Infrared Thermography

advertisement

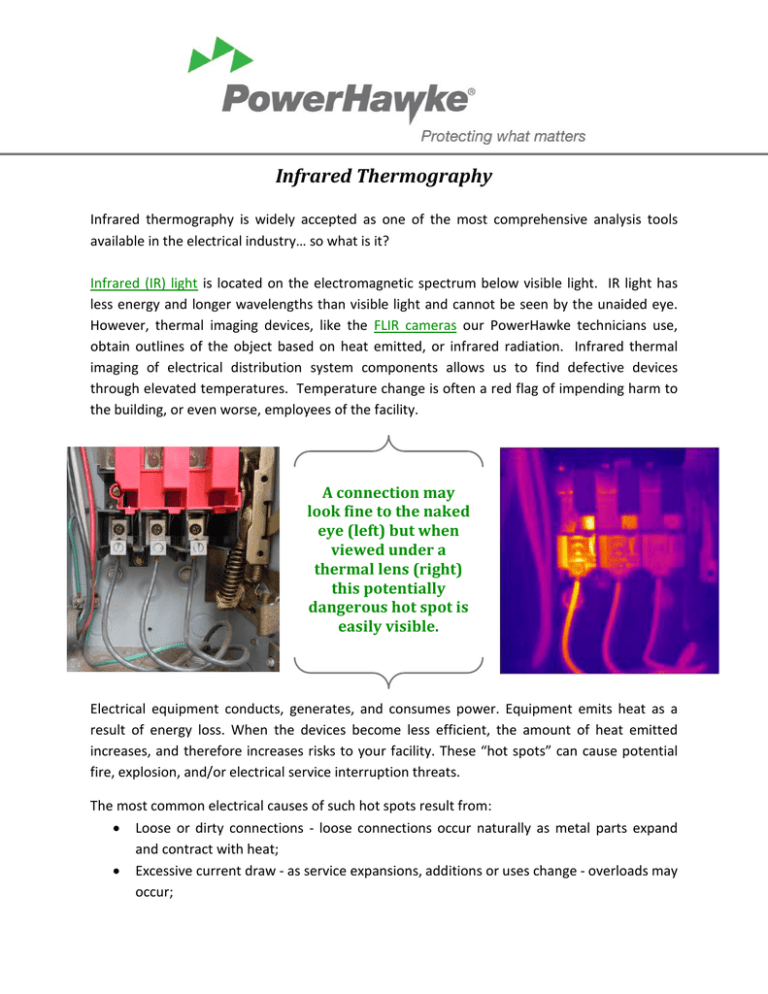

Infrared Thermography Infrared thermography is widely accepted as one of the most comprehensive analysis tools available in the electrical industry… so what is it? Infrared (IR) light is located on the electromagnetic spectrum below visible light. IR light has less energy and longer wavelengths than visible light and cannot be seen by the unaided eye. However, thermal imaging devices, like the FLIR cameras our PowerHawke technicians use, obtain outlines of the object based on heat emitted, or infrared radiation. Infrared thermal imaging of electrical distribution system components allows us to find defective devices through elevated temperatures. Temperature change is often a red flag of impending harm to the building, or even worse, employees of the facility. A connection may look fine to the naked eye (left) but when viewed under a thermal lens (right) this potentially dangerous hot spot is easily visible. Electrical equipment conducts, generates, and consumes power. Equipment emits heat as a result of energy loss. When the devices become less efficient, the amount of heat emitted increases, and therefore increases risks to your facility. These “hot spots” can cause potential fire, explosion, and/or electrical service interruption threats. The most common electrical causes of such hot spots result from: • Loose or dirty connections - loose connections occur naturally as metal parts expand and contract with heat; • Excessive current draw - as service expansions, additions or uses change - overloads may occur; • Defective components - electrical components don’t always fail open. Excessive heat for long periods of time may cause a protection device to fuse closed which will result in a failure. In fact, loose connections and parts account for 30.3% of all electrical distribution failures. The connection problem leads to an increase in temperature at a higher point of resistance. With no intervention, these components can reach a state of catastrophe, resulting in an electrical fire or a total shutdown. So how can you prevent this from happening? Infrared and visual inspections, as part of a regular PowerHawke preventive maintenance plan, can result in net savings for your company, depending upon the number and category of the problems found. A typical survey results in financial savings from $10,000 to $20,000. The information acquired from the infrared survey cuts down on maintenance time, prevents future interruptions and costly replacements. A business benefits from a more reliable and productive system as well as there being fewer “panic” situations for managers and employees. Most importantly, infrared inspections, done safely and according to NFPA 70E, contribute to a safe work environment. Infrared surveys are a non-contact and non-invasive procedure performed on your energized electrical equipment. The assessments are conveniently performed under normal loads with no interruption or power shutdown. Detailed reports of equipment are provided to reveal the location, problem description, and mitigation recommendation for thermal hotspots. PowerHawke helps you protect what matters. Infrared thermography can predict a problem before it occurs, saving you time and money by increasing the reliability and productivity of your entire operation. An infrared inspection can give you peace of mind by protecting your most important assets – your valued employees and your building. Contact Bob O’Meara for more information on how infrared thermography can help your facility by calling 860-507-8813 or emailing him. 132 Scott Swamp Road ▪ Farmington, CT 06032 Phone: 860-606-0065 ▪ Fax: 860-606-0026 http://powerhawke.com ▪ www.facebook.com/powerhawke