Liberty User Manual

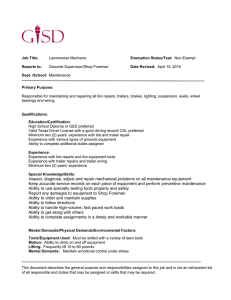

advertisement