurf uses a more expensive washed silica

sand. This silica sand has the ideal shape and hardness to ensure proper performance and long term

durability. Before being installed, our washed silica sand and cryogenic rubber is tested for shape, size, safety,

consistency and durability.

[22]

Manufacturing Excellence

During the manufacturing process there are three aspects to turf construction – Fiber Production, Tufting,

and Coating. What’s important to know is that FieldTurf controls all three aspects of the value chain.

Nothing is left to a third party. Nothing is left to chance. This provides FieldTurf clients with a level of quality

assurance that simply cannot be matched.

Fiber Production: FieldTurf’s fibers are produced at our very own facility in Germany. This state-of-theart facility was opened in 2010 and as a result has turned FieldTurf into one of the most vertically integrated

companies in the world. The quality control process at the facility includes stringent testing of the yarn

properties (tensile strength, uniformity, color verification).

FieldTurf Fiber Production Plant Absteinach, Germany

Tufting and Coating: Once the fiber is produced it is ready for tufting and coating which takes place at

FieldTurf’s 500,000 square-foot facility in Calhoun, Georgia. Our triple ISO certification ensures rigorous

quality control and inspection under World Class Manufacturing (WCM) principles.

FieldTurf Tufting & Coating Plant Calhoun, GA

World Class Installations

In the turf industry, good materials aren’t enough. A world class installation team is needed to assemble the

materials properly. FieldTurf ensures the longevity and overall quality of our surfaces by taking the following

measures:

Experienced Installation Crews - By using only crews who have experience with the FieldTurf product,

FieldTurf is able to assure its customers that only those who fully understand the product and its construction

requirements handle the installation.

Sewn Seams - With so much riding on the quality of the seam construction job, FieldTurf has chosen to invest

in sewn seams rather than the cheaper glued alternative. FieldTurf’s panel seams are sewn with a double lock

stitch and FieldTurf has a proven record for fields without seam problems.

When it comes to the quality and safety of your field, you can be certain that FieldTurf settles for nothing less than the

best materials and most thorough seam installation around. There is no compromise for quality.

Make sure that your supplier

meets the following criteria:

Quality

n Self performs all fiber manufacturing, tufting, and coating

n Is ISO 9001, ISO 14001, OHSAS 18001 certified

n Sews all turf seams

[23]

The World Leader In Artificial Turf.

Why Do Customers Choose FieldTurf?

Doing business with FieldTurf is more than just about a high end product. It’s about dealing

with a company that goes above and beyond to provide its clients with a service and peace

of mind that is unmatched by any other company in the industry. This is achieved through:

n

n

n

n

n

n

n

Financial Strength

The Best Warranty Protection

A Strong Commitment to the Environment

Leadership in Innovation

First Class Customer Service

Turf Purchasing Made Simple

Financial Strength

With one of the strongest equity bases in the industry, there is no better partner than

FieldTurf. Through Tarkett, in operation since 1872, FieldTurf enjoys a bonding capacity

of over $75,000,000 and has the financial strength of a company with over 130 years of

experience in the surfacing business. In 2008, renowned investment firm KKR (Kohlberg,

Kravis, & Roberts Co.) purchased 50% of Tarkett. KKR, with over $60 billion in assets,

is known in all circles of the world as a company that is among the world’s elite in

strengthening businesses and creating value.

n

The Best Warranty Protection

Even though you’ll probably never need to use it, you can rest easy knowing that you’re

protected by the industry’s best third-party insured warranty in the unlikely event

something goes wrong with your field. It’s peace of mind that sets FieldTurf apart.

n

n

n

n

[24]

Yearly Aggregate Claim Limit of $32,000,000

Per Claim Limit of $32,000,000

All fields are automatically covered upon issuance of the Warranty Certificate

Pre-Paid for 8 years

“After having FieldTurf for 10 years, we can

honestly say that this is the best turf system on the

planet. FieldTurf obviously spends a lot of time on

R&D as their newest product that will be installed

on our field is expected to last even longer than the

previous field we had which is incredible. In our

minds FieldTurf is the safest and most durable turf

on the market.”

“All the savings in time and money that were

promised to us from the start continue to remain

true today. Even after 10 years we continue to see

a return on our investment as we maximize usage

out of our all weather FieldTurf field. We have

gone from a philosophy of keeping people off our

field to save the grass, to a philosophy of putting

everything on the field that we can.”

Brother Murphy - President,

Bergen Catholic High School

Tex Nolan - Longtime Athletic Director,

Amarillo ISD

Did You Know?

n

Strong Commitment to the Environment

The environmental benefits of artificial turf have been well documented for years. Hundreds of

studies have been completed to discover the truth about any potential risks of artificial turf. In

every case, new generation artificial turf has been found to be completely safe.

FieldTurf was the first

artificial turf company

in the world to fully

recycle a turf field. It

happened in 2010 at

War Memorial Stadium

in Arkansas.

FieldTurf was one of

the first companies to

introduce “lead free”

products and to this day

continues to use only

lead free fibers. FieldTurf Recycles

FieldTurf is 100% recyclable. When a FieldTurf installation finally comes to the end of its long life

– it continues to help our planet. FieldTurf was the first company in the industry to remove entire

turf systems and recycle them. After removal, old turf fields can now be turned into new turf infill

and backing, as well as other products, such as crude oil, custom bi-products and artificial lumber.

FieldTurf proudly offers a “Take Back” program for both sports fields and landscape applications,

whereby FieldTurf will provide customers with the option, in writing, that fields will be recycled at

the end of their useful life when replaced with another FieldTurf system.

FieldTurf’s 3-step recycling process

Field Removal

Grinding

Pelletizing

Commitment

[25]

The World Leader In Artificial Turf.

n

Leadership In The Field Of Innovation

It’s no secret that FieldTurf pioneered what is now commonly accepted as “artificial turf.” What started

with our invention of long pile, infilled artificial turf has continued with numerous industry-changing

innovations. FieldTurf has introduced engineered products that are tailor made for each segment of the

business and owns more than 30 patents that protect the company’s product offering for sporting and

non-sporting applications.

FieldTurf Innovation & Performance Center

All of FieldTurf’s systems are tested using the latest equipment in our Innovation and Performance

Center. Located at the company’s headquarters the center ensures that any and all of FieldTurf’s existing

and new systems set superior standards for performance in their respective classes.

Penn State Center for Sports Surface Research

Center for Sports

Surface Research

FieldTurf & Penn State University joined forces to mark a historic industry first in sports surface research.

The Center for Sports Surface Research is an intercollegiate program managed within the Department

of Crop and Soil Sciences in Penn State’s College of Agricultural Sciences. It is headed by Dr. Andrew

McNitt, who is regarded as a pioneer in the world of sports surface research, particularly as it relates to

natural and synthetic turf. For more information on the Penn State Center for Sports Surface Research,

please visit: ssrc.psu.edu

n

First Class Customer Service

Providing a high quality product and outstanding customer service has been a part of FieldTurf’s

successful business model since day one. Our customers are our number one priority, which is why we

have taken the time to assemble an experienced and dedicated customer service department. We follow

up with each and every one of our customers to ensure complete and consistent satisfaction.

In addition, our customer service department has assembled a comprehensive manual that covers

all field care issues. Each FieldTurf customer receives a main guide that covers everything from field

maintenance to field protection. Our devotion to our customers and their fields can be further confirmed

by the extensive line of field care products and equipment designed and catered specifically for a

FieldTurf field.

FieldCare

The ‘FieldCare’ national maintenance program is geared towards making our synthetic turf field systems

perform at their optimal level for even longer. The FieldCare program is comprised of complete field

inspections and regular maintenance done by FieldTurf authorized maintainers. The company’s large

network of skilled maintainers has enabled us to focus on longer lasting fields, greater savings and an

expanded potential for our customers to generate revenue from their fields.

[26]

“Using the SmartBuy Purchasing Program was a big time saver for our staff. We did not have to use our time to write

specifications and do all the extra research. We got the Beynon running track and FieldTurf field we wanted and saved time.”

Janice Essenberg - Director of Administrative Services, David Douglas School District

n

Turf Purchasing Made Simple

Aside from finding the right products for our customers, we’ve also taken the necessary steps to

make the turf purchasing process as easy as possible.

Just follow the 4 key steps to our Simplified Purchasing Program:

SmartBuy Purchasing Program: With our SmartBuy purchasing program, our customers get