- Econsense

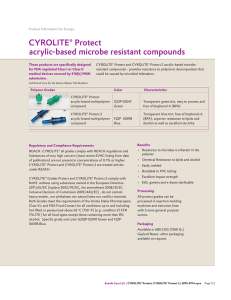

advertisement