Components General Notes Mechanical Assembly

advertisement

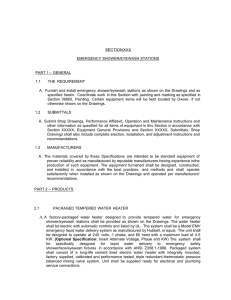

Operation & Maintenance Guide GFR3300 Series H eat Traced Eyewash and Shower Safety Station, Control Panel with Trace Light and Temperature Warning Lights, Rated for Class 1, Division 2 Environments Components Item Part Number A B C D E F G H I J Description 600-106 300-10U Shower Valve, 1" IPS Brass 1-1/4" IPS Female Union Inlet AP450-032ORG AP450-048 AP050-079 AP250-048R AP470-048R AP470-105FP 600-103 500-04-03-4 150-032 Orange ABS Plastic Shower Head A Stainless Steel Shower Head Shower Pull Rod Assembly B Spray Head Dust Cover (pkg of 2) Spray Head Assembly (pkg of 2) Eyewash Assembly C Eyewash 3-Way Valve, 1/2" IPS Brass Drain Tube for 3-way Ball Valve Floor Flange General Notes D Installation of heat traced safety station requires that mechanical and electrical connections be made. Installation should be performed by a licensed plumber and a licensed electrician. All work must be done in accordance with applicable regulations, including local plumbing codes, electrical codes and OSHA regulations pertaining to lockout of electrical equipment. It is recommended that a shut-off valve is installed upstream of the unit to facilitate maintenance. Provisions must be made to prevent unauthorized closure of the shut-off valve. E F G Mechanical Assembly • Secure unit to floor using floor flange on base of unit. H • Connect water supply to the 1-1/4" IPS union connection at the top or bottom of unit. If outdoors, make sure water supply pipe is protected from freezing. I • Test unit for leaks and ensure both the eyewash and shower work properly. • Drain pipe under the eyewash valve allows water to drain after use to prevent the eyewash from freezing. Drain must remain unobstructed. Model GFR3307 Shown Guardian Equipment 1140 N North Branch St. Chicago, IL 60642 312 447 8100 telephone 312 447 8101 facsimile gesafety.com J rev. 1015 Operation & Maintenance Guide GFR3300 Series H eat Traced Eyewash and Shower Safety Station, Control Panel with Trace Light and Temperature Warning Lights, Rated for Class 1, Division 2 Environments Electrical Wiring • Connect the incoming power wire (hot) to terminal block L1. • Connect neutral wire to terminal block L2. • Connect ground wire to ground terminal block. • In order to meet Class I, Division 2 requirements, approved conduit and fittings must be used. All threaded electrical connections must have hazardous location rated sealant applied to threads Electrical Schematic 120/240V, 1A, 60HZ FLA = 1.5 L1/H L2/N 1 2 L1 L2 3 4 HT CABLE 2A 5 6 AREA LIGHT 1A 7 8 9 10 HORN ALARM LIGHT 1A 1A SET POINT GROUND 70 60 100ĀF ALARM (HIGH) 100 90 ALARM (LOW) 120ĀF 60 30 Guardian Equipment 1140 N North Branch St. Chicago, IL 60642 FLOW/ PROX PROX 1 3 312 447 8100 telephone 312 447 8101 facsimile gesafety.com 2 4 EVENT 1A 5 6 DRY ALARM 1A 7 8 60ĀF RED RED RTD WHT rev. 1015