Product Information for Europe

CYROLITE® Protect

acrylic-based microbe resistant compounds

These products are specifically designed

for FDA regulated Class I or Class II

medical devices covered by 510(k) PMN

submission.

CYROLITE® Protect and CYROLITE® Protect 2 acrylic-based microbe

resistant compounds - provides resistance to polymeric decomposition that

could be caused by microbial infestation.

Call Evonik Cyro for the Device Master File Numbers.

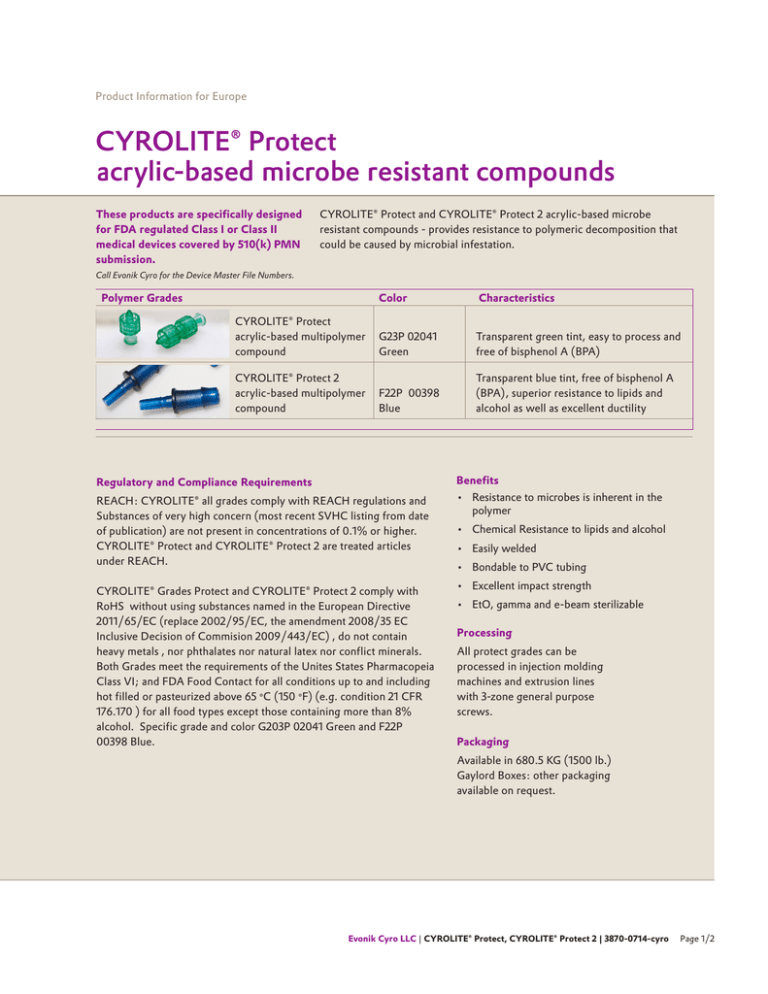

Polymer Grades

Color

Characteristics

CYROLITE® Protect

acrylic-based multipolymer

compound

G23P 02041

Green

Transparent green tint, easy to process and

free of bisphenol A (BPA)

CYROLITE® Protect 2

acrylic-based multipolymer

compound

F22P 00398

Blue

Transparent blue tint, free of bisphenol A

(BPA), superior resistance to lipids and

alcohol as well as excellent ductility

Regulatory and Compliance Requirements

Benefits

REACH: CYROLITE® all grades comply with REACH regulations and

Substances of very high concern (most recent SVHC listing from date

of publication) are not present in concentrations of 0.1% or higher.

CYROLITE® Protect and CYROLITE® Protect 2 are treated articles

under REACH.

• Chemical Resistance to lipids and alcohol

CYROLITE® Grades Protect and CYROLITE® Protect 2 comply with

RoHS without using substances named in the European Directive

2011/65/EC (replace 2002/95/EC, the amendment 2008/35 EC

Inclusive Decision of Commision 2009/443/EC) , do not contain

heavy metals , nor phthalates nor natural latex nor conflict minerals.

Both Grades meet the requirements of the Unites States Pharmacopeia

Class VI; and FDA Food Contact for all conditions up to and including

hot filled or pasteurized above 65 °C (150 °F) (e.g. condition 21 CFR

176.170 ) for all food types except those containing more than 8%

alcohol. Specific grade and color G203P 02041 Green and F22P

00398 Blue.

• Resistance to microbes is inherent in the

polymer

• Easily welded

• Bondable to PVC tubing

• Excellent impact strength

• EtO, gamma and e-beam sterilizable

Processing

All protect grades can be

processed in injection molding

machines and extrusion lines

with 3-zone general purpose

screws.

Packaging

Available in 680.5 KG (1500 lb.)

Gaylord Boxes: other packaging

available on request.

Evonik Cyro LLC | CYROLITE® Protect, CYROLITE® Protect 2 | 3870-0714-cyro Page 1/2

CYROLITE® Protect polymer grades

Properties

Unit

ASTM

CYROLITE®

Protect 2

F22P

CYROLITE®

Protect

G23P

Mechanical Properties

Typical Value

Typical Value

Tensile Strength

MPa (psi)

D 638

40.3 (5,840)

47.2 (6,850)

Tensile Modulus

GPa (x106 psi)

D 638

1.8 (0.26)

2.1 (0.33)

Tensile Elongation @ Yield

%

D 638

4

3

Tensile Elongation @ Break

%

D 638

17

8

Flexural Strength

MPa (psi)

D 790

61 (8,840)

70.2 (10,200)

Flexural Modulus

Gpa (x106 psi)

D 790

1.9 (0.28)

2.2 (0.325)

Notched Izod on ¼'' bar @23°C

J/m (ft-lb/in)

D 256

91 (1.7)

64 (1.3)

Thermal Properties

Vicat Softening Point

°C (°F)

D 1525

94 (201)

100 (212)

Deflection Temperature,

Annealed 1.8MPa, 0.250''

°C (°F)

D 648

65 (149)

75 (167)

Rheological Properties

Melt Flow Rate @ 230°C g/10min

D 1238

2.5 @5.0 kg

10.0 @5.0 kg

Optical Properties

Light Transmission

%

D 1003

11 @1.5mm

40 @3mm

Haze

%

D 1003

32 @1.5 mm

48 @3mm

Processing Conditions

Predrying Temperature

°C (°F)

71 (160)

79 (175)

Predrying Time

hour

3 to 4

3 to 4

Melt Temperature

°C (°F)

238 - 254 (460 - 490)

232 - 249 (450 - 480)

Mold Temperature

°C (°F)

60 - 77 (120 - 170)

50 - 82 (120 - 180)

Evonik Cyro LLC | CYROLITE® Protect, CYROLITE® Protect 2| 3870-0714-cyro Page 2/2

This information and all technical and other advice are based on Evonik’s present knowledge and experience. However, Evonik assumes no liability for

such information or advice, including the extent to which such information or advice may relate to third party intellectual property rights. Evonik reserves

the right to make any changes to information or advice at any time, without prior or subsequent notice. EVONIK DISCLAIMS ALL REPRESENTATIONS

AND WARRANTIES, WHETHER EXPRESS OR IMPLIED, AND SHALL HAVE NO LIABILITY FOR, MERCHANTABILITY OF THE PRODUCT OR ITS

FITNESS FOR A PARTICULAR PURPOSE (EVEN IF EVONIK IS AWARE OF SUCH PURPOSE), OR OTHERWISE. EVONIK SHALL NOT BE RESPONSIBLE FOR CONSEQUENTIAL, INDIRECT OR INCIDENTAL DAMAGES (INCLUDING LOSS OF PROFITS) OF ANY KIND. It is the customer’s sole responsibility to arrange for inspection and testing of all products by qualified experts. Reference to trade names used by other companies is neither a recommendation nor an endorsement of the corresponding product, and does not imply that similar products could not be used.

CYROLITE® is a registered trademarks of Evonik Cyro LLC, an Evonik Corporation group company.

©2013 Evonik Cyro LLC. All rights reserved. Printed in USA.

Evonik Cyro LLC – Acrylic Polymers

299 Jefferson Road, Parsippany, NJ 07054 USA

www.cyrolite.eu e-mail: cyrolite-europe@evonik.com