CEAG EURO ZB.1

CEAG EURO US.1

Mounting and operating instructions

Target group part 1: Qualified electrician acc. to DIN VDE 0105, part 1

Target group part 2: Electrical instructed persons

Content

Content

1 IMPORTANT NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PRODUCT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 BATTERIES FOR EMERGENCY POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Tending and Checking Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 MODULES FUNCTIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Functions of Batterie Control Modul BCM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Functions of Charging Modules CM 1,7 A and CM 3,4 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Functions of the DC/DC converter.2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Functions of the ST 20 E Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Functions of Circuit Changeover SKU 2 x 3 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.6 Functions of Circuit Changeover SKU 1 x 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.7 Functions of Circuit Changeover SKU 4 x 1 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.8 Circuit Changeover Units at a Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.9 Functions of Event Printer PD 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.10 Print-out - Event Printer PD 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.11 Function of the Relay Module CG IV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.12 Functions of the TLS Switching Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.13 F

unctions of Permanent Light Switch Checking DLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.14 Functions of the SDS 8 Switching Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 BLOCK DIAGRAM EURO ZB.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Installation Example Euro ZB.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Installation Example Euro US.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 IMPORTANT NOTES ON SAFETY AT WORK AND SAFE OPERATION

OF THE EMERGENCY LIGHTING SYSTEM EURO ZB.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 INTENDED USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 TRANSPORT, STORAGE AND DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.1 Mounting the Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11 INSTALLATION OF EMER-GENCY LIGHTING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

11.1 Connection of the Mains Power Supply to EURO ZB.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.2 Mains Connections to Substations EURO US.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.3 Connecting the Battery Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.4 C

onnecting the Supply of a EURO ZB.1 Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.5 Connecting the Supply of a EURO US.1 Substation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.6 Connection of a Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.7 Mounting and Connection of Internal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.8 Connection of a DSL Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.9 Connection of SDS 8 Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.10 Connection of TLS Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.11 Mounting and Connection of a CEAG 3-phase monitor with 24 V loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.12 Connection of a Remote Switch/F3 Remote Indicating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

Content

12 COMMISSIONING AND FURTHER WORK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.1 Disconnecting/Switching-on an Emergency Lighting System under Battery Supply. . . . . . . . . . . . . . . . . . . . 49

12.2 Disconnecting/Switching-on a EURO ZB.1 Control Cabinet or EURO US.1 . . . . . . . . . . . . . . . . . . . . . . . . . . 50

12.3 Block/Release the Control of a EURO ZB.1 Control Cabinet or EURO US.1. . . . . . . . . . . . . . . . . . . . . . . . . . 50

12.4 Checking all Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

12.5 Testing/Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

12.6 Checking and Replacing Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

13 SWITCHING THE SYSTEM ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14 CONTROLLING A EURO ZB.1 (EURO US.1) CENTRAL BATTERY SYSTEM . . . . . . . . . . . . . . . . . . . . . 54

14.1 C

ontrol and Indicating Elements of the Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15 PROGRAMMING THE ST 20 E CONTROL UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

16 THE SETTING OF THE TRIPPLE CHARGE-VOLTAGE AT THE BATTERIE CONTROL MODULE (BCM). 58

17 M

ONITORING OF THE FINAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

18 PROGRAMMING THE CIRCUIT MONITORING FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

19 PROGRAMMING THE FINAL CIRCUIT SWITCHING VARIANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

20 PROGRAMMING FINAL CIRCUITS TO SWITCHED MAINTAINED LIGHT. . . . . . . . . . . . . . . . . . . . . . . 62

21 PROGRAMMING FINAL CIRCUITS TO SELECTIVE EM. LIGHTING CHANGEOVER (SDS 8). . . . . . . . 63

22 PROGRAMMING FINAL CIRCUITS TO STAIRCASE LIGHTING (TLS). . . . . . . . . . . . . . . . . . . . . . . . . . 64

23 PROGRAMMING STAIRCASE LIGHTING CUT-IN TIMES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

24 TROUBLESHOOTING OVERVIEW CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

25 STARTING FUNCTION/DURATION TEST AND BLOCKING THE SYSTEM. . . . . . . . . . . . . . . . . . . . . . . 67

26 FUNCTION TEST ASSESSMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

27 REPLACING MODULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

28 CANCEL FAULT MESSAGES AFTER REMEDIAL ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

29 VDE REQUIREMENTS GOVERNING TELECOMMUNICATION CONTACTS AND BUZZERS . . . . . . . . 71

30 LUMINAIRE POSITION PLANS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

31 CUSTOMER SERVICE REQUESTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

3

1 Important Notes

1 Important Notes

Mounting work must only be carried out by skilled electrical personnel (see IN VDE 0105 Part 1; the Accident

Prevention Rules BGV A4 of the (German) Trade Workers’

Compensation Association (Hauptverband der gewerblichen Berufsgenossenschaften) or equivalent provisions

and guidelines applicable in the country where the system

is installed and operated). Other persons may perform the

work described in this manual only if

–they have been expertly instructed and trained,

–their tasks and activities have been accurately defined

and understood,

–the work is carried out under the supervision of expert

electrical personnel.

When working with this manual the following notes

provided with attention-attracting graphical symbols and

identifiers (eg Note) shall be carefully observed:

NOTE

indicates important hints and advice in connection with

handling or manipulating the appliances or plant units

described.

Moreover, when using this mounting and operating

manual observe the following:

WARNING!

The figures and elementary diagrams in this mounting and operating manual sometimes serve the sole

purpose of providing elucidation on the subject matter

described. Wherever

–dimensionally true work is to be performed or

–precise drawings or circuit diagrams tailored to

local needs are required,

the drawings and diagrams especially prepared for

the lighting system must be strictly adhered to.

NOTE

In the event a polyphase operation is not at all or only

conditionally allowed, observance of the applicable

national rules and regulations is to be viewed as a prerequisite in the sense of the Intended Use Paragraph (see

«8 Intended Use»).

ATTENTION!

draws attention to dangerous situations that may

result in damage to plants or plant units as well as

environmental hazards.

WARNING!

draws attention to dangerous situations that may

result in personal injuries or major damage to plants

or plant units as well as major environmental damage.

WARNING!

• Only perform work for which you are adequately

qualified and specifically trained in the framework

of local and operational needs!

• Work necessary for extensions, retrofits or repairs

that has not been described in this manual must

be carried out by specially trained expert service

personnel (to be delegated by CEAG as manufactgurer or sales and service companies authorized by

CEAG)!

DANGER!

draws attention to dangerous situations that may

result in life-threatening personal injuries or most

serious damage that consequentially may endanger

persons or the environment.

ATTENTION!

When performing work on the unit ESD protection

rules must be observed!

ATTENTION!

If a reset occurs in battery mode the failure „battery

disconnected“ is shown after the restart.

4

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

2 Product Description

2 Product Description

The central battery system serves for the battery-backed

control and emergency supply of an emergency lighting

system.

All settings are saved to a non-volatile memory so that

they are not lost in case the entire power supply (230 V

mains and battery backup) is down.

The functions of the individual circuits are defined with

the help of a user-friendly parameterization system.

Three operating modes can be set:

Low-maintenance batteries are used to power the

emergency lighting system in the event the normal 230 V

power supply system is on failure. During normal operation the system monitors the batteries’ charging condition

and, whenever needed, performs charging as necessary.

••

Circuit monitoring

Requirements: Electronic ballasts/modules meet all the

requirements prescribed by EN 60924 and EN 60598-2-22).

Non-maintained mode

Maintained mode

•• Switched maintained mode

••

••

These operating modes enable the emergency lighting

system to be activated as follows:

••

Non-maintained mode: The emergency lighing is

switched on

– if the general lighting system fails due to the general

power supply being interrupted,

– when functional or operating duration testing has been

activated manually or automatically.

••

Miantained mode: The emergency lights are always

on.

••

Switched maintained mode: The emergency lighing is

switched on

The system has been designed and manufactured in

conformity with the following EU guidelines:

••

Low-voltage guideline 73/23/EWG as amended by

guideline 93/68/EWG

••

Guideline 89/336/EWG on electromagnetic compatibility

Details of national (DIN), European (EN) and international

(IEC) standards complied with are included in the unit’s

CE Statement of Compliance.

WARNING!

Since the central battery system is an important

component within a facility’s security system, any

planning, commissioning and parameterization activities have to be performed by experts perfectly familiar with the related safety equipment and systems.

– if the general lighting system fails due to the general

power supply being interrupted,

– when functional or operating duration testing has been

activated manually or automatically,

– as a result of switching checks (eg initiated by DLS

modules).

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

5

2 Product Description

To suit local conditions a number of different system

configurations are employed. These standardized configurations are identified, for example, as follows:

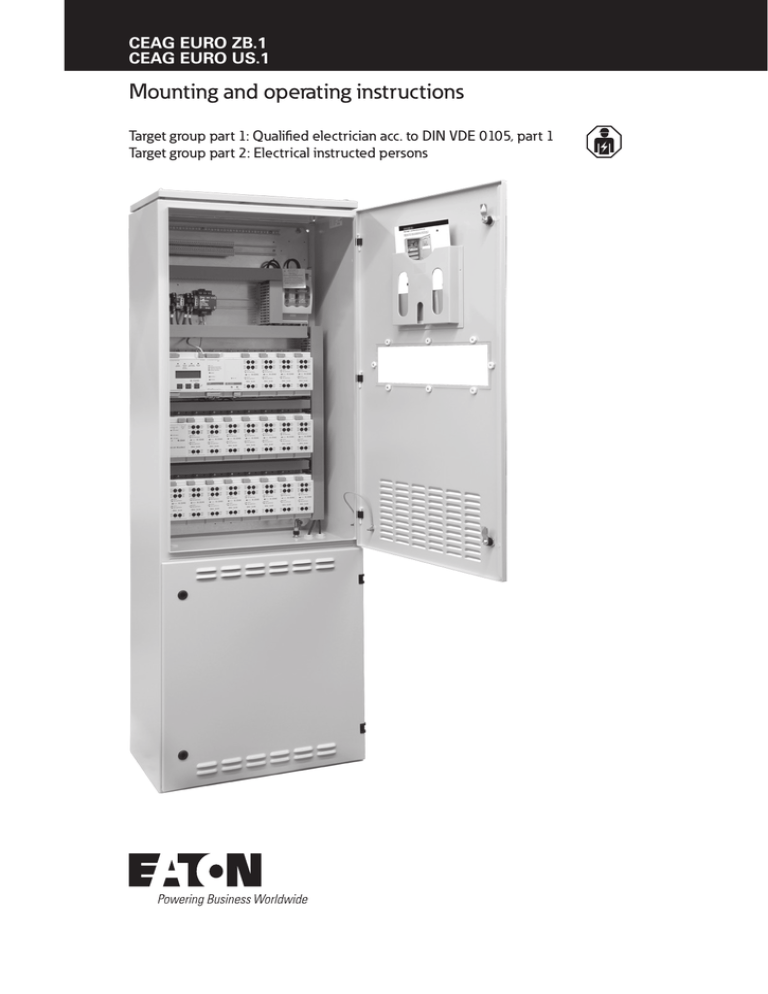

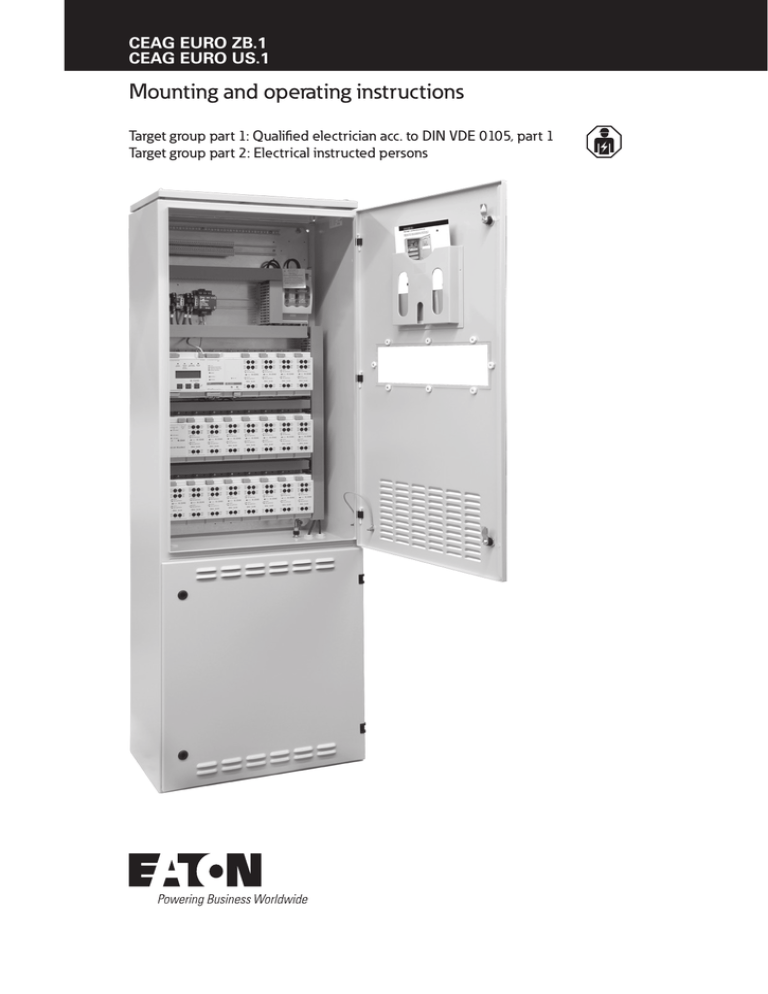

Fig. 1: EURO ZB.1 of type EURO ZB.1/200S

and for operation with a battery capacity of up to 245 Ah

and up to 26 SKU modules.

••

EURO ZB.1/52

To operate max. 26 circuit modules type SKU. Up to 6

substations EURO US.1 can be supplied with battery

and mains power (up to 6 substations, single-phase).

••

ZB 96/LAD

These are designed as charging and monitoring units

for the mains and battery power supply of a greater

number of substations type EURO US.1. Up to two SKU

modules can be energized and controlled.

••

EURO ZB.1/20K, EURO ZB.1/188K

Designed (as regards dimensions) to be operated in

conjunction with CEAG compact battery cabinets (max.

10 or 18 SKU modules).

••

EURO US.1/72 or EURO US.1/26

Designed as substations for operation with max. 36, 13

etc. circuit modules types SKU to perform only control

and monitoring tasks for subsystems of the lighting

equipment.

These substations do not provide for charging means for

the connected battery emergency supply; the battery

and mains power supply is effected via the EURO ZB.1

system.

What is included in this manual also applies analogously

to the EURO US.1 configurations listed under «3 Technical

Data».

For emergency power supply CEAG battery cabinets or

racks are employed. The storage capacity of the battery

banks to be connected (battery cabinets or racks) is

governed, inter alia, by the available charging capacity

(see configurations listed under«3 Technical Data»).

NOTES

••

Planning and design information can be seen from the

CEAG catalog „Safety Luminaires and Safety Lighting

Systems“ as amended under catchwords / chapters

such as:

– Equipment Overview / Technical Data

– Planning

– Equipment Possibilities

– Inquiry Texts

••

Under the heading «Components and Options» brief

charactericts, technical data and ordering numbers for

modules and supplements can be found that may be

operated via a EURO ZB.1 or EURO US.1 system.

••

Moreover, CEAG offers consultation and training

services for planning, set-up and operation of lighting

systems comprising the EURO ZB.1 system.

••

For relevant information please visit our website

www.ceag.de.

Fig. 2: EURO ZB.1 of type ZB 96/ LAD for operation

with battery capacities of up to 240 Ah and up to 10

charging modules CM 3.4 A. This unit is capable of

powering up to 15 type EURO US.1 substations with

230 V mains and battery power.

6

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

2 Product Description

A EURO ZB.1 system supplies and monitors lighting /

emergency lighting circuits comprising luminaires and

electronic ballasts included in the CEAG Safety Luminaires Program. For emergency power supply battery

cabinets from the CEAL supply program can be used

having a storage capacity of up to 240 Ah (see standard

cabinet types under „3 Technical Data“).

the system’s operating state can be detected and indicated for example via the LEDs of a CEAG F3 remote

indication unit.

The maximum load rating of the connections for these

signalling contacts is 24 V AC/DC and 0.5 A; the maximum line length is 1000 m.

••

The following supplementary functions

can be realized:

Connecting CEAG 3-phase detectors (3PhW) to monitor

the general supply system or its subdistribution boards.

This enables a mains-to-emergency power switchover

in case a phase of the general mains supply for general

lighting purposes fails.

– When using conventional CEAG 3-phase detectors

in distribution boards signallingis effected via a 24-V

current loop (connections S3 / S4 on the ST 20 E

control unit).

Depending on its settings the ST 20 E control unit will

then control the emergency lighting circuits and signals

are transmitted to a higher-ranking annunciator (F3

module or CG controller) or to a building automation

system or the E/G/A bus.

Functional monitoring via a higher-ranking supervision

system.

For this purpose CEAG emergency lighting systems

offer a CG controller or the CG Vision supervisory

system.

••

Monitoring the switching state of switches to enable

local control of the general lighting system via DLS

or SDS 8 modules. (see circuit diagrams under „11.7

Mounting and connection of Internal Modules“ et sqq.).

Messages indicating the current switching states are

sent via the internal bus to the ST 20 E control unit.

Depending on its settings the control unit will then

switch the relevant circuits „ON“ or „OFF“.

••

Monitoring the switching states of staircase buttons for

general lighting purposes by means of TLS modules.

Similar to the above mentioned DLS modules the

current switching states are transmitted to enable the

respective emergency lighting circuits to be controlled.

••

Floating signalling contacts of the ST 20 E control unit:

Via 3 signalling relay contacts on the ST 20 E control unit

••

Further information in this context can be taken from the

CEAG catalog or respective operating manuals.

Connection of a CEAG F3 remote indicator unit (with

key-operated switch).

This device combines a status indication via the

signalling contacts of the ST 20 E control unit and a

key-operated switch to deactivate/block the emergency

lighting system.

Messages indicated:

– System operative

– Battery operation

– System on failure

This F3 remote indicating unit may have a line length of

up to 1000 m.

The maximum cross sectional area is 2.5 mm².

••

NOTE

In the Federal Republic of Germany a remote indicating

system must be mounted in permanently attended place

as prescribed by DIN VDE 0108. Make sure to observe

any national regulations ruling in the country where the

lighting system is to be operated.

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

7

2 Product Description

Fig. 3: Example of a control cabinet layout (EURO ZB.1/52)

1

3

2

4

7

Frontansicht geöffnet

Innere Seitenansicht links

Innere Seitenansicht rechts

ESCH

BMK

VDK

X12

VDK

E-G-A Filter

PE

A A

GG

E E

E GA

EMV-DR

5

TR

ST20 ZB96 kpl

BGT1

X1

SKU

11122122 3132

Batterie- Netzausfall

betrieb Mains Failure

Battery

Operation

Storung

Failure

Ein/On

Starkladung / Boost-Charge

Ladestorung / Charge-Failure

ISO-Fehler / ISO-Failure

Service

CEAG

Sicherheitstechnik

ZB 96 Version 0.21

A-1

DC-DC

BGT2

X2

1

IN

24V In

+ -

SKU

- +- +

2

24VDC

OUT

Ein/On

1

+

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

5AT

Ein/On

Storung/Failure

2

Batt.

-

1

Batt.

5AT

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

-

2

-

CCB

+

2

1

Batt.

5AT

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

2

Batt.

5AT

Batt.

5AT

5AT

1

Ein/On

Storung/Failure

-

2

5AT

-

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

5AT

Ein/On

Storung/Failure

-

1

5AT

-

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

2

-

Netz

Mains

5AT

Batt.

+

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

2

SKU CG 2x3A

Batt.

Batt.

5AT

5AT

-

1

2

+

1

SKU CG 2x3A

Batt.

5AT

2

Batt.

Batt.

Ein/On

Storung/Failure

2

+

5AT

-

1

Ein/On

Storung/Failure

Service

Batt.

-

2

Batt.

Ein/On

Storung/Failure

SKU CG 2x3A

5AT

2

+

1

Netz

Mains

5AT

2

Ein/On

Storung/Failure

Service

2

Batt.

5AT

2

SKU

Netz

Mains

5AT

Batt.

2

+

1

+

1

Batt.

-

1

SKU CG 2x3A

Batt.

5AT

5AT

SKU CG 2x3A

Batt.

5AT

Ein/On

Storung/Failure

Service

2

Batt.

-

1

Batt.

+

Ein/On

2

Storung/Failure

2

+

1

SKU CG 2x3A

Batt.

-

1

U1 01 U2 02

Netz

Mains

5AT

5AT

+

U1 01 U2 02

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

SKU

Netz

Mains

5AT

Batt.

Ein/On

Storung/Failure

Service

Netz

Mains

5AT

Batt.

2

+

1

Batt.

-

1

-

2

+

1

Ein/On

Storung/Failure

-

2

CCB

+

-

SKU

Netz

Mains

5AT

Batt.

Ein/On

Storung/Failure

Service

SKU CG 2x3A

Batt.

-

1

-

5AT

S2

+

2

+

1

Batt.

S1

-

SKU

Netz

Mains

5AT

5AT

SKU CG 2x3A

Batt.

-

5AT

S2

+

Batt.

Ein/On

Storung/Failure

2

SKU CG 2x3A

DC-DC Wandler.2

CM 1.7A DC

Charger Module

S1

2

Ein/On

Storung/Failure

Service

1

5AT

SKU CG 2x3A

+

Ein/On

Storung/Failure

Service

1

Batt.

+

Ein/On

2

Storung/Failure

Ein/On

CM 1.7A DC

Charger Module

SKU

Netz

Mains

5AT

Batt.

2

Batt.

24V intern

U1 01 U2 02

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

1

F

+ -

SKU

U1 01 U2 02

Netz

Mains

5AT

24V extern

6V intern

CCB

I

+ - + -

Netz

Mains

5AT

Batt.

2

+

5AT

ISO-Test BCM

Battery Control Module

6

1

Batt.

ISO-Test +

Menu

Drucker/Printer

S1S2S3S4UHGND

SKU

SKU

U1 01 U2 02

Netz

Mains

5AT

11 12 21 22 31 32 + BST

E GA

Betrieb

Operation

Batt.

-

2

-

5AT

1

2

6

SKU

BGT3

8

a

b

c

X3

SKU

U1 01 U2 02

Netz

Mains

5AT

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

5AT

5AT

2

Batt.

+

1

+

5AT

Ein/On

Storung/Failure

Service

1

2

Ein/On

Storung/Failure

-

1

BGT4

5AT

1

5AT

1

+

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

Batt.

-

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Batt.

5AT

5AT

1

-

1

Batt.

Batt.

5AT

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

2

Batt.

5AT

5AT

-

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

2

-

Batt.

5AT

5AT

2

5AT

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

2

-

Batt.

Batt.

5AT

5AT

5AT

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

2

Batt.

5AT

5AT

Batt.

5AT

1

+

Ein/On

Storung/Failure

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

5AT

-

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

Batt.

5AT

5AT

-

2

2

10

a)

b)

c)

+

5AT

Ein/On

Storung/Failure

SKU CG 2x3A

Batt.

5AT

5AT

2

Batt.

Ein/On

Storung/Failure

Service

2

Batt.

-

1

Netz

Mains

5AT

2

+

1

SKU CG 2x3A

Batt.

-

2

-

5AT

1

Ein/On

Storung/Failure

Service

2

Batt.

-

2

+

1

+

5AT

Ein/On

Storung/Failure

SKU CG 2x3A

Batt.

5AT

2

SKU

Batt.

Ein/On

Storung/Failure

Service

Netz

Mains

5AT

Batt.

Ein/On

Storung/Failure

Service

2

Batt.

-

1

2

+

1

SKU CG 2x3A

-

SKU CG 2x3A

Batt.

-

1

U1 01 U2 02

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

2

5AT

2

+

1

Netz

Mains

5AT

Batt.

2

+

1

Batt.

5AT

2

SKU

Batt.

Ein/On

Storung/Failure

Service

-

2

Batt.

Batt.

-

1

SKU CG 2x3A

-

1

-

2

+

1

U1 01 U2 02

Netz

Mains

5AT

+

Ein/On

Storung/Failure

SKU CG 2x3A

5AT

SKU

5AT

Ein/On

Storung/Failure

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

2

Batt.

5AT

2

SKU

Batt.

2

+

1

Batt.

-

Batt.

Ein/On

Storung/Failure

Service

SKU CG 2x3A

Batt.

-

1

Batt.

+

1

2

+

1

U1 01 U2 02

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

-

SKU

5AT

+

Netz

Mains

5AT

Batt.

Ein/On

Storung/Failure

Service

SKU CG 2x3A

Batt.

2

SKU

2

+

1

Ein/On

Storung/Failure

Batt.

Ein/On

Storung/Failure

SKU CG 2x3A

2

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

SKU CG 2x3A

-

2

Ein/On

Storung/Failure

Service

2

-

2

2

5AT

SKU

Batt.

2

+

1

Batt.

1

+

1

Ein/On

Storung/Failure

SKU CG 2x3A

Batt.

-

5AT

5AT

5AT

2

SKU

Batt.

Ein/On

Storung/Failure

Service

2

Batt.

Batt.

-

1

2

+

1

SKU CG 2x3A

U1 01 U2 02

Netz

Mains

5AT

+

Ein/On

Storung/Failure

SKU CG 2x3A

-

SKU

Batt.

+

5AT

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

2

5AT

SKU

Batt.

2

+

1

Batt.

5AT

-

2

Batt.

2

Batt.

Batt.

2

SKU

U1 01 U2 02

Netz

Mains

5AT

1

U1 01 U2 02

Netz

Mains

5AT

+

-

1

SKU

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

SKU CG 2x3A

Batt.

5AT

2

SKU

Batt.

Ein/On

Storung/Failure

Service

2

Batt.

-

5AT

2

+

1

SKU CG 2x3A

Batt.

X4

SKU

Batt.

-

-

5AT

1

2

NBV

E18 AC

AD

X71

X7

Q1

L1 L2 L3

L1 L2 L3

E18-DC

E18-DC

AD

AD

AD

AD

+

-

X9

Q2

+ -

Batterie

BGT5

X6

BGT6

9

a

b

X6.1

Ein

Booster On

Ein

Booster On

Ein

Booster On

Ein

Booster On

Ein

Booster On

11

a

b

Ein

Booster On

X8

SO

1: Control cabinet including:

2:Top cover with prepunched cable glands for M type glands (eg. for end circuit leads

and/or the supply of EURO US.1 substations)

3:Control cabinet with mounted components (examples - right-hand door hinge)

4:Control unit, Battery Control Unit BCM and Charging Module CM 1.7 (max. 2

modules) and 2 slots for LON module and CGIV module l

5:DC/DC converter (for internal power supply to electronic compontents) and SKUmodules

6:2 x 8 slots SKU 2 x 3 A, SKU 1 x 6 A or SKU 4 x 1 A

7:Terminal block for connection of emergency lighting circuit protective conductor

8:(a) Load-break switch/lv hrc fuses (mains), (b) outgoing distributor/mains

optional for up to 6 EURO US.1 substations (1-phase) and (c) distributor (mains) for

the EURO ZB.1 control cabinet

9:Terminals for (a) N and (b) PE for mains supply and distribution

10:(a) Load-break switch/lv hrc fuses (batteries), (b) outgoing distributor (batteries) optional for up to 6 EURO US.1 substations and (c) distributor (batteries) for

the EURO ZB.1 control cabinet

11:(a) Mounting rack with 2 charging modules CM 3.4 A

(b) Mounting rack with 4 charging modules CM 3.4 A

8

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

2 Product Description

Fig. 4: Detail view of control unit, DC/DC converter, charging unit and SKU circuit changeover

1

2

3

1: Control unit EURO ZB.1

2: Pluggable screw terminal blocks, removable for

installation/removal of modules, used for all cabinet

assemblies 2)

4

3: Batterie Control Module BCM and Charging

Module CM 1.7A 3) for charging and monitoring of the

appropriate battery lines

4: Power changeover modules SKU for circuit changeover, three modules of type SKU 2 x 3 A are shown 1)

1)

External incoming and outgoing lines are connected to the modules. The protective conductor is connected to terminal strip X12.

For further details and technical description consult current issue of CEAG catalog „Safety Luminaires and Safety Lighting Systems“.

3)

For bigger battery capacities additional charger modules are necessary. (see fig. 3 pos. 11). The battery control module BCM regulates via charge

control bus the CM charger modules (see fig. 4 pos. 3).

2)

EURO ZB.1 system components:

Control unit

ST 20 E

Circuit changeover modules

SKU 2 x 3 A

DLS, SDS 8 module and

TLS, LON and CGIV module

Battery Control Module

BCM

Charging Module

CM 1.7 A

Charging Module

CM 3.4 A

DC/DC converter.2

Event printer

PD 2

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

9

2 Product Description

Fig. 8: Detail view of control unit ST 20 E (terminal blocks on module serve to facilitate mounting

and removal ov the module.

1

2

4

9

5

10

8

6

3

1: Control unit housing

7

2:

Safety screw for the plug-type control unit module

8:

„UP ()“, „DOWN ()“ buttons

These buttons serve programming or status inquiry

selection purposes.

3:

24V query contacts for blocking the system via

remote switches (S1/S2) and emergency light request

(S3/S4), eg. through a (conventional) CEAG 3-phase

detector.

9:

E/G/A bus connections

Up to 256 devices can be centrally connected to the

monitoring/supervision system (CG Vision) via these

terminals.

4:Floating signalling relay contacts 1 ... 3, with

contact assignment NC open (11/12), NO open (21/22)

and (31/32)

10:LEDs for operating status indication

5:

Contact identification for the signalling relay contacts

(see Item 5), eg. for remote indication (mains operation

/ battery operation / fault) or freely configurable signalling behavior (default settings as per DIN VDE 108

available) as needed for higher-ranking building automation purposes.

6:

LC backlit display (4 lines, 20 characters each)

7:

Menu button

The „menu“ button serves for central battery system

programming. Pressing the button causes menu items

to be shown on the display which can be selected via

the „UP ()“ and „DOWN ()“ buttons.

10

Green LED - Operation - is illuminated when the unit

is operative.

Yellow LED - Battery operation - is illuminated if the

battery powers the safety lighting system.

Red LED - Mains failure - is illuminated if the external

phase detectors signal mains failure via the 24-V monitoring loop or in case the mains supplying the EURO

ZB.1 is down.

Red LED - Fault - is illumianted if a centralized alarm/

fault exists. The cause of the fault is shown on the

display.

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

3 Technical Data

3 Technical Data

Fig. 9: Inside view of

EURO ZB.1/52

Frontansicht geöffnet

eitenansicht links

EURO ZB.1 Control Cabinet

EURO ZB.1/52

Rated operating voltage:

400 / 230 V 50 Hz

Innere Seitenansicht rechts

Control unit EURO ZB.1

1

DC/DC converter.2

1

Batterie Control Module BCM

1

Circuit module SKU

0 - 26 6)

Charging Module CM 1.7 A

0 - 2 1)

Charging Module CM 3.4 A

0 - 6 1)

Outgoing distributor, 1-phase outgoing circuits (optional)

0 - 6 2)

Dimensions (W x H x D in mm)

800 x 2050 x 400

plus optional base (H in mm)

100 / 200

ESCH

BMK

VDK

X12

VDK

E-G-A Filter

PE

A A

GG

E E

E GA

ST20 ZB96 kpl

BGT1

X1

SKU

11122122 3132

Batterie- Netzausfall

betrieb Mains Failure

Battery

Operation

Storung

Failure

Ein/On

Starkladung / Boost-Charge

Ladestorung / Charge-Failure

ISO-Fehler / ISO-Failure

Service

CEAG

Sicherheitstechnik

ZB 96 Version 0.21

DC-DC

BGT2

X2

1

IN

24V In

+ -

SKU

- +- +

2

24VDC

OUT

U1 01 U2 02

Netz

Mains

5AT

1

+

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

5AT

CCB

+

-

2

5AT

+

Batt.

5AT

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

2

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Batt.

5AT

5AT

-

Ein/On

Storung/Failure

-

SKU

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

-

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

5AT

Batt.

5AT

2

-

Batt.

+

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

2

SKU CG 2x3A

Batt.

Batt.

5AT

5AT

-

1

Batt.

-

2

-

5AT

1

SKU

Netz

Mains

5AT

2

+

1

SKU CG 2x3A

Batt.

5AT

2

SKU

Ein/On

Storung/Failure

-

1

Ein/On

Storung/Failure

Service

2

+

5AT

Ein/On

Storung/Failure

Service

SKU CG 2x3A

5AT

2

+

1

Batt.

-

1

SKU

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

-

+

2

Batt.

5AT

2

SKU

Batt.

2

Netz

Mains

5AT

2

Batt.

1

Batt.

-

SKU CG 2x3A

Batt.

5AT

2

5AT

+

Ein/On

Storung/Failure

-

1

+

2

Batt.

-

1

5AT

1

SKU CG 2x3A

5AT

Ein/On

Storung/Failure

Service

SKU CG 2x3A

Batt.

2

Batt.

Ein/On

Storung/Failure

Service

2

Batt.

5AT

2

+

1

U1 01 U2 02

Netz

Mains

5AT

SKU

Batt.

Ein/On

Storung/Failure

Service

Netz

Mains

5AT

Batt.

2

+

1

Batt.

-

1

-

2

+

1

Ein/On

Storung/Failure

1

SKU

CCB

+

-

SKU

Batt.

Ein/On

Storung/Failure

Service

-

2

-

5AT

S2

+

SKU CG 2x3A

Batt.

-

1

5AT

1

Ein/On

Storung/Failure

Batt.

S1

-

2

+

1

SKU CG 2x3A

Batt.

5AT

-

SKU

Batt.

Ein/On

Storung/Failure

2

Batt.

S2

+

2

Ein/On

Storung/Failure

Service

2

SKU

U1 01 U2 02

Netz

Mains

5AT

2

SKU

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

1

2

+

1

+

Ein/On

Storung/Failure

Service

1

2

Ein/On

Storung/Failure

-

1

1

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

1

Batt.

+

+

5AT

5AT

Ein/On

Storung/Failure

Service

2

5AT

-

Ein/On

Storung/Failure

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

5AT

2

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

2

5AT

1

+

1

2

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

Ein/On

Storung/Failure

2

5AT

2

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

Netz

Mains

5AT

1

Batt.

+

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

2

2

U1 01 U2 02

Netz

Mains

5AT

2

+

1

-

5AT

1

Ein/On

Storung/Failure

2

SKU CG 2x3A

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

1

2

1

2

-

1

2

-

-

1

-

2

-

1

2

-

-

1

-

2

-

1

2

Batteries: Nominal temperature

+

5AT

Ein/On

Storung/Failure

Service

1

Batt.

5AT

-

-

-

1

- 20 °C to +40 °C

- 5 °C to +35 °C

Netz

Mains

5AT

Batt.

+

5AT

Batt.

5AT

-

storage

operation

2

Batt.

SKU CG 2x3A

Batt.

-

Adm. system temperature ranges:

Batt.

-

SKU

Batt.

Ein/On

Storung/Failure

Service

SKU CG 2x3A

SKU CG 2x3A

5AT

5AT

-

upon request

Ein/On

Storung/Failure

2

Batt.

5AT

2

Batt.

-

Weight (depends on components mounted)

+

Ein/On

Storung/Failure

Service

1

Batt.

-

1

2

+

1

SKU CG 2x3A

-

Netz

Mains

5AT

2

+

SKU CG 2x3A

Batt.

5AT

2

SKU

Batt.

2

+

5AT

5AT

1

+

Ein/On

Storung/Failure

Service

1

Batt.

-

1

SKU

Batt.

Batt.

Ein/On

Storung/Failure

-

2

+

SKU CG 2x3A

Batt.

5AT

2

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

2

Ein/On

Storung/Failure

Service

SKU CG 2x3A

1

+

1

Batt.

-

1

2

+

SKU CG 2x3A

Batt.

5AT

2

+

1

SKU CG 2x3A

1

+

SKU

5AT

Ein/On

Storung/Failure

2

2

Batt.

-

Batt.

Ein/On

Storung/Failure

Service

1

SKU CG 2x3A

1

Ein/On

Storung/Failure

-

2

+

5AT

Ein/On

Storung/Failure

2

Ein/On

Storung/Failure

Service

SKU CG 2x3A

5AT

2

+

SKU

1

+

5AT

Ein/On

Storung/Failure

Service

1

1

+

1

Batt.

Batt.

+

5AT

2

Batt.

5AT

2

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

2

Batt.

SKU CG 2x3A

1

Batt.

-

1

2

+

SKU CG 2x3A

Batt.

5AT

2

SKU

2

Batt.

Ein/On

Storung/Failure

2

Batt.

-

1

SKU

U1 01 U2 02

Netz

Mains

5AT

1

-

1

+

Ein/On

Storung/Failure

Service

1

SKU CG 2x3A

5AT

2

+

Ein/On

Storung/Failure

2

Batt.

5AT

2

SKU

1

+

Ein/On

Storung/Failure

Service

1

Batt.

-

5AT

2

+

SKU CG 2x3A

Batt.

X4

1

Batt.

SKU CG 2x3A

+

1

-

1

BGT4

5AT

SKU CG 2x3A

-

5AT

SKU

Batt.

Ein/On

Storung/Failure

2

Batt.

BGT3

U1 01 U2 02

Netz

Mains

5AT

Ein/On

Storung/Failure

Service

1

DC-DC Wandler.2

X3

Netz

Mains

5AT

5AT

+

5AT

U1 01 U2 02

Netz

Mains

5AT

Ein/On

Storung/Failure

Service

2

CM 1.7A DC

Charger Module

S1

SKU

Batt.

2

Batt.

24V intern

+

1

Ein/On

CM 1.7A DC

Charger Module

F

+ -

SKU

24V extern

6V intern

CCB

I

+ - + -

Netz

Mains

5AT

Batt.

2

5AT

Ein/On

ISO-Test BCM

Battery Control Module

A-1

1

Batt.

ISO-Test +

Menu

Drucker/Printer

S1S2S3S4UHGND

SKU

SKU

U1 01 U2 02

Netz

Mains

5AT

11 12 21 22 31 32 + BST

E GA

Betrieb

Operation

+20 °C 4)

2

Enclosure type

as per DIN EN 60 529

IP21

Prot. class

as per DIN EN 60 598

I

NBV

E18 AC

AD

X71

X7

Q1

L1 L2 L3

3-phase system division

Wiring block

Cable entry at top/bottom possible

yes / yes

L1 L2 L3

E18-DC

E18-DC

AD

AD

AD

Conductor size 3)

Battery and mains lead

Outgoing distributor

Final circuits

Control unit EURO ZB.1

AD

+

-

X9

Q2

+ -

Batterie

BGT5

X6

BGT6

X6.1

Ein

Booster On

Ein

Booster On

Ein

Booster On

Ein

Booster On

Ein

Booster On

up to

up to

up to

conductor size up to

50 mm2

16 mm2

2.5 mm2

2.5 mm2

Battery power supply via CEAG standard

battery cabinet (W x D x H in mm) 800 x 400 x 2050

Ein

Booster On

X8

1-fold: 23.3 - 89.4 Ah 5)

2-fold: 118 - 178.8 Ah 5)

4)

SO

when mounting 6 charging modules an additional booster carrier, 2-fold, must be arranged

2)

for 1-phase operation (for 3-phase operation

0-2 outgoing circuits)

3)

Conductor sizes of the connecting leads must

be selected to suit the type of mains power

supply and requirements of the consumer

circuits in line with the applicable regulations

and standards (ruling at the operating location

of the plant)

1)

Fig.10: Cable entries are prepunched (here EURO

ZB.1/52, other types, eg. sponge rubber, are

available on request)

1

3

The optimum operating temperature is +20 °C.

Lower temperatures will impair the available

capacity. Higher temperatures will reduce the

usability period. The technical data apply to a

nominal temperature of +20 °C.

5)

The battery capacity may be raised to 240 Ah

by a connection in parallel.

6)

Plus max. two additional slots in correlation of

CM 1.7 A and CM 3.4 A placement.

4)

4

1 = M40/M32

2 = M32

3 = M16

4 = M20/M25

2

3

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

11

3 Technical Data

Fig. 9a: Inside view of

EURO ZB.1/188K

Frontansicht geöffnet (ohne Batterie)

CS

X12

MP

PE

E-G-A Filter

L

F50

PE

L? N?

N PE

L? N?PE

F50

F10 F30

+ - PE

EE GG AA

F

+ -

ST

BGT1

SKU

11122122 3132

X1

Betrieb

Operation

E GA

Batterie- Netzausfall

betrieb Mains Failure

Battery

Operation

Ein/On

Starkladung / Boost-Charge

Ladestorung / Charge-Failure

ISO-Fehler / ISO-Failure

Service

CEAG

Sicherheitstechnik

ZB 96 Version 0.21

BGT2

1

X2

IN

24V In

+ -

SKU

- +- +

2

24VDC

OUT

1

+

1

2

-

5AT

1

1

2

Batt.

Batt.

5AT

5AT

5AT

5AT

-

CCB

+

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

2

Batt.

5AT

5AT

-

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

Ein/On

Storung/Failure

-

CCB

+

2

1

2

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

5AT

5AT

2

-

Batt.

5AT

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

2

5AT

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

5AT

5AT

2

1

+

Ein/On

Storung/Failure

-

2

Batt.

+

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

SKU 2x3A

Batt.

Batt.

5AT

5AT

-

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

Batt.

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

5AT

1

2

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

1

2

SKU 2x3A

Batt.

-

1

2

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

1

+

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

1

+

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

1

+

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

1

+

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

1

+

Batt.

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

2

+

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

SKU 2x3A

Batt.

Batt.

5AT

5AT

-

1

Netz

Mains

5AT

2

+

SKU 2x3A

Batt.

-

1

2

+

SKU 2x3A

Batt.

-

1

2

+

SKU 2x3A

Batt.

-

1

2

+

SKU 2x3A

Batt.

-

1

2

+

SKU 2x3A

Batt.

-

1

2

+

SKU 2x3A

Batt.

-

5AT

1

+

1

1

1

1

1

1

1

Battery Control Module BCM

1

1

1

1

Circuit module SKU

0 - 10 3)

0 - 10 3)

0 - 18 3)

0 - 10 3)

Charging Module 1.7 A

0-2

0-2

1

1

Charging Module 3.4 A

0 - 1 1)

0 - 2 2)

0

0

Outgoing distributor, 1-phase, Outgoing circuits

2

2

Dimensions (mm)

1

1

800

600

600

H 2050

2050

1800

1800

D 400

600

350

350

H 200

–

200

200

W 800

L

N

plus optional base (mm)

Netz

Mains

5AT

Batt.

2

1

DC/DC converter.2

+

-

SKU

U1 01 U2 02

Netz

Mains

5AT

1

Control unit EURO ZB.1

-

Netz

Mains

5AT

+

1)

Batt.

-

-

5AT

1

2

L

N

+

-

Weight (depends on outfit)

upon request

Adm. system temperature ranges:

storage

- 20 °C to +40 °C

- 5 °C to +35 °C

operation

Batteries: Nominal temperature

SO

18K

2

5AT

+

188K

5AT

1

Batt.

2

26K

230 V 50 Hz

Batt.

-

2

SKU

Netz

Mains

5AT

2

+

1

5AT

1

+

-

-

5AT

2

Batt.

+

L

N

Batt.

1

Ein/On

Storung/Failure

Service

1

SKU

Ein/On

Storung/Failure

-

SKU 2x3A

Batt.

5AT

2

Ein/On

Storung/Failure

Service

SKU 2x3A

Batt.

5AT

2

+

1

Batt.

-

1

SKU

Netz

Mains

5AT

+

2

+

EURO ZB.1/ 20K

Rated

operating

voltage

Innere

Seitenansicht

rechts

SKU

5AT

Ein/On

Storung/Failure

1

Batt.

-

Batt.

2

Ein/On

Storung/Failure

Service

-

2

Ein/On

Storung/Failure

1

SKU 2x3A

Batt.

-

1

Ein/On

Storung/Failure

Service

-

Netz

Mains

5AT

2

+

SKU 2x3A

Batt.

5AT

2

+

1

SKU 2x3A

Batt.

5AT

2

SKU

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

1

+

SKU

Batt.

Ein/On

Storung/Failure

Service

2

+

Batt.

-

1

-

2

+

1

Batt.

-

1

SKU

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

SKU 2x3A

Batt.

2

-

SKU

Batt.

2

+

1

-

5AT

S2

+

-

SKU

Batt.

Ein/On

Storung/Failure

1

1

+

SKU 2x3A

Ein/On

Storung/Failure

Service

-

2

Batt.

S1

S2

+

SKU 2x3A

Batt.

5AT

2

SKU

U1 01 U2 02

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

2

CM 1.7A DC

Charger Module

S1

2

+

1

Batt.

-

5AT

SKU

Batt.

Ein/On

Storung/Failure

Batt.

X3

U1 01 U2 02

Netz

Mains

5AT

Ein/On

Storung/Failure

Service

SKU 2x3A

DC-DC Wandler.2

BGT3

Netz

Mains

5AT

5AT

+

5AT

Netz

Mains

5AT

Batt.

1

Ein/On

Ein/On

CM 1.7A DC

Charger Module

F

+ -

SKU

Batt.

2

Batt.

24V intern

6V intern

CCB

I

+ - + -

SKU

U1 01 U2 02

Netz

Mains

5AT

24V extern

U1 01 U2 02

Netz

Mains

5AT

5AT

ISO-Test BCM

Battery Control Module

DC-DC

Netz

Mains

5AT

Batt.

5AT

1

Battery

SKU

Batt.

+

ISO-Test +

Menu

Drucker/Printer

S1S2S3S4UHGND

SKU

U1 01 U2 02

Netz

Mains

5AT

11 12 21 22 31 32 + BST

Storung

Failure

F

EGA

+ - PE

F10 F30

X7

X9

X8

L

N PE

Q2

Compact Control Cabinet

+20 °C

Enclosure type

as per DIN EN 60 529 IP21

IP21

IP21

IP21

Prot. class

as per DIN EN 60 598 I

I

I

I

3-phase system division

no

no

no

no

Cable entry at top/bottom possible

yes / no

yes / no

yes / no

yes / no

Conductor size

Battery and mains leads

up to

Outgoing distributor

up to

Final circuits

up to

Control unit ST 20

conductor size up to

16 mm2

35 mm2

2.5 mm2

2.5 mm2

Battery power supply via CEAG

(Ah)

compact battery cabinet (W x D x H in mm)

1)

5.5 - 49.5 5.5 - 89.4 5.5 - 23.3 5.5 - 23.3

see applicable mounting and operating manual

W hen mounting up to 1 Charging Module a 1-fold charging booster adapter must be provided.

2) When

3)

16 mm2

16 mm2

2.5 mm2

2.5 mm2

mounting up to 2 Charging Modules a 2-fold charging booster adapter must be provided.

Plus max. two additional slots in correlation of CM 1.7 A and CM 3.4 A placement.

ATTENTION!

When planning the equipment and during

subsequent operation make sure that

• the systems are sufficiently cooled (compare

remarks under „Adm. temperature ranges“),

• environmental requirements are met as per type

of enclosure and protection class (regarding protection against contact with live components and

ingress of dust, foreign materials or moisture),

• the line length of an emergency lighting circuit up to

the last luminaire of the circuit does not exceed the

admissible line length.

12

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

3 Technical Data

Fig. 9b: Inside view of

EURO ZB.1/204K

ansicht links

Compact Control Cabinet

Frontansicht geöffnet (ohne Batterie)

SKU

SKU

X8

X1

L

U1 01 U2 02

Netz

Mains

5AT

1

PE

NPE

+

1

A A

2

1

1

2

Batt.

1

Batt.

5AT

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

1

2

U1 01 U2 02

Netz

Mains

5AT

Batt.

1

+

5AT

Batt.

5AT

5AT

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

-

2

Batt.

+

5AT

1

2

Batt.

5AT

5AT

5AT

Ein/On

Storung/Failure

Batt.

-

2

-

5AT

1

2

E-G-A Filter

Batterie

VK

ST

SKU

SKU

SKU

BGT2

X2

11122122 3132

Betrieb

Operation

E GA

Batterie- Netzausfall

betrieb Mains Failure

Battery

Operation

Ein/On

1

X3

24V In

+ -

SKU

IN

2

- +- +

24VDC

OUT

1

+

6V intern

1

2

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

2

-

1

2

Batt.

5AT

5AT

S2

+

-

CCB

+

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

-

2

Batt.

5AT

1

Ein/On

Storung/Failure

2

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

Batt.

5AT

CCB

+

2

2

-

2

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

1

+

2

Batt.

5AT

5AT

-

5AT

2

Batt.

5AT

5AT

5AT

1

Ein/On

Storung/Failure

-

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

5AT

5AT

1

+

Ein/On

Storung/Failure

-

2

2

Batt.

5AT

5AT

+

5AT

Ein/On

Storung/Failure

-

5AT

2

BGT4

Netz

Mains

5AT

U1 01 U2 02

Netz

Mains

5AT

Batt.

Batt.

5AT

5AT

2

1

+

Ein/On

Storung/Failure

-

2

2

X6

Netz

Mains

5AT

2

1

Battery Control Module BCM

1

1

Circuit module SKU

0 - 14

0 - 14

Charging Module 1.7 A

0-2

0-2

Charging Module 3.4 A

0 - 1 1)

0 - 2 2)

–

–

+

5AT

Ein/On

Storung/Failure

Service

Ein/On

Storung/Failure

Dimensions (mm)

Ein

Booster On

SKU 2x3A

Batt.

5AT

5AT

Outgoing distributor, 1-phase, Outgoing circuits

Batt.

+

1

Batt.

-

1

1

1

Batt.

-

1

Ein/On

Storung/Failure

Service

1

DC/DC converter.2

SKU 2x3A

5AT

SKU 2x3A

Batt.

-

1

2

Batt.

5AT

2

+

1

Batt.

Ein/On

Storung/Failure

Service

SKU

Batt.

2

Ein/On

Storung/Failure

Service

Netz

Mains

5AT

2

+

1

Batt.

-

1

SKU 2x3A

Batt.

-

1

Batt.

+

SKU 2x3A

Batt.

5AT

2

+

1

SKU 2x3A

Batt.

-

1

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

U1 01 U2 02

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

SKU

Batt.

Ein/On

Storung/Failure

Service

Netz

Mains

5AT

Batt.

2

+

1

Batt.

-

1

-

2

+

1

SKU 2x3A

5AT

-

SKU

Batt.

Ein/On

Storung/Failure

Service

-

5AT

S2

+

2

+

1

Batt.

-

1

U1 01 U2 02

Netz

Mains

5AT

+

Batt.

S1

-

SKU

Batt.

Ein/On

Storung/Failure

Service

SKU 2x3A

Batt.

-

5AT

CM 1.7A DC

Charger Module

S1

2

+

1

SKU 2x3A

Batt.

SKM M20x1,5

Netz

Mains

5AT

5AT

+

5AT

Netz

Mains

5AT

5AT

Ein/On

Storung/Failure

Service

SKU 2x3A

CM 1.7A DC

Charger Module

F

+ -

SKU

Batt.

2

Batt.

24V intern

CCB

I

+ - + -

SKU

U1 01 U2 02

Netz

Mains

5AT

24V extern

DC-DC Wandler.2

2

Ein/On

ISO-Test BCM

Battery Control Module

BGT3

+

5AT

1

Batt.

2

Batt.

ISO-Test +

Menu

Drucker/Printer

DC

1

Ein/On

Starkladung / Boost-Charge

Ladestorung / Charge-Failure

ISO-Fehler / ISO-Failure

Service

ZB 96 Version 0.21

S1S2S3S4UHGND

U1 01 U2 02

Netz

Mains

5AT

11 12 21 22 31 32 + BST

Storung

Failure

CEAG

Sicherheitstechnik

Control unit EURO ZB.1

Ein/On

Storung/Failure

Service

SKU 2x3A

Batt.

-

1

Netz

Mains

5AT

2

+

SKU 2x3A

Batt.

-

1

2

Netz

Mains

5AT

Batt.

2

+

SKU 2x3A

Batt.

-

1

U1 01 U2 02

Netz

Mains

5AT

+

5AT

5AT

Ein/On

Storung/Failure

-

5AT

SKU

Netz

Mains

5AT

Batt.

2

+

Ein/On

Storung/Failure

Service

Batt.

E GA

Q2

-

Batt.

SKU 2x3A

F F

+

U1 01 U2 02

Netz

Mains

5AT

+

5AT

GG

E E

SKU

Netz

Mains

5AT

Batt.

2

Batt.

Batt.

-

-

5AT

1

2

W 800

SKMM20x1,5

VS M20x1,5

VS M20x1,5

plus optional base (mm)

TF

800

H 2050

2050

D 400

600

H 200

–

Weight (depends on components mounted)

X9

upon request

Adm. system temperature ranges:

AW

264K

230 V 50 / 60 Hz

VK-1

TK

BGT1

EURO ZB.1/ 204K

Rated

operating voltage

Innere Seitenansicht rechts

storage

operation

- 20 °C to +40 °C

- 5 °C to +35 °C

AW

Batteries: Nominal temperature

BK

AW

AW

+20 °C

Enclosure type

as per DIN EN 60 529 IP21

IP21

Prot. class

as per DIN EN 60 598 I

I

3-phase system division

no

no

Cable entry at top/bottom possible

yes / no

yes / no

BK

SO

Conductor size

Battery and mains leads

Outgoing distributor

Final circuits

Control unit ST 20 E

up to

up to

up to

conductor size up to

Battery power supply via CEAG

(Ah) 5.5 - 49.5

compact battery cabinet

1)

(W x D x H)

5.5 - 89.4

see pertinent mounting and

operating manual

W hen mounting up to 1 Charging Module a 1-fold charging booster adapter must be provided.

2) When

3)

16 mm2

–

2.5 mm2

2.5 mm2

mounting up to 2 Charging Modules a 2-fold charging booster adapter must be provided.

Plus max. two additional slots in correlation of CM 1.7 A and CM 3.4 A placement.

M25

x104

M40

x12

M16

x12

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

13

3 Technical Data

Fig.11: Inside view of

EURO US.1/72

Substation

EURO US.1/ 72

Rated operating voltage

42

230 V 50 / 60 Hz

Control unit ST 20 E

1

DC/DC converter (model DC/DC.2)

1-2

Circuit module SKU

0 - 36

Outgoing distributor/ circuits (optional)

none

Dimensions (mm)

1

1

0 - 21

1)

none

W 800

plus optional base (mm)

1200

D 400

300

H 100 / 200

300

Weight (depends on components mounted)

Adm. system temperature ranges:

600

H 2050

upon request

storage

operation

- 20 °C to +40 °C

- 5 °C to +35 °C

Batteries

–

Enclosure type

as per DIN EN 60 529

IP21

IP21

Prot. class

as per DIN EN 60 598

I

I

3-phase system division

no

no

Cable entry at top/bottom possible

yes / yes

yes / no

Conductor size

Battery and mains lead

Outgoing distributor

Final circuits

Control unit ST 20 E

2)

up to

up to

up to

conductor size up to

Battery and mains power supply

1)

35 mm2

–

2.5 mm2

2.5 mm2

via outgoing distributor in a

EURO ZB.1 control cabinet

ne DC/DC.2 converter can supply operating voltage to a max. of 26 modules; for more than 26 modules

O

an additional DC/DC.2 converter must be installed.

2) C onductor

sizes of the connecting leads must be selected to suit the type of mains power supply and

requirements of the consumer circuits in line with the applicable regulations and standards (ruling at the

operating location of the plant).

Fig.12: Cable entries are prepunched (other types, eg. sponge rubber,

are available on request)

1 = M40/M32

1

3

2 = M32

3 = M16

4 = M20/M25

2

14

3

MANUAL EURO ZB.1, EURO US.1 30080001416 May 2016 www.ceag.de

4

3 Technical Data

Substation

EURO US.1/ 26

10

Rated operating voltage

ESF-E30/17 9)

ESF-E30/28 9)

230 V 50 / 60 Hz

Control unit ST 20 E

1

1

1

1

DC/DC converter (model DC/DC.2)

1

1

1

1

0 - 13

Circuit module SKU

Dimensions (mm)

plus optional base (mm)

0-5

0 - 17

0 - 26

W 600

400

885

885

H 800

600

1150

2190

D 250

250

405

405

H –

–

–

–

Weight (depending on components mounted)

Adm. system temperature ranges:

upon request

storage

operation

Batteries

- 20 °C to +40 °C

- 5 °C to +35 °C

–

–

–

–

Enclosure type

as per DIN EN 60 529 IP 54

IP 54

IP 54

IP 54

Prot. class

as per DIN EN 60 598 I

I

I

I

3-phase system division

no

no

no

no

Cable entry at top/bottom possible

yes / no

yes / no

yes / no

yes / no

Conductor size 2)

Battery and mains lead

Outgoing distributor

Final circuits

Control unit ST 20 E

35 mm2

–

2.5 mm2

2.5 mm2

16 mm2

–

2.5 mm2

2.5 mm2

16 mm2

–

4.0 mm2

4.0 mm2

16 mm2

–

4.0 mm2

4.0 mm2

up to

up to

up to

conductor size up to

Battery and mains power supply

via outgoing distributors in a EURO ZB.1 control cabinet