PAU-PPI-C-VDM-HG46A-VM001 REV.E OPERATION AND MAINTENANCE MANUAL

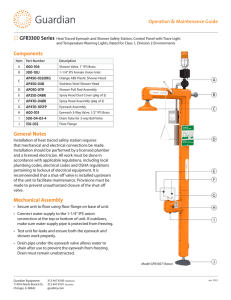

advertisement

Page 1/9 OPERATION AND MAINTENANCE MANUAL Doc. No : PAU-PPI-C-VDMHG46A-VM001 Rev. [E] Page: [1] of [9] OPERATION AND MAINTENANCE MANUAL Project Title: Bolivia YPFB Ammonia/Urea Project Project Number: SC-2566 Requisition Description: Requisition Number: Puchase Order Number: Item Description: FINAL HG46A 4500150733 EYE WASHER & SAFETY SHOWER Item Number: □ APPROVED □ REVIEWED □ WITH COMMENTS □ RESUBMIT THIS APPROVAL OR REVIEW DOES NOT RELIEVE THE VENDOR/SUBCONTRACTOR OF HIS RESPONSIBILITIES TO MEET ALL OF THE SPECIFIED REQUIREMENTS OF THE PURCHASE ORDER ORIGINATOR CHECKED APPD(PR) SIGN DATE SAMSUNG ENGINEERING CO., LTD E 7 OCT 2015 FINAL Y.OZAWA K.MATSO Y.KAWASHIMA REV. DATE DESCRIPTION MADE BY CHECKED BY APPROVED BY ABLE-YAMAUCHI CO., LTD. SAMSUNG ENGINEERING CO., LTD. YACIMIENTOS PETROLIFEROS FISCALES BOLIVIANOS Page 2/9 TABLE OF CONTENTS ………… Page 3 1-1. To Operate Shower ………… 3 1-2. To Operate Eyewash ………… 3 1-3. Scald Protection Valve ………… 3 2. PRE-OPERATION CHECK ………… 4 3. MAINTENANCE AND TRAINING ………… 4 4. TROUBLE SHOOTING ………… 5 1. OPERATION ATTACHMENT Attachment-1 Assembling Procedure for Shower and Eyewasher ………… 6 Attachment-2 Whole Drawing for Shower and Eyewasher ………… 7 Attachment-3 Scald Protection Valve Data Sheet ………… 8-9 Page 3/9 INSTALLATION, OPERATION & MAINTENANCE MANUAL Shower& Eyewash Eyewash Instruction 1. OPERATION 1-1. To Operate Shower 1) To flow water Pulling down PULL ROD allows VALVE (A) to open, so the water flows instantly from SHOWER HEAD. ○ NA ○ ○ ○ ○ 2) To stop water flow Pushing up PULL ROD allows VALVE (A) to close, so the water stops flowing from SHOWER HEAD. 1-2. To Operate Eyewash 1) To flow water Turning the PUSH PLATE or Stepping on to Foot Pedal allows VALVE (B), so the water flows instantly from FLOW HEADS. 2) To stop water flow Turning the PUSH PLATE back to the original position allows VALVE (B) to close,so the water stops flowing from FLOW HEADS. 1-3. Scald Protection Valve Scald Protection Valve is installed to the unit for scald protection. A rise in temperature causes the valve to open. The valve closes when the fluid temperature drops, below the preset temperature. Opening Temperature: 40.6 deg-C(105 deg-F) Closing Temperature: 35.0 deg-C(95 deg-F) *For details refer to Attachment-3(Scald protection valve data sheet) Page 4/9 OPERATION & MAINTENANCE MANUAL Shower& Eyewash Eyewash Instruction 2. PRE-OPERATION CHECK After EMERGENCY SHOWER & EYEWASHER is installed, it shall be tested in accordance with following procedure. ○ ○ 2-1. ○ ○ ○ ○ ○ NA ○ ○ ○ ○ 2-2. 2-3. 2-4. After the unit is connected to the water source and the VALVES are closed, visually check the piping connections for leaks. Open the VALVES to the full open position. The VALVES shall remain open without requiring further use of the operator's hands. Open the VALVE (A) to the full open position and check the flow from SHOWER HEADS is enough to spread over the body. Open the VALVE (B) to the full open position and check the flow streams from FLOW HEADS rise to approximately equal heights. 3. MAINTENANCE AND TRAINING 3-1. 3-2. 3-3. 3-4. Activate EMERGENCY SHOWER & EYEWASHER weekly to verify proper operation and record the test results. When hazardous materials splash on workers, wash hazardous materials away for 15 (fifteen) minutes before first aid is applied. When hazardous materials splash into workers' eyes, wash hazardous materials away for 15 (fifteen) minutes before first aid is applied. While washing eyes, open and move eyeballs. Instruct all workers, regarding the location and proper use of EMERGENCY SHOWER & EYE WASHER. Page 5/9 INSTALLATION, OPERATION & MAINTENANCE MANUAL 4. TROUBLE SHOOTING FAULT REASON REMEDY Water flows from flow heads are not level. Eyewash is not leveled correctly. Water flow from flow heads is lower than normal. Regulator is blocked with foreign matters. Malfunction of pull rod and / or push plate Contamination/block inside valve Overhaul and clean the valve. Low water pressure Check accurate operating pressure at inlet. To deliver the sufficient volume of water, operating pressure requires to be at a minimum of 0.207 MPaG. Water flow from shower head looks lower than normal Shower& Eyewash Eyewash ○ ○ ○ ○ ○ N/A ○ NA ○ NA ○ NA Re-install Eyewash at correct level Overhaul stream heads and remove the foreign matters. Re-assemble and check the flow. Check the inlet connection size is more than 1 inch. Low water flow Check there is no leakage or blocking in the pipes. Attachment-1 Assembling Procedure for Shower and Eyewasher Page 6/9 Attachment-2 Whole Drawing for Shower and Eyewasher Page 7/9 Page 8/9 Attachment-3 Scald Protection Valve Data Sheet Page 9/9