Effects of etching holes on complementary metal oxide

advertisement

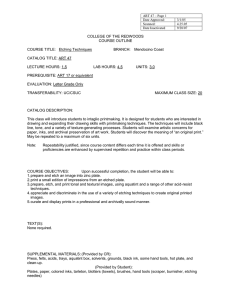

Article Effects of etching holes on complementary metal oxide semiconductor– microelectromechanical systems capacitive structure Journal of Intelligent Material Systems and Structures 24(3) 310–317 Ó The Author(s) 2012 Reprints and permissions: sagepub.co.uk/journalsPermissions.nav DOI: 10.1177/1045389X12449917 jim.sagepub.com Wei-Hsiang Tu1, Wen-Chang Chu2, Chih-Kung Lee1,2,3, Pei-Zen Chang2 and Yuh-Chung Hu4 Abstract Etching the large area of sacrificial layer under the microstructure to be released is a common method used in microelectromechanical systems technology. In order to completely release the microstructures, many etching holes are often required on the microstructure to enable the etchant to completely etch the sacrificial layer. However, the etching holes often alter the electromechanical properties of the micro devices, especially capacitive devices, because the fringe fields induced by the etching holes can significantly alter the electrical properties. This article is aimed at evaluating the fringe field capacitance caused by etching holes on microstructures. The authors aim to find a general capacitance compensation formula for the fringe capacitance of etching holes by the use of ANSYS simulation. According to the simulation results, the design of a capacitive structure with small etching holes is recommended to prevent an extreme capacitance decrease. In conclusion, this article provides a fringing field capacitance estimation method that shows the capacitance compensation tendency of the design of etching holes; this method is expected to be applicable to the design in capacitive devices of complementary metal oxide semiconductor–microelectromechanical systems technology. Keywords Actuator, sensor, autonomic structures Introduction To date, there have been numerous high-performance and low-cost microsensors or microactuators fabricated by microelectromechanical systems (MEMS) technology applied to the automobiles, biomedicine, and electronics industries. In the fabrication process of micro devices, it is generally required to etch the sacrificial layer under the microstructure to form a movable sensing or actuating microstructure: such a method is called the release process. To completely and rapidly etch the sacrificial layer, generally a lot of etching holes are made on the microstructure to be released, which enables the etchant to uniformly and rapidly permeate into the sacrificial layer. The arrangement of etching holes, including the density, size, shape, etc, depends on the properties of the etchant, namely the etching rate and selectivity between the materials of the microstructure and the sacrificial layer. However, etching holes may alter the characteristics of the device, such as mechanical properties, magnetic field, and electrical field, which will significantly decrease the fabrication yield of the micro devices. Some of the literature discusses the effect of etching holes. Rabinovich et al. (1997) employed the so-called effective medium method to investigate the effect of etching holes on the mechanical properties of microstructures. They made two identical sized unit modules, one with etching holes and the 1 Department of Engineering Science and Ocean Engineering, National Taiwan University, Taipei, Taiwan 2 Institute of Applied Mechanics, National Taiwan University, Taipei, Taiwan 3 President of Institute for Information Industry, Taipei, Taiwan 4 Department of Mechanical and Electromechanical Engineering, National Ilan University, Ilan, Taiwan Corresponding author: Yuh-Chung Hu, Department of Mechanical and Electromechanical Engineering, National Ilan University, No. 1, Sec. 1, Shen-Lung Road, Ilan 26041, Taiwan. Email: ychu@niu.edu.tw Tu et al. 311 other without, and compared the force–displacement behaviors of the two modules by exerting a series of normal and shear forces on them. Their results showed that the mechanical properties of structures are highly affected by etching holes. Fang et al. (2001) published a theoretical model that showed that the size and density of etching holes have a tremendous influence on the coercivity of a microstructure. Elshurafa and El-Masry (2006) employed a commercial finite element package COMSOL to analyze the influence of the size and density of etching holes on the tunable range of MEMS parallel plate variable capacitors. Their results showed that the deviation of the tunable range affected by etching holes is around 16%. Elshurafa and El-Masry (2007) discussed the effects of etching holes within one plate in a parallel plate varactor or in a two-plate varactor; their results showed the effect of etching holes in two-plate varactors is not extreme in regard to the capacitance value. Fang et al. (2010) discussed the effect of etching holes on variable capacitors and issued an analytical model to compute the effect of etching holes on pull-in voltage and capacitance. According to the aforementioned literature, the influence of etching holes on the characteristics of the devices needs to be considered in design and fabrication. For a long, flat plate whose length dimension is much greater than its width, we can consider it as a two-dimensional problem, Figure 1 shows a crosssectional view and geometric parameters of a long parallel plate capacitor. Apart from the uniform electrical field under the plate, illustrated as the blue field lines in Figure 1, fringe fields come from its top surface and two sides, illustrated as red and green field lines in Figure 1. Chang (1976) derived a fringe capacitance equation via two times Schwartz–Christoffel conformal mapping process and asserted that its deviation could be less than 1% to the finite element method as the ratio of thickness to gap is larger than 1, namely b/g . 1. Vandermeijs and Fokkema (1984) offered an empirical formula by curve-fitting Chang’s equation as follows " 0:25 0:5 # b b h Cunit length = e +1:06 + 0:77+ 1:06 g g g ð1Þ Figure 1. Schematic diagram and geometric parameters of two-dimensional fringe fields. Figure 2. Schematic diagram and geometric parameters of three-dimensional fringe fields. where b is the width of the plate, h is the thickness of the plate, g is the gap between two electrodes, and e is the permittivity. Compared with Chang’s equation, its deviation is within 2% as b/g . 1 and 0.1 \ h/g \ 4, and within 6% as b/g . 0.3 and h/g \ 10. If the plate’s length and width are not different, then three-dimensional (3D) fringe fields should be taken into consideration. As shown in Figure 2, not only the fringe fields from the top surface and the length sides but also the ones from the width sides should be considered. Sakurai and Tamaru (1983) utilized the subarea method to develop an empirical formula for 3D fringe capacitance C ðarea of the plateÞ = 1:15 e g 0:222 h + 1:40 ðcircumference of the plateÞ g 0:728 h g ð2Þ + 4:12 g Its deviation is within 10% under the condition of 0 \ b/L \ 1, 0.5 \ b/g \ 40, and 0.4 \ h/g \ 10. Vandermeijs and Fokkema (1984) presented a formula for calculating 3D fringe capacitance; yet it is imprecise. After surveying many literatures, we found that no literature mentioned how to calculate the fringe fields caused by etching holes, and only a few literatures mentioned the effects of etching holes on the variable capacitor (Elshurafa and El-Masry, 2006, 2007; Fang et al., 2010). Figure 3 shows the schematics of etching holes through which the field lines of the top surface, as well as the field lines from its inner-edges, pass. The etching holes make the electrical fields much more complicated than the case of a parallel plate capacitor and cause a nonideal electrical field, which is difficult for capacitance assessment and invalidating of foregoing formulas. Therefore, this article provides a compensative 312 Journal of Intelligent Material Systems and Structures 24(3) where CT is the total capacitance; Cp is an ideal capacitance of parallel plate, which can be calculated by the well-known equation Cp = eA=g; and Cf is the fringe field capacitance caused by the thickness and upper surface of a parallel plate capacitor. Similarly, the capacitance (CTe ) of a parallel plate capacitor with etching holes can be expressed as Figure 3. Schematic diagram of the fringe fields of etching holes. CTe = Cpe + Cfe formula of assessment of etching hole capacitance for a plate capacitor structure. For a capacitive MEMS device, ANSYS is utilized to simulate the capacitance under different sizes of etching holes, and an empirical formula is derived. We expect that this result can provide designers with a rule to precisely estimate the capacitance of a plate capacitor with etching holes. Methodology where Cpe and Cfe are the ideal capacitance and the total fringe capacitance, respectively, for the parallel plate with etching hole. Cpe can be represented as Cpe = Cp Cp removed where Cp removed is the ideal capacitance of the etching hole area. Cfe can be represented as Cfe = Cf + Cf hole where Cf hole is the fringe capacitance from the etching hole. A correction term will be carried out between capacitors with etching holes and those without etching holes. The formula of capacitance correction can be signified as follows DC = CTe CT = Cp There are three parts to this research. First, the authors comprehend the difference between a parallel plate capacitor and parallel plate capacitor with etching holes, and define the quantity of difference as capacitance correction term. Second, the authors employ ANSYS to compute the capacitance of a parallel plate capacitor and a parallel plate capacitor with etching holes with different dimensions, and gain the capacitance correction term that is necessary for compensating the difference. Finally, the authors utilize the capacitance correction term obtained under different dimensions to acquire the relation between capacitance correction and dimension via curve fitting, and provide an empirical formula. Analysis of capacitance The literatures show that the fringe fields of a parallel plate capacitor cannot be neglected in a micro scale. The fringe field from the thickness and upper surface of a parallel plate capacitor needs to be considered. For this reason, the capacitance of micro parallel plate capacitor can be expressed as CT = Cp + Cf ð3Þ ð4Þ removed + Cf hole ð5Þ Simulation The effect of etching holes is nonidentical under different dimensions, sizes, and densities of etching holes. Hence, this research employs ANSYS to simulate the influence of etching holes on the capacitance through designing different sizes of plates and etching holes. Usually, the alignment is an array, as shown in Figure 4(a), so a unit module of an etching hole can be taken out and simulated alone, as shown in Figure 4(b). Furthermore, the structure of an etching hole is symmetric, so the simulation can function by merely using a quarter of the structure and field. Table 1 shows the dimensions for simulation. The size of the etching hole is defined as the ligament efficiencies (m) meaning line width divided by the pitch of the etching hole. As shown in Figure 5, the m is expressed as m= l pitch ð6Þ The value of m is within 0–1; the bigger the m value, the smaller the size of the etching hole. Simulation of the parallel plate structure capacitor without etching holes (m=1) is conducted under three different Figure 4. (a) Schematic diagram of the capacitive structure and (b) schematic diagram of unit module. Tu et al. 313 Table 1. Structure dimensions for simulation. Length of the square unit module (mm) Thickness (mm) Gap (mm) Ligament efficiencies 4, 8, and 16 0.5 0.1, 0.2, 0.3, 0.4, 0.5, 0.75, 1.0, 1.5, 2.0, and 4.0 1, 0.7, 0.5, and 0.3 1 mm3). For the setting of c = 8 mm, h = 0.5 mm, m = 0.5 mm, and g = 1 mm, the amount of element is around 95,000. After simulation, characteristics of the structure’s electrical field and whole capacitance can be obtained. The whole plate capacitance, CT, corresponding to various sizes, can be obtained via simulation, and you can compute the ideal plate capacitance, CP, to solve fringe field capacitance, Cf, as shown in Table 3. Equivalently, the plate capacitance with etching holes, CTe , the ideal plate capacitance that subtracted the area of the etching holes from the full plate, Cpe , and the fringe field capacitance caused by the thickness of the etching hole fringe can be obtained, as shown in Table 4. Results and discussion Figure 5. Schematic of ligament efficiencies. conditions (c = 4, 8, and 16), and the dimensions of the plate structure capacitor with etching holes for simulation are m = 0.7, 0.5, and 0.3. The thickness of the plate (h) is 0.5 mm. The variable gap between two plates (g) is within 0.1–4.0 mm. ANSYS element Solid122 is employed in the electrical field analysis. Due to the symmetry of the structure, the simulation can be processed by taking just 1/4 of the model to build the electrical field. The analyzed electrical field is a cube with side lengths of 2c. The upper electrode is involved in the field, and the lower electrode is the bottom of the simulated field, as shown in Figure 6(a). The setting for the mesh size is shown in Figure 6(b) and Table 2 (e.g. the element size of X region from 0 to c/2 + 0.1, Y region from g + h + 0.1 to g + h + 2.1, and Z region from c/2 + 2.1 to 2c is 0.1 3 0.5 3 Based on the results of the simulations, when the gap increases, the ideal plate capacitance in the whole capacitance decreases, and the fringe field capacitance in the whole capacitance increases; this indicates that the effect of the fringe field is more prevalent. Afterward, just like the procedure for the capacitance correction, the plate structure capacitance with etching holes, CTe , and whole plate structure capacitance, CT, can be resolved, and the subtraction of these two values is the capacitance correction term DC. As shown in Figure 7, under identical ligament efficiencies (m = 0.5), the larger the unit module, the greater the capacitance correction. Taking into account the relation with the gap of electrodes, the capacitance correction and gap are roughly in inverse proportion. Considering the same area of square plates and cutting out the same area of etching holes with different sizes and densities, ligament efficiencies of m = 0.5, the samples include 16 unit modules with 4 mm for each Figure 6. (a) Scheme of analyzed electrostatic field and (b) scheme of mesh size distribution. 314 Journal of Intelligent Material Systems and Structures 24(3) Table 2. Mesh size in three distributions. X region Y region 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–c/2 + 0.1 c/2 + 0.1–c/2 c/2 + 2.1–2c 0–g + h + 0.1 g + h + 0.1–g + h + 2.1 0–c/2 + 0.1 g + h + 2.1–2c 0–g + h + 0.1 c/2 + 0.1–c/2 + 2.1 g + h + 0.1–g + h + 2.1 g + h + 2.1–2c 0–g + h + 0.1 g + h + 0.1–g + h + 2.1 c/2 + 2.1–2c Mesh size (mm3) Z region g + h + 2.1–2c Table 3. Simulation results of parallel plate capacitor. 0.1 3 0.1 3 0.1 0.1 3 0.1 3 0.5 0.1 3 0.1 3 1 0.1 3 0.5 3 0.1 0.1 3 0.5 3 0.5 0.1 3 0.5 3 1 0.1 3 1 3 0.1 0.1 3 1 3 0.5 0.1 3 1 3 1 0.5 3 0.1 3 0.1 0.5 3 0.1 3 0.5 0.5 3 0.1 3 1 0.5 3 0.5 3 0.1 0.5 3 0.5 3 0.5 0.5 3 0.5 3 1 0.5 3 1 3 0.1 0.5 3 1 3 0.5 0.5 3 1 3 1 1 3 0.1 3 0.1 1 3 0.1 3 0.5 1 3 0.1 3 1 1 3 0.5 3 0.1 1 3 0.5 3 0.5 1 3 0.5 3 1 1 3 1 3 0.1 1 3 1 3 0.5 13131 + 2.1 + 2.1 + 2.1 + 2.1 + 2.1 + 2.1 + 2.1 + 2.1 + 2.1 Table 4. Simulation results of parallel plate capacitor with etching hole. Length of square unit module (mm): 16 mm Gap (mm) CP (fF) CT (fF) Cf (fF) 0.10 0.20 0.30 0.40 0.50 0.75 1.00 1.50 2.00 4.00 22.666240 11.333120 7.555413 5.666560 4.533248 3.022165 2.266624 1.511083 1.133312 0.566656 24.313873 12.747548 8.848028 6.879083 5.687291 4.078149 3.259652 2.424500 1.996637 1.340618 1.647633 1.414428 1.292615 1.212523 1.154043 1.055984 0.993028 0.913418 0.863325 0.773962 side length, 4 unit modules with 8 mm for each side length, and 1 unit module with 16 mm for its side length, as shown in Figure 8. The total capacitance correction has been discussed under different circumstances (high density, small etching holes, and low density, large etching holes). The result shown in Figure 9 is that the longer the length of unit etching holes, the larger the capacitance correction. In contrast, even though it takes more small etching holes to attain the same area, the summation of all capacitance corrections is still less. Thus, a result can be inferred that the influence of small etching holes on the whole capacitance is small. When the gap between the electrodes Length of square unit module (mm): 16 mm and ligament efficiencies (m): 0.5 Gap (mm) CPe (fF) CTe (fF) Cfe (fF) 0.10 0.20 0.30 0.40 0.50 0.75 1.00 1.50 2.00 4.00 16.999680 8.499840 5.666560 4.249920 3.399936 2.266624 1.699968 1.133312 0.849984 0.424992 19.215937 10.366146 7.348762 5.810360 4.871035 3.586887 2.922502 2.231021 1.868358 1.293617 2.216257 1.866306 1.682202 1.560440 1.471099 1.320263 1.222534 1.097709 1.018374 0.868625 increases, the summation of capacitance correction in these three conditions is decreasing. Curve fitting In the above-mentioned simulation for the effect of etching holes, this research employs Mathematica to curve-fit the results of the simulation. The empirical formula of capacitance correction term of unit etching hole plate capacitor is deduced as follows Tu et al. 315 0 Capacitance difference (fF) 0 ∆C (fF) –1 –2 –3 –4 c = 4 (µm) c = 8 (µm) c = 16 (µm) –5 –1 –2 –3 –4 c = 4 (µm) c = 8 (µm) c = 16 (µm) –5 –6 –6 0 1 2 3 4 0 5 1 2 Gap (µm) Figure 7. Capacitance correction term DC with m = 0.5; c = 4, 8, and 16; and variable gap. CEH = C ð1 mÞ 3 4 5 Gap (µm) Figure 9. Capacitance correction term DC with the same area of square plates, cutting out the same area of etching holes with different sizes and densities. ð7Þ 0.0 ! 0:025 h + 44:940CEH 41:314CEH DC = e g g 2 CEH The first term indicates the plate capacitance of the area of etching holes. The second term indicates the capacitance caused by the fringe field on the thickness of the etching holes. When the structure is without etching holes (CEH = 0), the capacitance correction is zero. Because a small plate capacitor has small etching holes, the capacitance correction is small. The plate capacitance is smaller when the plate gap is larger and the capacitance correction decreases. According to the literature (Rebeiz, 2003), when the diameter of the etching hole less than 3–4 times the gap of the electrodes, the effect of the etching holes can be ignored, owing to the compensation of the fringe electric field for etching holes. Synthesizing all the above factors, this research ∆C (fF) ð8Þ –0.1 –0.2 –0.3 μ = 0.7, 2.5<h/g<5 Simulation μ = 0.7, 2.5<h/g<5 Empirical formula μ = 0.5, 1.25<h/g<5 Simulation μ = 0.5, 1.25<h/g<5 Empirical formula μ = 0.3, 1<h/g<5 Simulation μ = 0.3, 1<h/g<5 Empirical formula –0.4 –0.5 –0.6 0 1 2 3 4 5 6 h/g Figure 10. Comparison of analytical solution and ANSYS simulation with c = 4. neglects small and trivial values. Figures 10 to 12 show the comparison of results between the analytical solution of formula and the simulation of ANSYS. Figure 8. Schematic of square plates, cutting out the same area of etching holes with different sizes and densities. 316 Journal of Intelligent Material Systems and Structures 24(3) 30 0.0 Capacitance (fF) –0.5 ∆C (fF) Simulation Ideal parallel plate (Chuang, 2011) This work 25 –1.0 –1.5 μ = 0.7, 1.25<h/g<5 Simulation μ = 0.7, 1.25<h/g<5 Empirical formula μ = 0.7, 0.67<h/g<5 Simulation μ = 0.7, 0.67<h/g<5 Empirical formula μ = 0.7, 0.5<h/g<5 Simulation μ = 0.7, 0.5<h/g<5 Empirical formula –2.0 –2.5 20 15 10 5 0 –3.0 0 1 2 3 4 5 6 0 h/g 2 h/g 3 4 5 6 Figure 13. Comparison of capacitance with different gaps obtained from different models. Figure 11. Comparison of analytical solution and ANSYS simulation with c = 8. holes. The alignment of etching holes is usually an array; therefore, the quantity of etching holes can easily be calculated. Assuming there is a sample of unit etching holes (length of 16 mm, thickness of 0.5 mm, and ligament efficiencies m = 0.5). Now the sample is computed by three methods as follows: 0 –2 ∆C (fF) 1 –4 –6 μ = 0.7, 0.67<h/g<5 Simulation μ = 0.7, 0.67<h/g<5 Empirical formula μ = 0.5, 0.33<h/g<5 Simulation μ = 0.5, 0.33<h/g<5 Empirical formula μ = 0.3, 0.25<h/g<5 Simulation μ = 0.3, 0.25<h/g<5 Empirical formula –8 –10 1. 2. 3. Ideal capacitance formula; 3D structure capacitance formula; 3D structure capacitance with effect of etching holes. –12 0 1 2 3 4 5 6 h/g Figure 12. Comparison of analytical solution and ANSYS simulation with c = 16. This empirical formula of capacitance correction can be combined with 3D plate capacitance computation. Then, the 3D plate capacitance with etching holes can be appraised as follows ( " 0:23 0:23 # b h b CTotal = e + 0:73 1:06 + 3:31 g g h " 0:86 #) 0:18 h h L + e 4:2 b + 2:74 g g g ( ! ) 0:025 CEH 2 h + e + 44:940CEH 41:314CEH n g g ð9Þ The first term comes from the literature (Chuang et al., 2011), empirical formula for computing plate capacitance. The second term is the capacitance correction in this research. The n is the quantity of etching Then, we compare these with the results of an ANSYS simulation, as shown in Figure 13 and Table 5. According to the results, the best appraisal of etching hole structure is with the third method (error \ 1%); the smaller the gap, the better the appraisement compared with other methods. Conclusion This research utilized ANSYS to simulate the effect of etching holes for plate capacitor structures with etching holes. Under the conditions of cutting the same areas for etching holes, the small size of an etching hole means a high etching hole density, which causes minor capacitance changes. When dimension ranges m = 0.7, 4 \ c \ 16, and 0.25 \ h/g \ 5, the capacitance variation is less than 10%. This research also provides an empirical formula for the compensation of etching hole capacitance, combined with a 3D true thickness formula of plate capacitance. The mean error is less than 1%, which shows that this formula can be more accurate than other formulas (mean error . 10%). This empirical formula is able to provide designers with a criterion to appraise the effect of etching holes promptly and precisely. Tu et al. 317 Table 5. Comparisons of capacitances between simulation and formulae. h/g Simulation Chuang (2011) fF fF 24.2291 12.7037 8.8257 6.8706 5.6886 4.0946 3.2843 2.457 2.0319 1.3621 5 19.2159 2.5 10.3661 1.6667 7.3488 1.25 5.8104 1 4.871 0.6667 3.5869 0.5 2.9225 0.3333 2.231 0.25 1.8684 0.125 1.2936 Mean error % Ideal parallel plate This study Error % fF Error % fF Error % 26.09 22.55 20.1 18.25 16.78 14.15 12.38 10.13 8.75 5.29 15.447 16.9997 8.4998 5.6666 4.2499 3.3999 2.2666 1.7 1.1333 0.85 0.425 211.53 218 222.89 226.86 230.2 236.81 241.83 249.2 254.51 267.15 235.898 18.9501 10.201 7.2346 5.7286 4.8121 3.5638 2.9198 2.2498 1.8969 1.316 21.38 21.59 21.55 21.41 21.21 20.64391 20.091793 0.84291 1.53 1.73 20.377279 Funding This study was supported by the National Science Council of Taiwan through grant number NSC 100-2628-E-197-001MY3. References Chang WH (1976) Analytical IC metal-line capacitance formulas. IEEE Transactions on Microwave Theory and Techniques 24: 608–611. Chuang WC, Hu YC, Wang CW, et al. (2011) A fringing capacitance model for electrostatic microstructure. In: 13th international conference on mesomechanics, Vicenza, Italy, 6–8 July. Elshurafa AM and El-Masry EI (2006) Effects of etching holes on capacitance and tuning range in MEMS parallel plate variable capacitors. In: 6th IEEE international workshop on system on chip for real time applications (IWSOC), Cairo, Egypt, 27–29 December, pp. 221–224, Inst. of Elec. and Elec. Eng. Computer Society. DOI: 10.1109/IWSOC. 2006.348240. Elshurafa AM and El-Masry EI (2007) Design consideration in MEMS parallel plate variable capacitors. In: 50th IEEE Midwest symposium on circuits and systems (MWSCAS), 5–8 August, pp. 1173–1176, Institute of Electrical and Electronics Engineers Inc. DOI: 10.1109/MWSCAS.2007. 4488764. Fang DM, Li XH, Yuan QA, et al. (2010) Effect of etch holes on the capacitance and pull-in voltage in MEMS tunable capacitors. International Journal of Electronics 97: 1439–1448. Fang X, Myung N, Nobe K, et al. (2001) Modeling the effect of etch holes on ferromagnetic MEMS. In: 8th joint magnetism and magnetic materials—international magnetic conference—(MMM-Intermag), San Antonio, TX, 7–11 January, 37(4): 2637–2639, Institute of Electrical and Electronics Engineers Inc. DOI: 10.1109/20.951259. Rabinovich VL, Gupta RK and Senturia SD (1997) The effect of release-etch holes on the electromechanical behaviour of MEMS structures. In: International conference on solid state sensors and actuators, TRANSDUCERS ’97, Chicago, IL, 16–19 June, 2: 1125–1128. IEEE. Rebeiz GM (2003) RF MEMS: Theory, Design, and Technology. Hoboken, NJ: John Wiley & Sons, Inc. Sakurai T and Tamaru K (1983) Simple formulas for twodimensional and three-dimensional capacitances. IEEE Transactions on Electron Devices 30: 183–185. Vandermeijs NP and Fokkema JT (1984) VLSI circuit reconstruction from mask topology. Integration-the VLSI Journal 2: 85–119.